Powder coating is a popular finishing technique that offers numerous advantages over traditional paint. If you're wondering, "Apa Itu Powder Coating," this process involves applying a dry powder to a surface, which is then heated to create a durable and attractive finish. This method is frequently used in various industries, including automotive, furniture, and home appliances, due to its ability to provide a thick, uniform coating that is resistant to chipping, scratching, and fading.

In this article, we will explore the top ten things you need to know about powder coating, highlighting its benefits, applications, and the differences between powder coating and traditional liquid paint. Understanding these key aspects will help you appreciate why powder coating is becoming a preferred choice for many manufacturers and consumers alike. Whether you are considering a powder-coated surface for your next project or just curious about the process, this overview will provide you with essential insights into this innovative finishing technique.

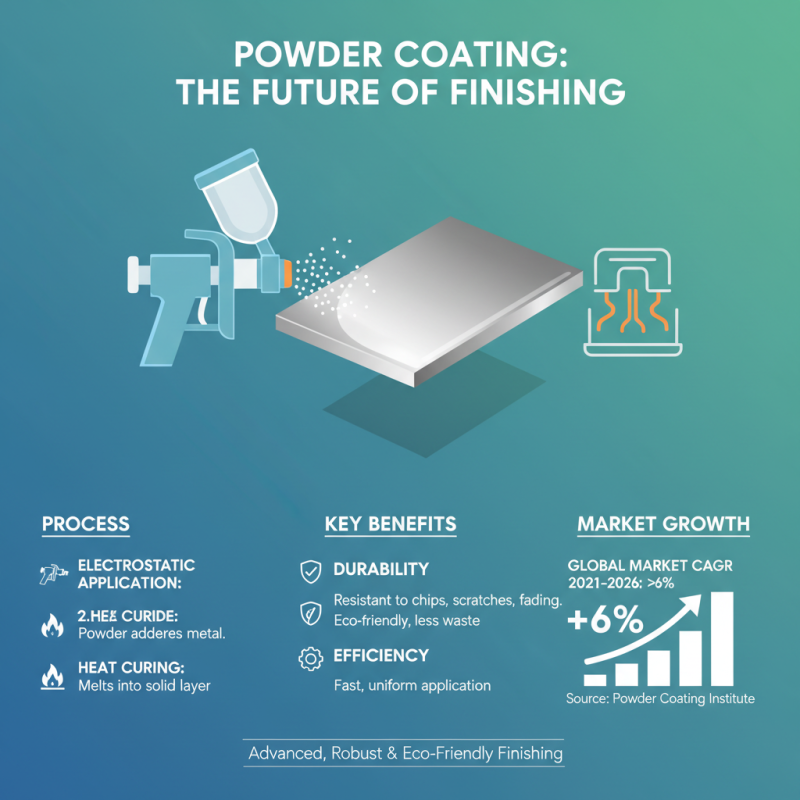

Powder coating is an advanced finishing process used to create a hard, durable surface on various materials, particularly metals. This technique involves using finely ground particles of pigment and resin that are electrostatically applied to a surface and subsequently cured under heat. Upon curing, the powder melts and forms a solid, robust layer that is not only aesthetically pleasing but also resistant to chipping, scratching, and fading. According to the Powder Coating Institute, the global powder coating market is projected to grow at a CAGR of over 6% from 2021 to 2026. This growing demand indicates a shift towards more sustainable and efficient coating solutions in various industries.

When considering powder coating, it’s essential to be aware of the surface preparation process, which plays a significant role in the final finish quality. Proper cleaning and pretreatment of the surface ensure maximum adhesion and durability of the coating. It’s recommended to use methods like sandblasting or chemical cleaning to prepare surfaces effectively.

Tip: Always conduct a test patch on a small area before full application to ensure that the desired finish and adhesion quality meet expectations. Another important consideration is to choose the right powder type based on the application environment; for instance, outdoor applications may require powders specifically designed to withstand UV exposure and harsher conditions.

Powder coating has emerged as a superior finishing method compared to traditional paint, offering numerous advantages that are reshaping manufacturing and maintenance practices across various industries. One of the most significant benefits of powder coating is its durability; it is known to be more resistant to scratches, chips, and fading. According to a report by the Powder Coating Institute, powder-coated surfaces can exhibit up to three times greater toughness compared to their painted counterparts, making them ideal for outdoor applications and high-traffic areas.

Additionally, the environmental impact of powder coating is substantially lower than that of conventional painting methods. Powder coating contains no volatile organic compounds (VOCs), which are common in traditional paints and contribute to air pollution and health hazards. A study conducted by Environmental Protection Agency (EPA) highlighted that transitioning to powder coating could reduce VOC emissions by 98%, supporting a more sustainable manufacturing landscape. Furthermore, the application process of powder coating is more efficient, as it allows for minimal overspray and maximum utilization of materials, resulting in reduced waste and cost savings for manufacturers. This combination of enhanced performance, environmental benefits, and economic efficiency positions powder coating as a leading choice for modern surface finishing.

The chart above illustrates the top 10 advantages of powder coating over traditional paint. Each advantage is rated based on its significance, showcasing powder coating's benefits in durability, environmental impact, cost efficiency, and more.

