When selecting the right Spray Powders, understanding your specific needs is vital. The global powder coating market is expected to reach $13.5 billion by 2027, largely driven by technological advancements. This growth indicates a rising demand for efficient and durable products. However, with so many options available, making an informed decision can be overwhelming.

Choosing the best Spray Powders involves considering various factors. For instance, the application method greatly influences product performance. The choice between manual and automated systems can affect the powder's efficiency and finish. Moreover, many users report confusion about which powder types best fit their projects. Not all powders perform equally in every industry segment.

Beware of common pitfalls. Relying solely on price can lead to subpar quality. Similarly, overlooking the importance of product certifications may result in unsatisfactory outcomes. Reflect on these aspects to make a better choice. Conduct thorough research and consult with experts before making any commitments. Remember, the right Spray Powders can enhance both the process and the final results.

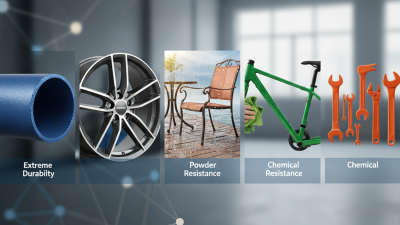

When exploring spray powders, understanding their types can significantly impact your choice. Common options include matte, glossy, and translucent powders. Each serves a unique purpose. For instance, matte powders often provide a soft finish and are ideal for reducing shine. In contrast, glossy powders can enhance colors and create a vibrant look.

A study from the Cosmetic Science and Technology Journal indicates that over 70% of consumers prefer translucent powders for their versatility. These powders fit various skin tones and minimize the risk of a caky appearance. Translucent options are especially important for professional settings where natural looks are essential.

Choosing the right powder shouldn't be rushed. Different formulations may react differently on varied skin types. A survey showed that 50% of users experienced irritations or allergic reactions when switching products. It's crucial to test samples first. Remember, the right choice has nuances. Not all sprays fit all needs.

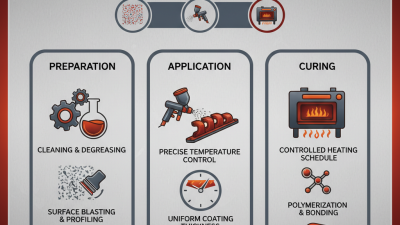

Choosing the right spray powders can be challenging. Evaluating their properties is crucial for specific applications. Start by identifying the desired particle size. Smaller particles provide finer finishes but can clog equipment. Larger particles offer robust application but may not achieve the same detail.

Consider the flow characteristics. Powders that flow smoothly are easier to work with. They reduce clumping, leading to better consistency in application. However, not all materials will flow perfectly. Testing is key. Sometimes, modifications may be required to achieve optimal flow.

Don't overlook the thermal stability of spray powders. High temperatures can affect performance. Some powders may degrade, impacting the final product. Always check the thermal properties before selection. Inadequate understanding can lead to unsatisfactory results.

Evaluate other properties such as adhesion, density, and surface tension. Each can influence your application’s success. For instance, poor adhesion can lead to flaking. You might need to reflect on how these properties align with your project goals.

Choosing the right spray powders demands a careful assessment of how they will interact with your existing equipment and processes. Compatibility plays a crucial role in achieving optimal results. Evaluate the specific equipment you use, whether it’s for coating, painting, or other applications. Each machine has its own specifications, which can dictate which powders are suitable. A powder that works well in one setting might not perform as expected in another.

Consider the characteristics of the spray powders, such as particle size, flowability, and viscosity. These factors influence how well the powder moves through the machinery. If you're working with a spray gun, for instance, it needs to handle your chosen powder efficiently. Take note of any previous difficulties with powders not performing well. Sometimes, despite thorough research, the outcomes may fall short. Experimentation can also lead to unexpected results; be ready for trial and error, as not every combination will yield success.

Choosing the right spray powders involves careful consideration of environmental and safety factors. The materials you select can impact both health and the surroundings. Understanding the ingredients is crucial. Some powders contain chemicals that may harm aquatic life or soil. Always check for eco-friendly options.

Safety should be a top priority. Certain powders can release harmful vapors when sprayed. Proper ventilation is essential during application. Wearing protective gear protects you when handling these substances. Even the best products can have risks if not used correctly. Assess your workspace for potential hazards before proceeding.

