Chengdu Daguang New Materials Co., Ltd.

-

2 +millionAnnual output value

-

8 +powder production lines

-

1000 +customers

-

5000 +tons of various powders

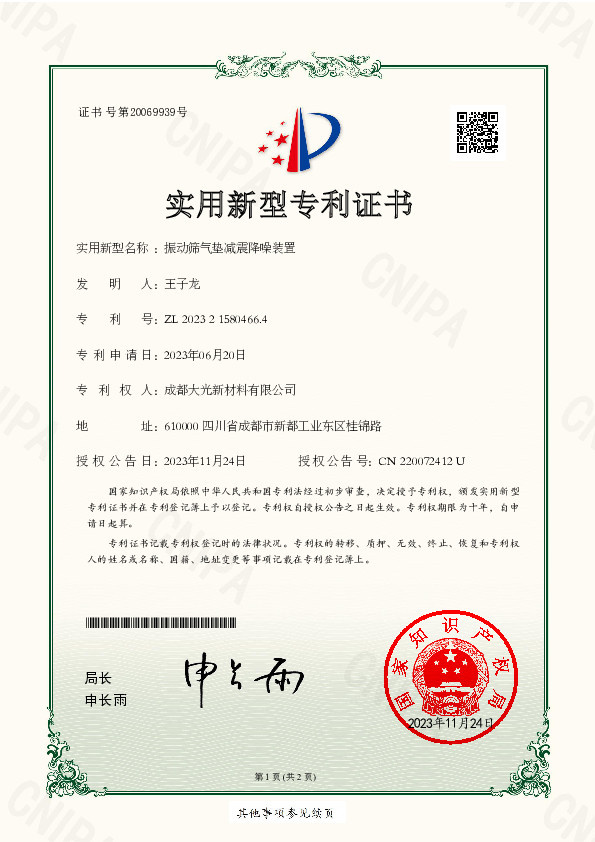

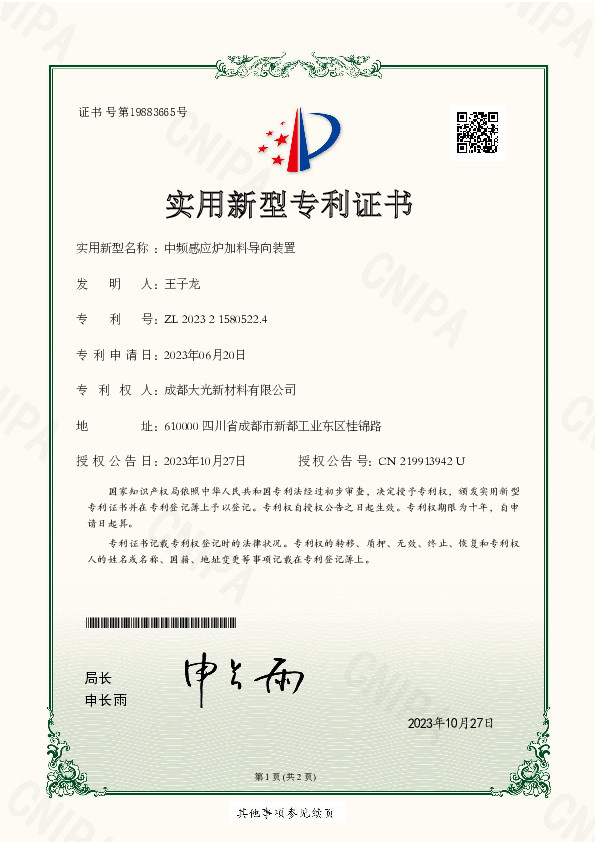

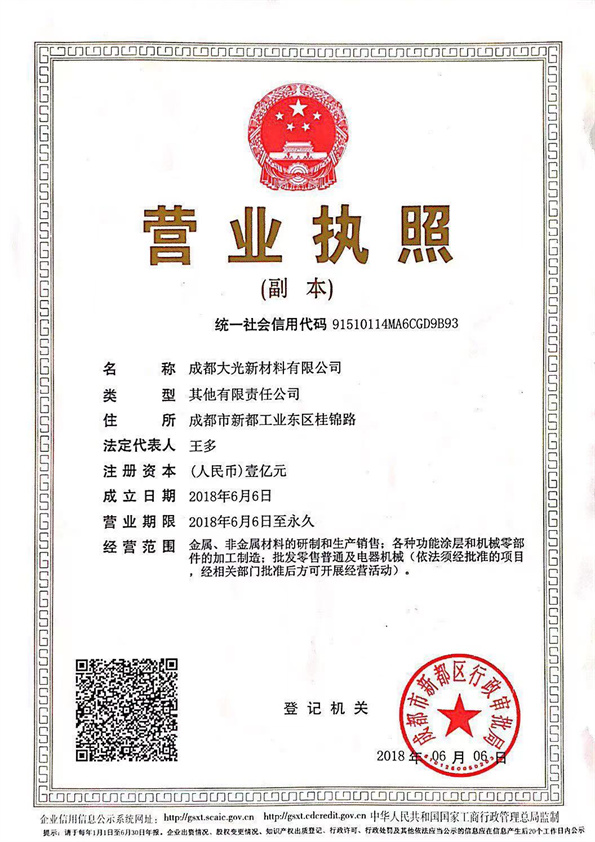

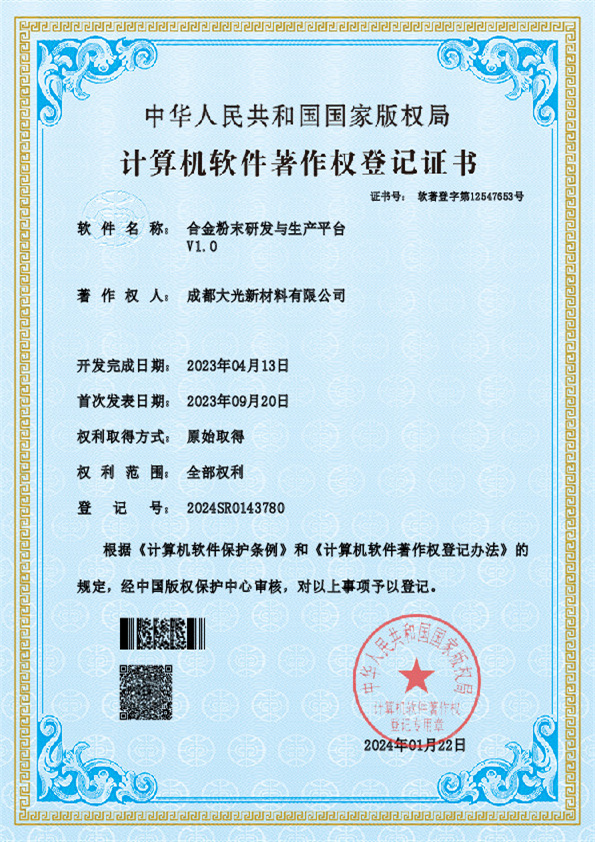

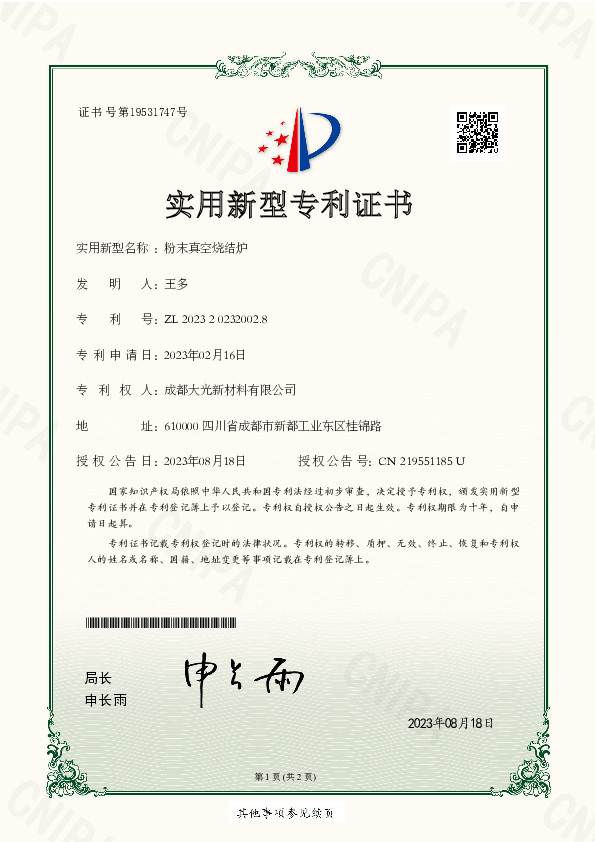

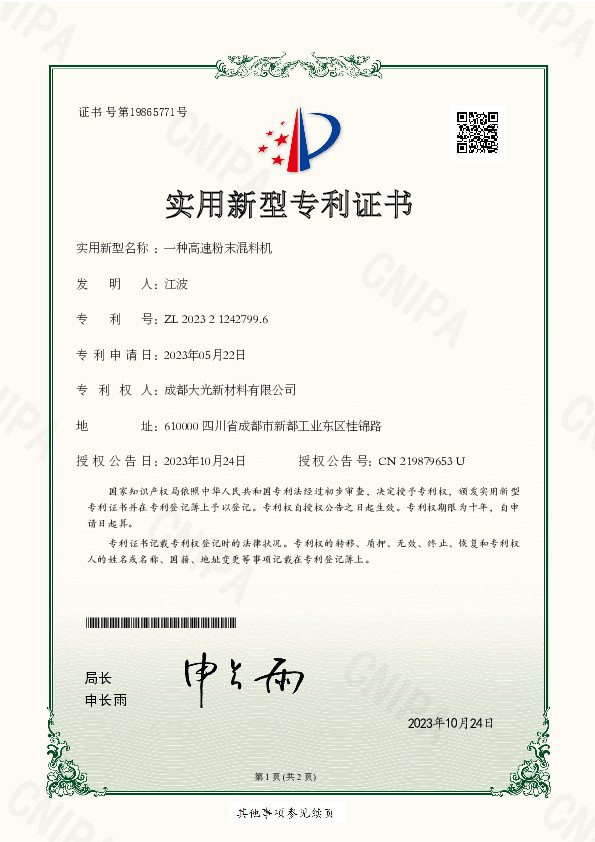

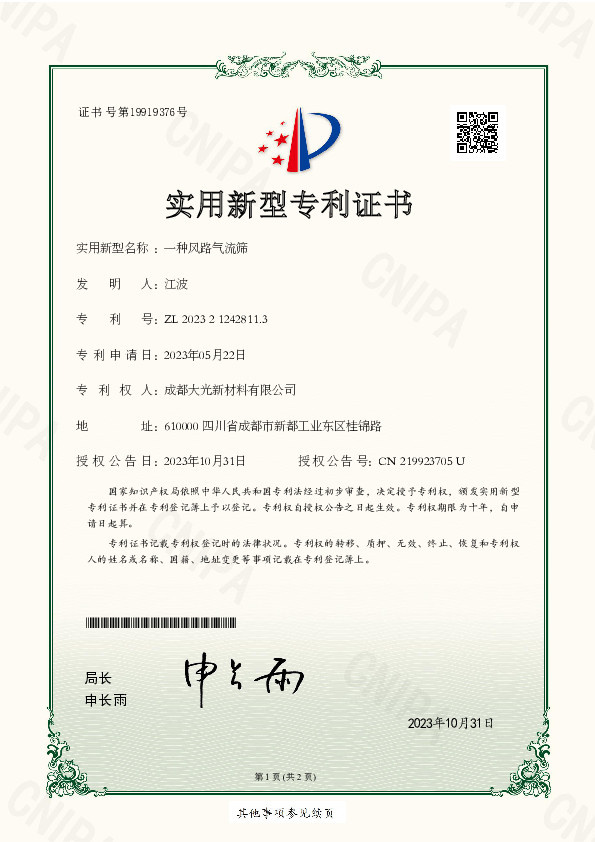

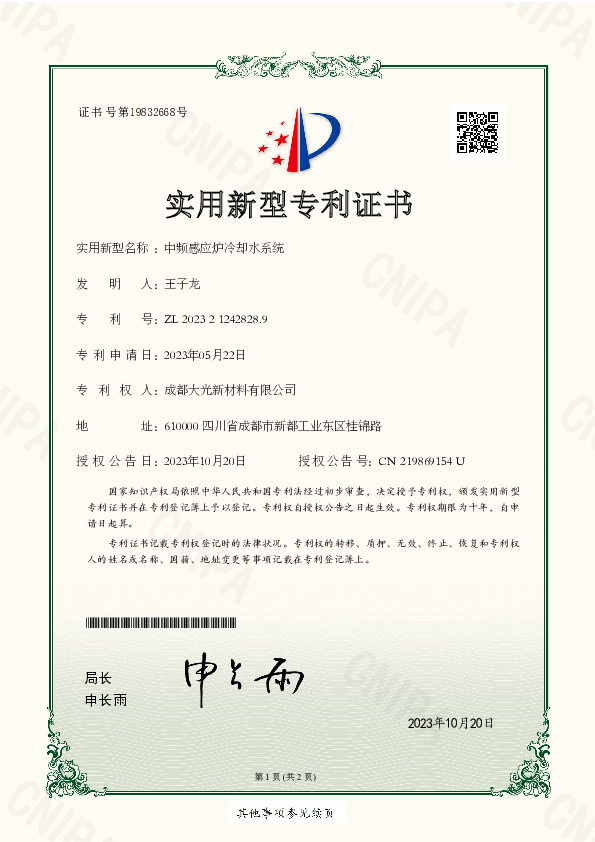

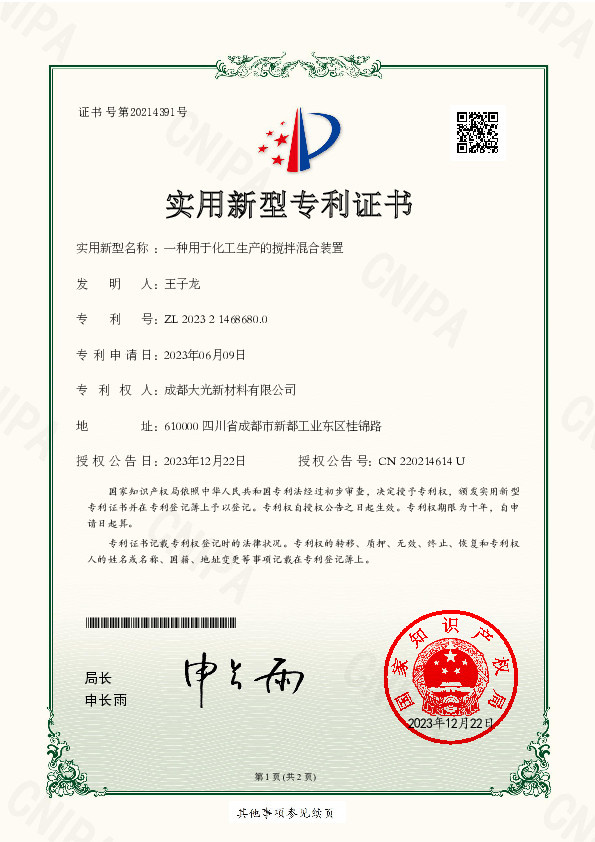

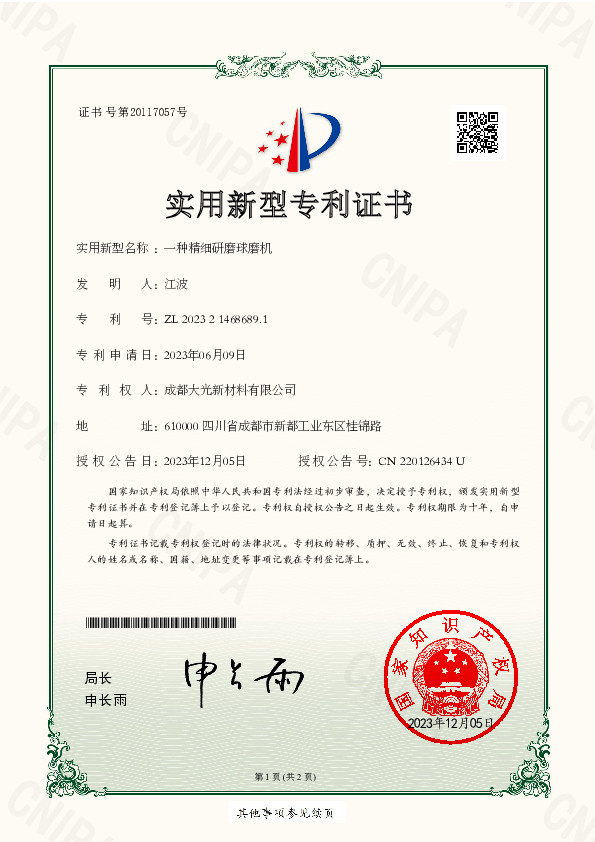

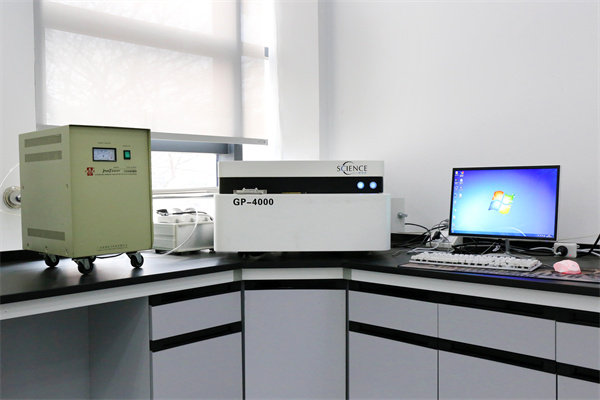

Honor and qualification

CHARACTERISTIC ADVANTAGES

Excellent service

