Nickel Molybdenum Alloy has increasingly become a vital component in various industries, particularly in aerospace, chemical processing, and energy production. According to a recent market analysis by Fortune Business Insights, the global nickel alloys market is projected to grow significantly, with a compound annual growth rate (CAGR) of approximately 6.21% from 2021 to 2028. This growth is largely attributed to the unique properties of Nickel Molybdenum Alloy, such as its high strength, corrosion resistance, and ability to withstand extreme temperatures.

Nickel Molybdenum Alloy has increasingly become a vital component in various industries, particularly in aerospace, chemical processing, and energy production. According to a recent market analysis by Fortune Business Insights, the global nickel alloys market is projected to grow significantly, with a compound annual growth rate (CAGR) of approximately 6.21% from 2021 to 2028. This growth is largely attributed to the unique properties of Nickel Molybdenum Alloy, such as its high strength, corrosion resistance, and ability to withstand extreme temperatures.

As industries seek materials that combine durability with performance, Nickel Molybdenum Alloy stands out. Its application in high-pressure and high-temperature environments makes it essential for components like turbine blades and valves. However, working with such advanced materials requires a thorough understanding of their properties and the best practices for fabrication and welding. Businesses that integrate Nickel Molybdenum Alloy into their projects must be equipped with specific knowledge and techniques to optimize their results and ensure safety and reliability. This article outlines the top five essential tips for effectively working with Nickel Molybdenum Alloy, ensuring that projects not only meet but exceed industry standards.

Nickel molybdenum alloy is known for its exceptional properties that make it an ideal choice for various high-performance applications. One of its most significant characteristics is its outstanding corrosion resistance, especially in hostile environments such as oil and gas production, chemical processing, and marine applications. This alloy can withstand both acidic and alkaline conditions, providing durability that surpasses many other materials. Additionally, nickel molybdenum alloy demonstrates excellent mechanical strength at elevated temperatures, making it a preferred option for components subjected to extreme conditions.

Another important property of nickel molybdenum alloy is its excellent weldability and formability. These features enable engineers and fabricators to easily manipulate the material for specific design requirements without compromising its structural integrity. Its thermal stability is crucial when designing components that need to maintain their shape and performance under varying temperatures. Furthermore, the alloy’s ability to retain its strength over time enhances the longevity of the products made from it, reducing maintenance costs and increasing overall efficiency in industrial applications.

This chart illustrates the essential properties of Nickel Molybdenum Alloy, including corrosion resistance, strength, melting point, thermal conductivity, and cost. Each property is scored on a scale of 1 to 10, highlighting the unique advantages that Nickel Molybdenum Alloy offers for various applications in engineering and manufacturing projects.

Nickel molybdenum alloy is a versatile material widely utilized across various industries due to its exceptional strength, corrosion resistance, and heat tolerance. In the aerospace sector, this alloy is integral in manufacturing components subjected to extreme conditions, such as jet engines and gas turbines. Its lightweight properties combined with high-performance capabilities make it ideal for ensuring safety and efficiency in flight.

In the oil and gas industry, nickel molybdenum alloy's resistance to high pressures and corrosive environments makes it a preferred choice for pipelines and valves. This alloy enhances the durability and lifespan of equipment, ultimately reducing costs associated with maintenance and replacements.

When working with nickel molybdenum alloy in your projects, consider these essential tips:

