High Temperature Powder Coating is becoming a popular technique for various industries. It offers unmatched durability and resistance against harsh conditions. This coating method withstands extreme temperatures, making it ideal for automotive parts, appliances, and industrial equipment.

Many manufacturers seek the best practices for High Temperature Powder Coating to ensure longevity. The application process can be tricky, requiring precise temperature control and proper surface preparation. Achieving a flawless finish isn't always easy, and imperfections can occur. Understanding these details is crucial for consistent results.

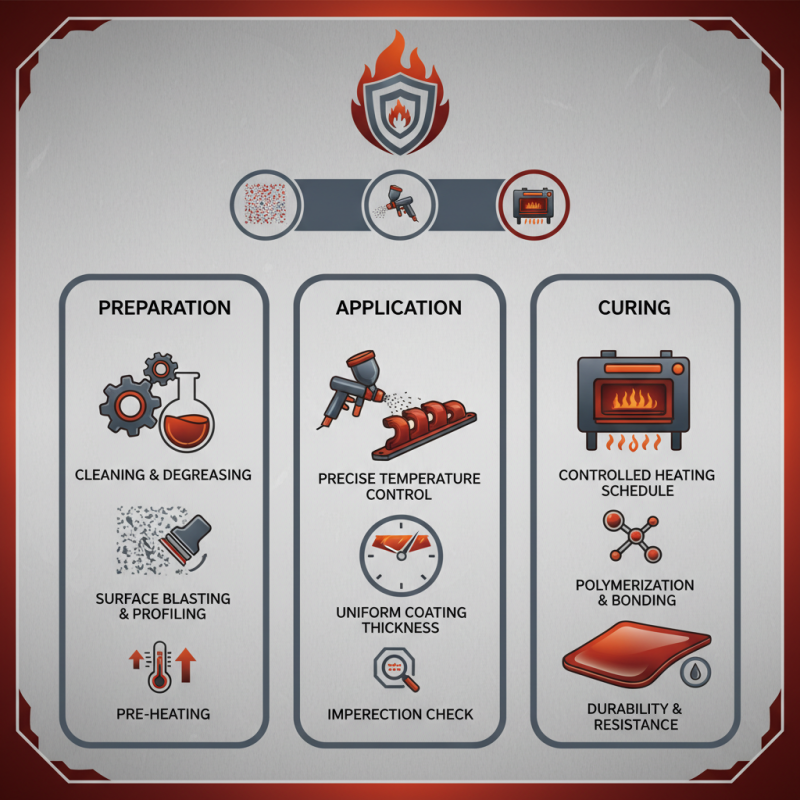

In this guide, we will explore effective techniques for High Temperature Powder Coating. Strategies will focus on preparation, application, and curing mechanisms. While there are common practices, each project holds unique challenges. Reflecting on past experiences can lead to better outcomes.

High temperature powder coating techniques are crucial for enhancing durability in various applications. These methods provide a tough, protective layer that withstands extreme conditions. Proper surface preparation is vital. Cleaning, sanding, and priming surfaces ensure adherence. Neglecting this step can lead to peeling or chipping.

The application process generally involves a spray gun, where the powder is electrostatically charged. This charge helps the powder cling to the surface. Adequate curing is essential. It typically requires temperatures around 350°F to 400°F for proper bonding. Overheating can cause defects, while under-curing may result in a weak finish.

Experimentation is key in achieving optimal results. Adjusting powder thickness and airflow can improve outcomes. It's all about trial and error. Document the process to track what works and what doesn’t. Embrace the imperfections; learn from them to refine your technique. Durability is not just about the coating; it’s also about perfecting your process.

High temperature powder coating offers remarkable durability. This technique is especially useful in industries like automotive and aerospace. It withstands extreme heat and harsh environments. The process typically involves applying a dry powder to a surface. The coated object is then cured using high temperatures, resulting in a strong bond.

One might overlook the importance of surface preparation. Proper cleaning and priming can significantly affect the final outcome. Skipping these steps may result in poor adhesion. Variability in the curing process can also lead to unexpected results. Factors like temperature and time must be closely monitored.

Another challenge is color consistency. Maintaining uniformity across multiple batches can be tricky. Even slight variations can impact the overall appearance. It is essential to perform testing regularly to ensure quality. Reflecting on these potential pitfalls can enhance the effectiveness of high temperature powder coating techniques.

| Technique | Temperature Range (°F) | Curing Time (minutes) | Durability Rating | Common Applications |

|---|---|---|---|---|

| Standard High Temp | 400-480 | 15-30 | 8/10 | Automotive parts, industrial equipment |

| Ceramic-Based Coating | 600-800 | 20-40 | 9/10 | Exhaust systems, high-performance engines |

| Epoxy Coating | 300-400 | 10-20 | 7/10 | Marine and automotive components |

| Silicone Powder Coating | 500-700 | 15-25 | 9/10 | Industrial textiles, HVAC systems |

| Hybrid Coating | 400-600 | 15-35 | 8/10 | Heavy machinery, outdoor applications |

High-temperature powder coatings are essential in various industrial applications. They enhance durability and provide protection against extreme conditions. These coatings can withstand temperatures up to 600°F (315°C), making them suitable for automotive and aerospace sectors. According to recent industry reports, high-temperature coatings can extend the lifespan of components by 50% compared to traditional finishes.

