Hard Rock Cutting techniques are vital for mining success. Mastering these techniques can significantly enhance productivity and safety. Experts in the field emphasize their importance. Dr. Alice Chen, a renowned Mining Engineer, once stated, “Precision in Hard Rock Cutting determines the efficiency of extraction.” Her insights highlight the intricate relationship between technique and outcome.

In today's mining industry, the challenges in Hard Rock Cutting remain profound. Operators often encounter unpredictable rock formations. The tools and methods applied must adapt swiftly. This variability can lead to inefficiencies and increased operational costs. Striking the right balance between speed and precision is essential.

The journey to mastering Hard Rock Cutting is not straightforward. It involves continual learning and adaptation to new technologies. Many miners struggle with aspects like tool wear and selection. Reflecting on these challenges can lead to improved strategies. Embracing the nuances of Hard Rock Cutting can pave the way for mining excellence.

Hard rock mining poses numerous challenges. It requires specialized techniques and equipment that can withstand tough underground conditions. The density and hardness of the rock make drilling and blasting essential. However, these methods can be risky and expensive. Understanding these challenges is crucial for success in the mining industry.

One key tip is to invest in proper training. Workers must know how to handle machinery safely. Experienced operators can identify potential hazards quickly. Equipment should be regularly inspected and maintained to prevent breakdowns. Encourage a culture of safety where workers feel empowered to voice concerns.

Another tip involves planning and preparation. Create detailed maps of the mining area to identify rock formations. This helps in choosing the right cutting techniques. Using the right technology can improve efficiency. However, technology alone cannot solve all problems. It requires continuous evaluation and adaptation to tackle unforeseen issues that arise during mining operations.

| Technique | Description | Challenges | Best Practices |

|---|---|---|---|

| Continuous Miner | A machine that cuts and gathers material while continuously moving through the mine. | High initial costs; requires skilled operators. | Regular training and maintenance are crucial. |

| Drilling and Blasting | Involves drilling holes and blasting rock to break it into manageable pieces. | Safety hazards and environmental concerns. | Follow strict safety protocols and adjust blasting techniques for rock type. |

| Diamond Wire Sawing | Uses a wire with diamonds attached to cut through hard rock with precision. | Requires high power and specialized equipment. | Utilize the latest technology for efficiency and accuracy. |

| Hydraulic Breakers | Attach to excavators, used for breaking rock with hydraulic power. | Noise and vibration can be problematic. | Implement noise reduction measures and proper equipment management. |

| Underground Ore Pass | A vertical or inclined shaft for transporting ore from above to underground levels. | Caving and ground stability issues. | Regular geological assessments to ensure stability. |

Mastering hard rock cutting techniques is vital for successful mining operations. To achieve efficiency, miners must invest in essential tools and equipment tailored for this task. Proper tools significantly enhance productivity and safety during rock cutting. According to industry reports, the right equipment can improve cutting depth by up to 30%.

Key tools include diamond drill bits, heavy-duty rock saws, and high-performance grinding machines. Diamond bits are known for their durability and effectiveness. They can penetrate hard rock formations with ease. Heavy-duty saws, on the other hand, excel in larger operations. They offer precision and speed, minimizing downtime. Using a combination of these tools often yields the best results.

Tip: Regular maintenance of equipment is crucial. This prolongs the lifespan of tools and ensures optimal performance. Keep an eye on the wear and tear of drill bits. Ignoring this could lead to costly delays.

Tip: Training staff on new equipment is essential. Inexperienced operators may misuse tools, resulting in inefficiencies. Investing time in training reduces accidents and improves outcomes. There remains a learning curve with advanced technology, highlighting the need for ongoing education. Balancing investment in equipment and training is key to operational success in hard rock mining.

Hard rock cutting techniques are critical for successful mining operations. Effective methods can greatly enhance productivity and reduce costs. The right tools, like diamond saws and rotary drills, improve efficiency. According to the International Council on Mining and Metals, adopting advanced rock cutting technologies can reduce operational costs by as much as 20%. This is a significant saving for any mining company.

