In the evolving field of spray particle technology, achieving high efficiency remains a challenge. Dr. Emily Carter, an expert in the field, stated, "Optimizing spray particle design can lead to significant improvements in application outcomes." This highlights the importance of refining our methods to enhance performance.

Spray particle technology plays a crucial role in various industries, including agriculture and manufacturing. Efficient spray particles ensure precise application and reduce waste. Yet, many practices still rely on outdated techniques that may not yield the best results. Understanding the nuances of particle size and distribution is vital.

Moreover, there is a need for continuous assessment of current methodologies. What works today may not be suitable tomorrow. Innovative research must explore new materials and techniques. The future of spray particle technology hinges on our ability to adapt and optimize for increased efficiency.

Spray particle technology is a vital tool in many industries. It plays a significant role in agriculture, pharmaceutical manufacturing, and automotive sectors. This technology helps in applying coatings and delivering substances evenly. Understanding this technology can lead to improved efficiency and effectiveness.

Tips: Always assess the droplet size. It plays a crucial role in how substances are absorbed. Smaller droplets may evaporate faster, while larger droplets deliver more volume. Experiment with different nozzles to see their impact on your outcomes.

Another consideration is the pressure settings during spray application. Higher pressure can lead to finer mist, but it may result in overspray. Adjusting the pressure can enhance control. Evaluate your setup regularly for adjustments.

Moreover, consider the environment where spraying occurs. Wind and humidity can significantly affect spray patterns. Unchecked, this could lead to wasted resources. Monitor these conditions consistently to optimize performance. The goal is to achieve precise application and lessen the chances of overspray or waste.

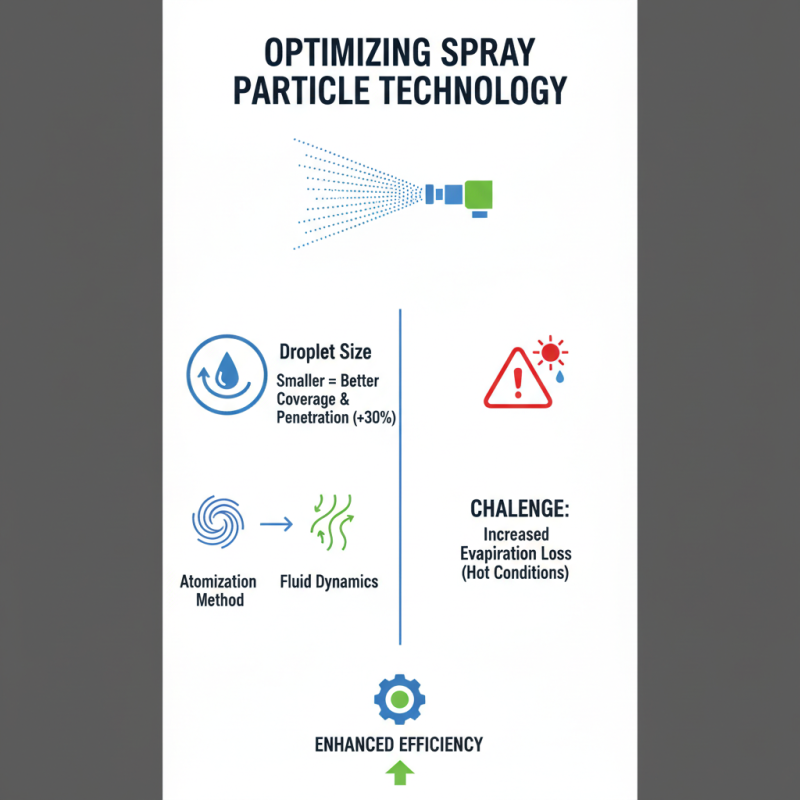

Optimizing spray particle technology is crucial for enhancing efficiency. Key factors influencing spray particle efficiency include droplet size, atomization method, and fluid dynamics. Studies show that reducing droplet size can improve coverage and penetration by nearly 30%. However, smaller droplets might lead to increased evaporation losses, especially in hot conditions.

The atomization method plays a critical role. Air, pressure, and ultrasonic atomizers each have unique efficiencies under different conditions. For example, pressure atomizers can achieve an efficiency of 90% when conditions are optimal. Still, they may lag behind in applications needing finer particles.

