High Strength Stainless Steel has emerged as a revolutionary material in various industrial applications, combining remarkable strength with the corrosion resistance that stainless steel is renowned for. According to a recent report by the International Stainless Steel Forum, the demand for high strength alloys has surged by over 25% in the last five years, driven by industries such as aerospace, construction, and automotive. These sectors increasingly require materials that not only withstand extreme environments but also contribute to weight reduction and enhanced durability.

Dr. Emily Thornton, a leading expert in materials science, emphasizes the significance of High Strength Stainless in modern engineering: "The unique properties of High Strength Stainless allow manufacturers to push the boundaries of design and performance, resulting in safer and more efficient structures." This innovative material is not only pivotal in meeting stringent safety standards but also plays a crucial role in sustainability by extending the lifespan of products and minimizing maintenance needs. As industries continue to evolve, High Strength Stainless stands out as a vital component in the quest for advanced, high-performance materials that address the challenges of the future.

High strength stainless steel is a specialized alloy known for its enhanced mechanical properties and durability. Defined primarily by its high tensile strength, this material typically incorporates elements such as chromium, nickel, and molybdenum, which contribute to its unique performance characteristics. The addition of these alloying elements not only improves corrosion resistance but also allows the steel to withstand higher stresses compared to standard stainless steel grades. Recent studies indicate that high strength stainless steel can achieve tensile strengths exceeding 1,000 MPa, making it ideal for various demanding applications across industries, including aerospace, construction, and automotive.

The composition of high strength stainless steel often varies depending on the specific grade, but it commonly contains 10-30% chromium and 5-20% nickel, along with other additives like nitrogen and titanium. This combination enhances not only strength but also oxidation resistance, making it suitable for high-temperature applications. According to a report from the International Stainless Steel Forum, the market for high strength stainless steel has been growing steadily, with projected growth rates hinting at an increase in demand due to its applications in critical infrastructure and advanced manufacturing processes. Such characteristics position high strength stainless steel as a significant material choice in modern engineering and industrial operations, where performance and reliability are paramount.

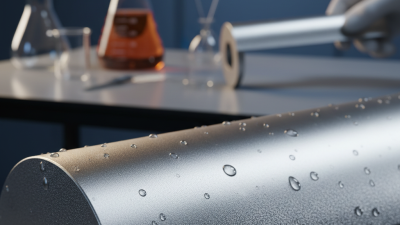

High strength stainless steel is an advanced material commonly utilized in various industrial applications due to its remarkable properties. One of the key properties of this alloy is its exceptional tensile strength, which often exceeds 700 MPa. This makes it suitable for demanding environments where mechanical stress is a concern. Additionally, high strength stainless steel offers excellent resistance to corrosion and oxidation, ensuring longevity and durability under harsh conditions. According to a report by the International Stainless Steel Forum, over 30% of stainless steel production is focused on high-performance grades, highlighting the growing demand for such materials in sectors like aerospace, automotive, and construction.

Another noteworthy property is its adaptability to extreme temperatures. High strength stainless steel can maintain its structural integrity in temperatures ranging from cryogenic levels to high heat applications, making it ideal for industries such as petrochemical and energy production. Furthermore, its lightweight nature, combined with strength, provides a significant advantage in reducing overall system weight without compromising safety and performance. A study from the Materials Science Institute reports that components made from high strength stainless steel can result in a 40% reduction in weight compared to conventional materials, contributing to energy savings and efficiency in operations.

Tip: When selecting high strength stainless steel for your projects, consider factors such as the specific mechanical requirements and environmental conditions. Conducting a thorough analysis of the application can help in choosing the appropriate grade and maintaining the integrity of your structures over time.

High strength stainless steel has emerged as a pivotal material in various industrial applications, offering distinct advantages over traditional alloys. One of the foremost benefits is its superior tensile strength, which can reach levels exceeding 1,000 MPa. According to a report from the International Stainless Steel Forum (ISSF), the demand for high strength stainless steel has grown substantially, particularly in sectors like aerospace and automotive, where weight reduction and performance enhancement are critical. The exceptional strength-to-weight ratio allows for the design of lighter structures without compromising durability, enabling manufacturers to enhance fuel efficiency and reduce emissions.

In addition to its mechanical properties, high strength stainless steel boasts superior corrosion resistance compared to conventional alloys. A study published by the ASM International highlights that the advanced compositions and surface treatments of high strength stainless steels create a robust barrier against environmental factors, greatly extending the lifespan of components in harsh conditions. This durability not only minimizes maintenance costs but also reduces the need for frequent replacements, providing a significant economic advantage. As industries continue to seek innovative solutions for robust and sustainable manufacturing, the benefits of high strength stainless steel become increasingly evident, transforming the landscape of material selection and engineering design.

High strength stainless steel is increasingly becoming the material of choice across various industries due to its exceptional durability and resistance to corrosion while providing enhanced strength. One of the primary sectors utilizing this advanced material is the aerospace industry, where components are subjected to extreme conditions. High strength stainless steel is essential in manufacturing aircraft frames, engine parts, and fasteners, where both weight reduction and structural integrity are crucial for performance and safety.

Another significant industry that benefits from high strength stainless steel is construction. In structural applications, such as beams and columns, this material provides the necessary strength to support large loads while maintaining resistance to rust and environmental wear. Additionally, the automotive industry has also embraced high strength stainless steel for use in body panels and structural components, contributing to lighter vehicles that improve fuel efficiency without compromising safety. Its versatility and performance characteristics make it a vital material in various applications, ensuring reliability and longevity across these critical sectors.

The future of high strength stainless steel development

is poised for significant advancements driven by innovations in material science and manufacturing technologies. One of the most exciting trends is the incorporation of advanced alloying elements

that enhance the mechanical properties and corrosion resistance of stainless steel. Research is currently focused on developing lightweight yet robust materials that can withstand extreme environments and reduce overall weight in applications ranging from aerospace to automotive industries.

Another key trend is the integration of smart manufacturing processes, including additive manufacturing and automation. These technologies allow for more precise control in producing high strength stainless steel components, resulting in improved performance and efficiency. Furthermore, sustainability is becoming a pivotal factor in the development of materials. The industry is exploring ways to recycle stainless steel effectively

and minimize the carbon footprint associated with its production. This shift not only meets regulatory demands but also aligns with the growing consciousness towards environmentally responsible practices in manufacturing.