Key properties of these coatings include thermal resistance, chemical stability, and excellent adhesion. They help prevent rust and corrosion, crucial for parts exposed to harsh environments. The application process allows for a thick coating layer with a smooth finish, which can reduce the need for frequent maintenance. However, achieving proper curing is vital; improper curing can lead to inadequate performance.

Tips: Ensure that the surface is prepped correctly. Dust or grease can affect adhesion. Monitor the curing temperature closely. Even small deviations can compromise the coating performance. Additionally, experiment with different powder formulations to find the best fit for your specific needs. The right choice can save money in the long run. Be aware that not every technique will yield the same results. Regular testing and adjustments are necessary for optimal outcomes.

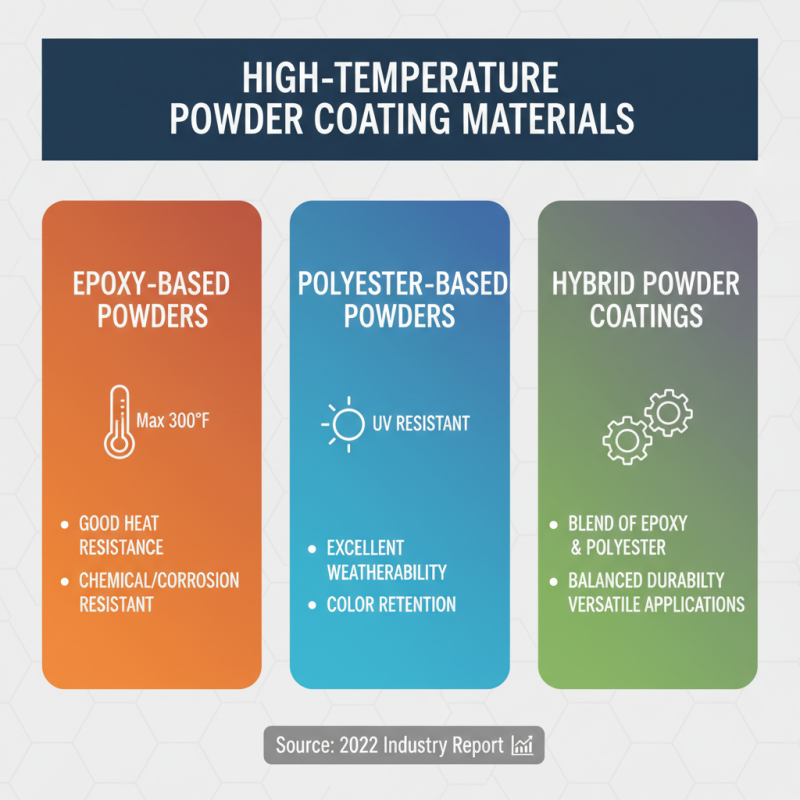

When considering high-temperature powder coating, selecting the right materials is crucial for durability. Coating materials vary significantly in their heat resistance. For instance, epoxy-based powders can withstand temperatures up to 300°F, while polyester powders offer better UV resistance. According to a 2022 industry report, hybrid powder coatings blend properties from both types, providing an optimal balance for many applications.

Tips: Always evaluate application environments. Knowing the maximum heat levels ensures the right choice. Temperature variations can affect coating performance.

Ceramic-based powder coatings have gained traction for extreme conditions. They can endure temperatures above 1,000°F. This makes them ideal for aerospace and automotive industries. However, they may not bond as well to metals as other coatings. A recent study noted issues with adhesion on certain substrates. This emphasizes the importance of substrate preparation.

Tips: Surface preparation is key. Ensure thorough cleaning and priming before applying coatings. This can increase durability and longevity.

High temperature powder coatings excel in extreme conditions. Their durability relies on several key techniques. One effective method is optimizing the curing process. Proper heat application allows the powder to bond tightly to the substrate. However, controlling temperatures can be tricky. Too high might damage the part, while too low leads to poor adhesion.

Another technique involves selecting the right formulations. Some powders contain additives that enhance resistance to ultraviolet light and chemicals. This can be crucial for outdoor applications. Yet, not every formulation performs equally under all conditions. It's essential to test different powders to find the best fit for your specific needs.

Surface preparation plays a vital role. Thorough cleaning and profiling can significantly improve adhesion. Ignoring this step often leads to costly failures in the field. After all, even the best coatings can fail if the surface is not properly prepared. Consistency in applying these techniques leads to a more durable finish, though it's a process that requires careful adjustment and attention to detail.

The article "Best High Temperature Powder Coating Techniques for Durability" explores the essential aspects and applications of High Temperature Powder Coating in various industrial settings. It highlights the key properties that make these coatings suitable for high heat environments, such as excellent thermal resistance and chemical stability. A comparative analysis of different coating materials showcases their performance regarding heat resistance, helping industries make informed choices.

Additionally, the article discusses various techniques to enhance the durability of High Temperature Powder Coating, emphasizing the importance of adhering to industry standards and utilizing effective testing methods to ensure reliability and longevity. By understanding these techniques and properties, manufacturers can better utilize High Temperature Powder Coating to achieve superior performance and durability in their products.