As industries strive for advanced materials, the demand for High Melting Point Alloys continues to rise. Dr. Emily Chen, a leading expert in materials science, states, "Choosing the right alloy can revolutionize performance." Her insights highlight the importance of making informed choices.

High Melting Point Alloys are critical in aerospace, automotive, and energy sectors. These materials withstand extreme temperatures and maintain integrity. They offer durability, making them suitable for challenging environments. However, selecting the best alloy can be daunting. Factors such as cost, availability, and mechanical properties must be weighed carefully.

The landscape of High Melting Point Alloys is evolving. New formulations emerge, yet it can confuse buyers. Some materials may not perform as expected. It’s essential to conduct thorough research and testing. Reflecting on past decisions can lead to better choices in 2026 and beyond.

When selecting high melting point alloys for 2026, understanding their key characteristics is essential. Alloys such as tungsten, molybdenum, and tantalum hold extreme thermal stability. Tungsten, for instance, has a melting point of 3,422°C. This makes it a top choice for applications in aerospace and nuclear reactors. These materials can withstand harsh environments, making them invaluable for high-temperature applications.

Molybdenum offers excellent strength and thermal conductivity, with a melting point of 2,623°C. It is widely used in manufacturing furnace components and in the defense industry. Tantalum, with a melting point of 2,466°C, exhibits outstanding resistance to corrosion. This makes it ideal for high-performance electronics and medical devices. According to a recent market report, the demand for high melting point alloys is expected to grow by 5% annually through 2026. This reflects the increasing need for materials that endure extreme conditions.

Despite their many advantages, selecting the right alloy requires careful consideration. Not all high melting point alloys perform equally in every scenario. For instance, while tungsten is extremely hard, it can be brittle. Molybdenum may face challenges in certain corrosive environments. It’s important to analyze the specific requirements of each application to ensure optimal performance.

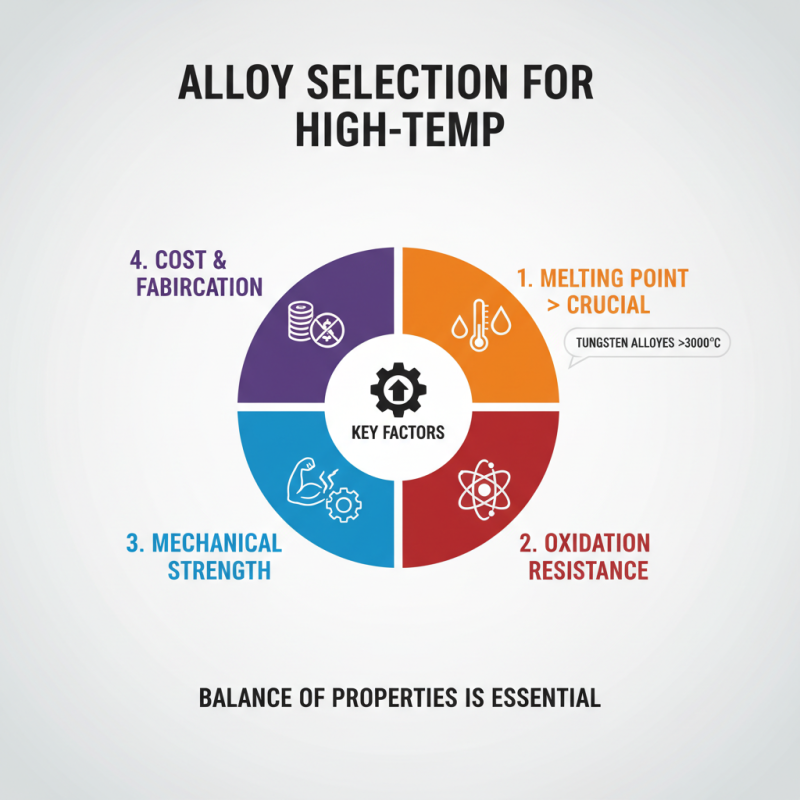

When it comes to high-performance alloys, melting points are crucial. Different alloys have varying melting points, affecting their application in extreme conditions. For enthusiasts and engineers alike, knowing these details can guide material selection.

Titanium alloys generally exhibit high melting points, making them suitable for aerospace applications. In contrast, tungsten alloys can withstand even higher temperatures. However, these materials can be difficult to work with. Their resistance to heat also makes them brittle at times.

Nickel-based alloys present another option. They are versatile and can endure high temperatures. But they may not always be the best choice in all situations. The cost and machining difficulties can limit their use. Ultimately, understanding melting points helps in making informed decisions for future projects.

This chart displays the melting points of several leading high-performance alloys to help in selecting the best option for various applications in 2026.

High melting point alloys are gaining traction due to their unique properties. These materials withstand extreme temperatures and harsh environments. Industries like aerospace and automotive increasingly rely on them. The demand for these alloys is expected to surge by 2026. As companies seek materials that enhance durability and performance, high melting point alloys fit the bill.

Market trends indicate a strong growth trajectory. Innovations in metallurgy are paving the way for new applications. However, this growth comes with challenges. Sourcing raw materials can be difficult. Manufacturers must balance cost and quality to stay competitive. Additionally, researchers are exploring recycling options to reduce waste. Sustainability is becoming a crucial aspect of alloy production.

The landscape is shifting. Emerging technologies could redefine how these alloys are produced. The need for continuous improvement drives exploration into new alloy compositions. Companies that adapt quickly may gain a significant advantage. Nevertheless, the complexity of alloy production requires careful consideration. The future of high melting point alloys promises exciting possibilities but demands thoughtful execution.

Selecting the right alloy for high-temperature environments is a complex task. Several factors come into play. First, the melting point is crucial. An alloy with a high melting point can maintain strength in extreme heat. For instance, tungsten alloys can withstand temperatures over 3000°C. However, not all high-melting alloys are ideal.

The thermal expansion coefficient is another important consideration. Alloys expand when heated, which can lead to structural issues. A material with a low coefficient is preferable. Additionally, corrosion resistance plays a key role. Environments with high oxidation need materials that resist this damage. Nickel-based alloys often perform well, but their cost can be high.

Mechanical properties should be assessed too. Yield strength and ductility determine how well an alloy will perform under stress. Sometimes, the best choices are not just about high melting points. Balancing these factors is a challenge. In reality, compromises are often necessary. Engineers need to reflect on these choices carefully.

High melting point alloys are critical in many advanced applications. Research shows a growing trend toward these materials in aerospace and defense industries. According to a recent report by the Materials Research Society, the market for high melting point alloys is expected to reach $4.5 billion by 2026. This growth is driven by increasing demand for lightweight, high-strength materials that can withstand extreme temperatures.

Innovative approaches in alloy design are emerging. Researchers are exploring new combinations of elements. These aim to balance melting point with mechanical strength. For instance, tungsten-based alloys are gaining attention. They can perform in environments exceeding 3000 degrees Celsius. However, the challenge remains in their brittleness at room temperature, requiring further refinements.

While there is excitement, some aspects still need improvement. Many alloys exhibit complex manufacturing challenges. Techniques like additive manufacturing offer potential, yet they introduce variability in material properties. Future advancements may address these issues, particularly in processing capabilities and material reliability. Continuous investment in research is essential to unlock the full potential of high melting point alloys in diverse fields.