When it comes to protective coatings, Thermal Spray Powder stands out. This technology offers unique advantages in various industries. It enhances the performance and lifespan of components.

Using Thermal Spray Powder can greatly improve surface properties. It provides resistance to wear, corrosion, and high temperatures. These qualities are essential for maintaining machinery in harsh environments. However, it is important to choose the right powder for specific applications.

Despite its benefits, choosing Thermal Spray Powder can be complex. There are various types available, each with different characteristics. Users may feel overwhelmed by these options. Careful consideration and research are necessary to make an informed choice. Quality and compatibility are crucial for optimal results.

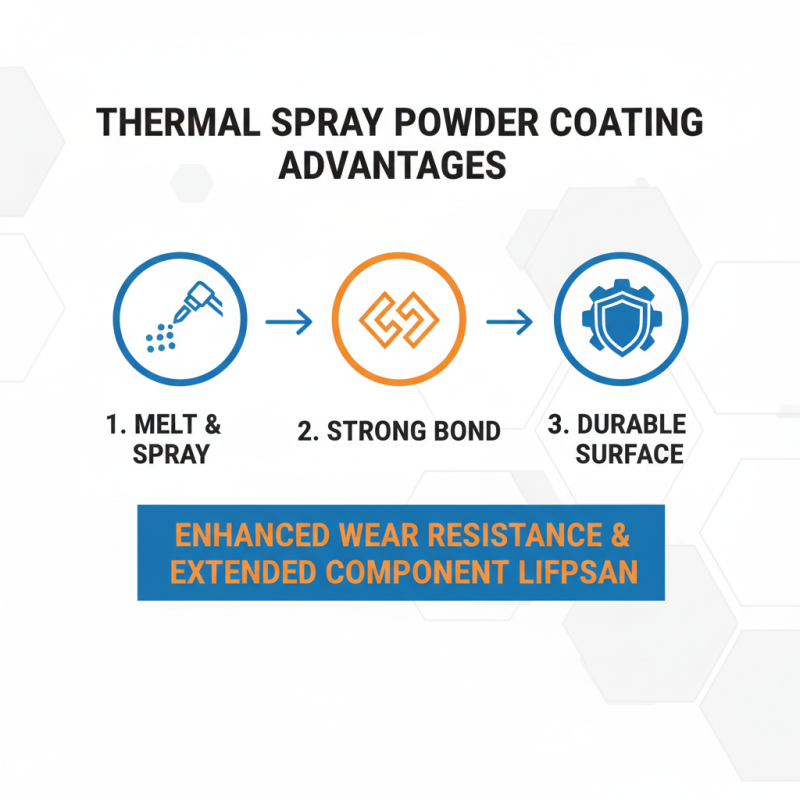

Thermal spray powder offers unique advantages for coating applications. This method provides durable and robust surfaces. The process involves melting the powder and spraying it onto surfaces. The result is a strong bond that enhances wear resistance. This improved durability can extend the lifespan of components.

Another benefit is the variety of materials available. Users can choose from ceramics to metals, depending on their needs. Each material brings specific properties. For example, ceramic coatings resist high temperatures. Metal powders, on the other hand, might be better for corrosion resistance. However, selecting the right powder requires careful consideration. Not every material suits every application.

It's worth noting that the thermal spray process can be complex. Achieving the right thickness and uniformity can be challenging. Improper application may lead to weak spots. It’s crucial to test and evaluate the finished coating. Ensuring its performance takes effort. However, when done correctly, the benefits of using thermal spray powder are undeniable.

Thermal spray powders come in various types, each tailored for specific applications. Ceramics are widely used in thermal barrier coatings. These coatings help protect engines and turbines from high temperatures. A report by the Global Thermal Spray Market estimates that ceramics dominated approximately 40% of the market share in 2022. This shows their importance in industries requiring heat resistance.

Metals are also popular in thermal spraying. Nickel-based alloys are often used for coatings in the aerospace and automotive sectors. Their properties enhance corrosion resistance and wear performance. According to a recent industry analysis, metal powders are projected to grow at a CAGR of 5.2% through 2027. This reflects increasing demand for durability in high-stress environments.

However, the choice of powder isn't straightforward. Factors like powder composition and particle size affect performance drastically. Not all applications benefit equally from each type of powder. Some processes may require adjustments. Thus, selecting the right thermal spray powder requires careful consideration of specific needs.

When selecting thermal spray powders for coatings, several factors must be considered. The primary consideration is the substrate material. Different powders perform uniquely on various substrates, such as metal or ceramic. The compatibility between the powder and substrate affects adhesion and durability.

Another crucial factor is the operating environment. Will the coated item face high temperatures or corrosive elements? Understanding the application's conditions helps narrow down the powder options. Each powder has distinct properties that suit specific environments.

Tips:

Choose a powder that matches the end-use conditions. This is critical to the coating’s performance. Also, think about the desired finish. Textured or smooth coatings require different powders.

Lastly, don't overlook the powder's particle size. The size influences the process efficiency and final coating quality. A variation in size can lead to uneven applications. Consult with experts to ensure you make the right choice.

Thermal spray coatings are used in various industries, providing vital protection and enhancing performance. These coatings are versatile and can be applied to improve wear resistance, corrosion protection, and thermal insulation. According to a recent market report, the thermal spray coating market is projected to reach $12 billion by 2026, demonstrating significant growth.

In the aerospace sector, thermal sprays are essential. They protect components from extreme temperatures and corrosive environments. For example, turbine blades often receive thermal spray coatings to withstand harsh conditions. A study showed that these coatings can extend the lifespan of blades by up to 30%. However, the application process can be complex and requires careful management.

The automotive industry also benefits from thermal spray coatings. Engine components frequently use these coatings for enhanced durability. Reports indicate that approximately 40% of all thermal spray coatings are utilized in automotive applications. Despite these advantages, issues like inconsistent coating thickness can affect performance. Regular inspections and quality control measures are crucial for optimal results, ensuring coatings meet the necessary standards.

Thermal spray powder offers distinct advantages over traditional coating methods. Unlike liquid coatings, thermal spray creates a thicker layer. This brings better durability and wear resistance. The process involves melting powdered materials and spraying them onto a surface. It results in a robust bond that is hard to replicate with paint or dip coatings.

Moreover, thermal spray can be used on various materials. Metals, ceramics, and composites can all be coated effectively. Liquid methods often struggle with such versatility. However, achieving a perfect coating may not always be possible. Surfaces need careful preparation to avoid imperfections. Inconsistent spraying can lead to weak spots.

Comparing costs is also important. Thermal spray requires specialized equipment and skilled operators. Initial expenses might be higher. Yet, the long-term savings in maintenance can justify the investment. It’s crucial to weigh these factors against the specific needs of each project. Consider the long-lasting benefits of thermal spray. It may provide the superior performance needed for demanding applications.