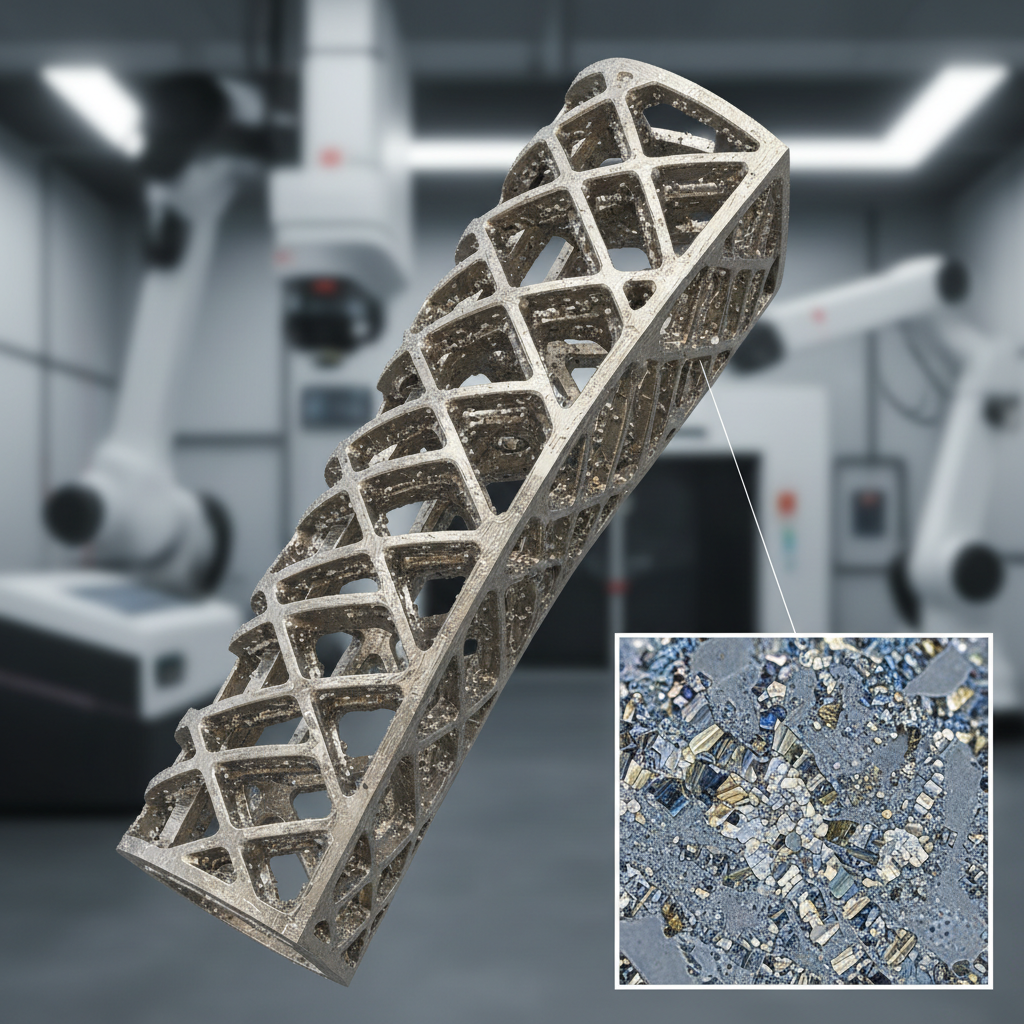

Nickel molybdenum alloy, particularly Inconel 718, has gained prominence in the additive manufacturing landscape, owing to its exceptional mechanical properties and corrosion resistance. The incorporation of this nickel alloy into the manufacturing process can significantly enhance component performance, especially in high-temperature applications such as aerospace and medical devices. Recent studies highlight the importance of understanding the processing-structure-property-performance relationship, as these factors directly influence the microstructure characteristics, fatigue resistance, and impact toughness of additively manufactured components.

