When it comes to achieving high-quality finishes in powder coating, the significance of determining the right powder coating temperature cannot be overstated. The success of the powder coating process largely hinges on applying the right temperature, which directly affects the curing and adhesion of the powder to the substrate. Proper powder coating temperature ensures that the powdered material melts, flows, and forms a cohesive bond while maintaining the integrity and appearance of the coated object.

Understanding the nuances of powder coating temperature is essential for anyone looking to maximize the performance of their coating application. Factors such as the type of powder being used, the substrate material, and the desired finish all play critical roles in establishing the optimal temperature settings. Balancing these variables not only enhances the durability and aesthetic quality of the final product but also streamlines the application process and improves operational efficiency.

In this guide, we will explore the essential principles behind determining the appropriate powder coating temperature, delve into the critical factors influencing this decision, and provide practical tips to help you achieve optimal results. By mastering the art of temperature control, you can elevate your powder coating projects to new heights, ensuring a flawlessly finished product every time.

Powder coating is a widely used finishing process that involves applying a dry powder to a surface, where it is then cured under heat to form a durable and aesthetically pleasing finish. Understanding the basics of powder coating is essential for achieving optimal results in various applications, from automotive parts to household appliances. According to a report by the Powder Coating Institute, the $15 billion global powder coating market is expected to grow significantly by 2027, driven by its environmental benefits and superior finish compared to traditional liquid coatings.

The powder coating process begins with the selection of the appropriate powder, which can be composed of various resins, pigments, and other additives. Ensuring the right application technique and curing conditions is crucial for obtaining a uniform and durable finish. For instance, the temperature during the curing phase typically ranges between 350°F to 450°F (175°C to 232°C), as reported in industry studies. This heat activates the curing agents in the powder, allowing it to form a cross-linked structure that enhances its resistance to chipping, scratching, and fading.

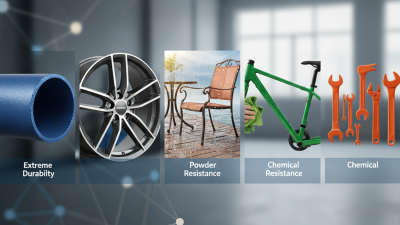

Applications of powder coating span multiple industries, reflecting its versatility. In the automotive sector, powder coating is utilized for wheel rims, bumpers, and other components due to its durability and resistance to harsh environments. In architectural applications, it is applied to aluminum and steel surfaces for windows, doors, and railings, which can benefit from the coating’s protective properties and wide range of color options. The ability to customize finishes supports the growing trend towards utilizing powder coating in both industrial and consumer markets, making it an increasingly popular choice for a variety of products.

When it comes to powder coating, the temperature plays a critical role in achieving optimal results. Several key factors influence the right powder coating temperature, ensuring that the applied powder cures correctly and adheres well to the substrate. One primary factor is the type of powder being used. Different powders have varying curing temperatures, which can significantly impact finish quality. Additionally, the thickness of the substrate and the environment in which the coating process occurs are vital considerations.

Tips for achieving the best results include ensuring that the powder coating is evenly distributed across the substrate. An uneven application can lead to inconsistencies in the curing process. Another helpful suggestion is to conduct test runs with smaller pieces to gauge the optimal temperature settings before moving on to larger projects. This approach allows for adjustments to be made according to the specific conditions of your workspace.

The substrate material itself also influences the necessary coating temperature. Metals like aluminum or steel may require different thermal processing compared to plastics. It is essential to take these variables into account, as overheating can affect the integrity of the material, while under-curing can lead to poor adhesion. Always consult the powder manufacturer’s guidelines to align your application with their recommended temperature ranges for the best possible outcome.

| Key Factors | Optimal Temperature Range (°F) | Impact on Finish Quality | Common Issues |

|---|---|---|---|

| Material Type | 350 - 400 | Ensures proper adhesion and finish | Poor adhesion |

| Powder Type | 375 - 450 | Enhances color and texture | Color fading or inconsistent texture |

| Humidity and Temperature | 350 - 425 | Prevents moisture entrapment | Blistering |

| Thickness of Coating | 350 - 400 | Achieves desired durability | Uneven finish |

