High Strength Stainless steel (HSS) plays a crucial role in modern engineering and manufacturing. According to a market report by Research and Markets, the global high strength stainless steel market is projected to reach $5.57 billion by 2026. This growth is driven by its increasing usage in aerospace, automotive, and construction industries. HSS offers superior strength-to-weight ratios and exceptional corrosion resistance, essential for demanding applications.

Experts in the field emphasize the importance of High Strength Stainless. Dr. Emily Carter, a renowned materials scientist, states, "High Strength Stainless materials are transforming industries by providing durability and reliability." HSS not only enhances product performance but also contributes to sustainability by enabling lightweight designs, which can reduce energy consumption and emissions.

Despite its advantages, the production of High Strength Stainless can be challenging. Achieving the desired mechanical properties and consistency requires advanced processing techniques. The need for innovation in alloy development remains critical to meet industry demands. The landscape is evolving, and continuous improvement is essential for future advancements in High Strength Stainless applications.

High strength stainless steel exhibits remarkable durability and resistance to corrosion. Commonly, it is classified as martensitic or austenitic. These types contain higher levels of chromium and nickel. According to a recent report from the International Stainless Steel Forum, the global market for high strength stainless steel is projected to grow by 5% annually through 2025. This growth reflects the rising demand in various industries.

In construction, high strength stainless steel is crucial. It allows for lighter structures without sacrificing load-bearing capacity. For instance, it is used in bridges and skyscrapers. The material can withstand harsh environments, making it ideal for offshore applications. However, its high production costs can hinder widespread use. A study from the American Society of Mechanical Engineers indicates that while high strength stainless steel performs better, it requires careful consideration of manufacturing techniques.

In the automotive industry, this material is increasingly used to enhance safety and efficiency. Lightweight components can improve fuel economy and lower emissions. Yet, the industry still grapples with the challenge of recyclability. The complexity of recycling high strength stainless steel compared to traditional steel is a concern. Addressing these issues will be essential as demand continues to rise.

High strength stainless steel is renowned for its exceptional durability and resistance to corrosion. Its chemical composition plays a crucial role in determining its strength. Key elements include chromium, nickel, molybdenum, and nitrogen. These elements enhance the steel’s resistance to wear and fatigue. The combination of these metals creates a strong, resilient alloy.

There are different grades of high strength stainless steel. For example, grades like 304 and 316 are commonly used in various industries. Grade 304 is often found in kitchen applications due to its corrosion resistance. Meanwhile, grade 316 is used in marine environments because it withstands saltwater corrosion. However, the selection of the appropriate grade can sometimes be challenging. Not all projects require the same strength or resistance. This can lead to over-engineering or under-engineering of components.

Understanding the specific needs of an application is vital. Sometimes, choosing the wrong grade can affect performance. A thorough analysis of environmental conditions and stress factors is essential. This approach avoids costly mistakes. High strength stainless steel offers versatility but requires careful consideration during selection.

This bar chart illustrates the chemical composition of various high strength stainless steel grades. Each grade has unique properties suited for different applications.

High strength stainless steel is defined by its remarkable mechanical properties. It boasts exceptional strength, often exceeding 2000 MPa, making it suitable for various demanding applications. This material showcases significant toughness, resisting fracture even under extreme conditions. A study by the International Stainless Steel Forum highlights that these steels maintain their integrity at both high and low temperatures.

Corrosion resistance is another key property of high strength stainless steel. This alloy often contains a higher percentage of chromium, enhancing its ability to withstand oxidation and acidic environments. Reports from industry sources indicate that high strength stainless steel can resist pitting in chloride environments, which is critical in marine applications. As industries evolve, the need for reliable materials grows stronger. Yet, many engineers still overlook the potential of high strength stainless steel for innovative solutions.