Labor productivity also plays a vital role. Regular training can help miners adapt to the latest techniques. The challenge lies in addressing skill gaps. A report by the Global Mining Industry Group found that many miners feel underprepared for modern hard rock cutting. Additionally, the integration of automation can be tricky, with studies indicating that 30% of mining companies faced delays in technology adoption.

Investing in research and development also matters. Many companies overlook this, focusing instead on immediate needs. However, continuous innovation can lead to long-term success. Failing to prioritize cutting-edge techniques can result in lost opportunities and increased operational risks. The industry is competitive, and not evolving can be detrimental.

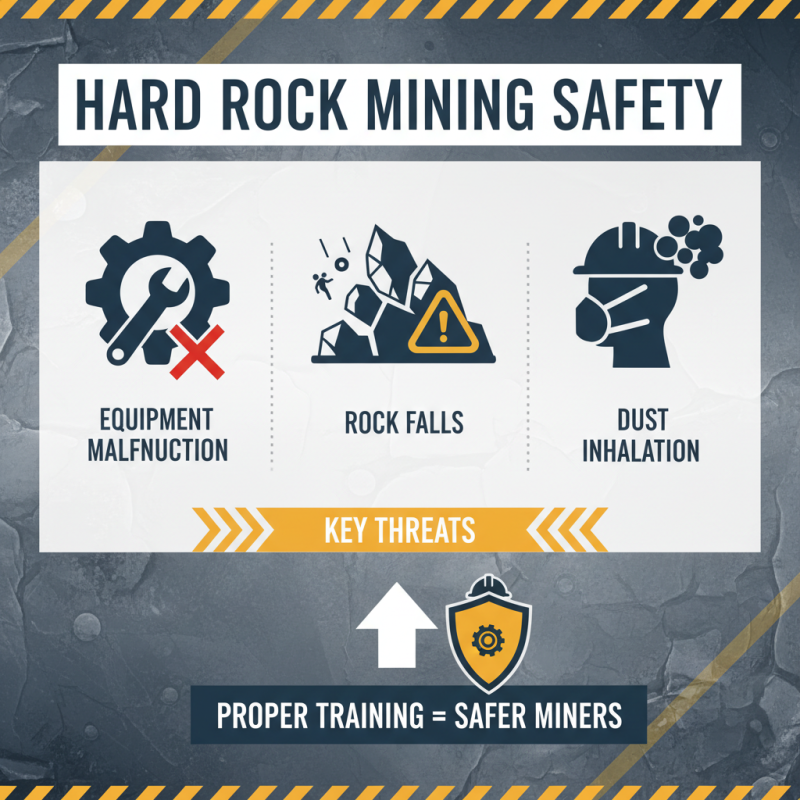

Safety is paramount in hard rock mining operations. Miners face various hazards every day. Understanding these risks can save lives. Equipment malfunction, rock falls, and dust inhalation are significant threats. Workers must be trained properly to handle such dangers.

Tips: Always wear personal protective equipment. This includes helmets, gloves, and masks. Regular safety drills can enhance readiness. Equipments should be inspected daily, identifying potential issues early. Communication is crucial in the mining environment. Use clear signals and maintain awareness of all workers.

Maintaining safety protocols can be challenging. Some teams may overlook procedures under pressure. Regular reviews and meetings can help reinforce the importance. Checklists can also ensure that essential steps are not missed. This constant vigilance can foster a culture of safety that protects everyone involved.

Advancements in technology are transforming hard rock mining. Newer tools and techniques make cutting rock more efficient. Automated machines assist in drilling and blasting, reducing labor costs. Innovations, such as remote-controlled equipment, allow for safer operations in hazardous areas. It's fascinating to see how technology can streamline processes.

However, not every advancement is flawless. Sometimes, new technologies can lead to unexpected challenges. For instance, automated systems require a skilled workforce to operate and maintain them. This need for training poses a hurdle for many mining companies. Additionally, the initial investment can be substantial, raising questions about long-term profitability.

Data analytics is also key in optimizing operations. Mining companies can collect vast amounts of data to improve decision-making. Yet, interpreting this data effectively is not always simple. There may be a steep learning curve. Overall, while these technological advancements offer great promise, they also require careful consideration and ongoing evaluation.