The Master Alloy market is poised for significant growth as industry trends continue to evolve, particularly highlighted by the upcoming 2025 China Import and Export Fair. Recent market analysis indicates that the global Master Alloy industry is expected to reach approximately USD 3 billion by 2025, growing at a CAGR of around 6.5% during the forecast period. This surge is largely attributed to the increasing demand for lightweight and high-performance materials in the aerospace, automotive, and electronics sectors. Moreover, advancements in manufacturing technologies are enhancing the production capabilities and applications of Master Alloys, ultimately driving their adoption across various industries.

As participants gather at the 138th Canton Fair, they will have the opportunity to explore new business ventures and network with industry leaders, thus unlocking potential in this dynamic market landscape.

As participants gather at the 138th Canton Fair, they will have the opportunity to explore new business ventures and network with industry leaders, thus unlocking potential in this dynamic market landscape.

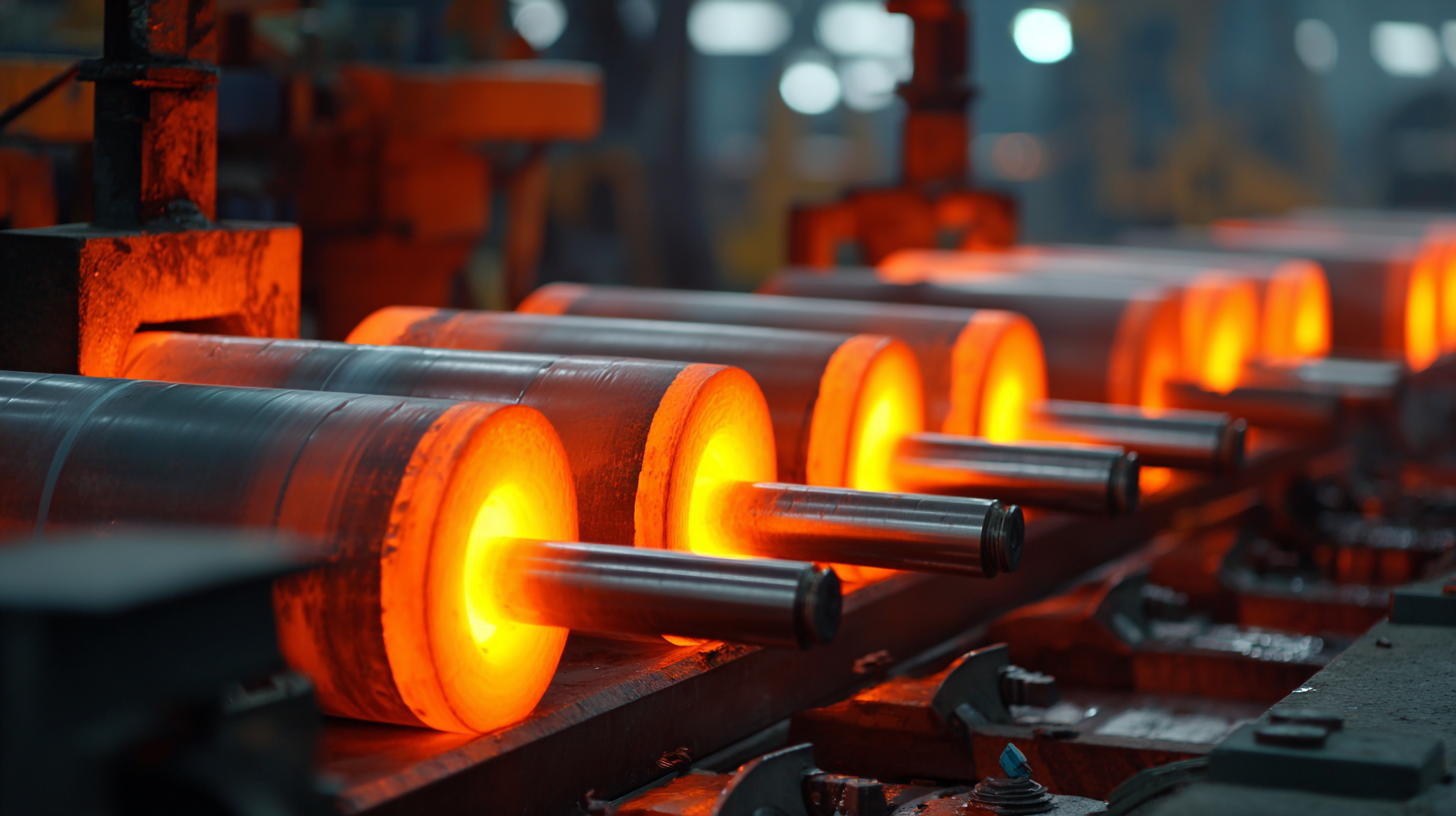

Master alloys have become an essential component in modern manufacturing industries, significantly influencing the properties and performance of various materials. These alloys, which are composed of base metals combined with specific alloying elements, enhance characteristics like strength, ductility, and corrosion resistance. Industries ranging from aerospace to automotive and electronics rely on master alloys to innovate and improve their product offerings, making them a critical factor in competitive manufacturing.

