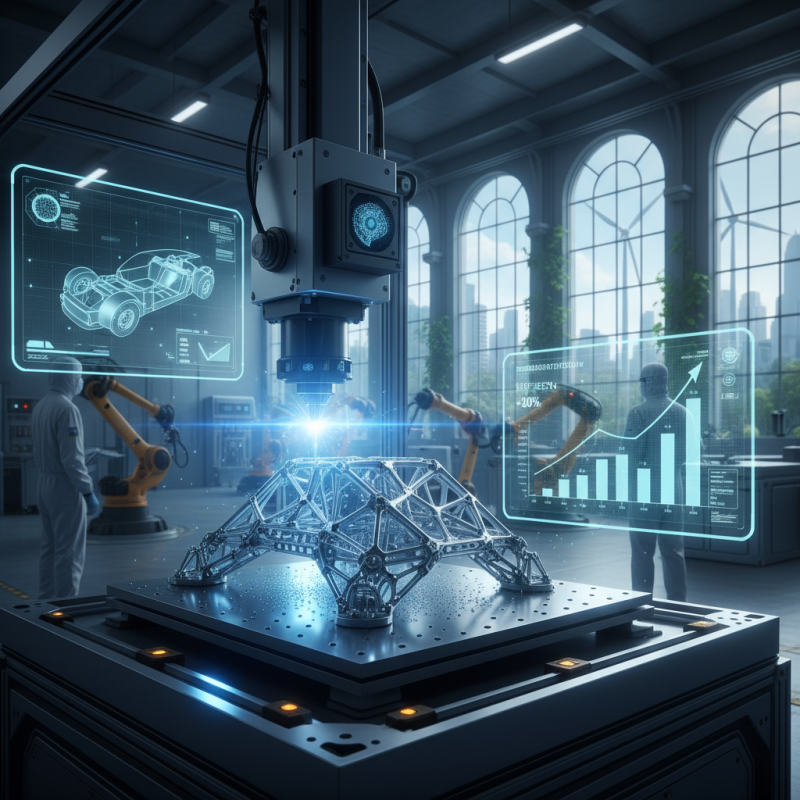

In 2026, the significance of Laser Powder in industrial applications will be undeniable. Recent industry reports indicate that the global market for laser powder is projected to grow significantly, with a compound annual growth rate (CAGR) of over 20%. This growth is driven by advancements in additive manufacturing and precision engineering.

Laser Powder enables the production of complex geometries with remarkable accuracy. For instance, its application in aerospace and automotive sectors highlights its ability to reduce material waste. Companies that adopt Laser Powder technologies report a 30% decrease in production costs. However, challenges remain, such as the need for specialized equipment and skilled operators.

While the benefits are clear, there is a need for deeper research into long-term impacts and sustainability. The industry must reflect on the environmental implications of increased Laser Powder usage. Is the speed of innovation outweighing potential risks? Balancing advancement with responsibility will be crucial as we embrace the future of manufacturing.

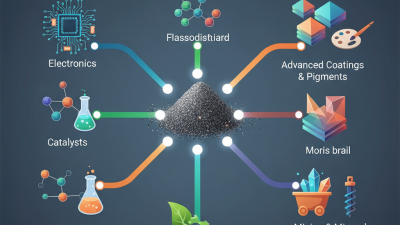

In 2026, laser powder technology is expected to revolutionize various industries. This innovation enhances additive manufacturing, making it more efficient. According to a recent industry report, laser powder applications could see a market growth of 35% by 2026. Recent studies indicate that using laser powder can significantly reduce waste and material costs. This makes the production process more sustainable.

One of the main benefits of laser powder is its ability to create complex geometries. This capability can lead to lighter and more durable products, a trend noted in aerospace and automotive sectors. Yet, adopting this technology poses challenges. Many companies struggle with the initial costs of investment and training. Data suggests that 40% of businesses hesitate due to high entry barriers.

Moreover, the efficiency of laser powder can vary based on the material used. Some powders may not perform well under certain conditions. This inconsistency requires continual research and adaptation. The industry needs to address these gaps before fully harnessing the potential of laser powder technology. Without proper investment in research, the risks may outweigh the benefits.

In 2026, laser powder technology is reshaping manufacturing efficiency. This innovation allows for precise material deposition. Recent reports show that laser powder bed fusion can reduce manufacturing time by up to 50%. This is crucial for industries demanding rapid production cycles, like aerospace and automotive.

Moreover, laser powder enhances material utilization. Studies indicate that it can decrease waste by 30% compared to traditional methods. This efficiency is particularly valuable when using expensive materials. However, the learning curve remains steep. Many companies struggle to integrate this technology smoothly. The skill gap can impact the expected benefits.

Laser powder offers significant advantages, but challenges exist. Adapting existing processes is not always straightforward. Companies must invest time and resources. Improvement is required in operator training and system integration. As the industry grows, these factors will determine overall success.

