In today's rapidly evolving industrial landscape, the pursuit of durability and efficiency in project materials is more critical than ever. One innovative solution that has gained significant traction is the use of Powder Coating High Temp. This advanced finishing technique not only enhances the aesthetic appeal of various products but also offers unparalleled protection against harsh environmental conditions, extreme temperatures, and heavy wear. Understanding the myriad benefits of this method is essential for manufacturers and project planners seeking long-lasting and resilient solutions.

By utilizing Powder Coating High Temp, professionals can ensure that their projects maintain a high standard of quality while also benefiting from the energy efficiency and reduced environmental impact associated with this coating process. From automotive parts to industrial equipment, the versatility of powder coating allows for a wide range of applications, making it a preferred choice across various industries. This introduction serves as a gateway to exploring the top ten benefits of Powder Coating High Temp solutions, shedding light on how this innovative technology can transform project outcomes and elevate performance standards.

Powder coating has emerged as a vital process in enhancing the durability and aesthetic appeal of various surfaces, especially in high-temperature environments. Unlike traditional liquid coatings, powder coating utilizes a dry powder that is applied electrostatically and then cured under heat. This process not only creates a thicker and more uniform coating but also results in a finish that is highly resistant to chipping, scratching, and fading. High-temperature resistance is particularly beneficial in applications such as automotive components, industrial equipment, and outdoor fixtures, where exposure to extreme conditions can significantly affect performance and longevity.

Understanding the importance of powder coating in high-temperature solutions lies in its ability to withstand thermal stress without compromising structural integrity. The cured powder forms a robust barrier that protects underlying materials from oxidation and corrosion, which are common issues in high-temp applications. Additionally, powder coatings can be formulated to withstand elevated temperatures, ensuring that the finish remains intact under challenging operational scenarios. This characteristic not only prolongs the lifespan of the coated items but also minimizes maintenance costs and enhances safety by preventing failures associated with temperature-induced degradation.

| Benefit | Description |

|---|---|

| Durability | Powder coating offers superior resistance to chipping, scratching, fading, and wearing compared to traditional paint. |

| Chemical Resistance | High temp powder coatings are resistant to a wide range of chemicals, making them ideal for harsh environments. |

| Heat Resistance | Designed to withstand high-temperature applications, ensuring long-lasting performance without degrading. |

| Environmentally Friendly | Contains no volatile organic compounds (VOCs) and produces less pollution during application. |

| Color Variety | Available in a wide range of colors and finishes, providing aesthetic flexibility for various projects. |

| Quick Application | Application is faster compared to traditional liquid coatings, which improves project turnaround times. |

| Lower Maintenance | Requires less frequent maintenance due to its resilient surface, reducing overall lifecycle costs. |

| Enhanced Adhesion | Powder coating bonds chemically to the substrate, resulting in superior adhesion compared to other finishes. |

| Customizable Thickness | Can be applied in various thicknesses according to the requirements of different projects. |

| Increased Value | The enhanced appearance and durability can increase the overall value of the finished products. |

