Metal Powder Bed Fusion is transforming the landscape of additive manufacturing. According to a recent report by MarketsandMarkets, the metal 3D printing market is projected to reach $2.5 billion by 2025, driven significantly by this technology. This growth reflects the increasing demand for complex parts in various industries. The aerospace sector, for instance, is leading this shift. Lightweight components created using Metal Powder Bed Fusion can reduce fuel consumption and improve efficiency.

Despite its advantages, challenges remain. The process can be time-consuming. Quality control is crucial to ensure the integrity of parts produced. Reports indicate that around 20% of metal 3D printed parts fail during the post-processing stage. This highlights the need for ongoing improvements in techniques and equipment. Adopting Metal Powder Bed Fusion also requires investment in training and technology. Companies must weigh these factors against the potential benefits.

Innovations in software and hardware are essential. As Metal Powder Bed Fusion technology evolves, it promises to create new opportunities. The potential for customization and design flexibility stands out. However, the industry must be prepared to address challenges, ensuring product success and reducing production waste. This balance between innovation and practicality will define the future of metal additive manufacturing.

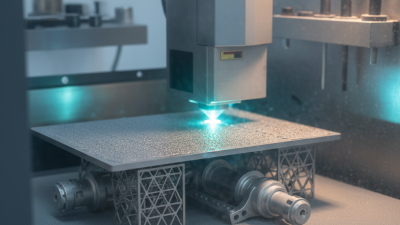

Metal Powder Bed Fusion (MPBF) is reshaping the landscape of additive manufacturing. This technique uses a laser to fuse metal powders layer by layer. It is gaining traction across industries such as aerospace, automotive, and medical devices. According to recent industry reports, the global market for metal additive manufacturing is projected to reach $11.58 billion by 2028. This growth highlights the increasing demand for complex geometries that traditional methods cannot easily achieve.

One of MPBF's benefits is its ability to create lightweight structures. These designs can significantly reduce the weight of components while maintaining strength. However, the process has challenges. Issues like residual stress and part warping often arise. These factors can impact the final part quality. It’s essential for users to develop expertise in optimizing parameters to mitigate such risks.

Tips: Consider investing in simulation software. This can help predict the behavior of parts during the printing process. Understanding the material properties is crucial as well. Different powders yield varying results. Also, consistent powder quality is necessary for successful prints. Addressing these aspects can lead to better outcomes in MPBF projects.

Metal Powder Bed Fusion (MPBF) technology is transforming additive manufacturing with several key advantages. This technique allows for the production of complex geometries that traditional methods struggle to achieve. According to a recent report from a leading industry analysis group, MPBF can reduce material waste by up to 75%. This reduction not only saves costs but also promotes sustainability.

Another advantage is its ability to combine multiple materials. This versatility leads to structures with unique mechanical properties. The same report indicates that MPBF can produce parts with mechanical performance exceeding that of cast components. However, the complexity of parameters in MPBF means that process optimization is still a challenge.

While MPBF technology excels in precision, there are limitations. The speed of production often lags behind other manufacturing techniques. For certain applications, this can lead to longer lead times. Additionally, surface finish quality can vary, requiring post-processing. Thus, while Metal Powder Bed Fusion is indeed revolutionary, it is essential to continue refining and addressing these issues for broader market adoption.

Metal Powder Bed Fusion (MPBF) is reshaping various industries through its applications in component manufacturing. This technology is versatile. It is used in automotive, aerospace, medical, and tooling sectors. In automotive, parts are produced faster and lighter. Complex geometries can be achieved that were impossible before. Aerospace benefits similarly with high-performance components, reducing weight and enhancing fuel efficiency.

In medical applications, MPBF allows for the creation of custom prosthetics. Tailoring implants to individual needs improves patient outcomes. However, producing high-quality and precise parts remains a challenge. The process is sensitive to parameters like temperature and powder quality. In tooling, MPBF can create unique tool designs that traditional methods cannot replicate. Still, the durability of these tools needs careful evaluation.