Despite these advantages, challenges exist. Fabrication can be complex. Joining techniques must be carefully selected. If not, weaknesses may develop at welded joints. The cost of high strength stainless steel also remains relatively high. Companies must weigh initial costs against long-term benefits. It's a balancing act, requiring thoughtful consideration and strategy.

| Property | Description | Typical Values |

|---|---|---|

| Tensile Strength | The resistance of a material to breaking under tension. | More than 700 MPa |

| Yield Strength | The stress at which a material begins to deform plastically. | Over 600 MPa |

| Elongation | The amount of plastic deformation that occurs before fracture. | 10% - 30% |

| Corrosion Resistance | The ability to withstand corrosion in various environments. | Excellent in many environments |

| Toughness | The ability to absorb energy and plastically deform without fracturing. | High toughness values |

| Applications | Common uses include aerospace, marine, and construction industries. | Aircraft components, marine equipment |

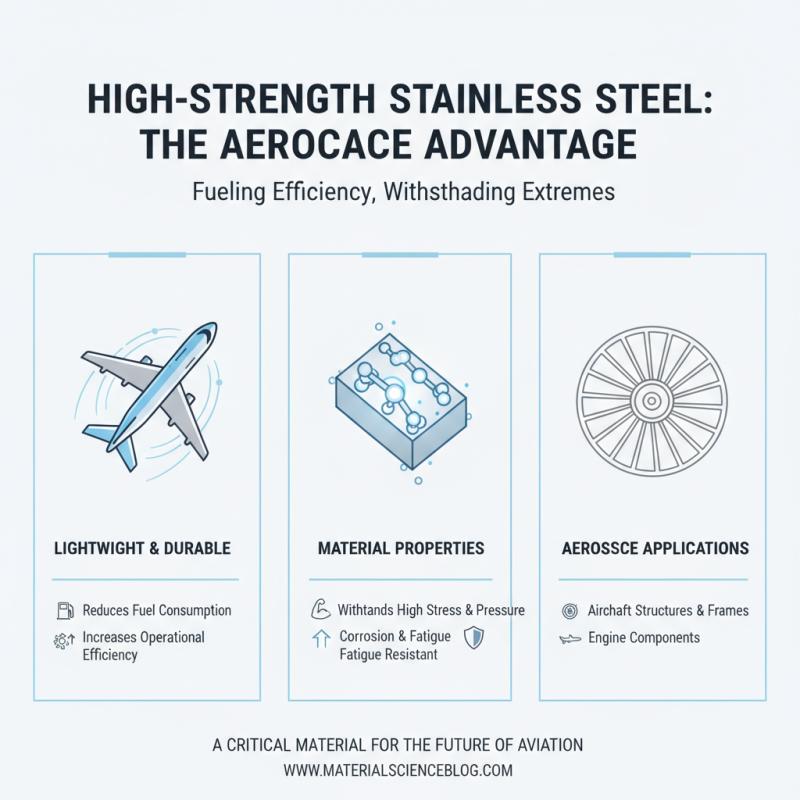

High-strength stainless steel is a vital material in various industries. In aerospace, its lightweight and durable nature is key. Aircraft need materials that withstand high stress while being as light as possible. High-strength stainless steel helps reduce fuel consumption and increase efficiency.

In the marine industry, this metal resists corrosion and damage from saltwater. Ships and submarines use it in components that face extreme conditions. This durability enhances safety and longevity, reducing maintenance costs.

**Tips:** Always consider environmental factors. Corrosion can still occur if protections aren’t maintained. Inspect regularly to ensure optimal performance. In construction, high-strength stainless steel offers robust structural integrity. It supports large buildings and bridges, ensuring safety. Designers and engineers sometimes struggle with balancing weight and strength. This material provides a solution, but cost can be a concern. Proper analysis is essential when specifying materials for any project.

High-strength stainless steel is gaining popularity due to its unique properties. It is recognized for its superior corrosion resistance and strength-to-weight ratio. The material is becoming essential in various sectors, including aerospace and construction.

Recent data from the Stainless Steel Council indicates that the global high-strength stainless steel market is projected to grow by 5% annually. Innovations in production processes are making these materials more accessible. For instance, advancements in alloy compositions are enhancing their mechanical properties. As industries strive for sustainability, manufacturers are focusing on eco-friendly production techniques, which could reduce environmental impact.

However, challenges remain. The cost of high-strength stainless steel can be prohibitive for smaller manufacturers. This barrier might slow innovation adoption. Also, while the material shows great promise, it sometimes lacks versatility in extreme temperatures. Ongoing research will be critical to overcome such limitations. The future landscape of high-strength stainless steel is poised for transformation, but it requires a balance between innovation and practical application.