To maximize the benefits of master alloys in your production processes, consider the following tips: First, conduct thorough research on the specific alloy compositions that suit your product requirements. Tailoring these materials to meet particular performance standards can lead to substantial improvements in product quality. Second, collaborate with suppliers who specialize in master alloys. Their insights into the latest advancements can help you stay ahead in the rapidly evolving manufacturing landscape. Lastly, regular training for your team on the application of master alloys ensures that your workforce remains skilled in utilizing these materials effectively, thus enhancing overall production efficiency.

In exploring the role of master alloys further, it’s clear that these materials not only streamline manufacturing processes but also contribute to sustainability efforts by reducing waste and optimizing resource use. Their adaptability and performance-driven properties make them invaluable in shaping the future of manufacturing industries.

| Alloy Type | Market Share (%) | Growth Rate (2020-2025) (%) | Key Applications | Region |

|---|---|---|---|---|

| Aluminium Master Alloys | 30 | 5 | Automotive, Aerospace | Asia Pacific |

| Copper Master Alloys | 25 | 4.5 | Electronics, Electrical | North America |

| Nickel Master Alloys | 20 | 6 | Marine, Petrochemical | Europe |

| Titanium Master Alloys | 15 | 5.8 | Aerospace, Medical | Asia Pacific |

| Zinc Master Alloys | 10 | 7 | Construction, Coatings | Africa |

The master alloy market is poised for significant growth by 2025, driven by several key trends that define its landscape. One of the most prominent trends is the increasing demand for lightweight materials across various industries, particularly in automotive and aerospace. Manufacturers are actively seeking innovative solutions to improve energy efficiency and reduce emissions, which has led to a surge in the use of master alloys, especially aluminum and titanium-based ones. This shift not only enhances product performance but also aligns with global sustainability goals.

Another critical trend shaping the master alloy market is the rapid technological advancements in production processes. The introduction of sophisticated manufacturing techniques, such as additive manufacturing and precision casting, has improved the quality and application of master alloys. These advancements enable the customization of alloys to meet specific industry requirements, further driving demand. Additionally, the growing emphasis on recycling and sustainable practices in metallurgy is expected to bolster the market, as reclaimed master alloys offer both economic and environmental benefits. Overall, these trends signify a dynamic landscape for the master alloy market leading up to 2025.

The evolving landscape of trade policies significantly influences the dynamics of the master alloy market. As countries tighten their regulations and impose tariffs, exporters face new challenges in navigating these complexities. For instance, the introduction of stricter import quotas can hinder trade flows, impacting manufacturers reliant on imported master alloys for their production processes. This shift not only affects pricing but also prompts companies to seek alternative suppliers or adapt their strategies to remain competitive in a restricted market.

Moreover, trade policies that promote sustainable practices may create both challenges and opportunities for master alloy imports and exports. Regions investing in green technologies and sustainable sourcing can lead to increased demand for specific master alloys that align with these goals. Consequently, businesses must stay informed and agile to capitalize on favorable trade agreements while mitigating the risks associated with evolving regulations. Understanding the intricacies of these policies will be crucial for players in the master alloy sector as they plan their strategies for the upcoming years.

The upcoming 138th Canton Fair presents a significant networking opportunity for stakeholders in the master alloy market. As the industry witnesses a surge in demand, participants can establish valuable connections that foster collaboration and innovation. The fair serves as a melting pot for manufacturers, suppliers, and end-users, offering a platform to share insights on the latest trends and technological advancements in master alloys. Stakeholders can engage in discussions that not only enhance their understanding of market dynamics but also identify potential partnerships that can drive growth.

Furthermore, the 138th Canton Fair emphasizes the importance of relationship building in an evolving market landscape. By engaging with a diverse range of professionals, attendees can explore new avenues for business expansion and diversification. The fair will feature numerous sessions and exhibitions focused on master alloys, enabling participants to showcase their products and capabilities while learning about cutting-edge practices. This environment encourages the exchange of ideas and strategies essential for navigating the complexities of the industry and unlocking new opportunities ahead.

The growing emphasis on sustainability within the master alloys market signals a significant shift in innovation strategies. Future advancements in master alloys are rooted in the principles of eco-friendliness and resource efficiency, particularly as companies explore new methods to recycle and repurpose metals. Enhanced aluminium separation technologies, like advanced sorting systems, have emerged as key players in driving sustainable solutions. These innovations not only streamline recycling processes but also contribute to the circular economy—a critical framework for reducing waste and conserving resources.

Tips: When considering sustainable innovations, focus on materials that can be easily recycled or have a lower environmental impact. Collaborating with technology providers can enhance the efficiency of your recycling processes, increasing the quality of end products.

Moreover, initiatives such as the transformative projects that successfully convert waste into high-purity materials highlight the potential for a more sustainable future. The integration of energy storage technologies complements these innovations, facilitating a more robust infrastructure for renewable energy sources. As the industry evolves, collaboration among stakeholders to promote innovative and sustainable practices will be essential in unlocking new opportunities in the market.

Tips: Regularly assess partnerships and technologies that align with sustainability goals, as collaboration can enhance your market position and lead to groundbreaking innovations. Keeping up with industry trends will also ensure that you remain competitive in a rapidly changing landscape.