Powder Coating Stainless Steel offers significant benefits in both durability and aesthetics. The process of powder coating involves applying a dry powder that is then cured under heat. This results in a hard, protective layer that enhances the metal's resistance to corrosion and wear. According to a report by the Powder Coating Institute, powder-coated surfaces can last two to three times longer than traditional paint finishes.

In the industrial sector, this process is particularly vital. For example, powder coating stainless steel used in outdoor furniture can withstand harsh weather conditions. However, it is important to note that not all powder coatings are created equal. Some may not adhere well to all stainless steel grades, requiring careful selection and application.

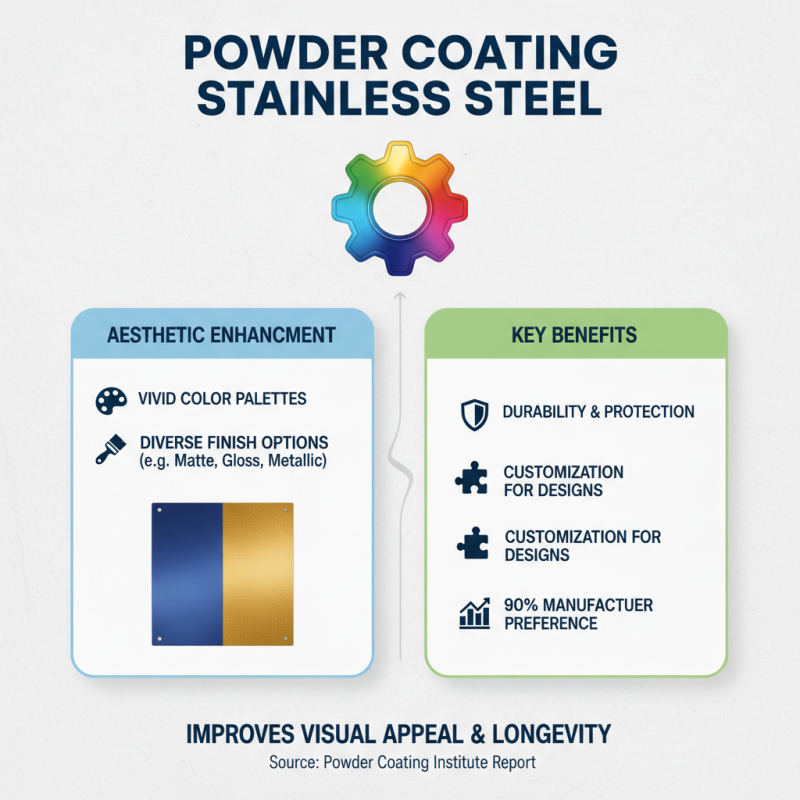

The aesthetics of powder coating are appealing too. With a wide range of colors and finishes available, powder coating allows for customization that enhances visual appeal. While some industries prioritize function over form, the reality is that a visually pleasing finish can significantly impact consumer perception. Yet, a lack of standardization in quality can lead to variations in outcome. This inconsistency can make it challenging for manufacturers to guarantee results.

