As industries evolve, innovative manufacturing solutions continue to emerge. Metal Powder Works plays a crucial role in this transformation. These materials are reshaping the landscape of manufacturing, offering unique properties that traditional methods cannot match.

The demand for advanced materials is rising. Metal powders are increasingly favored for their versatility and efficiency. They can improve product performance while reducing waste. However, the challenge remains in selecting the right powder for specific applications. Not every metal powder works for every purpose.

Reflection is essential in this evolving field. The integration of metal powder technology can lead to unexpected complications. Businesses must evaluate their processes carefully. Understanding the properties of various metal powders is vital. This knowledge can help in making informed decisions, ensuring that manufacturing solutions align with specific needs and standards.

Choosing the right metal powder is essential in modern manufacturing. Different powders serve various applications. For instance, aluminum powders are lightweight and ideal for aerospace industries. They offer strength but can be challenging to process due to their reactivity. Processing methods must be carefully monitored to prevent safety hazards.

Another example is titanium powder, known for its excellent strength-to-weight ratio. It's often used in medical implants. However, its high cost may limit its use in some projects. Manufacturers must consider budget constraints alongside performance.

Innovative manufacturing relies on these decisions. A poor choice in metal powder can lead to weak structural integrity. It can also result in costly rework. Thus, researching material properties and manufacturing processes is crucial. Each metal powder has unique features that require thoughtful consideration.

This chart displays the popularity and performance of various metal powders used in innovative manufacturing solutions in 2026. The data is based on industry trends and applications in additive manufacturing.

Metal powders are essential for innovative manufacturing solutions. Their unique properties allow for advanced applications in various industries. The particle size, shape, and distribution significantly influence performance. For instance, finer powders enhance sintering and density, but their handling can be trickier.

Different shapes like spherical or irregular affect the flowability of the powders. Spherical powders often provide better packing density, yet they can be more challenging to produce consistently. Irregular shapes may flow better but might not achieve the same mechanical properties upon sintering.

Consideration must be given to the materials used. For example, lightweight alloys can deliver strength while reducing weight, but they may increase costs. Selecting the right metal powder requires a balancing act between desired properties and production feasibility. The quest for the perfect powder continues as manufacturers strive for better performance and efficiency.

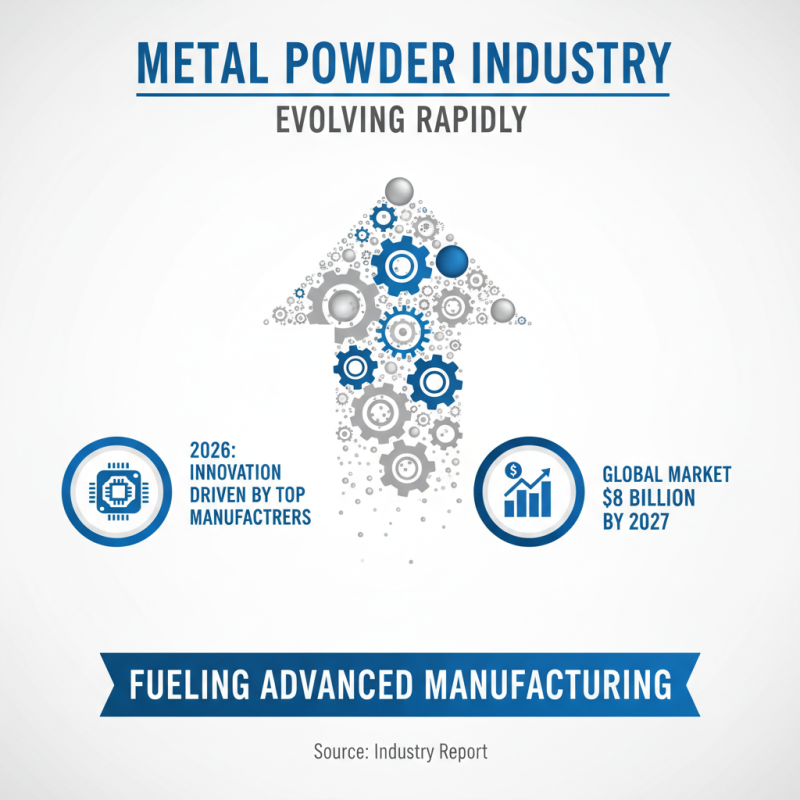

The metal powder industry is evolving rapidly. In 2026, top manufacturers are driving innovations that redefine manufacturing. According to a recent industry report, the global metal powder market is projected to reach $8 billion by 2027. Such growth indicates a rising demand for advanced manufacturing solutions.

Leading companies are focusing on optimizing production efficiency. They are experimenting with new alloy compositions and refining techniques. For instance, powder bed fusion and metal injection molding are gaining traction. However, some manufacturers still struggle with scalability. Finding the right balance between cost and quality remains a challenge.

Environmental concerns are also shaping practices. Sustainable production methods are emerging as necessary. Yet, integrating eco-friendly materials can be complex. Reports show that approximately 30% of companies are hesitant to switch to greener options. The push for innovation is here, but the journey may not be straightforward.

Metal powders play a crucial role in modern manufacturing. They are fundamental in additive manufacturing, commonly known as 3D printing. These powders create intricate designs that were once impossible. They allow for lightweight structures in aerospace or automotive applications. For instance, titanium powders can produce parts that are both strong and light.

Another area where metal powders shine is in the production of sintered parts. This method enhances material properties through heat and pressure. It is used extensively in the creation of tools and components. However, the challenge lies in achieving uniformity in powder quality. Any inconsistency can lead to flaws in the final product. Manufacturers must invest in better quality control measures.

Moreover, metal powders are used in coatings and surface treatments. They improve wear resistance and corrosion protection. In industries like oil and gas, this is especially important. Yet, the methods to apply these coatings can be inefficient. There is still room for innovation. Enhanced techniques could lead to better performance and reliability in harsh environments.

The landscape of metal powder development is evolving rapidly. As we advance toward 2026, several trends are emerging. One crucial trend is the growing focus on sustainability. Manufacturers are increasingly seeking ways to minimize waste. This includes recycling metal powders and developing eco-friendly processes. New technologies are being explored to achieve this goal.

Another important aspect is the enhancement of powder properties. Innovations in powder metallurgy are leading to enhanced mechanical properties. For instance, finer powder particles can improve density and strength. However, achieving uniformity in particle size remains a challenge. Variations in size can affect the final product's performance. This unpredictability requires ongoing research and adaptation in manufacturing practices.

Moreover, the demand for customized solutions is rising. Industries are looking for tailored powder compositions. These can meet specific performance criteria for various applications. Despite these advancements, hurdles remain. Balancing cost and performance should not be overlooked. This balance is vital for widespread adoption of innovative powders. As we look ahead, reflecting on these challenges is essential for progress.

| Metal Powder Type | Applications | Particle Size Range (µm) | Development Trends | Sustainability Practices | Market Growth Rate (2021-2026) |

|---|---|---|---|---|---|

| Stainless Steel | Aerospace, Automotive | 10-50 | Enhanced processing techniques | Recycled materials usage | 6.5% |

| Titanium | Medical implants, Aerospace | 5-25 | Increased powder purity | Energy-efficient production | 8.2% |

| Aluminum | Automotive, Consumer Electronics | 20-100 | Innovative alloy designs | Closed-loop recycling | 7.0% |

| Copper | Electronics, Energy | 15-30 | Powder metallurgy advancements | Eco-friendly extraction | 5.5% |

| Nickel Alloys | Aerospace, Chemical processing | 10-60 | Advanced alloy compositions | Resource optimization practices | 6.0% |