Various industries are exploring MPBF, but obstacles exist. Equipment costs can be high, and expertise is limited in some areas. Research and development are crucial to overcome these hurdles. Continuous improvements are necessary for MPBF to reach its full potential. The interplay between innovation and practical application defines its future.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Production of lightweight components | Reduced weight and improved fuel efficiency |

| Automotive | Manufacture of complex engine parts | Increased performance and reduced costs |

| Medical | Custom implants and prosthetics | Personalized fit and enhanced patient outcomes |

| Defense | Production of durable weapon components | Increased reliability and strength |

| Energy | Manufacture of turbine blades and heat exchangers | Enhanced thermal performance and efficiency |

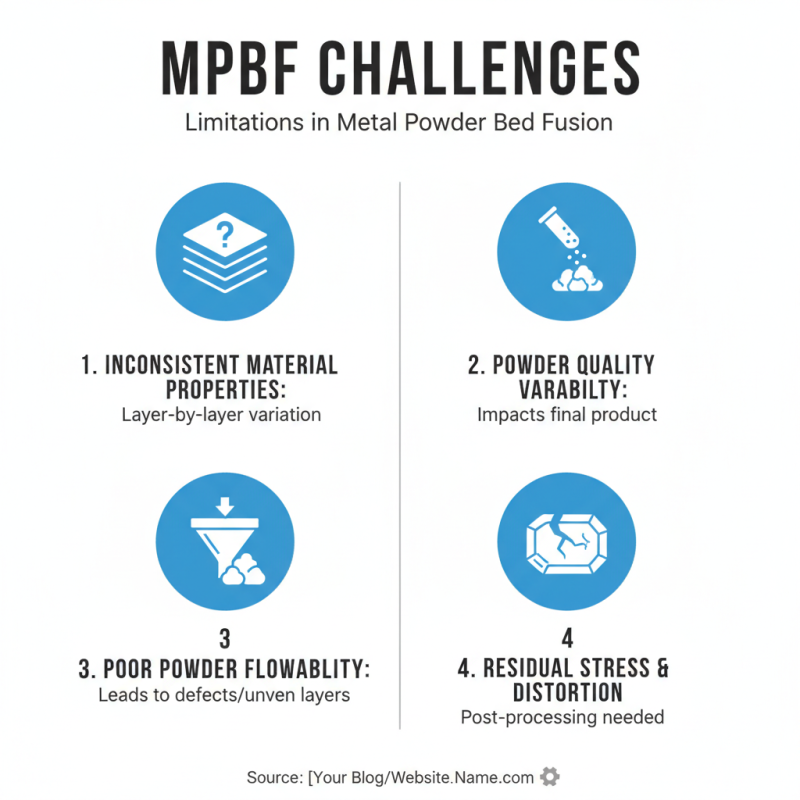

Metal Powder Bed Fusion (MPBF) offers unique opportunities in additive manufacturing. However, this process comes with various challenges and limitations. The layer-by-layer approach can lead to inconsistent material properties. Variability in powder quality impacts the final product. Poor flowability can result in defects and uneven layers.

Heat management during the fusion process is another concern. Excessive heat can cause warping or residual stresses. This challenge requires careful control, which can complicate the process. Additionally, the need for post-processing often transforms completed parts. Smoothing and refining surfaces add time and cost. It often feels like a never-ending cycle of adjustments.

Another limitation lies in the build size. Current equipment often restricts the dimensions of manufactured parts. Larger components may not fully benefit from the MPBF's capabilities. This constraint hampers innovation. Designers must be cognizant of these limitations, yet they still push boundaries. The journey in mastering MPBF continues, demanding reflection and improvement.

Metal Powder Bed Fusion is not just a trend; it's a transformative force in additive manufacturing. This technique employs lasers to fuse metal powder layer by layer. The applications are vast, spanning industries from aerospace to medical. This technology enables complex geometries that traditional methods can't achieve. However, it also brings challenges like powder handling and equipment costs.

Future innovations might introduce better materials. New metal alloys could improve strength and reduce costs. Bio-compatible metals for medical implants are on the horizon, too. But the process isn't flawless. Controlling the quality and consistency of each layer remains tricky. Researchers are focused on addressing these inconsistencies. Improvements in software aimed at process monitoring and optimization could make a difference.

Another exciting prospect is automation. Robotics can streamline production, reducing human error. Yet, the industry must assess potential job impacts. As Metal Powder Bed Fusion evolves, sustainability concerns will also play a critical role. The production waste must be minimized. Continuous investment in research will be essential for overcoming existing barriers. The future holds promise, but challenges lie ahead.