In industrial applications, the role of Thermal Spray Powder is pivotal. As noted by expert Dr. Jane Hughes, “Thermal Spray Powder is the backbone of surface engineering.” This material enhances durability and resistance to wear, corrosion, and heat. Companies rely on it for coating components in various sectors, including aerospace and automotive.

Despite its importance, not all Thermal Spray Powders are created equal. The selection process can be complex. Factors like particle size and composition significantly impact performance. A mismatch can lead to inefficiencies. Many industries still overlook the nuances of this critical material.

Incorporating Thermal Spray Powder effectively requires knowledge and precision. It's more than just a coating; it's a vital part of manufacturing excellence. As industries evolve, the demand for high-quality Thermal Spray Powder will continue to rise. Understanding and improving the application of this powder can inspire innovation and enhance productivity.

Thermal spray powder plays a crucial role in modern industry. It is not just about coating surfaces; it is about enhancing functionality. Industries rely on thermal spray for wear and corrosion resistance. The right thermal spray powder can significantly extend the life of components. For instance, turbine blades benefit from protective coatings, allowing for improved efficiency.

Moreover, the application process requires precision. Each powder type has unique properties, affecting adhesion and durability. Sometimes, even minor variations in temperature can lead to less than optimal results. Companies need to fine-tune their processes repeatedly. This iterative approach may seem tedious but is necessary for achieving excellence.

Adopting thermal spray technology can be challenging, especially for smaller enterprises. They might struggle with initial costs or expertise. The learning curve can be steep, leading to mistakes along the way. However, those who embrace this technology often find remarkable improvements. With the right investment in training and equipment, the benefits become evident. Ultimately, finding the right balance in application leads to greater success in industrial operations.

Thermal spray powders play a crucial role in various industrial applications. These powders come in various types, each tailored for specific requirements. Metallic powders are often used for their strength and durability. Materials like aluminum or nickel are common. They provide excellent coatings for wear resistance.

Ceramic powders are another category worth noting. Common examples include zirconia and alumina. These materials offer high-temperature stability and can resist corrosion. They are frequently utilized in the aerospace and energy sectors. The unique properties enhance the performance of components exposed to extreme environments.

Polymer powders are also emerging in this field. They offer flexibility and can be applied to various surfaces. These are useful for applications that require a softer touch. It’s important to choose the right powder for specific needs. Each type has strengths and weaknesses. A mismatch can lead to failures. Therefore, understanding the application context is essential for successful coating processes.

| Type of Thermal Spray Powder | Composition | Common Applications | Benefits |

|---|---|---|---|

| Ceramic Powders | Alumina, Zirconia | Thermal Barrier Coatings, Wear Resistance | High Temperature Resistance, Low Thermal Conductivity |

| Metal Powders | Nickel, Cobalt, Iron | Corrosion Resistance, Structural Restoration | Strong Bonding, High Durability |

| Polymer Powders | Nylon, Polyurethane | Electrical Insulation, Low Friction Coatings | Lightweight, Flexible Coatings |

| Composite Powders | Metal-Ceramic Mixtures | Advanced Wear Protection | Excellent Hardness, Anti-Wear Properties |

Thermal spray powder plays a vital role in protective coatings. This technique enhances surface properties effectively. It helps to mitigate wear and corrosion. The process creates strong, durable layers. These coatings can prolong the lifespan of machinery and components. Industries value its versatility across different materials.

Using thermal spray powder has clear benefits. It enhances strength without adding significant weight. This is crucial in aerospace and automotive sectors. The coatings are also resistant to extreme temperatures. This makes them suitable for high-demand environments. Quality control can sometimes be an issue, leading to inconsistent results.

Moreover, thermal spray powder can be customized for specific needs. Different formulations can target various challenges. However, not every application achieves the desired outcome. Understanding the specific requirements is essential. Utilizing thermal spray powder effectively requires knowledge and expertise. Efficient use can lead to impressive results in protecting assets.

When selecting thermal spray powders, various factors come into play. The material composition is crucial. It directly impacts the coating's performance and durability. Different applications require specific powder types. For instance, powders made from ceramics serve a different purpose than metallic ones.

Another significant factor is particle size. The size can affect the spray process and the coating's characteristics. Finer particles can create a denser coat but may require careful handling. Meanwhile, larger particles can lead to rough surfaces. This balance is vital for achieving the desired outcome.

The intended application environment is equally important. Powders designed for high-temperature applications differ from those used in corrosive settings. If the right powder isn’t chosen, the coating could fail. Material compatibility and environmental factors need careful consideration to ensure long-lasting performance.

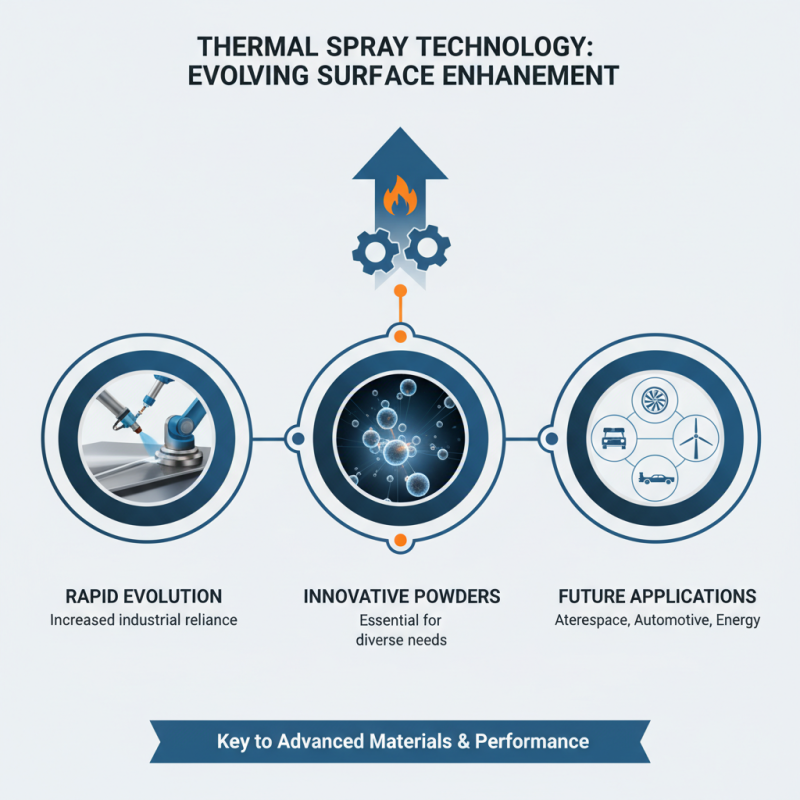

Thermal spray technology is evolving rapidly. Industries are increasingly relying on it for surface enhancement. The future holds exciting possibilities for various applications. Innovations in thermal spray powders are essential to meet the diverse needs of sectors like aerospace, automotive, and energy.

One trend is the development of new powder materials. These materials improve adhesion and wear resistance. They can withstand extreme temperatures and pressures. Enhanced properties result in longer-lasting components. Innovators are also exploring environmentally friendly coatings. This focus aligns with global sustainability goals.

Tips for choosing the right thermal spray powder include considering application-specific requirements. Check the temperature limits and compatibility with substrates. Assess the powder size and distribution, as these affect the coating's microstructure. Finally, don’t underestimate the importance of thorough testing for your specific context. Regular evaluations can reveal areas for improvement.