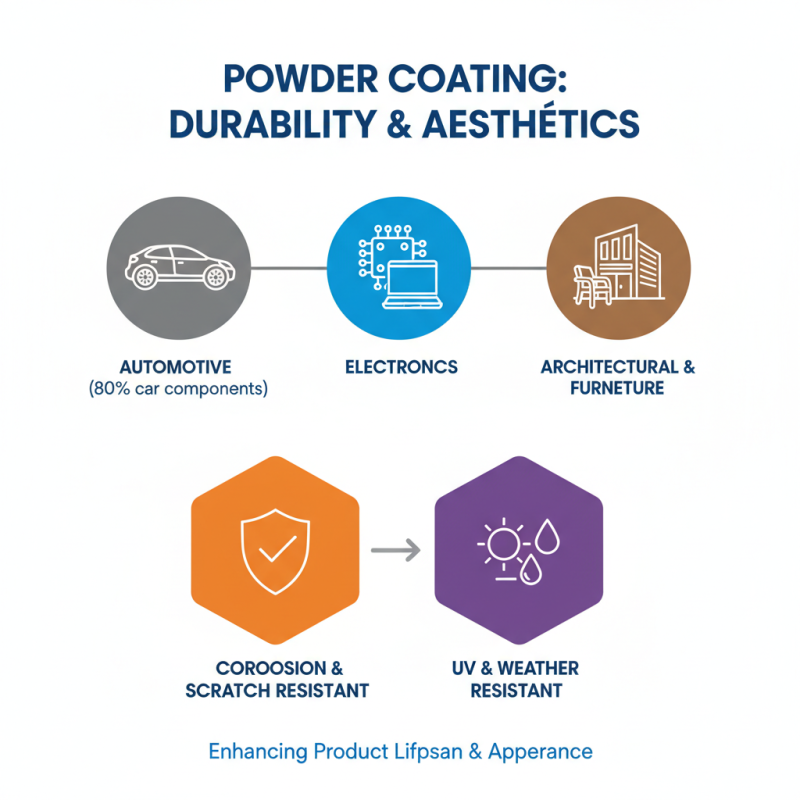

Powder coating has become a popular finishing technique across various industries due to its durability and aesthetic appeal. Industries such as automotive, electronics, and architectural applications utilize powder coating to enhance the lifespan and appearance of their products. In the automotive sector, it's estimated that over 80% of car manufacturers use powder coating for components like wheels and frames, providing not only a vibrant finish but also resistance to corrosion and scratches. Similarly, in the furniture industry, powder-coated finishes are used extensively due to their resistance to chemicals, UV exposure, and wear, making them ideal for outdoor furniture that faces harsh weather conditions.

When considering powder coating for industrial applications, here are some tips: first, ensuring surface preparation is critical; proper cleaning and profiling can significantly impact adhesion and overall finish quality. Next, selecting the right type of powder is essential, as different formulations offer varied properties suited for specific environments. For instance, high-temperature applications may require specialized powders to ensure performance under heat stress. By keeping these considerations in mind, businesses can optimize their production processes and achieve high-quality results in their powder-coated products.

The powder coating process is a highly efficient and environmentally friendly method for applying a protective finish to metal surfaces. It involves several key steps, each designed to ensure uniformity, durability, and adhesion. The initial phase includes surface preparation, which is crucial as it helps eliminate impurities that could interfere with adhesion. This preparation can involve cleaning, sanding, or chemical treatments to ensure a clean surface. According to a report from the Industrial Coatings Association, surface preparation can improve coating performance by up to 30%.

Once the surface is ready, the object is coated with powdered paint using an electrostatic spray gun. This step utilizes an electric charge to attract powder particles to the grounded metal surface, ensuring even coverage. Following this, the coated items enter a curing oven, where the powder is heated to form a hard, durable finish. The curing process usually occurs at temperatures around 180-200°C for a specific duration, depending on the powder type, which can significantly affect the coating's final properties.

Tips: To achieve the best results with powder coating, it's essential to maintain proper oven temperatures and avoid overloading the curing oven, as this can lead to an uneven finish. Additionally, consider the selection of powder type; epoxy-based powders offer excellent corrosion resistance, while polyester powders provide better UV protection. Regular maintenance of the equipment used in the process can also enhance efficiency and longevity, thereby improving the overall quality of the finished product.

Proper care and maintenance of powder-coated surfaces is essential to ensure their longevity and aesthetic appeal. One of the key practices is regular cleaning, which helps to remove dirt and contaminants that can degrade the finish over time. Using a soft cloth and mild soap diluted in water, gently wipe the surface to maintain its sheen. It's crucial to avoid harsh chemicals or abrasive scrubbers, as they can scratch or damage the coating.

In addition to regular cleaning, it's important to inspect the powder-coated surfaces periodically. Look for any signs of chipping or peeling, as early detection can prevent more significant damage from occurring. If you notice any degradation, address it promptly by touching up the affected areas or consulting a professional if necessary. Furthermore, protecting powder-coated items from extreme weather conditions by storing them in a sheltered location can also help preserve their appearance and structural integrity over time.

| Key Aspect | Description |

|---|---|

| Durability | Powder coating is known for its strong resistance to scratching, chipping, and fading. |

| Environmentally Friendly | It releases negligible volatile organic compounds (VOCs) compared to liquid paint. |

| Color Variety | Available in a vast range of finishes and colors, offering flexibility in design. |

| Application Process | It requires electrostatic spraying of the powder and curing in an oven for a durable finish. |

| Maintenance | Should be cleaned regularly with mild soap and water to maintain appearance. |

| Heat Resistance | Can withstand high temperatures without deforming or losing finish integrity. |

| Scratch Resistance | Provides a significantly tougher surface than conventional paint. |

| UV Stability | Resistant to UV light, helping prevent color fading over time. |

| Cost-Effectiveness | While the initial cost may be higher, its durability results in lower long-term maintenance costs. |

| Safety | Non-toxic powders ensure a safer work environment compared to solvent-based paints. |