In the rapidly evolving field of surface finishing, achieving optimal Powder Coating Corrosion Resistance has become a critical objective for manufacturers and professionals alike. As highlighted by industry expert Dr. Jane Smith, a leading specialist in material science, "Enhancing corrosion resistance in powder coatings is essential for extending the lifespan of coated products and ensuring their performance in harsh environments." This underscores the significance of understanding and implementing best practices in powder coating techniques to combat corrosion effectively.

The advancement of powder coating technology offers a plethora of methods to bolster corrosion resistance. From selecting the right materials to optimizing application processes, each step plays a vital role in enhancing the durability of coated surfaces. As industries face increasing demands for longevity and reliability, it becomes imperative to adopt innovative strategies that not only improve the aesthetic appeal of products but also fortify them against the relentless effects of corrosion.

In this guide, we will explore top tips and techniques for enhancing Powder Coating Corrosion Resistance, focusing on practical solutions that can be integrated into existing workflows. By leveraging expert insights and proven methodologies, manufacturers can ensure that their powder-coated surfaces stand the test of time and environmental challenges, ultimately leading to superior product performance and customer satisfaction.

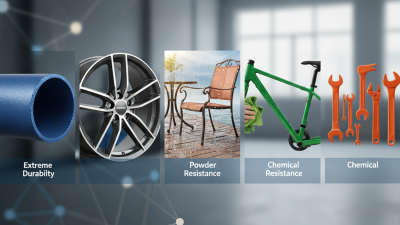

Powder coating is a widely used finishing technique that offers a durable and aesthetically pleasing surface for various metal products. As an application method, powder coating differs significantly from traditional liquid paint, primarily due to its unique composition and application process. Comprised of finely ground particles of pigment and resin, powder coating is electrostatically charged and applied to a surface before being cured under heat. This method creates a strong bond with the substrate, resulting in a finish that is not only visually appealing but also highly resistant to chipping, scratching, and fading.

Understanding the importance of powder coating, particularly in enhancing corrosion resistance, is essential for ensuring the longevity and performance of coated products. The robust layer formed through the curing process effectively seals the underlying metal from environmental factors such as moisture, salt, and chemicals, which can lead to rust and degradation. Moreover, choosing the appropriate type of powder coating tailored to specific environmental conditions can significantly improve corrosion resistance. By appreciating these aspects, manufacturers and consumers alike can make informed decisions to maximize the durability and aesthetic quality of their products.

When it comes to powder coating, ensuring corrosion resistance is paramount for the longevity and durability of coated surfaces. Key factors affecting corrosion resistance primarily include the composition of the powder, the thickness of the coating, and the application process. High-quality raw materials that exhibit excellent adhesion properties and resistance to environmental factors are crucial. This includes utilizing powders with superior chemical and UV stability, which can help mitigate the degradation typically caused by harsh weather conditions or exposure to corrosive elements.

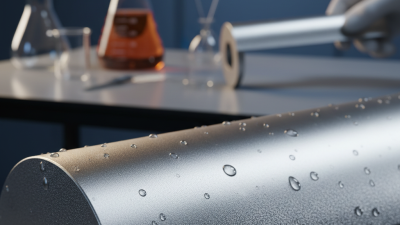

Another essential aspect is the application technique, which directly influences the coating thickness and uniformity. A more uniform coating with appropriate thickness not only enhances appearance but also provides a better barrier against moisture and corrosive agents. Additionally, pre-treatment of the substrate plays a significant role; surfaces should be thoroughly cleaned and, where possible, chemically treated to improve adhesion and reinforce the coating's integrity. These preparatory steps help in forming a durable bond that enhances the overall performance of the powder coating in resisting corrosion over time.

| Technique | Description | Key Factors | Expected Improvement |

|---|---|---|---|

| Proper Surface Preparation | Removing contaminants and ensuring a clean surface for adhesion. | Surface roughness, contamination levels | Up to 30% improvement |

| Optimized Powder Formulation | Using corrosion-resistant additives and materials. | Additive types, resin quality | Up to 50% improvement |

| Controlled Application Process | Ensuring even coverage and proper thickness during application. | Spray technique, thickness measurement | Up to 25% improvement |

| Effective Curing Process | Following recommended time and temperature for curing. | Curing temperature, times | Up to 40% improvement |

| Regular Maintenance and Inspection | Conducting periodic checks for wear and damage. | Inspection frequency, techniques | Up to 15% improvement |