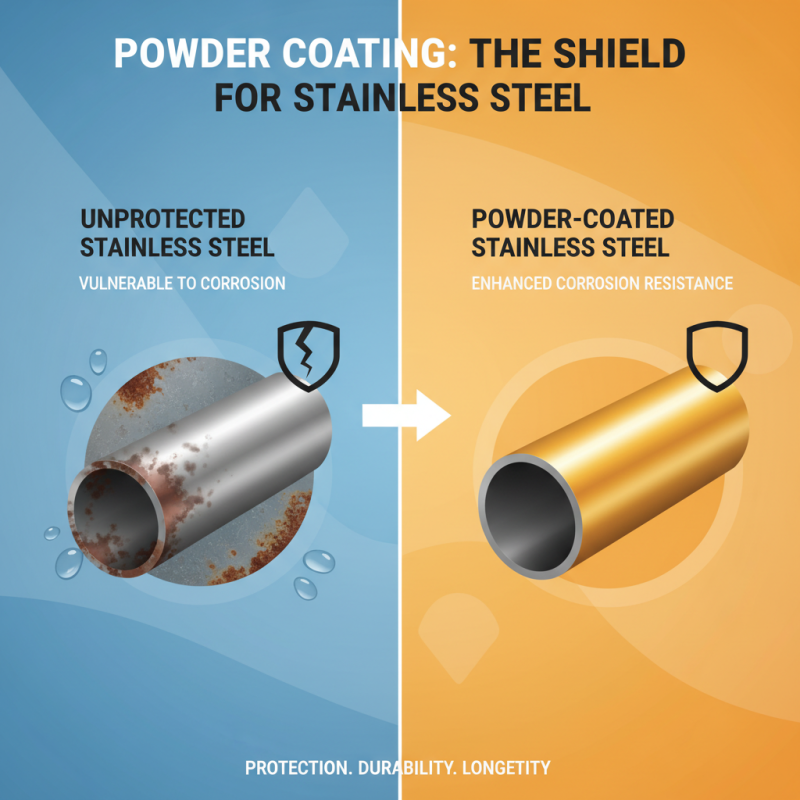

Powder coating stainless steel offers significant benefits for both durability and aesthetics. According to industry reports, coated stainless steel can resist corrosion up to three times longer than untreated surfaces. This increased protection is crucial for outdoor applications, where weather conditions can be harsh. The tough layer of powder coat acts as a shield, safeguarding the metal underneath from physical damage and environmental stressors.

Aesthetically, powder coating enhances the visual appeal of stainless steel. It provides a wide range of colors and finishes, enabling designers to create unique looks. A study found that over 75% of architects prefer powder-coated finishes for their projects due to superior color retention. However, it’s worth noting that not all powder coatings are created equal. Some cheaper options may fade or peel over time, requiring careful selection to ensure long-lasting results.

While powder coating adds to the overall durability, it can be less effective in high-heat environments. Metal parts exposed to extreme heat might see coatings break down faster. Attention to the specific application and environment is essential. Opting for powder coating should involve a thorough assessment of conditions to maximize both durability and aesthetic appeal.

Powder coating is a popular finish for stainless steel. The process involves applying a dry powder that is then cured under heat. This method offers a robust protective layer, enhancing durability against corrosion and abrasion. According to industry reports, powder-coated surfaces can last up to three times longer than traditional paints. This makes powder coating a sensible choice for various applications.

The materials used in powder coating typically include epoxy, polyester, and acrylic. Each type serves different aesthetic and performance needs. For instance, polyester coatings are often favored for their UV resistance, making them ideal for outdoor use. It's notable that while powder coating is generally more durable, imperfections during application can lead to flaws. These can include uneven coverage or orange peel effects, which might detract from the overall look.

Monitoring the curing process is critical. If the temperature is not adequately controlled, the powder may not adhere properly. This can compromise both visual appeal and durability. While powder coating offers many benefits, it's essential to perfect each step. Skipping quality checks can lead to issues that undermine the advantages of this finishing process.

Powder coating has become popular for enhancing stainless steel products. This finish helps improve corrosion resistance significantly. When stainless steel is exposed to moisture, it can corrode despite being durable. Applying a powder coat creates a protective barrier that keeps water and other elements away.

This coating does more than just prevent rust. It also shields against scratches and impacts. However, not all powder coatings are created equal. Some may wear off or chip easily, which can compromise their protective qualities. Regular maintenance is essential to ensure the coating remains effective.

Applying powder coating requires precise methods. The surface must be cleaned thoroughly before coating. Any contaminants can affect adhesion. This step is crucial; it might lead to poor corrosion protection if overlooked. Additionally, colors and textures can vary, impacting aesthetics. Choosing the right finish is not always straightforward.

Powder coating stainless steel significantly enhances its aesthetic appeal. The vivid color palettes and diverse finish options allow for customization. Industries often rely on powder coating for projects requiring specific designs. According to a report by the Powder Coating Institute, around 90% of manufacturers prefer powder coating for its vibrant colors and durability.

Color choices can transform ordinary stainless steel into captivating art. Popular options include matte, gloss, and metallic finishes. These alternatives not only improve the visual aspect but also provide essential protection. However, achieving consistent color can be challenging. Variations may occur due to application methods or environmental factors.

Maintaining the aesthetic quality of powder-coated surfaces can also be a concern. Over time, fading may happen due to prolonged sun exposure. A proper maintenance regimen is crucial. Regular cleaning can help preserve the finish. Even minor scratches or dents can disrupt the smooth appearance. Overall, while powder coating presents many benefits, attention to detail remains vital.

Powder coating stainless steel has gained significant traction in industries seeking both durability and aesthetic appeal. Recent industry statistics highlight a marked improvement in the longevity of powder-coated surfaces. In fact, surfaces treated with powder coating can experience up to 60% increased resistance to corrosion and wear. This robust finish not only enhances visual appeal but also ensures that products endure the test of time.

When considering powder coating, ensure proper surface preparation. Any imperfection can lead to poor adhesion. Clean and sand the steel thoroughly before applying the coating. A flawless base is crucial. Additionally, remember that colors may vary after baking, so always test a small sample. It's a step that could save time and frustration later.

Understanding the limitations is essential. Powder coating is not immune to the elements. Extreme temperatures can affect its durability. Regular inspections and maintenance are necessary to keep the surfaces looking their best. Even a small chip can expose the steel, leading to corrosion over time. Keeping an eye on potential damage can make a significant difference in appearance and longevity.