Thermal Spray Ceramic Coating is a powerful technique for enhancing the durability of metallic surfaces. It creates a protective layer that can withstand harsh environments. This coating process is increasingly popular in various industries, including aerospace and automotive.

Applying Thermal Spray Ceramic Coating effectively requires careful planning. The surface must be cleaned and prepped thoroughly. Even minor contaminants can lead to adhesion issues. Different applications demand specific techniques. The choice of materials and equipment is crucial. A mismatch can result in poor coating performance.

The application process may not always go smoothly. Mistakes can happen, leading to unsatisfactory results. Regular assessments can help identify such issues. Understanding the dynamics of your specific project will lead to better decisions. Remember, successful coatings are the result of careful attention and ongoing improvement.

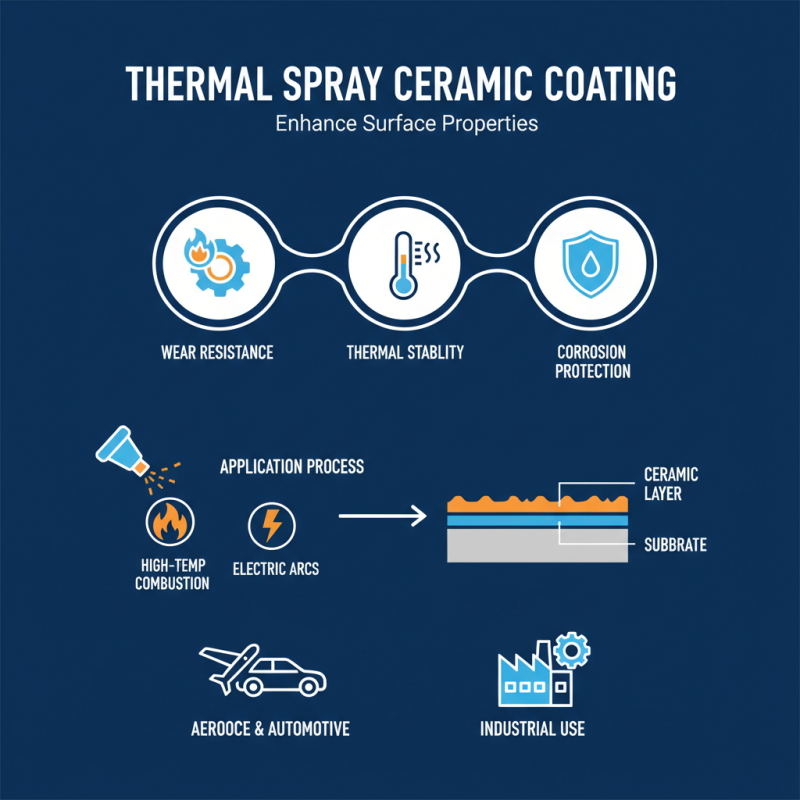

Thermal spray ceramic coating is a remarkable process. It applies a thin layer of ceramic material to enhance surface properties. This technique improves wear resistance, thermal stability, and corrosion protection. Industries like aerospace and automotive use it frequently. The application process involves high-temperature combustion or electric arcs.

Understanding the intricacies of thermal spray coatings requires attention. Pre-treatment of surfaces is crucial. Any contaminants can affect adhesion. The selection of material must align with application needs. Different ceramics offer varied performance; zirconia, for instance, excels in high-temperature environments. Yet, mistakes in application can lead to failures. An incorrect spray angle or distance may yield uneven coatings.

Moreover, the post-application phase is vital. Sometimes, a coated surface needs additional finishing. Not everyone recognizes this necessity. Monitoring the thermal cycle during application can be overlooked. Operators must be trained to avoid common pitfalls. Overall, the effectiveness of thermal spray ceramic coating hinges on careful execution.

