Choosing the right materials for a project is crucial. In the realm of construction and design, "Powder Coated Stainless Steel" stands out. Industry expert John Miller emphasizes, "The finish defines not just the look, but the longevity of a project."

Powder Coated Stainless Steel offers a sleek appearance while providing protection against corrosion. Many wonder how to select the best option for their needs. Various colors and textures are available, adding flexibility to designs. Yet, one must consider the environment. Will it stand up to harsh weather? This is a critical question.

There's a fine line between aesthetics and functionality. Overlooking the quality of the powder coating can lead to costly repairs later. Some products may fade or chip over time, losing their charm. Looking closely at the vendor’s reputation helps ensure a good choice. Make sure to gather samples and assess your options carefully; an informed decision will benefit your project significantly.

Powder coated stainless steel has become a popular choice for many projects. Its durability is one of its key features. The powder coating adds a protective layer, enhancing resistance to scratches and corrosion. This makes it ideal for outdoor use. For example, a garden bench made of powder coated stainless steel withstands rain and sunlight, keeping it looking new.

Another benefit is the variety of finishes available. You can choose from glossy to matte, and even textured surfaces. This versatility allows you to match various design aesthetics. However, not all colors resist fading equally. Some shades may lose vibrancy over time. It's crucial to consider this when making decisions.

While powder coated stainless steel offers many advantages, one must think about maintenance. The surface can accumulate dirt and grime. Regular cleaning is necessary to maintain its appearance. Additionally, chips in the coating can expose the metal beneath. Planning for upkeep ensures the longevity of your project.

When selecting powder coated stainless steel, several factors are crucial for your project. The material's corrosion resistance is a key consideration. According to industry reports, stainless steel can perform well in harsh environments, but the powder coating enhances durability. Over 70% of industries benefiting from powder coating noted improved longevity and aesthetics.

Thickness of the powder coating matters, too. A standard thickness of 2 to 3 mils can provide adequate protection. However, in demanding conditions, a thicker layer may be necessary. A report indicated that 40% of users opt for a thickness exceeding 5 mils for added resilience. The choice of color and finish can affect both appearance and performance. Different colors may have varying UV resistance, influencing their longevity outdoors.

Cost considerations can't be ignored. Budget constraints often lead to compromises. It's not uncommon for projects to overlook the total lifecycle expenses. A study found that 25% of users regretted choosing cheaper options, as they incurred higher maintenance costs. Weighing immediate savings against long-term durability is a common dilemma. Understanding your requirements thoroughly can help you make a better choice.