Reflect on waste management as well. Excess powder can create a mess and lead to unnecessary pollution. Consider how much you really need. Opt for containers that reduce excess usage. It’s not just about the results; it’s about how you get those results.

| Tip Number | Tip Description | Environmental Considerations | Safety Features |

|---|---|---|---|

| 1 | Evaluate the application method | Ensure compatibility with environmental regulations | Choose non-toxic formulations |

| 2 | Research the composition of powders | Opt for biodegradable materials when possible | Ensure minimal flammability |

| 3 | Check performance specifications | Assess long-term environmental impact | Look for certifications like OSHA compliant |

| 4 | Consult with industry experts | Get insights on sustainable practices | Inquire about health and safety documents |

| 5 | Assess cost-effectiveness | Consider lifecycle costs and waste management | Look for anything that reduces risk |

| 6 | Review supplier reputation | Check sustainability ratings | Research safety records |

| 7 | Test samples before bulk purchase | Evaluate disposal methods | Follow necessary workplace safety protocols |

| 8 | Look for user reviews and feedback | User ratings on environmental impact | Community safety assessments |

| 9 | Consider compatibility with equipment | Ensure minimal emissions during application | Equipment safety compliance |

| 10 | Stay updated with industry regulations | Comply with environmental laws | Follow the latest safety standards |

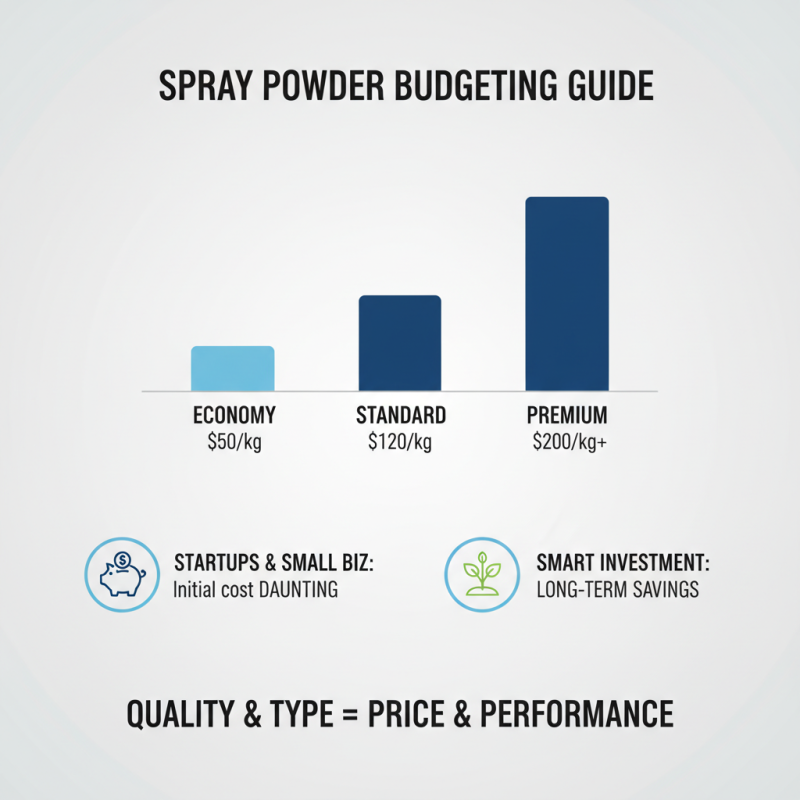

When choosing spray powders, budgeting is crucial. Prices can vary widely based on quality and type. A recent industry report indicates that budget-conscious buyers can expect to spend between $50 to $200 per kilogram. This range can seem daunting, especially for startups and small businesses. However, investing wisely can lead to long-term cost savings.

Understanding the total cost of ownership is vital. This includes not just the initial purchase price but also any additional expenses, such as application equipment, mixed ratios, and wastage. According to studies, improper selection can increase wastage rates by 20% or more, inflating overall costs. Look for powder consistency and application ease, as these factors can influence both efficiency and budget.

Sometimes, the cheapest option can lead to regret. Lower-quality powders may require more frequent reapplication or may not perform well, costing more in the long run. A thorough evaluation is necessary. Examine different suppliers. Seek customer feedback and performance reviews to gain insights. Quality should never be overlooked, even when trying to stick to a budget. Balancing cost and quality will yield the best results.