When selecting the right Carbide Powder, many factors come into play. Carbide Powder is crucial for various applications, from cutting tools to coatings. With the increasing demand for high-performance materials, the importance of choosing the right type has never been clearer.

Understanding the different grades of Carbide Powder can be daunting. Each grade offers unique properties, influencing performance in specific applications. Consider your project requirements carefully. Are you focused on durability or precision? Each choice carries consequences that may not be immediately evident.

Many buyers overlook practical details. Supplier reputation, cost, and material consistency are vital. Make sure to ask questions about production methods and quality checks. Potential flaws in these areas can lead to future problems. By making an informed choice, you set the foundation for project success.

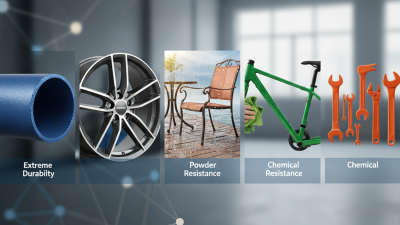

When choosing carbide powder, it's essential to understand its types and properties. Carbide powder is a versatile material extensively used in cutting tools, wear-resistant applications, and even electronics. The two main types are tungsten carbide and silicon carbide, each with distinct characteristics. Tungsten carbide is known for its hardness and durability, while silicon carbide has excellent thermal conductivity.

Consider your specific needs when selecting carbide powder. For example, if you require high wear resistance,

tungsten carbide might be suitable. Be mindful of particle size too. Finer particles can improve the performance in some applications, but may not be necessary for others. A common tip is to consult with material specialists to match the powder type to your requirements.

Lastly, the processing method matters. The way carbide powder is manufactured can influence its properties. Some methods yield purer powders, while others enhance certain characteristics. It's worth reflecting on these aspects. Each choice can significantly impact your final product's performance. Always weigh these factors carefully when making decisions.

When selecting carbide powder, several key factors come into play. Purity is crucial. High-purity carbide powder leads to better performance. Reports indicate that even minor impurities can reduce tool life by 30%. These contaminants can affect mechanical properties. Thus, sourcing from reputable manufacturers is vital.

Particle size is another important consideration. Different applications require specific sizes for optimal results. For instance, finer powders offer better sintering properties. Conversely, coarser powders might be suitable for durability in harsh environments. Specifications can vary significantly, with some applications favoring particle sizes as small as 1 micron.

Cost is always a factor, yet it shouldn’t overshadow quality. A low price can mask poor performance. An industry survey revealed that companies using higher-quality powders experienced a 20% increase in productivity. Cheaper options can lead to more frequent tool changes, ultimately costing more in the long run. Balancing cost with performance is a common dilemma. This requires careful evaluation of supplier offerings and a clear understanding of your specific needs.

Carbide powder is vital in many industries. Its hardness and durability make it invaluable. In mining, carbide tools drill through tough rock. They withstand high pressure and temperature. These tools enhance efficiency and reduce downtime. However, selecting the right carbide is essential. Not all powders are equal, and this can affect performance.

In the manufacturing sector, carbide powder is often used in cutting tools. These tools shape metals and plastics with precision. The right carbide enhances the lifespan of tools. Yet, some users overlook grade specifications. This can lead to premature wear. Software and technology in machining also rely heavily on carbide applications.

The construction industry benefits from carbide powder as well. It is used in road construction and drilling equipment. Here, the challenges are different, such as durability under varying conditions. Understanding these applications can greatly influence choice. Reflecting on project requirements is crucial. It helps in achieving the desired outcomes efficiently.

When selecting carbide powders, quality and purity are crucial. Start by evaluating the source of the powder. Look for suppliers with a good reputation in the industry. Sometimes, suppliers may not provide full transparency about their products. Investigating independently can help you avoid poor choices.

Purity levels in carbide powders can impact your projects. High-purity powders often yield better performance, while lower purity can lead to failures. Be aware that not all certifications are equal. Double-check the validity of any claim. Sometimes, a supplier’s documentation may not align with reality. It's beneficial to request actual test results or samples for personal evaluation.

Consider the application of the carbide powder. Different processes may require varying purity levels. Understanding your specific needs is essential. It’s easy to assume one size fits all, but that’s rarely the case. Inconsistent quality can lead to unexpected challenges. Taking time to evaluate before making a decision can save you from significant issues later on.

| Tip Number | Tip Description | Quality Indicators | Purity Levels |

|---|---|---|---|

| 1 | Assess the application requirements. | Particle size distribution, hardness. | 99% purity and above. |

| 2 | Check supplier certifications. | ISO certifications, quality control processes. | Minimum 98% purity verified. |

| 3 | Compare different manufacturers. | Material properties, performance in tests. | Purity testing results provided. |

| 4 | Analyze the cost-effectiveness. | Cost vs performance ratios. | Evaluate ROI on purity improvements. |

| 5 | Seek expert recommendations. | Peer reviews, expert insights. | Consensus on purity standards. |

| 6 | Review product data sheets. | Detailed specifications, properties. | Inclusive purity metrics documented. |

| 7 | Evaluate compatibility with existing systems. | Interoperability of materials. | Ensure compatible purity specifications. |

| 8 | Consider supply chain stability. | Supplier reliability, delivery timelines. | Check purity during transit consistency. |

| 9 | Investigate packaging and storage options. | Protection against contamination. | Maintain integrity of purity. |

| 10 | Test samples before final purchase. | Performance metrics from trials. | Verify purity outcomes in conditions. |

When purchasing carbide powder, cost is a critical factor. Many variables influence the final price. Quality, particle size, and source impact expenses greatly. Cheaper options may seem attractive at first. However, lower prices can lead to poor performance. This could cause delays in projects. Selecting quality over cost can save money in the long run.

Consider the quantity needed. Bulk purchases often reduce unit costs. Yet, storing large amounts can be tricky and costly. It may be necessary to assess expected usage. Balance between immediate needs and future requirements is essential. Additionally, shipping costs can add up. Some suppliers charge high fees for delivery.

Do not overlook hidden costs. Sometimes, lower-priced powders lack essential certifications. This might require spending more later on replacements or fixes. Researching suppliers and comparing options can mitigate unexpected expenses. Remember, the cheapest option isn't always the best. Reflect on the long-term value of your investment. Prioritize quality to meet your specific needs effectively.