In the world of manufacturing, choosing the right Powder Metal Coating solution is crucial. According to John Smith, a leading expert in Powder Metal Coating, "The right coating can make or break the durability of your product." This highlights the importance of selecting the appropriate coating to enhance product performance.

Powder Metal Coating involves complex decision-making processes. Each choice impacts quality and longevity. Various factors come into play, such as application method, curing temperature, and the environment where the product will be used. However, many manufacturers overlook critical details. This can lead to inefficiencies and defects in the final product.

Reflecting on these choices is essential. Understanding the specific requirements of the project can help avoid costly mistakes. Ultimately, careful selection of Powder Metal Coating should drive the success of manufacturing. Investing in quality solutions not only protects your product but can elevate your brand's reputation as well.

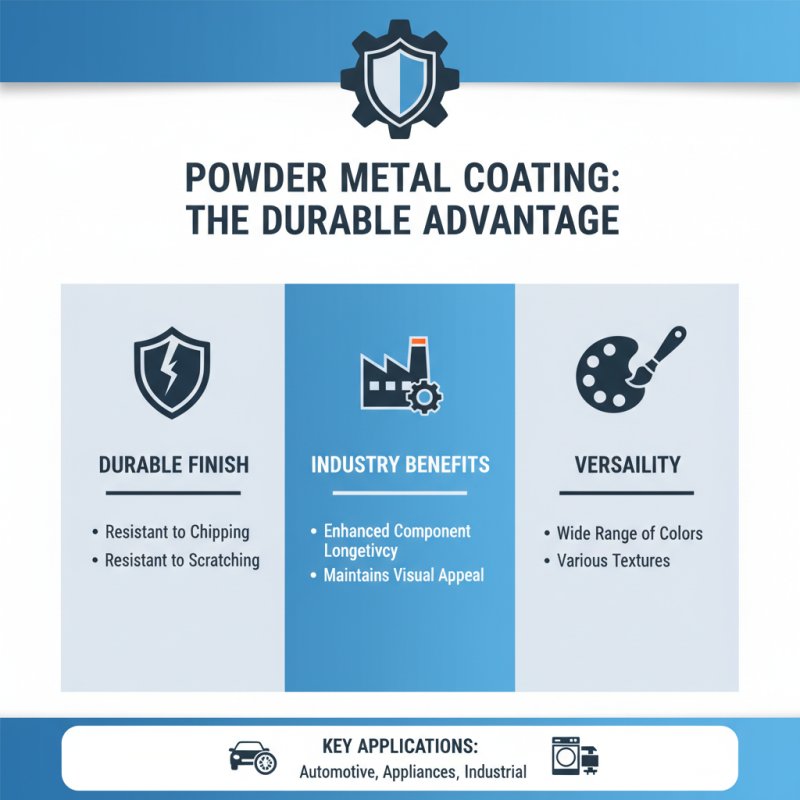

Understanding powder metal coating is crucial for effective application. This method provides a durable finish that is resistant to chipping and scratching. Many industries benefit from this technology. It enhances the longevity of components while maintaining visual appeal. Powder coatings offer a wide range of colors and textures, making them versatile for different requirements.

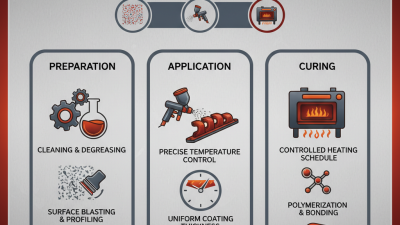

Choosing the right powder metal coating can be daunting. Here are some tips: Consider the environment where the coated items will be used. This affects the type of powder needed. For example, harsh weather may require a more robust formulation. Additionally, ensure that the surface preparation is adequate. Poor preparation can lead to adhesion issues.

Think about the application method as well. Electrostatic spray is common, but not always the best choice for every project. It's critical to weigh the options based on the specific needs. Remember to investigate the curing process. Improper curing can result in performance problems. Exploring these features will guide you towards making informed decisions.