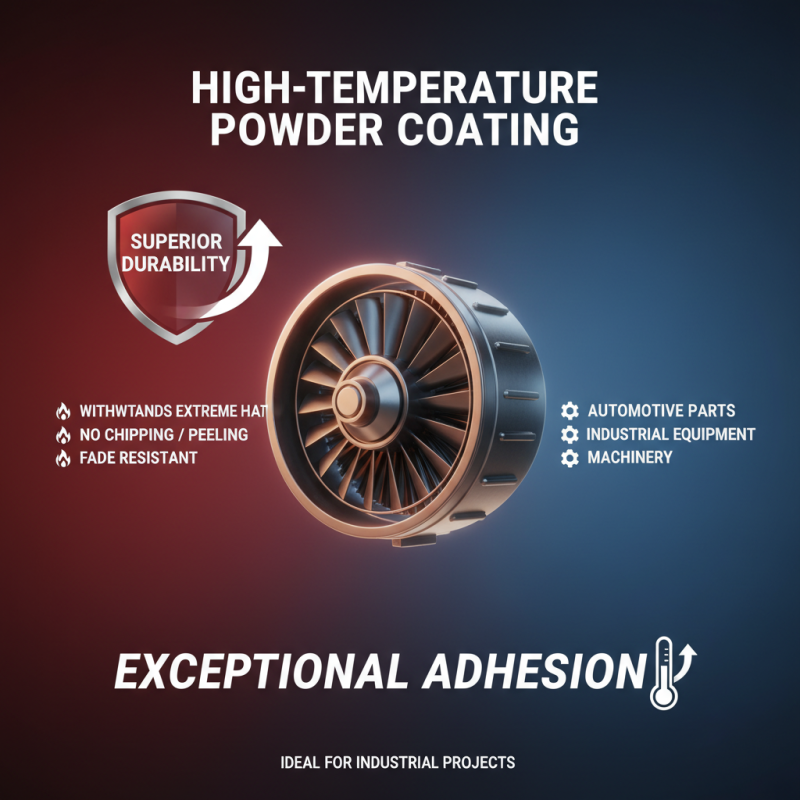

Powder coating offers significant advantages in high-temperature applications, making it an ideal choice for various industrial projects. One of the primary benefits is its exceptional durability, as powder coatings are designed to withstand extreme heat without degrading or losing their protective qualities. This is particularly crucial in environments where items are exposed to regular high temperatures, such as automotive parts, industrial equipment, and machinery. The superior adhesion of powder coatings ensures that they maintain their integrity over time, preventing issues like chipping, peeling, or fading.

Moreover, powder coating provides a robust protective layer against corrosion, which is especially important for components that may be subjected to harsh conditions. This corrosion resistance extends the lifespan of the coated materials, reducing the need for frequent replacements or repairs, ultimately leading to cost savings. Additionally, the versatility of powder coatings allows for a wide range of finishes and colors, giving designers the flexibility to achieve both aesthetic and functional goals. By choosing powder coating for high temperature applications, project managers can ensure that their products remain not only visually appealing but also structurally sound under challenging conditions.

One of the most significant advantages of powder coating high-temperature solutions is its impressive durability and longevity. Unlike traditional paint, powder coating creates a thicker, more resilient finish that withstands harsh environments, extreme temperatures, and chemical exposure. This advanced coating technique offers superior resistance to scratches, chips, and corrosion, making it an ideal choice for projects requiring long-lasting aesthetic appeal and functional performance. As a result, structures and components coated with powder often maintain their integrity and appearance for years, reducing the need for frequent touch-ups or replacements.

Additionally, powder coating contributes to the overall lifespan of projects by providing enhanced protection against environmental factors. The electrostatic application process ensures a uniform coating that adheres effectively to various surfaces, minimizing the risk of uneven wear or degradation. This not only helps in preserving the underlying materials but also supports sustainability efforts by reducing the waste associated with repainting or re-coating. By investing in powder coating, project managers can ensure that their ventures remain visually and structurally sound over time, ultimately promoting cost-effectiveness and resource conservation.

Cost-effectiveness is a crucial consideration for any project, and powder coating high-temperature solutions offer significant economic advantages. One of the primary benefits of powder coating is its durability, which reduces the need for frequent repairs or replacements. Unlike traditional paint, powder coatings create a robust and long-lasting finish that can withstand extreme temperatures and environmental conditions. This durability translates into lower maintenance costs over time, making it a financially sound choice for long-term projects.

Additionally, powder coating processes are typically more efficient than conventional methods. The application of powder coatings generates less waste, which contributes to lower material costs. Furthermore, the curing process requires less energy compared to wet paint drying, resulting in reduced utility expenses. When considering the overall lifecycle costs, projects that utilize powder coating high-temperature solutions can achieve substantial savings, allowing funds to be allocated to other essential areas. This makes powder coating not only a practical choice but also a strategic investment in enhancing the value and longevity of your projects.

Powder coating has emerged as a leading choice in surface finishing due to its numerous eco-friendly attributes. Unlike traditional liquid coatings, powder coating utilizes a dry finish process, which significantly reduces volatile organic compounds (VOCs) emissions. According to the Environmental Protection Agency (EPA), using powder coatings can reduce VOC emissions by up to 90% when compared to solvent-based systems. This reduction not only minimizes harmful air pollution but also contributes to a healthier work environment for operators and nearby communities.

Moreover, the powder coating process generates less waste. Since the powder material can be recycled and reused, this approach ensures that less material is wasted during application. In fact, reports indicate that about 98% of the powder used in the coating process can be reused, leading to lower material consumption and reduced environmental impact. Additionally, powder coatings are typically more durable and resistant to corrosion, which can extend the lifecycle of products and decrease the need for frequent refinishing.

The combination of these factors not only supports environmental sustainability but also enhances the efficiency of manufacturing processes, making powder coating a smart choice for green initiatives in various industries.