Fluid dynamics also significantly affects performance. Proper nozzle design can help improve the uniformity of spray patterns. Data indicate that a well-designed nozzle can enhance the distribution efficiency by 25%. Yet, many systems still struggle with issues like clogging and uneven spray distribution. Continuous reflection on these factors is necessary for consistent improvements in spray particle technology.

Optimizing spray particle technology is crucial for enhancing efficiency in various applications. Effective spray distribution and coverage can significantly impact the quality of results. Industry reports indicate that poorly distributed sprays can lead to wastage of up to 30% of materials. This inefficiency not only increases costs but also affects environmental sustainability.

To enhance spray distribution, consider the nozzle design. Different nozzles produce varying droplet sizes. Smaller droplets provide better coverage but may drift away. Conversely, larger droplets offer more control but can lead to uneven coverage. Always choose the right type based on your specific needs.

Tips: Use a spray pattern indicator to visualize coverage. This helps identify areas that need adjustment. Regularly calibrate your equipment for consistent performance. Maintaining equipment can sometimes be overlooked but is essential for effective spraying. If the calibration is off, the output can be unpredictable and inefficient.

Also, experiment with pressure settings. Higher pressure can improve droplet atomization but may also cause overspray. Balancing pressure and material viscosity is key. Monitoring these factors ensures better application and reduces waste. Adjusting your technique based on feedback may take time, but it often leads to improved outcomes.

| Technique | Description | Efficiency Improvement (%) | Application Area |

|---|---|---|---|

| Adjusting Nozzle Design | Optimizing the shape and size of the nozzle for better droplet formation and distribution. | 15% | Agriculture |

| Pressure Adjustment | Modifying the spray pressure to achieve optimal droplet size for target coverage. | 20% | Pest Control |

| Chemical Additives | Incorporating surfactants to improve adhesion and spread of spray particles. | 25% | Industrial Coatings |

| Fan Adjustment | Optimizing air flow patterns to enhance spray distribution over the target area. | 18% | Field Spraying |

| Electrostatic Spraying | Using electrostatic forces to improve particle attraction to surfaces. | 30% | Paint and Coatings |

When optimizing spray particle technology, nozzle design plays a crucial role. Different nozzles create varying spray patterns and droplet sizes. A study by the American Society of Agricultural and Biological Engineers highlights that efficiency can vary by over 30% based on nozzle choice. This significant difference impacts both material usage and application effectiveness.

Selecting the right nozzle involves understanding application needs. For instance, flat-fan nozzles are great for broad coverage, while hollow-cone nozzles excel in target application. However, improper selection can lead to overspray or drift. An analysis from the Spray Technology Association found that 5% of the sprayed material often misses the target due to poor nozzle design. This waste not only increases costs but can also harm the environment.

Many operators overlook this nuance. They might default to a standard nozzle without assessing specific requirements. Rethinking spray conditions is vital. Factors like pressure and viscosity must align with nozzle capabilities. Ignoring these details can diminish the expected efficiency gains. Actors in the industry should seek data-driven insights to refine their nozzle choices.

This chart illustrates the performance of different nozzle designs in optimizing spray particle technology efficiency. The data represents the average distribution of spray efficiency based on various nozzle types.

Effective spray particle technology relies heavily on monitoring and analyzing spray patterns. Consistent evaluation is key to optimizing performance. Each pattern delivers distinct particle sizes and distributions. Slight variations can lead to uneven coverage. This is where observation plays a vital role.

Using high-speed cameras can reveal how droplets disperse. However, not all setups capture the full picture. Sometimes reflections and lighting distort the data. It’s essential to revisit these parameters frequently. Regular checks help identify anomalies that may affect efficiency. Analyzing data in real-time allows for quicker adjustments. Over time, these small changes can lead to significant improvements.

Feedback loops are crucial for continuous enhancement. Operators should document outcomes after each spray session. Not every application is perfect, and that’s okay. Learning from these moments fosters better practices. Inconsistent results may indicate a need for equipment recalibration. Reflection on failures sometimes uncovers unexpected insights. This ongoing analysis ultimately drives innovation in spray technology.