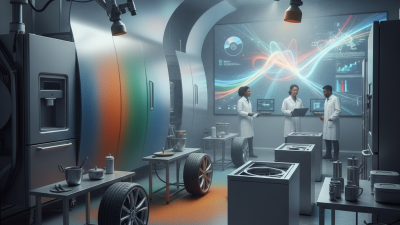

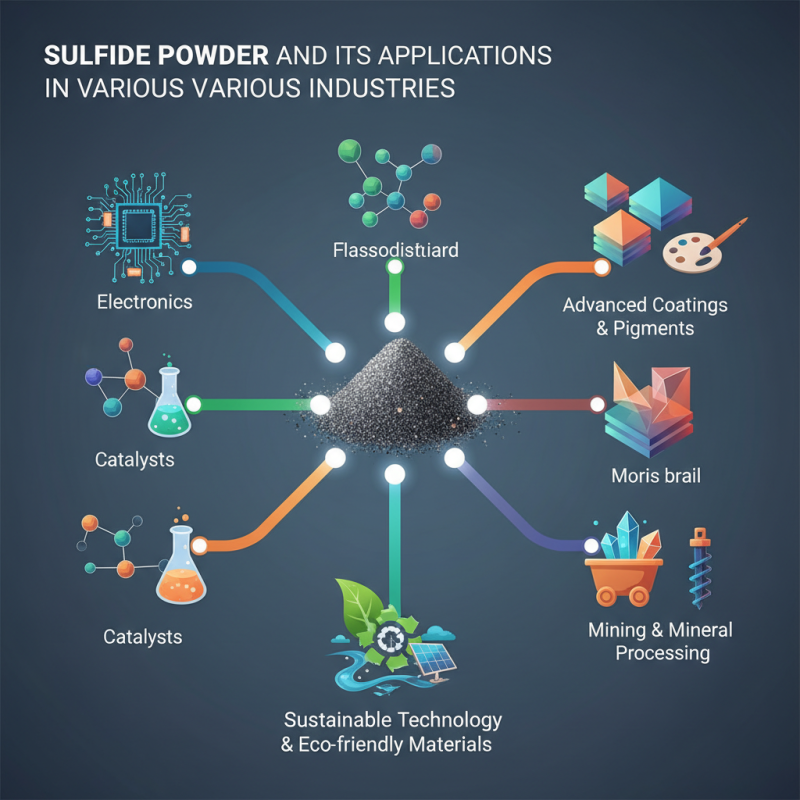

Sulfide Powder is a crucial material that finds extensive applications across various industries due to its unique chemical properties and versatility. This fine powder, formed by the combination of sulfur with a variety of metals and non-metals, plays a significant role in advancing technologies ranging from electronics to environmental management. Its ability to conduct electricity and its reactive nature make it an essential component in the manufacture of semiconductors, batteries, and catalysts, thereby enhancing the efficiency and performance of these products.

Beyond its applications in electronics, Sulfide Powder is also pivotal in the field of materials science. It is employed in the development of advanced coatings and pigments, which are vital for enhancing the durability and aesthetic appeal of various surfaces. In addition, the powder’s unique properties are harnessed in the realm of mining and mineral processing, where it aids in the extraction of valuable metals. The growing demand for sustainable technology emphasizes the importance of Sulfide Powder in developing eco-friendly materials and processes that align with the global trend towards greener solutions.

As industries continue to explore innovative ways to utilize Sulfide Powder, understanding its characteristics and potential applications becomes increasingly vital. This article delves into the properties of Sulfide Powder and examines its diverse applications across different sectors, highlighting its significance in both current and future technological advancements.

Sulfide powder refers to a class of compounds that contain sulfur in a negative oxidation state. Typically, sulfides are formed by the combination of sulfur with metals or non-metals, leading to compounds like metal sulfides or nonmetallic sulfides. The most common example is zinc sulfide, which is used widely in various industries due to its semiconducting properties. In terms of composition, sulfide powders are generally crystalline in structure, with varying physical properties depending on the specific metal or non-metal involved in the reaction.