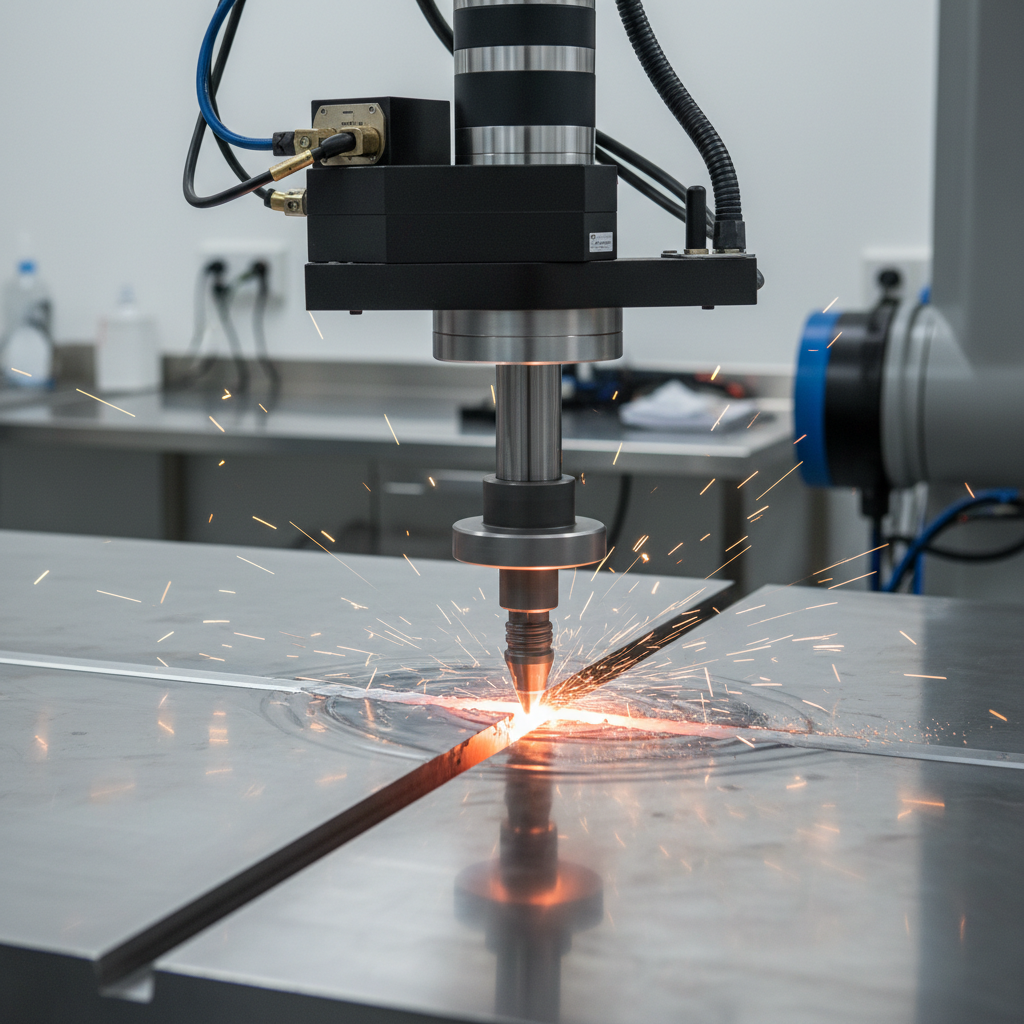

Best practices for fabricating nickel molybdenum alloy components involve a combination of precise design and advanced manufacturing techniques. For instance, adopting laser powder bed fusion enables the creation of intricate geometries with improved material efficiency. Research indicates that optimizing parameters during the additive process can lead to superior superelasticity and mechanical properties, showcasing the alloy's potential in producing components for critical applications. By focusing on careful material selection and diligent quality assurance throughout the fabrication process, manufacturers can ensure that the final products meet the rigorous standards required in demanding industries.

When working with nickel molybdenum alloy, particularly in welding and joining processes, it is crucial to understand the specific techniques that enhance material performance under stress. Recent advancements in welding technology, such as friction-stir welding, have shown promising results for similar alloys, including alloy 625. This solid-state welding process minimizes the risk of intergranular corrosion while ensuring a strong joint integrity, making it a valuable technique for projects involving nickel molybdenum.

In addition, the optimization of pulsed mode parameters in additive manufacturing processes is transforming how we approach the fabrication of nickel-based superalloys. By fine-tuning the single-layer bead geometry during wire arc additive manufacturing (WAAM), manufacturers can achieve superior mechanical properties and reduce defects. This ongoing research highlights the importance of adapting current welding methodologies to exploit the unique compositions of nickel molybdenum alloys, ultimately leading to more effective and durable structures in engineering applications.

When working with nickel molybdenum alloy products, proper maintenance and handling are crucial for ensuring their longevity and performance. First, it is essential to keep these materials clean and free from contaminants. Regular cleaning with appropriate solvents can help prevent corrosion and maintain surface integrity. Additionally, any signs of wear or damage should be addressed immediately to avoid compromising the alloy’s structural properties.

Handling nickel molybdenum alloys requires careful consideration to prevent mechanical damage. Using the right tools and techniques during assembly and disassembly is vital. It is advisable to employ soft handling equipment to minimize the risk of scratching and other surface imperfections. Furthermore, storing the alloy products in a controlled environment, away from moisture and extreme temperatures, will help protect them from environmental factors that could lead to deterioration. Properly labeling and organizing materials can also streamline workflows and ensure that handling remains safe and efficient throughout the project duration.

| Tip Number | Tip Description | Reason | Frequency of Maintenance |

|---|---|---|---|

| 1 | Use appropriate tools designed for nickel-moly alloys. | Prevents damage and maintains integrity. | Every Project |

| 2 | Store in a dry, designated area. | Minimizes risk of corrosion. | Regularly |

| 3 | Inspect for surface damage before use. | Ensures safe operation and longevity. | Every Use |

| 4 | Apply protective coatings if necessary. | Enhances resistance to harsh environments. | As Required |

| 5 | Follow manufacturer’s welding guidelines. | Prevents structural weaknesses. | Every Project |

| 6 | Use proper cleaning agents. | Avoids contamination and ensures performance. | As Needed |

| 7 | Monitor temperature during machining. | Prevents thermal distortion. | During Operation |

| 8 | Ensure compatibility with other metals. | Reduces risk of galvanic corrosion. | Every Project |

| 9 | Avoid excessive impacts during handling. | Maintains material integrity. | Always |

| 10 | Document all processing conditions. | Improves future project execution. | After Each Project |