The landscape of modern manufacturing is continually evolving, driven by technological advancements and innovative materials. One area that has witnessed remarkable progress is the field of Welding Powder Metal. This technique, which integrates the principles of powder metallurgy with welding practices, offers unprecedented versatility and efficiency in creating complex components. As industries demand higher performance and more sustainable practices, Welding Powder Metal stands out as a transformative solution, facilitating the production of lightweight, durable, and intricate parts that were previously difficult to achieve.

This exploration into the future of Welding Powder Metal reveals not only current innovations but also potential applications that could revolutionize manufacturing processes across various sectors. From aerospace to automotive, the adaptability of this technology promises enhanced material properties and cost-effectiveness. As we delve into the top five trends and advancements shaping the future of Welding Powder Metal, it becomes evident that these developments are setting the stage for a new era in manufacturing, characterized by precision engineering and tailored solutions to meet the diverse needs of modern industries.

The field of welding powder metal is witnessing a transformative evolution driven by innovative materials and advanced processes. As manufacturers seek to enhance the performance and efficiency of their products, new alloy compositions and coatings are being developed to improve the mechanical properties and corrosion resistance of welded components. These innovations not only optimize the functionality of the materials but also open new avenues for application across various industries, including aerospace, automotive, and biomedical sectors.

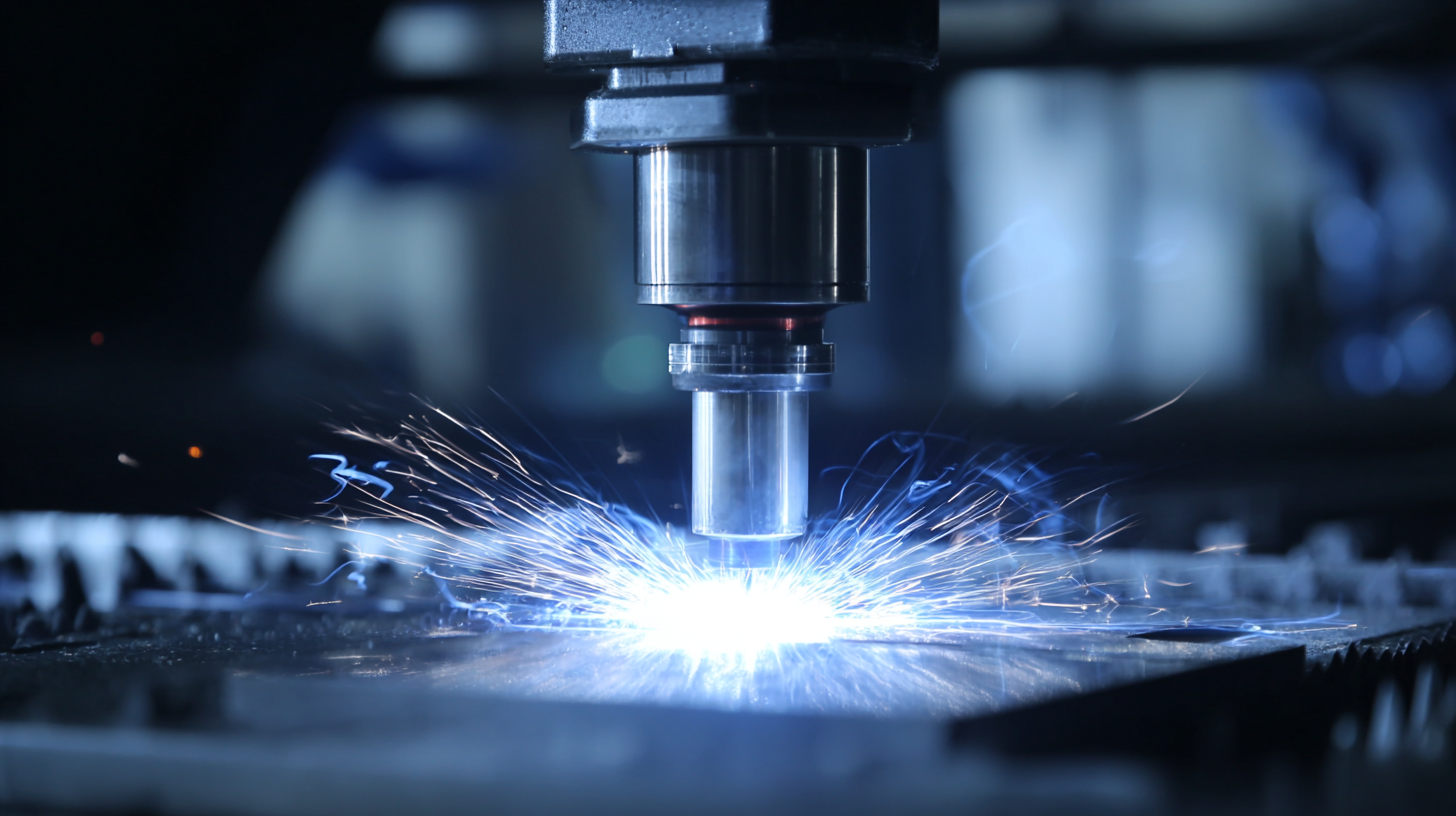

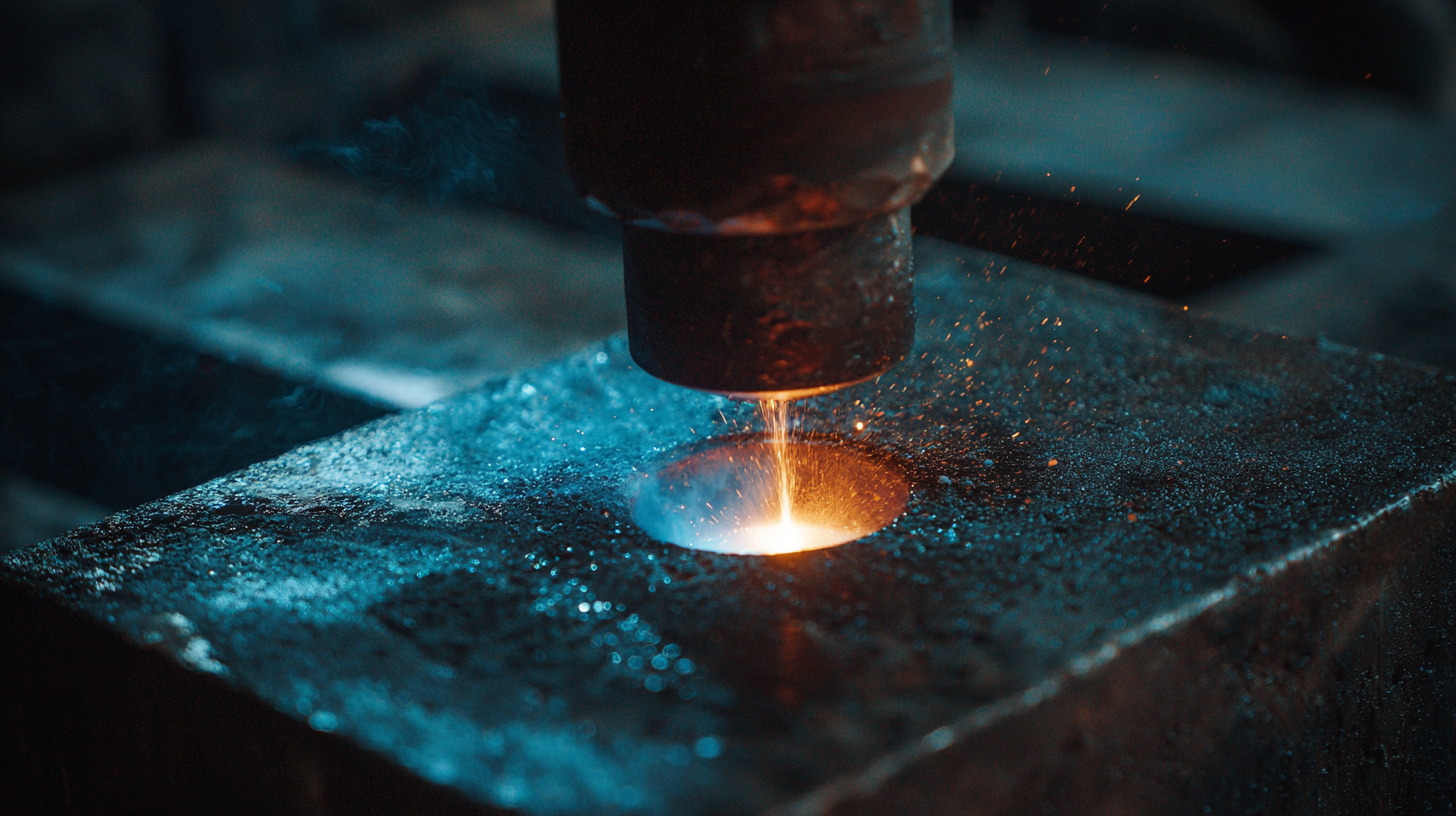

Moreover, advancements in additive manufacturing techniques have significantly impacted the welding powder metal landscape. Techniques such as laser sintering and electron beam melting allow for precise control over the microstructure and properties of the welds. This level of customization enables the creation of complex geometries that were previously unattainable, thereby enhancing design possibilities and reducing waste. The integration of smart technologies, including real-time monitoring and AI-driven process optimization, further elevates the capabilities of welding powder metal, fostering a future where production is both smarter and more sustainable.