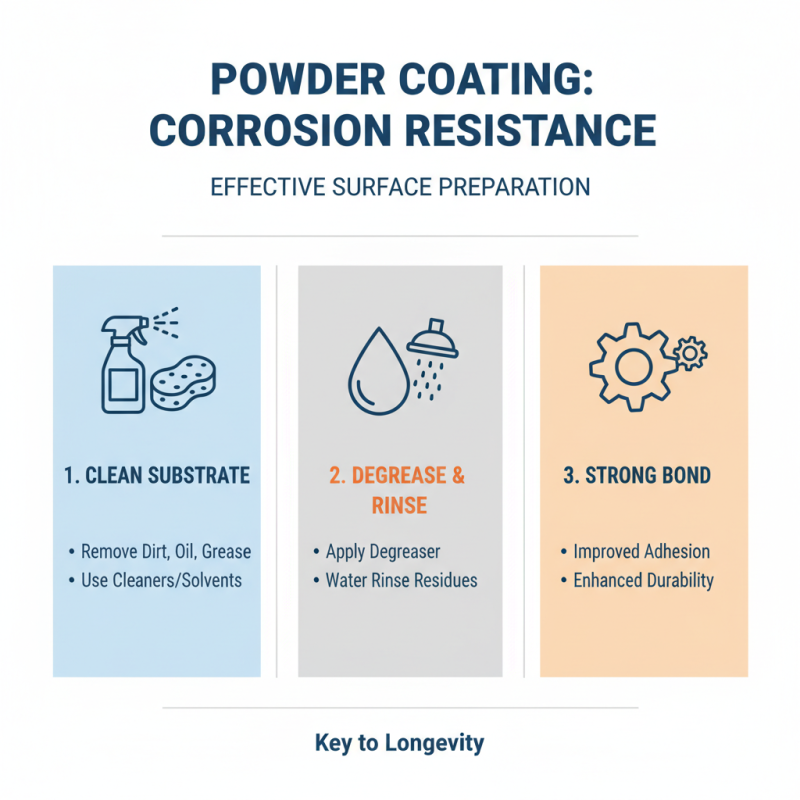

When it comes to enhancing the corrosion resistance of powder coating, one of the most critical steps is effective surface preparation. Properly preparing the surface before applying powder coating ensures a strong bond between the coating and the substrate, leading to improved durability and corrosion protection. The first step in this process is to thoroughly clean the substrate. This often involves removing contaminants such as dirt, oil, and grease using suitable cleaners or solvents. Tips for achieving optimal cleanliness include using a degreaser followed by rinsing the surface with water to eliminate any residues that may interfere with adhesion.

Another essential aspect of surface preparation is the removal of existing coatings, rust, or oxide layers. Sandblasting or shot blasting can effectively achieve this, ensuring the surface is abraded to a profile that enhances mechanical adhesion. Additionally, it is crucial to check for any surface imperfections post-blasting. If necessary, sanding or grinding can be employed to create an even surface. Tips for achieving a uniform finish include regularly inspecting the surface for inconsistencies and using a consistent technique during the abrasion process.

Finally, applying a suitable pre-treatment, such as a phosphate or conversion coating, can significantly enhance corrosion resistance. This layer not only promotes better adhesion of the powder coating but also provides an additional barrier against corrosion. Tips for successful pre-treatment include ensuring proper application conditions, such as maintaining correct temperature and humidity levels, to achieve the desired results. Following these best practices will set the groundwork for a high-quality powder coating finish with enhanced corrosion resistance.

Selecting the right powder coating material is crucial for ensuring optimal durability and maximum corrosion resistance in various applications. Different types of powder coatings, such as epoxy, polyester, and hybrid formulations, offer distinct levels of protection.

Epoxy powder coatings provide superior adhesion and chemical resistance, making them ideal for environments with high exposure to moisture or chemicals. However, they may not be suitable for outdoor applications due to their susceptibility to UV degradation. On the other hand, polyester powders are designed to withstand UV radiation, making them a preferred choice for outdoor use where sunlight exposure is a concern.

When choosing a powder coating material, it's essential to consider the specific environmental conditions the coated surface will encounter. For instance, if the application involves exposure to harsh chemicals or extreme weather conditions, selecting a more robust formulation or a specialized coating that includes additives for enhanced UV stability might be necessary. Additionally, factors such as the substrate type, desired gloss level, and application method will also influence the selection process.

Careful evaluation of these criteria will ensure that the chosen powder coating provides the best possible performance, enhancing the longevity and effectiveness of the protective layer against corrosion.

To ensure the longevity of powder-coated surfaces, implementing robust testing and maintenance strategies is essential. Regular inspections can help detect early signs of corrosion or wear. Utilizing techniques such as adhesion testing and visual assessments can aid in evaluating the integrity of the coating. Considering environmental factors during these evaluations, such as humidity and exposure to chemicals, is crucial for accurate assessments.

One effective tip for enhancing the corrosion resistance of powder coatings is to apply a topcoat designed specifically for durability. This additional layer can provide extra protection against moisture and corrosive elements. Furthermore, maintaining a clean surface is vital; regular cleaning with appropriate non-abrasive solutions can prevent the buildup of harmful contaminants that may compromise the coating’s integrity.

Another strategy involves monitoring for scratches or damage during routine maintenance. Promptly repairing any imperfections can prevent corrosion from taking hold. Additionally, scheduling periodic re-coating can ensure that the protective qualities remain effective, safeguarding the underlying materials from environmental stressors. Adopting these practices will help extend the lifespan of powder-coated surfaces and maintain their aesthetic appeal.