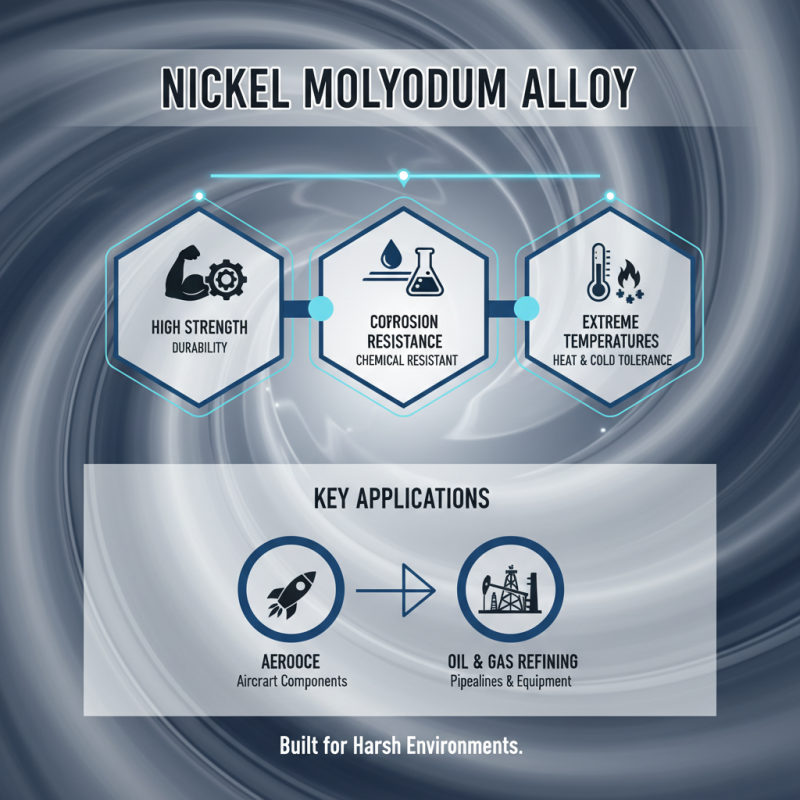

In the realm of advanced materials, the Nickel Molybdenum Alloy stands out. Its unique properties make it a sought-after option in various applications. This alloy blends nickel with molybdenum, offering excellent strength and corrosion resistance.

Industries such as aerospace and petrochemicals often rely on this alloy. Components made from Nickel Molybdenum Alloy withstand extreme conditions. They perform reliably in high temperatures and corrosive environments. However, there are still challenges in its production. Costs can be high, and sourcing raw materials may pose difficulties.

Understanding the benefits of Nickel Molybdenum Alloy is crucial. It offers durability and longevity in demanding applications. Overall, it is essential to weigh its advantages against potential drawbacks in specific scenarios. This exploration highlights where this alloy can shine and where improvement is needed.

Nickel molybdenum alloy is notable for its unique properties. It boasts high strength and excellent corrosion resistance. These characteristics make it suitable for harsh environments. The alloy can withstand extreme temperatures. This is crucial in industries like aerospace and oil refining.

In addition to strength, the alloy's malleability is remarkable. It can be fabricated easily into various shapes. This flexibility allows for adaptability in design and engineering. However, the cost of nickel molybdenum alloy can be a concern. It often requires careful consideration in budget planning. Industries must weigh the benefits against the expenses.

Heat treatment can enhance the properties of the alloy. This process improves toughness and hardness. Yet, improper heat treatment can lead to brittleness. That presents a challenge in achieving the desired balance. Users must be diligent during production to prevent issues. Collaboration with specialists may help refine these processes.

Nickel molybdenum alloys are gaining traction across different industries due to their unique properties. These alloys exhibit excellent resistance to high temperatures and corrosion, making them ideal for demanding environments. For instance, in aerospace applications, these materials are used in components that experience extreme stress and temperatures, ensuring safety and reliability.