Good service attitude is a highlight of our factory. From the first moment of customer consultation, our professional team will greet every visitor with enthusiasm, patience and sincere attitude. No matter how big or small the problem is, we listen carefully, answer carefully, and are committed to providing customers with the most intimate service. We know that good service is not only about answering questions, it is also the cornerstone of building a long-term, trusting relationship with our customers. Every communication, every smile, convey our respect and care for customers, so that customers feel the warmth of home.

Prompt delivery

Speed of delivery is another advantage we have. In these fast-paced times, time is money. We understand the importance our customers place on time, so we constantly optimize our production processes to improve work efficiency. From order confirmation to product delivery, every link is closely coordinated and races against the clock. With efficient management and strong execution, we ensure that products can be delivered to customers in the shortest possible time, and never delay the production schedule of customers. This ability to respond quickly saves time and costs for customers, and also wins high praise from customers.

High quality, low price

High quality and low price is the principle that our factory always adheres to. We are committed to providing high quality thermal spraying materials, using advanced production technology and strict quality control system to ensure that every product meets national standards. At the same time, we pass benefits to customers by optimizing cost management and reducing production expenses. We believe that only by allowing customers to obtain real value, our business can develop in the long run.

-

2024The Xindu factory will be officially put into operation in 2024, with the largest thermal spray powder production workshop in China and an annual output of 800 tons;

-

2021the annual output value of the company reached 200 million yuan, and the total production of nickel-based alloy powder reached 500 tons, accounting for 60% of the market share;

-

2020I will participate in key R&D projects in Sichuan Province: development and process technology development of high-performance spherical metal powder plasma atomization equipment for additive manufacturing, and the application fields are: high-performance 3D printing materials;

-

2019200 million yuan will be invested to build a new factory in Xindu, covering an area of 21,000 square meters;

-

2012the company set up scholarships in Southwest Jiaotong University, Xi 'an Jiaotong University, School of Materials and Engineering to support the development of thermal spraying industry;

-

2012In the second half of 2012, Academician of Chinese Academy of Sciences (Innovation) workstation was established, and Professor Li Chang supported our research and development work as the company's consultant;

-

1996The company was established in 1996, is the first domestic thermal spray material factory;