The advancements in laser powder technologies hold great promise for environmental sustainability. These technologies can significantly reduce waste during manufacturing processes. By using laser powder, industries can create products more efficiently. This method minimizes unnecessary material use and cuts down on pollutants released during production.

Additionally, laser powder techniques focus on recycling efforts. They allow for the reuse of powder materials, which leads to lower resource extraction. This is vital as raw material depletion remains a pressing global issue. While these technologies offer benefits, challenges persist. Implementing laser powders requires substantial investment and training, which not every business can afford.

The impact of these technologies on energy consumption is also noteworthy. Laser systems often consume less energy compared to traditional methods. However, proper energy management practices must be established to truly leverage these benefits. Overall, the integration of laser powder technologies presents an opportunity for greener manufacturing, yet it calls for a careful examination of feasibility and accessibility.

This chart illustrates the projected environmental impact reduction achieved through laser powder technologies by 2026, focusing on key benefits such as reduced waste, lower energy consumption, and emissions decrease.

The advancements in laser powder technology are revolutionizing material quality in 2026. Industries are seeing improvements in strength and precision. Devices created from laser-sintered powders exhibit remarkable durability. This innovation is crucial for sectors like aerospace and automotive. The ability to manipulate material properties at a microscopic level is game-changing.

Despite these breakthroughs, some challenges remain. The consistency of powder quality can vary. This inconsistency potentially leads to defects in the final product. Industries need to implement rigorous testing protocols. Ensuring quality control will help address these imperfections. It's important to reflect on the balance between innovation and reliability.

Additionally, the performance of laser powder in complex assemblies offers intriguing possibilities. The ability to produce lightweight yet robust components is drawing attention. However, the costs associated with high-quality laser materials can be prohibitive. Companies must weigh cost against performance benefits. Finding this balance is essential for widespread adoption. The potential is vast, yet careful consideration is required.

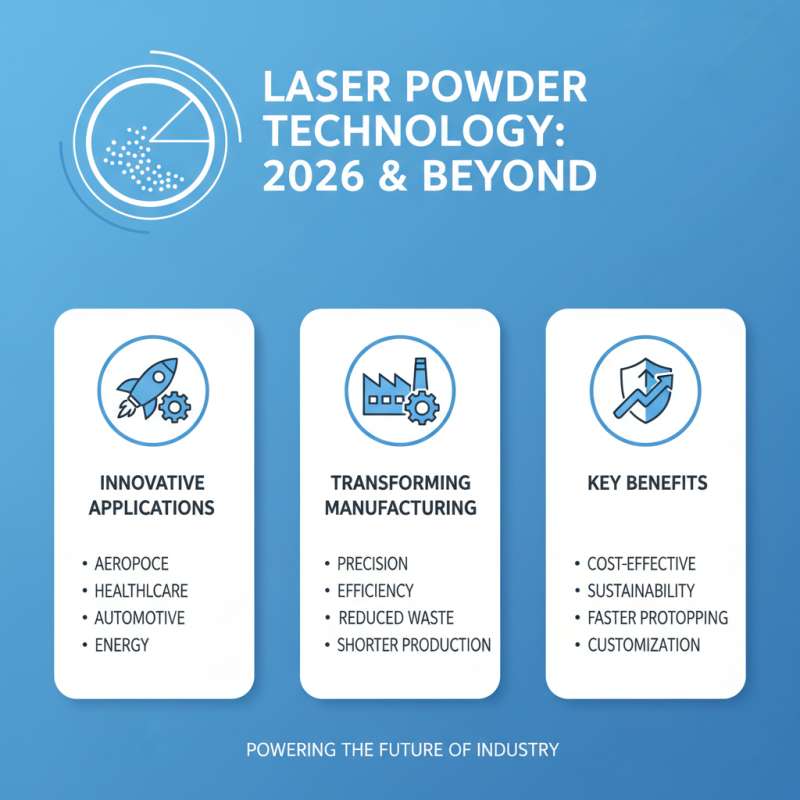

The future of laser powder technology in 2026 holds immense potential. Industries are exploring innovative applications. From aerospace to healthcare, the use of laser powder is transforming manufacturing processes. Its precision and efficiency reduce waste and shorten production times.

In aerospace, lightweight components made from laser powder can improve fuel efficiency. In healthcare, custom implants are being created to fit individual patients. The flexibility of laser powder allows for complex designs that traditional manufacturing methods cannot achieve. This adaptation is crucial for industries looking to innovate.

Tip: Ensure that you stay updated on technological developments. Embrace training sessions or workshops. Networking with industry experts can provide insights into best practices.

As industries adopt laser powder more heavily, challenges may arise. The cost of materials and technology can be a barrier. Additionally, the learning curve for employees can be steep. Organizations must prioritize training programs to address these hurdles.

Tip: Invest in employee education. Regularly assess staff skills. This ensures that your team is equipped for the future.