Carbide powder is an essential material widely utilized across various industries, known for its superior hardness and resistance to wear and corrosion. According to a recent report by the Global Carbide Powder Industry Analysis, the demand for carbide powders is projected to reach USD 3.5 billion by 2025, driven largely by their applications in manufacturing cutting tools, mining equipment, and wear-resistant parts. As the market grows, understanding the diverse uses of carbide powder becomes crucial for engineers and project managers aiming to enhance durability and efficiency in their operations.

Expert in materials science, Dr. John Smith, emphasizes the significance of carbide powder in contemporary manufacturing, stating, "The versatility and resilience of carbide powders are unmatched, making them pivotal for cutting-edge applications in industries such as aerospace and automotive." From enhancing the performance of industrial tools to their role in constructing high-density components, carbide powder serves as a linchpin for numerous projects, fostering innovation and advancement across sectors. As we explore the top ten uses of carbide powder, it’s evident that investing in this material not only improves product longevity but also assures a competitive edge in today’s fast-paced market.

Carbide powder, primarily composed of tungsten carbide or silicon carbide, is renowned for its exceptional hardness and wear resistance, making it an invaluable material in various industrial applications. According to a report by Allied Market Research, the global tungsten carbide market is projected to reach $24.9 billion by 2026, driven by the growing demand in sectors such as mining, construction, and manufacturing. With a hardness level just below that of diamond, carbide powder is ideal for creating cutting tools, abrasives, and wear-resistant surfaces.

The unique properties of carbide powder stem from its composition. Tungsten carbide (WC) is a compound of tungsten and carbon with a melting point of around 2870°C, which gives it strong structural integrity even under demanding conditions. In contrast, silicon carbide (SiC) boasts excellent thermal conductivity and chemical stability, making it a preferred choice for applications that require high thermal efficiency and resistance to oxidation. A study from MarketsandMarkets indicates that the silicon carbide market is expected to grow at a CAGR of 19.6% from 2020 to 2025, underscoring its significance in the semiconductor and electronics industries. These attributes not only enhance the performance of tools but also contribute to improved productivity across various projects.