The versatility of sulfide powder makes it applicable across multiple sectors, including electronics, mining, and materials science. In electronics, for instance, sulfide powders are important for producing semiconductor materials that can be used in solar cells and photodetectors. Additionally, in the mining industry, sulfide minerals are often subjected to flotation processes to extract valuable metals such as copper and lead. The unique properties of sulfur compounds, such as their ability to absorb light or facilitate chemical reactions, also bolster their use in various chemical processes, making them essential to advancements in materials development and environmental applications.

The manufacturing process of sulfide powder involves several critical steps aimed at ensuring the quality and efficiency of the final product. The process typically begins with the selection of raw materials, which may include sulfide minerals like copper, lead, or zinc. These minerals undergo grinding and milling to achieve a fine powder form. After milling, the powdered minerals are subject to a series of chemical reactions, often involving sulfur or sulfur-containing compounds, to facilitate the formation of sulfide.

During the synthesis phase, temperature control is crucial. The mixture is usually heated to specific temperatures to encourage the reaction between the metal oxides and sulfur. This ensures the maximum yield of sulfide powder. After the reaction, the resulting product undergoes purification processes to remove impurities, which may involve washing or filtration. The final sulfide powder is then dried and characterized to assess its properties, which are essential for its applications in various industries.

Tips: When handling sulfide powders, always ensure proper safety measures are in place, including the use of personal protective equipment (PPE) to minimize inhalation or contact risks. Additionally, maintaining a controlled environment during the manufacturing process can significantly improve the consistency and quality of the final product. Proper storage in airtight containers can also help prevent oxidation and degradation of the powder, ensuring it remains effective for its intended applications.

Sulfide powder, a compound formed by the combination of sulfur with metals or nonmetals, is known for its unique properties that make it valuable across various industries. One of its key characteristics is its diversity in particle size and morphology, which can be tailored through various synthesis methods, such as precipitation and co-precipitation. According to a recent market analysis report from Research and Markets, the global sulfide market is expected to reach USD 10.5 billion by 2026, driven primarily by the chemical and electronics sectors, indicating its significant utility in manufacturing processes.

The electrochemical properties of sulfide powder are particularly noteworthy, as they exhibit excellent conductivity and reactivity. This makes them essential in battery production, notably in lithium-sulfide battery systems, which are gaining traction due to their potential for higher energy densities compared to conventional lithium-ion batteries. A study published in the Journal of Power Sources highlights that sulfide-based solid electrolytes can enhance battery performance, improving cycle stability and safety—qualities crucial for the burgeoning electric vehicle market, projected to be valued at over USD 1 trillion by 2027. Furthermore, the ability of sulfide powders to catalyze chemical reactions has fostered their use in industrial chemical processes, including the synthesis of various compounds in the pharmaceutical industry.

Sulfide powder plays a critical role in various applications within the chemical industry, largely due to its unique properties and reactivity. This fine powder is primarily composed of sulfur combined with metals or non-metals, and it has become an essential raw material in synthesizing a wide array of chemical compounds. According to a report by MarketsandMarkets, the global sulfur compounds market is projected to reach approximately $32 billion by 2025, with a significant portion attributed to sulfide powder applications across different sectors.

In the chemical industry, sulfide powder is utilized in the production of semiconductors, batteries, and catalysts. For instance, in semiconductor manufacturing, metal sulfides are critical for creating thin films, which exhibit semiconductor properties crucial for electronic devices. Furthermore, the use of sulfide powder in lithium-sulfur batteries has gained traction due to its high energy density and lower environmental impact compared to traditional lithium-ion counterparts. A study published in the Journal of Power Sources highlights that lithium-sulfur batteries could reach energy densities surpassing 500 Wh/kg, indicating the potential for sulfide powder to revolutionize energy storage solutions.