Advanced technology is poised to revolutionize the performance of welding powders, offering solutions that enhance efficiency and reduce costs in modern manufacturing. Innovations such as the development of advanced aluminum alloys for additive manufacturing underscore the potential of new materials to drive growth across various sectors, including aerospace and automotive. These advancements not only improve mechanical properties but also increase the versatility of welding applications, enabling manufacturers to tackle more complex projects with precision and reliability.

Advanced technology is poised to revolutionize the performance of welding powders, offering solutions that enhance efficiency and reduce costs in modern manufacturing. Innovations such as the development of advanced aluminum alloys for additive manufacturing underscore the potential of new materials to drive growth across various sectors, including aerospace and automotive. These advancements not only improve mechanical properties but also increase the versatility of welding applications, enabling manufacturers to tackle more complex projects with precision and reliability.

Moreover, the integration of advanced techniques like laser-assisted cold spray demonstrates how combining different technologies can lead to significant improvements in welding processes. This method, which uses localized heating to enhance the adhesion of metals and cermets, opens up new possibilities for part fabrication, coating, and repair in challenging environments. As companies continue to explore and invest in innovative materials and techniques, the future of welding powder metal looks set to benefit from a wave of enhanced performance and efficiency, tailored to meet the demands of modern industry.

Sustainability is becoming increasingly critical in the realm of powder metal manufacturing and welding. As industries strive to minimize their environmental footprint, innovations in material sourcing and production processes are emerging. Companies are focusing on utilizing recycled metals and eco-friendly additives, which not only reduce waste but also lower energy consumption during the manufacturing process. This shift towards sustainable practices is not just beneficial from an environmental perspective; it also enhances the overall efficiency and cost-effectiveness of production.

Moreover, employing advanced technologies in powder metal welding can further contribute to sustainable practices. Techniques such as laser welding and additive manufacturing allow for precision that minimizes material waste. These technologies enable manufacturers to achieve complex geometries and optimized designs without the excess scrap commonly associated with traditional methods. By adopting these innovative solutions, the powder metal industry is not only advancing in terms of productivity but also aligning itself with global sustainability goals, ensuring that future manufacturing practices are responsible and environmentally conscious.

| Innovation/Practice | Description | Sustainability Impact | Applications |

|---|---|---|---|

| Additive Manufacturing | Utilizing 3D printing technology with powder metals for complex designs. | Reduces material waste and allows for lightweight structures. | Aerospace, medical implants, automotive parts. |

| Recycling Metal Powders | Processes to reclaim and reuse unused powder metal materials. | Minimizes waste and conserves resources. | General manufacturing, tool production. |

| Environmentally Friendly Binders | Use of bio-based binders in powder metal compaction and sintering. | Decreases environmental toxins from production. | Consumer goods, automotive parts. |

| Smart Manufacturing Technologies | Integration of IoT and AI to monitor and optimize welding processes. | Enhances efficiency and resource management. | High-precision manufacturing, aerospace, automotive. |

| Energy Efficient Sintering | Developing techniques to reduce energy consumption in sintering. | Lower carbon footprint and resource savings. | General manufacturing of powder metal components. |

The integration of automation and artificial intelligence (AI) into the welding powder metal production process is poised to revolutionize modern manufacturing. Recent advancements in intelligent robotics are set to streamline workflows, enhance precision, and reduce operational costs in this sector. Companies are adopting AI-driven systems that can monitor production processes in real-time, predict failures, and adjust parameters automatically, resulting in increased productivity and higher quality outputs.

Moreover, the trend toward implementing smart technologies extends beyond just automation. It involves sophisticated data analytics that leverage machine learning to optimize material properties and welding techniques. This not only improves the efficiency of the welding process but also contributes to innovation in design and material science. As these technologies continue to evolve, manufacturers can expect a significant shift in how welding powder metals are produced, leading to more sustainable practices and tailored solutions for diverse applications in industries such as automotive, aerospace, and energy.

In the realm of modern manufacturing, powder metallurgy (PM) has emerged as a transformative technology, paving the way for innovative applications across various industries. A notable case study is the automotive sector, which has seen a dramatic increase in the use of PM components for lightweight structures. According to a recent report by the Metal Powder Industries Federation, the automotive industry has expanded its use of powder metal components by over 30% in the past five years, driven by the need for enhanced fuel efficiency and reduced emissions. Manufacturers like General Motors have successfully integrated PM parts in transmission systems, showcasing significant performance improvements and weight reductions.

Similarly, the aerospace industry is harnessing the advantages of powder metallurgy to produce complex geometries that traditional machining methods cannot achieve. Companies such as Boeing have adopted advanced powder metal techniques for turbine blades and other critical components, resulting in a 15% reduction in production costs and a 20% increase in component lifespan, as evidenced by research published in the International Journal of Aerospace Powder Metallurgy. These successful implementations highlight the potential of powder metal innovations, showcasing how they not only boost efficiency but also enhance the overall quality and sustainability of manufacturing processes.