| Cure Time | 400 - 450 | Ensures full cross-linking | Incomplete curing |

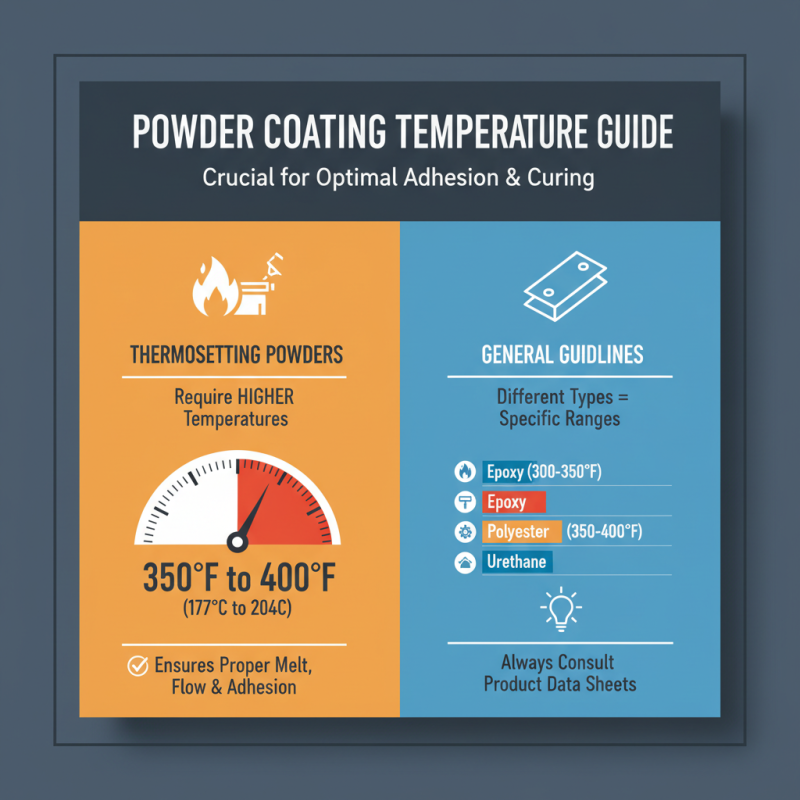

When it comes to powder coating, selecting the appropriate temperature is crucial for achieving optimal results. Different types of powder coatings have specific temperature ranges that facilitate proper adhesion and curing. For example, thermosetting powders typically require higher temperatures for activation. A common recommended temperature range for these powders is between 350°F to 400°F (177°C to 204°C). Operating within this range ensures that the coating properly melts, flows, and adheres to the substrate.

On the other hand, thermoplastic powders generally cure at lower temperatures, often between 325°F to 375°F (163°C to 191°C). While these materials do not undergo a chemical change during the curing process, the appropriate temperature is still necessary to achieve the desired finish and durability. Additionally, specialized powders, such as high-temperature or low-temperature formulations, have their unique requirements. Each type has its optimal temperature range that can significantly impact the coating's performance and longevity, making it essential to understand the specific needs of the powder being used for successful application.

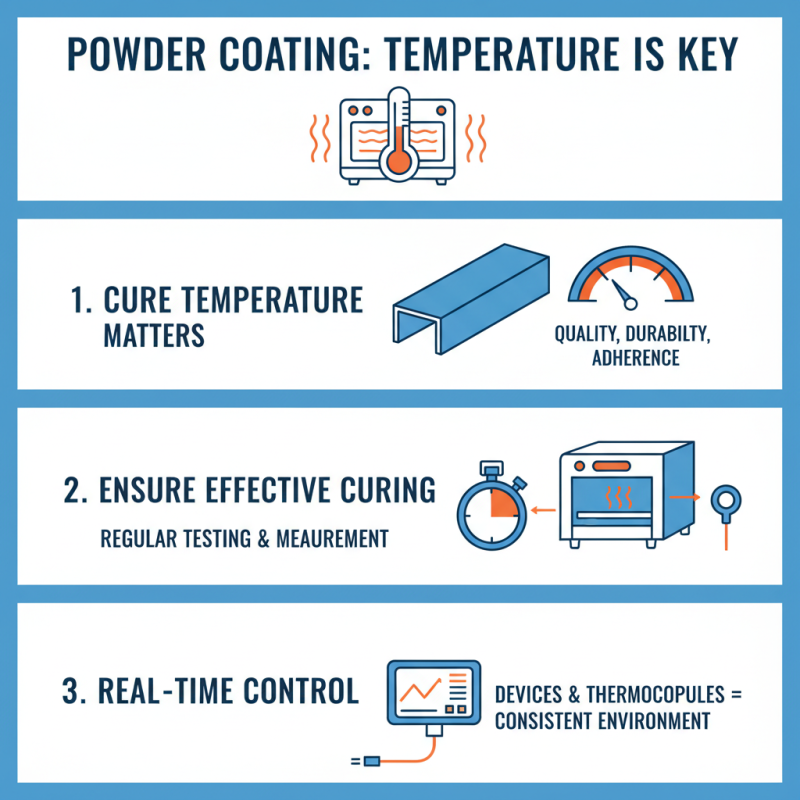

When it comes to achieving optimal results in powder coating, ensuring accurate temperature measurements is essential. The temperature at which powder is cured plays a crucial role in determining the final finish's quality, durability, and adherence. To guarantee that the coating process is effective, it is vital to regularly test and measure the curing oven's temperature. Utilizing temperature control devices and thermocouples can provide real-time data that helps maintain a consistent environment for the powder coating application.

Tips: Always calibrate your temperature measurement tools before use to ensure their accuracy. Regular checks at different points inside the oven can provide insights into temperature fluctuations that might occur throughout the curing process. Additionally, considering the thermal dynamics involved, allow the powder to reach the specified temperature for the recommended duration listed in the specific powder's guidelines.

Another essential aspect of temperature accuracy is understanding the impact of different substrates on heat absorption. Factors such as the material type and thickness can influence how quickly the powder coating reaches the desired temperature. Adjusting the oven settings based on these variables can optimize the curing process and improve the overall finish quality. By diligently monitoring and adjusting the temperature, you can achieve superior powder coating results that meet your quality standards.

When it comes to powder coating, maintaining the correct temperature is crucial for achieving optimal results. Common issues can arise from incorrect powder coating temperatures, negatively impacting both the final appearance and durability of the coated surface. For instance, if the temperature is too low, the powder may not melt properly, leading to a rough texture and poor adhesion. Conversely, excessive heat can cause bubbling and discoloration, compromising the integrity of the finish.

To avoid these pitfalls, it is essential to regularly calibrate your equipment to ensure accurate temperature readings. Additionally, preheating the substrate can facilitate better powder flow and adhesion, particularly for large or complex shapes.

Tips for achieving the right temperature include using a thermal imaging camera to monitor the surface temperature during the coating process. This technology can help identify hot or cold spots that may require adjustment. Furthermore, always refer to the powder manufacturer's guidelines for recommended curing temperatures and times, as this varies significantly depending on the type of powder utilized. Implementing these strategies will help you achieve a flawless and durable finish in your powder coating projects.