Before applying thermal spray ceramic coatings, proper preparation is crucial. The right surface preparation ensures better adhesion and performance. According to industry reports, improper preparation can lead to adhesion issues, reducing coating lifespan by up to 30%. Start by cleaning the substrate thoroughly to remove contaminants. This step is often overlooked, yet it plays a vital role in the success of the coating process.

Abrasive blasting is highly recommended for surface preparation. It creates a rough texture that enhances coating adhesion. Use a suitable abrasive material for your substrate. This should match the coating's requirements and the surface type. Remember, not all abrasive types work well with every material. Testing on a small section can prevent costly mistakes later.

**Tips:** Monitor the ambient conditions during preparation. High humidity can affect adhesion. Aim for a clean, dry surface before spraying. After blasting, inspect for any missed spots. This attention to detail can save a lot of trouble down the line. Also, consider applying a primer designed for thermal spray coatings for added support.

When applying thermal spray ceramic coatings, preparation is vital. Surface cleanliness plays a crucial role. Dust, oil, or rust can lead to poor adhesion. Achieving the right temperature for the substrate is equally important. This helps the coating to bond effectively. The ambient conditions, such as humidity and temperature, also affect application. Pay attention to these factors.

Techniques for application can vary. The distance between the spray gun and the surface often influences the coat's thickness. Aiming for the right angle enhances coverage. Practicing with different settings can lead to better results. However, mistakes can happen. Sometimes coatings may not adhere as expected. Reflect on these errors to improve future applications.

Monitoring the spray pattern is essential. An uneven pattern can cause uneven thickness. It's essential to adjust the gun settings to maintain consistency. Overlapping passes will help create a more uniform finish. Regularly inspecting the coating during the process can give valuable feedback. Each step of this application is a learning opportunity.

Post-application treatments are essential to enhance the performance of thermal spray ceramic coatings. Effective surface preparation is crucial. A report from the Coatings Research Institute emphasizes that proper surface roughness can improve adhesion by up to 30%. Without adequate preparation, coatings may peel or chip easily.

Another important consideration is post-spray heat treatment. Studies suggest that controlled heating can relieve residual stresses in the coating. This process can increase its resistance to thermal shock. However, improper temperature management can lead to deformation or cracking. Achieving the right balance is key.

Additionally, applying a secondary sealing layer can further protect the coating. Data shows that such treatments can improve corrosion resistance by 40%. Yet, choosing the correct material is vital. Not all sealants are compatible with ceramic coatings. It requires careful selection and testing to ensure optimal performance. Each of these treatments requires thorough evaluation to prevent long-term issues.

| Application Method | Coating Material | Post-Application Treatment | Expected Performance Improvement (%) |

|---|---|---|---|

| Plasma Spraying | Zirconia | Heat Treatment | 20% |

| HVOF Spraying | Alumina | Surface Polishing | 15% |

| Arc Spraying | Titania | Chemical Sealing | 25% |

| Cold Spraying | Ceramic Composite | Surface Roughening | 18% |

Thermal spray ceramic coating is a practical solution for enhancing surface properties. However, several challenges can arise during the coating process. One common issue is inconsistent coating thickness. This can happen due to improper operating parameters or poor equipment calibration. It's essential to regularly check and adjust the spray distance and speed. Monitoring these factors helps achieve a more uniform application.

Another challenge is adhesion failure. This issue often leads to delamination. It can be caused by contamination on the surface before coating. A thorough cleaning and preparation routine is crucial. Sometimes, operators overlook the importance of this step. Employing techniques like grit blasting can enhance surface roughness, improving bond strength.

Temperature control during spraying also plays a significant role. If the substrate is too cold, the coating may not adhere properly. Conversely, excessive heat can damage the base material. Operators need to find a balance. Regularly assessing the material's temperature can prevent these problems. Troubleshooting is essential. Reflect on previous applications to identify areas for improvement.

This chart illustrates the common challenges faced during the thermal spray ceramic coating process and their corresponding impact levels based on a survey of industry professionals. The data showcases issues such as adhesion strength, surface preparation quality, and thermal gradient management.