Additionally, sulfide powder finds applications in the manufacture of various chemical catalysts, particularly in petrochemical processes. Its role as a catalyst in hydrodesulfurization helps remove sulfur from fuels, addressing the urgent need for cleaner energy sources in response to stringent environmental regulations. The growing emphasis on lowering sulfur content in fuels is underscored by the global trend aiming for a reduction of sulfur emissions by 2025, a target highlighted in the International Energy Agency (IEA) reports, showcasing the importance of sulfide powder in shaping a more sustainable future for the chemical industry.

| Application Area | Description | Benefits | Common Types |

|---|---|---|---|

| Chemical Manufacturing | Used as a reagent for producing various chemicals, such as sulfides and thioureas. | Enhances reaction rates and product yields. | Ammonium sulfide, Sodium sulfide |

| Mining | Sulfide powders are used in flotation processes to extract metals from ores. | Increases the efficiency of metal recovery. | Copper sulfide, Zinc sulfide |

| Agriculture | Used as a soil amendment to improve sulfur content. | Enhances crop yield and quality. | Calcium sulfide |

| Pharmaceuticals | Utilized in the synthesis of pharmaceutical compounds. | Facilitates the development of effective medications. | Mercaptans, Thioethers |

| Electronics | Sulfide powders are used in semiconductor manufacturing. | Improves the electrical properties of devices. | Cadmium sulfide, Lead sulfide |

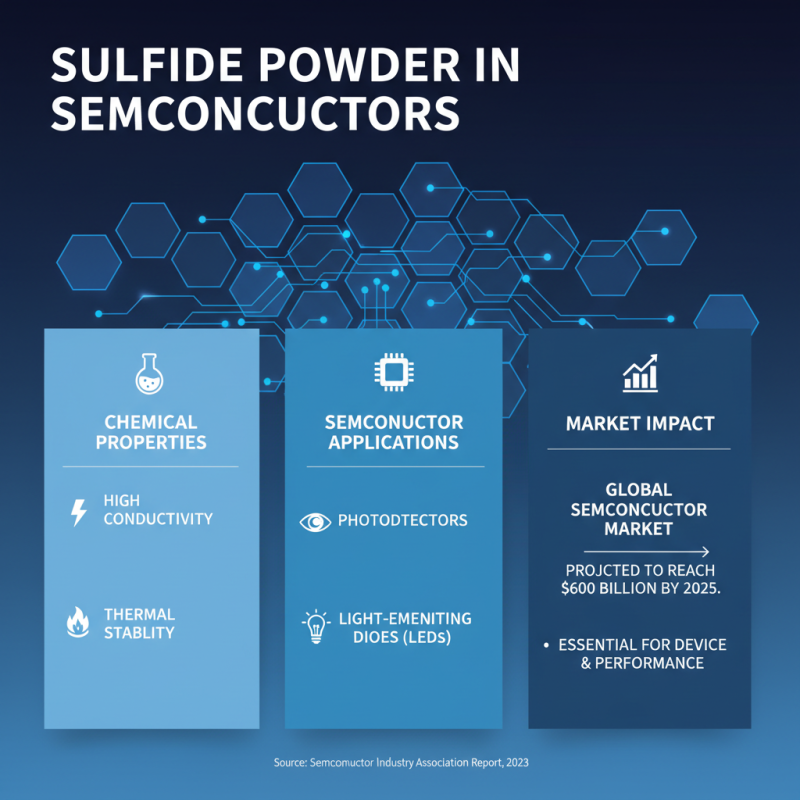

Sulfide powder, particularly in its semiconductor applications, has gained significant traction in the electronics industry due to its unique chemical properties, which include high conductivity and thermal stability. In semiconductor manufacturing, sulfide compounds are primarily utilized in the production of photodetectors and light-emitting diodes (LEDs). According to a recent report by the Semiconductor Industry Association, the global semiconductor market is projected to reach $600 billion by 2025, and materials like sulfide powder are essential in advancing device efficiency and performance.

In electronics, the integration of sulfide powder has led to innovations in various applications, including solar cells and thin-film transistors. Studies indicate that sulfide materials can enhance the photoelectric conversion efficiency of solar technology, contributing to a projected 20% growth in solar energy adoption over the next decade. As the industry strives for more efficient and sustainable materials, sulfide powders stand out as promising candidates for developing next-generation electronic components.

Tips: When working with sulfide powder in semiconductor applications, ensure optimal storage conditions to prevent moisture absorption. Always follow safety guidelines, as appropriate handling can significantly enhance the performance of your materials while minimizing risks. Additionally, keeping abreast of the latest research can provide valuable insights into emerging trends and innovative uses of sulfide compounds in electronics.