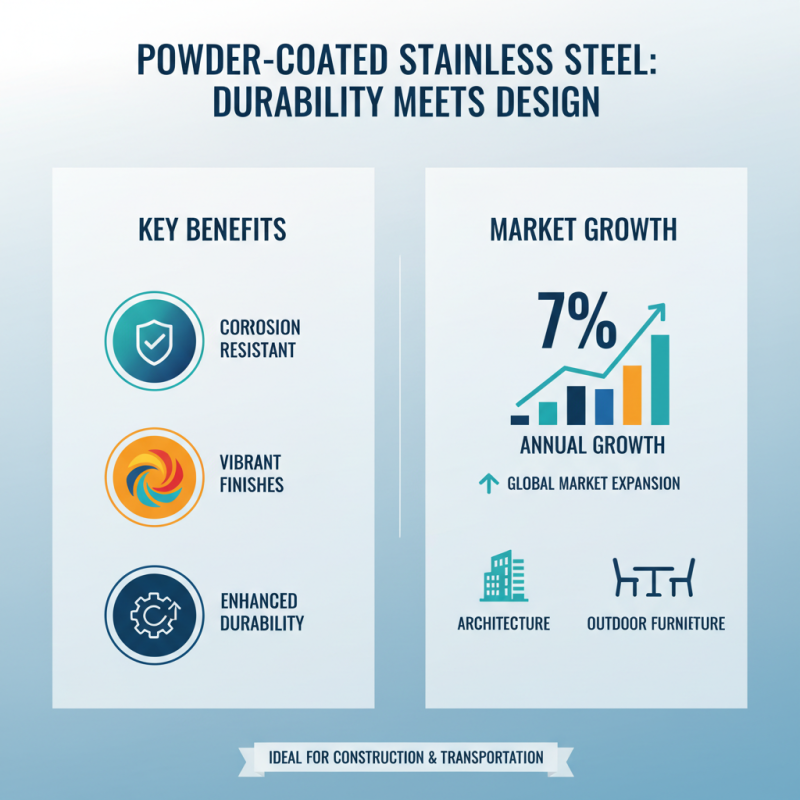

This chart illustrates the importance of various factors to consider when choosing powder coated stainless steel for your projects. Corrosion resistance stands out as the most critical aspect, followed by durability and aesthetic appeal.

When considering powder-coated stainless steel for your project, it's essential to explore the variety of finishes and colors available. Reports from industry experts suggest that around 70% of consumers prefer customized colors to match their design aesthetics. Powder coating offers a range of finishes including matte, glossy, and textured options. These finishes can enhance the visual appeal and durability of stainless steel products.

Color variety is another significant advantage. Common colors include black, white, and various shades of gray. However, through custom blending, you can achieve nearly any color imaginable. According to recent studies, projects utilizing diverse colors often see a 30% increase in client satisfaction. While the vibrancy of powder coatings is impressive, there are challenges with color uniformity during application. This issue underscores the importance of working with skilled professionals to ensure consistency.

It's also important to consider the environmental impact. Powder coating is often touted as more eco-friendly than traditional paint due to its low volatile organic compound (VOC) levels. Yet, questions remain regarding the recyclability of some powder-coated products. As the industry evolves, ongoing reflection on these aspects is crucial for making informed choices. Always weigh the aesthetic benefits against practical considerations.

| Finish Type | Color Options | Applications | Durability |

|---|---|---|---|

| Matte | Black, White, Grey | Furniture, Fixtures | High |

| Glossy | Red, Blue, Green | Architectural Elements | Moderate |

| Textured | Tan, Olive, Bronze | Outdoor Structures | Very High |

| Satin | Silver, Champagne | Consumer Products | High |

When considering powder coated stainless steel for your project, durability is a key factor. This finish provides a protective layer against corrosion, scratches, and UV rays. The powder coating process involves applying a dry powder that bonds to the metal surface when heated. This creates a tough finish that can withstand harsh environmental conditions. However, not all coatings are created equal; some may chip or fade over time. It's crucial to evaluate the quality of the coating before making a decision.

Maintenance is another important aspect. Powder coated surfaces are generally easy to clean. Regularly wipe them down with a mild detergent and water. This helps preserve their appearance. Nevertheless, certain factors can affect longevity. For instance, areas with heavy foot traffic might experience wear faster. There may be scuffs or scratches, requiring touch-ups. It's essential to inspect these surfaces periodically. Understanding these dynamics will help you choose the right product for your needs.

Powder coated stainless steel offers a blend of durability and aesthetics, making it ideal for various applications. Industries such as construction and transportation increasingly prefer this material due to its corrosion resistance and vibrant finishes. According to a recent industry report, the global market for powder coated stainless steel is expected to grow by 7% annually. This points to a rising demand in areas like architecture and outdoor furniture.

In architectural projects, powder coated stainless steel provides a protective layer against environmental factors. It retains its color and sheen longer than traditional finishes. Outdoor signage and furniture benefit significantly from its weather resistance. Furthermore, the food and beverage industry utilizes it for equipment that requires hygiene and durability. However, challenges exist. Some powder coatings may not endure extreme temperatures, leading to a potential for chipping or fading over time. Clients should consider these aspects when selecting powder coated stainless steel for their needs.

Ultimately, the choice of powder coated stainless steel should be informed by specific project requirements. Weighing aesthetics against practical considerations is crucial. Industry professionals face recurring questions about compatibility with other materials and long-term maintenance. A thorough understanding of these factors is vital for successful implementation.