In the oil and gas sector, nickel molybdenum alloys are crucial. They are used to manufacture pipelines and valves that operate in harsh conditions. According to a market report, the demand for these alloys in oil and gas applications is anticipated to grow by 4% annually. Their strength and corrosion resistance help extend the lifespan of critical infrastructure.

Tips: When selecting nickel molybdenum alloys, consider the specific environment and stress factors. Not all alloys are created equal, and some may perform better than others in certain applications. Always request detailed reports on alloy performance in your desired conditions before making decisions.

Nickel molybdenum alloys have gained popularity in high-performance environments. These materials exhibit exceptional resistance to corrosion and fatigue. They withstand extreme temperatures and harsh conditions, making them ideal for various applications. In aerospace, for example, components made from these alloys perform reliably under intense stress.

The benefits are clear. These alloys enhance the longevity of equipment, reducing maintenance costs. Their strength-to-weight ratio is impressive, allowing for lighter designs without compromising durability. However, not all nickel molybdenum alloys are created equal. Some may not perform as expected in specific situations. It’s crucial to evaluate each application carefully.

Moreover, while these alloys are versatile, they can be challenging to work with. Machining difficulties may arise, leading to increased production times. Engineers must account for these factors during the design phase. Understanding the balance between performance and manufacturability is essential in optimizing their use.

Nickel molybdenum alloys (NiMo) are gaining traction across various industries. They excel in high-stress and high-temperature environments. Their corrosion resistance is impressive, particularly in acidic conditions. Compared to stainless steels, NiMo alloys offer superior performance in certain applications. For instance, in the oil and gas sector, NiMo’s ability to withstand sour gas environments is vital. Reports suggest that their use can extend equipment life by up to 50%, reducing maintenance costs.

However, they aren't without challenges. Nickel molybdenum alloys can be more costly to produce than other alloys. The manufacturing processes require careful handling, potentially leading to waste. Additionally, while NiMo holds advantages in corrosion resistance, it may lack strength at very high temperatures compared to high nickel alloys. Understanding these trade-offs is crucial for engineers selecting materials.

Comparative studies reveal that while nickel molybdenum alloys shine in specific applications, other alloys may be preferred for general use. For example, carbon steels remain dominant due to their lower costs and adequate performance in less demanding conditions. A recent survey indicated that 45% of manufacturers still rely heavily on traditional alloys. This highlights a significant area where NiMo can potentially grow by overcoming existing barriers in cost and processing efficiency.

| Application | Nik-Mo Alloy Features | Benefits | Comparison with Other Alloys |

|---|---|---|---|

| Oil & Gas Industry | High corrosion resistance, excellent strength | Durable in harsh environments | Superior to Carbon Steel and some Stainless Steels |

| Aerospace Components | Lightweight, good thermal stability | Reduce weight without sacrificing strength | Better performance than Aluminum Alloys |

| Chemical Processing | Resistant to pitting and crevice corrosion | Increased lifespan of equipment | Outperforms Nickel Alloys in specific conditions |

| Power Generation | High strength at elevated temperatures | Efficiency in high-stress applications | More reliable than conventional Steels |

| Marine Applications | Excellent resistance to seawater corrosion | Longevity in marine environments | Better than Titanium Alloys due to cost-effectiveness |

Nickel molybdenum alloys are increasingly popular in various industries. Their unique properties make them suitable for harsh environments. Applications range from aerospace to chemical processing. These materials offer superior corrosion resistance and strength. Companies continue to explore their potential in innovative projects.

Future trends will likely focus on optimizing alloy compositions. Researchers are investigating new ways to enhance performance. This includes refining manufacturing processes to reduce costs. The challenge lies in balancing quality with affordability. Collaboration between industries may lead to breakthroughs.

Additionally, sustainability is becoming a priority. Companies are looking into eco-friendly production methods. There is an ongoing need to recycle these materials effectively. The industry must address environmental impacts actively. Innovations in nickel molybdenum alloy technologies will shape the future. Mistakes from past practices should guide current choices. The road ahead is promising yet requires careful navigation.