In the realm of industrial applications, the selection of the right Nickel Powder is crucial for enhancing performance and ensuring the longevity of products. The global Nickel Powder market is projected to reach USD 2.5 billion by 2026, driven by the increasing demand in industries such as aerospace and electronics. According to a recent report by MarketsandMarkets, the growth of additive manufacturing technologies further underscores the need for high-quality Nickel Powder that meets specific industry requirements.

Industry expert Dr. Michael T. Simmons, a leading researcher in powder metallurgy, notes, “The choice of Nickel Powder can significantly impact the mechanical properties of the final product, making it essential to consider factors such as particle size, morphology, and purity.” This assertion highlights the importance of careful evaluation when selecting Nickel Powder to ensure optimal performance in various applications, including battery production, fuel cells, and specialized coatings. As industries continue to evolve, understanding these factors will be pivotal to harnessing the full potential of Nickel Powder in advancing technology and innovation.

When selecting nickel powder for industrial applications, understanding its properties is crucial to ensure optimal performance. Nickel powder is characterized by its fine particle size, high surface area, and excellent corrosion resistance. These properties make it suitable for various applications, including battery production, electronics, and metallurgy. The morphology of the nickel powder, whether spherical or irregular, can also significantly influence the material's flowability and compaction behavior, which are essential for processes such as additive manufacturing and sintering.

Another important property to consider is the nickel powder's purity. High-purity nickel is vital for applications where contamination can impair functionality or performance. Additionally, the particle distribution and density of the powder can affect how it behaves in different processing environments. Manufacturers must also evaluate the nickel powder's thermal and electrical conductivity, as these attributes are crucial for applications requiring efficient energy transfer. By carefully considering these properties, industries can select the most suitable nickel powder that meets their specific operational requirements.

When selecting the best nickel powder for various industrial applications, it's essential to consider the different types available and their specific uses. Carbonyl nickel powder is gaining significant traction, with the market projected to reach USD 1.6 billion by 2034. This growth is primarily driven by the increasing demand in advanced manufacturing sectors, including electronics and automotive industries. Notably, this type of nickel powder is particularly favored for its highly refined properties, making it suitable for precision applications in additive manufacturing.

Another vital aspect to consider is the expanding 3D printing metals market, expected to be worth $3.62 billion by 2030. Nickel powders, alongside other metal types, play a crucial role in this field due to their unique characteristics that enhance the performance of 3D printed components. As manufacturers explore advanced methods, selecting the right type of nickel powder—be it carbonyl or another form—will directly impact production efficiency and product quality.

Tips: When choosing nickel powder, always evaluate the powder’s particle size and morphology, as these factors significantly influence the flowability and sintering behavior during manufacturing processes. Additionally, ensure that the selected nickel powder conforms to industry-grade standards to meet specific application requirements efficiently.

When selecting the best nickel powder for industrial applications, there are several key factors to consider. One important aspect is the intended use of the powder in additive manufacturing. The demand for specialized metal powders, especially in 3D printing, is projected to grow significantly, with the 3D printing metals market expected to reach $3.62 billion by 2030. Nickel and cobalt-based powders are particularly valued for their high-performance capabilities in sectors like aerospace and gas turbine applications.

Additionally, the purity and particle size distribution of nickel powder play vital roles in determining its performance characteristics. For example, nickel-base superalloys are renowned for their mechanical properties, making them ideal for demanding environments, though they present limitations in terms of processing and cost.

Tips:

When selecting nickel powder for industrial applications, evaluating supplier quality and reliability is paramount. A reputable supplier should provide comprehensive information about their manufacturing processes and the purity of their nickel powder. High-quality nickel powder should meet industry standards and specifications, which can often be verified through certifications such as ISO or ASTM. Additionally, obtaining samples for testing can help ensure that the supplied powder meets your specific requirements regarding grain size, distribution, and chemical composition.

It is also crucial to consider the supplier’s track record and customer reviews. A reliable supplier will have a history of delivering consistent quality and timely shipments. Engaging with current and past customers can provide insights into the supplier's reliability and customer service responsiveness. Furthermore, assessing the supplier's ability to provide technical support and guidance can enhance the overall experience, ensuring that they can address any issues that may arise during your use of nickel powder in various applications.

This thorough evaluation process will enable businesses to build lasting partnerships with suppliers that meet their stringent quality expectations.

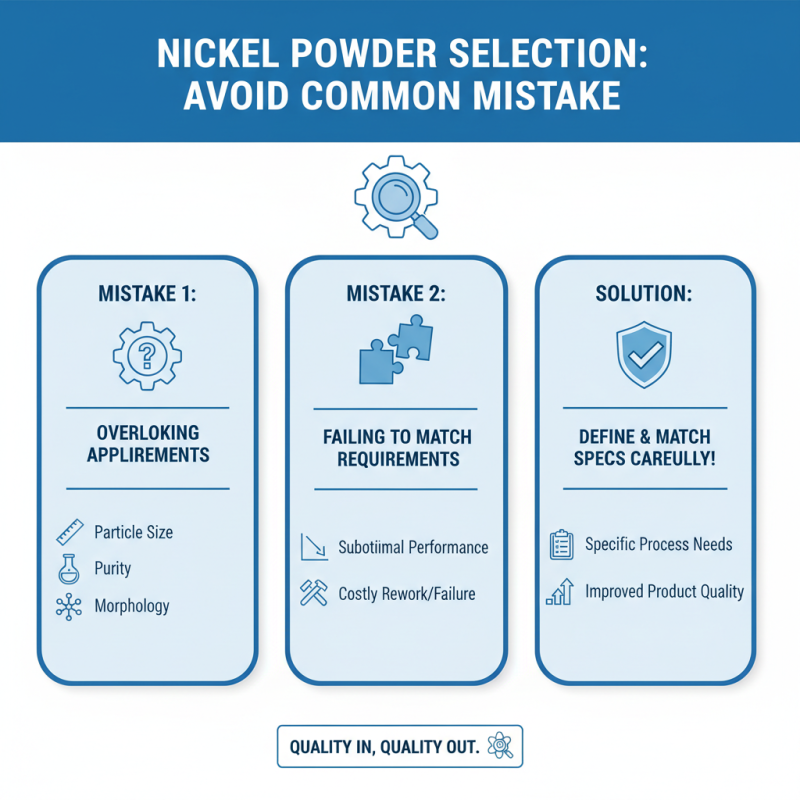

When selecting nickel powder for industrial applications, avoiding common mistakes can significantly impact the quality of your final product. One frequent error is overlooking the specific requirements of your application. Different industrial processes may demand specific particle sizes, purities, and morphologies. Failing to match these requirements could lead to suboptimal performance and costly rework or failure of the finished product.

Another common mistake is not considering the source and production method of the nickel powder. Some suppliers may provide powders that have inconsistent quality or trace impurities, which can affect the powder's behavior during processing. It is essential to conduct thorough research on the supplier's reputation and the manufacturing processes they employ, ensuring that their nickel powder meets industry standards. Additionally, neglecting to review material safety data sheets (MSDS) can lead to handling and processing issues, exposing workers to unnecessary risks. By being vigilant and informed, you can make a more confident and effective choice in selecting nickel powder for your needs.