As industries continue to evolve, the use of Powder Coating Stainless is gaining significant traction, particularly as manufacturers seek durable and aesthetically pleasing finishes for their products. Recent reports indicate that the global powder coating market is projected to reach $12.5 billion by 2025, driven by a growing demand for environmentally friendly coatings that offer superior resistance to corrosion and wear. This trend is especially relevant in sectors such as automotive, architecture, and consumer goods, where the performance and appearance of stainless steel components are paramount.

Expert in surface coatings, Dr. Emily Carter, emphasizes the importance of advancements in Powder Coating Stainless: "The ability to combine durability with aesthetic flexibility is revolutionizing the way we approach product design." With the continuous development of new formulation technologies, powder coatings not only enhance the protective qualities of stainless steel but also provide a palette of colors and textures, allowing for enhanced design possibilities.

As we delve deeper into the trends shaping the powder coating industry by 2025, it is essential to explore both the benefits and applications of Powder Coating Stainless, which are helping to redefine the standards for quality and sustainability in manufacturing processes. The focus on innovation, efficiency, and environmental impact will undoubtedly position Powder Coating Stainless at the forefront of numerous industries in the coming years.

In 2025, the powder coating industry for stainless steel is expected to witness significant trends that prioritize sustainability, aesthetics, and performance. The focus on eco-friendly formulations will continue to grow, with manufacturers developing low-VOC (volatile organic compounds) powders and waterborne options, reducing the environmental impact of the coating process. As businesses increasingly prioritize sustainability, these innovative formulations not only comply with stricter regulations but also appeal to environmentally conscious consumers.

Another major trend will be the enhancement of aesthetic choices available for stainless steel components. Customizable color palettes and textures will gain popularity, allowing for greater personalization and creativity in design. Metallic finishes and textured coatings will be particularly sought after, contributing to the visual appeal of various applications, from architectural elements to consumer products. Furthermore, advancements in technology, such as automated powder coating systems, will improve efficiency and reduce production costs, enabling more industries to adopt powder coating as a preferred finishing method.

As we move towards 2025, the environmental benefits of powder coating stainless steel are becoming increasingly significant. This eco-friendly application utilizes a dry powder that produces lower levels of volatile organic compounds (VOCs) compared to traditional liquid coatings. According to a report from the Powder Coating Institute, powder coating can reduce VOC emissions by up to 60%, aligning with global efforts to improve air quality and lower greenhouse gas emissions. This is particularly vital as industries seek sustainable solutions that minimize their environmental footprint.

In addition to reducing air pollution, powder coating stainless steel also offers durability and longevity, which contribute to overall resource conservation. Data from the American Iron and Steel Institute indicates that stainless steel, when powder coated, exhibits enhanced corrosion resistance and can extend the lifecycle of the material up to 20 years or more. This prolonged lifespan not only reduces the need for frequent replacements but also diminishes the energy and resources required for production. Given these advantages, many sectors, including automotive and construction, are increasingly adopting powder coating for stainless steel applications, recognizing that sustainability does not compromise performance but rather enhances it.

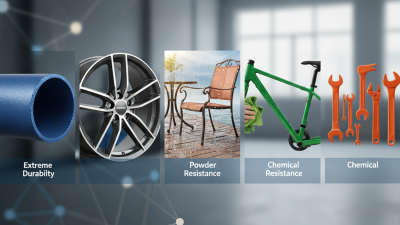

The application of powder coating on stainless steel is gaining traction across various industries, thanks to its unique benefits and innovative capabilities. One of the remarkable advantages of powder coating is its durability; it forms a resilient surface that is resistant to chipping, scratching, and fading. According to recent industry reports, the powder coating market is projected to grow at a CAGR of 6.5% from 2022 to 2028, reflecting its increasing adoption in sectors like automotive and architectural applications.

In the automotive industry, powder-coated stainless steel is used to enhance both functionality and aesthetics. This coating technique not only provides corrosion resistance but also allows for a spectrum of color finishes that can elevate vehicle design. Similarly, in the architectural sector, powder coating is applied to windows, doors, and other structural elements, increasing their resistance to the elements while offering customizable design options. Reports indicate that architectural applications represent over 40% of total powder coating usage, underscoring its significance in enhancing building longevity and appearance.

Tips: When considering powder coating for stainless steel, ensure proper surface preparation to maximize adhesion. Additionally, choosing eco-friendly powder coating options can not only reduce environmental impact but also meet the increasing demand for sustainable practices in the industry. As trends continue to evolve, staying informed about the latest advancements in powder coating technology can significantly benefit your project outcomes.

The powder coating market for stainless steel is projected to experience remarkable growth in the coming years, driven by its increasing applications across various sectors such as automotive, construction, and consumer goods. According to a recent market research report, the global powder coating market is expected to reach approximately $16 billion by 2025, with stainless steel accounting for a significant portion of this growth due to its durability and corrosion resistance. The ability of powder coating to enhance the aesthetic appeal and longevity of stainless steel products is making it a preferred choice among manufacturers and consumers alike.

Economically, the adoption of powder coating on stainless steel is not only beneficial for manufacturers in terms of cost-effectiveness, but it also contributes positively to environmental sustainability. With a reduced volatile organic compound (VOC) emissions profile, powder coating aligns with increasing regulatory demands for environmentally friendly practices. Industry forecasts suggest that the demand for powder-coated stainless steel is expected to grow at a compound annual growth rate (CAGR) of over 6% through 2025. This growth signifies a robust economic impact, as industries shift towards more sustainable coating solutions while maintaining the strength and aesthetic requirements of stainless steel products.

| Trend | Description | Benefits | Estimated Market Growth (%) | Economic Impact ($ Billion) |

|---|---|---|---|---|

| Eco-friendly Coatings | Increasing demand for environmentally safe powder coatings. | Reduced environmental impact, compliance with regulations. | 12% | 5.4 |

| Advancements in Technology | Utilization of smart coating technologies for better performance. | Enhanced durability, self-cleaning properties. | 10% | 6.1 |

| Customization Trends | Increased demand for bespoke color and texture options. | Greater customer satisfaction, differentiation in the market. | 15% | 4.3 |

| Sustainability Practices | Adoption of sustainable manufacturing practices in the coating process. | Lower energy consumption and waste generation. | 8% | 3.7 |

| Market Expansion | Growth in emerging markets for stainless steel applications. | Increased opportunities for manufacturers and suppliers. | 20% | 8.2 |

Technological advancements are significantly shaping the future of powder coating, particularly when applied to stainless steel. Innovations in formulation chemistry have led to the development of more resilient powders that can withstand harsh environments, ensuring long-lasting finishes that maintain their aesthetic appeal. Enhanced powder formulations also cater to a wider range of requirements, such as improved adhesion, flexibility, and UV resistance, making them suitable for varied applications, from industrial machinery to architectural elements.

Additionally, the integration of automation and robotics within powder coating processes is driving efficiency and precision. Automated systems can ensure consistent application thickness while reducing material waste through optimized spray patterns and recovery systems. This technological progression not only improves the quality of the finish but also significantly decreases production time, leading to a more sustainable and cost-effective operation. As these advancements continue to evolve, the powder coating industry is poised for transformative growth, especially in the realm of stainless steel applications, where durability and aesthetics are paramount.