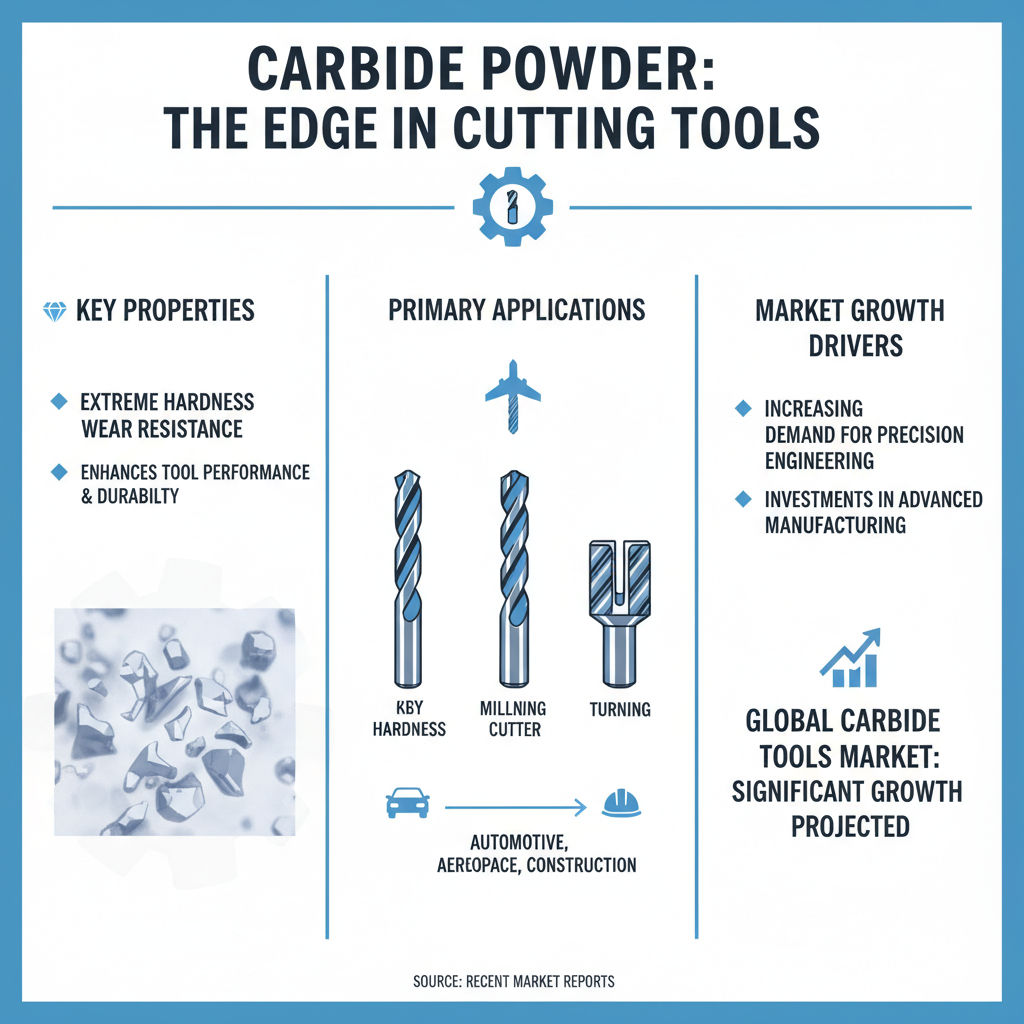

Carbide powder plays a critical role in the manufacturing of cutting tools used across various industries. Known for its hardness and resistance to wear, carbide enhances the performance and durability of products such as drilling tools, milling tools, and turning tools. According to recent market reports, the global carbide tools market is projected to witness significant growth, driven by the increasing demand for precision engineering in sectors like automotive, aerospace, and construction. This trend is reflected in the rising investments in advanced manufacturing technologies.

When utilizing carbide tools, it is essential to consider the type of material and application. For instance, the effectiveness of drilling tools made from carbide can dramatically improve when matched correctly with the workpiece material. Proper selection not only optimizes performance but also minimizes wear, saving costs in the long run.

**Tips:** Always maintain cutting speeds and feeds according to the carbide tool specifications to prevent damage and enhance tool life. Additionally, regular inspection and maintenance of your carbide tools can ensure they remain in optimal working condition, reducing unexpected downtime in your projects. By understanding and implementing these best practices, you can maximize the benefits of carbide tools in your operations.

Carbide powder has emerged as a critical material in the formulation of wear-resistant coatings, delivering enhanced durability for various industrial applications. According to a report by Freedonia Group, the global demand for wear-resistant coatings is projected to grow by 5.5% annually, largely due to the increasing need for durability in manufacturing and construction sectors. Carbide-based coatings are particularly favored for their outstanding hardness and high resistance to abrasive wear, making them ideal for tools and machinery exposed to extreme conditions.

The implementation of carbide powder in coatings significantly contributes to extending the lifespan of components. Research indicates that coatings incorporating tungsten carbide can reduce friction and wear rates by up to 50%, as noted in a study published in the Journal of Materials Engineering. Such advancements not only enhance performance but also contribute to cost savings in maintenance and operations. As industries evolve, the role of carbide powder in wear-resistant coatings is becoming increasingly vital, allowing for innovations that push the boundaries of durability in engineering and manufacturing processes.

Carbide powder is increasingly recognized for its pivotal role in enhancing the durability of construction materials. The incorporation of carbide powder into construction applications can significantly improve the wear resistance, hardness, and overall longevity of materials. According to a report by Grand View Research, the demand for carbide materials in the construction sector is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2021 to 2028. This surge is attributed to the need for stronger, more reliable materials capable of withstanding harsh environmental conditions.

When integrating carbide powder in construction projects, it's essential to consider the appropriate particle size and distribution. Finer particles tend to enhance the tensile strength of the final product, making it more suitable for applications requiring high durability, such as road construction and heavy machinery components. Additionally, it’s recommended to conduct thorough pre-mixing to ensure uniform dispersion of carbide powder, enhancing its effectiveness in improving material properties.

Tip: Always evaluate the specific mechanical properties required for your project before selecting carbide powder, as different formulations may yield varying results. Moreover, ensure to comply with safety guidelines while handling and mixing carbide powder to prevent any health risks.

Carbide powder has become an essential material in automotive engineering due to its exceptional hardness and wear resistance. As the automotive industry continually seeks improvements in efficiency and durability, carbide powder is increasingly used in the manufacturing of cutting tools, drill bits, and various components that undergo rigorous wear. With the projected growth of the global carbide tools market, anticipated to rise from $11.54 billion in 2024 to $18.41 billion by 2032, the demand for carbide applications in automotive engineering is set to soar.

Innovative applications of carbide powder extend beyond traditional cutting instruments, influencing advancements in high-performance engine components and brakes. Engineers and manufacturers are leveraging carbide's properties to produce parts that can withstand extreme conditions, thereby enhancing vehicle lifespan and performance. This integration is pivotal as the industry shifts towards more sustainable practices, with carbide powder playing a crucial role in developing long-lasting, efficient automotive technologies. As the market grows, we can expect further innovations that will position carbide powder as a cornerstone in automotive engineering.