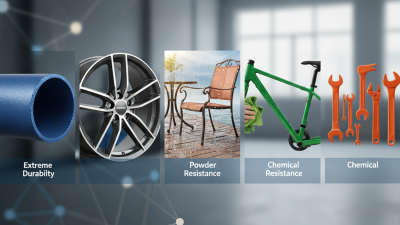

Choosing the right application for powder metal coatings is vital for achieving optimal performance. Understanding the environment in which the coated parts will operate is crucial. For instance, will they face high temperatures, chemicals, or abrasion? Identifying these factors early on can lead to better decision-making.

Another essential aspect to consider is the substrate material. Different materials react uniquely to coatings. For example, metals and plastics have distinct properties. This can affect adhesion and overall durability. Conducting surface preparation is often overlooked but plays a key role in success. A poorly prepared surface can lead to delamination issues, which may not be evident until much later.

Don't forget about cost vs. performance trade-offs. While a high-quality powder coating may offer excellent performance, it can come at a premium. Reflecting on the long-term benefits versus short-term costs is necessary. Gathering feedback from previous projects can help guide your choice. In some cases, a less expensive option may suffice, while in others, investing in a superior product pays off over time. Always reassess your choices based on practical outcomes.

When selecting powder coating solutions, evaluating material compatibility is crucial. Different substrates react uniquely to various powder coatings. For instance, metals, plastics, and ceramics each interact with coatings in specific ways. According to a recent industry study, almost 30% of coating failures arise from incompatibility. This statistic highlights the need for thorough material testing.

One major concern is the thermal expansion rates of materials. Mismatched rates can lead to delamination. A report from the Powder Coating Institute indicates that improper heating protocols further exacerbate this issue. It's essential to consider aspects like corrosion resistance and the environmental conditions for use. Notably, 45% of users overlook the implications of their selected coatings on long-term durability.

While some coatings may promise excellent visuals, they might not suit every surface type. Aesthetics shouldn't overshadow functional requirements. Test results often reveal that many coating materials perform poorly under specific conditions. Recent data shows that over 20% of users end up re-coating due to these mismatches. Reflecting on these factors reveals the importance of informed choices in powder coating selection.

When selecting powder metal coating solutions, it's crucial to assess the performance requirements for different coating types. The choice significantly impacts durability, aesthetics, and resistance to environmental factors. For instance, a recent industry report highlighted that coatings designed for outdoor applications should provide enhanced UV resistance and corrosion protection. In contrast, coatings used in food processing must meet strict safety standards while offering easy cleanup.

Performance metrics vary by application. Engineers often measure hardness, adhesion strength, and flexibility. According to the Powder Coating Institute, coatings with a hardness rating above H and excellent adhesion levels reduce maintenance costs. However, not all coatings perform well under extreme conditions, such as high temperatures or chemical exposure. Selecting coatings that fail these rigor tests can lead to significant operational challenges.

It's essential to consider application methods as well. Different techniques yield varied results. For example, electrostatic spray and fluidized bed methods introduce different thicknesses and textures in the final product. This can affect not just the appearance but also the functional characteristics. Often, manufacturers overlook these factors, resulting in suboptimal choices. A thorough evaluation of these parameters is crucial for achieving reliable performance.

Sustainability is becoming a critical factor in powder metal coating solutions. According to a 2022 report by the Powder Coating Institute, nearly 70% of manufacturers are prioritizing eco-friendly practices. This shift is not merely a trend; it reflects a growing focus on reducing environmental impact. Powder coatings often produce minimal waste, making them a favorable choice compared to traditional liquid coatings.

However, not all powder coatings are equally sustainable. The sourcing of raw materials can vary significantly. Some powders may rely on non-renewable resources. It's essential for businesses to scrutinize suppliers and their practices. Using bio-based or recycled materials can enhance sustainability efforts. A report from the Environmental Protection Agency highlights that using sustainable materials can cut energy consumption by 30%.

Additionally, energy efficiency during the application process is vital. Some powder coating processes consume excessive energy, leading to higher carbon footprints. Companies need to evaluate their manufacturing methods continuously. Implementing more energy-efficient ovens and equipment can drastically reduce emissions. A proactive approach in selecting coatings will ensure that environmental considerations are at the forefront of their operations.