In the ever-evolving landscape of coating technologies, understanding "Apa Itu Powder Coating" is essential. This finishing process offers durability and a smooth finish. Renowned expert Dr. Emily Huang states, "Powder coating is more than just a surface finish; it transforms the way we see aesthetics in engineering."

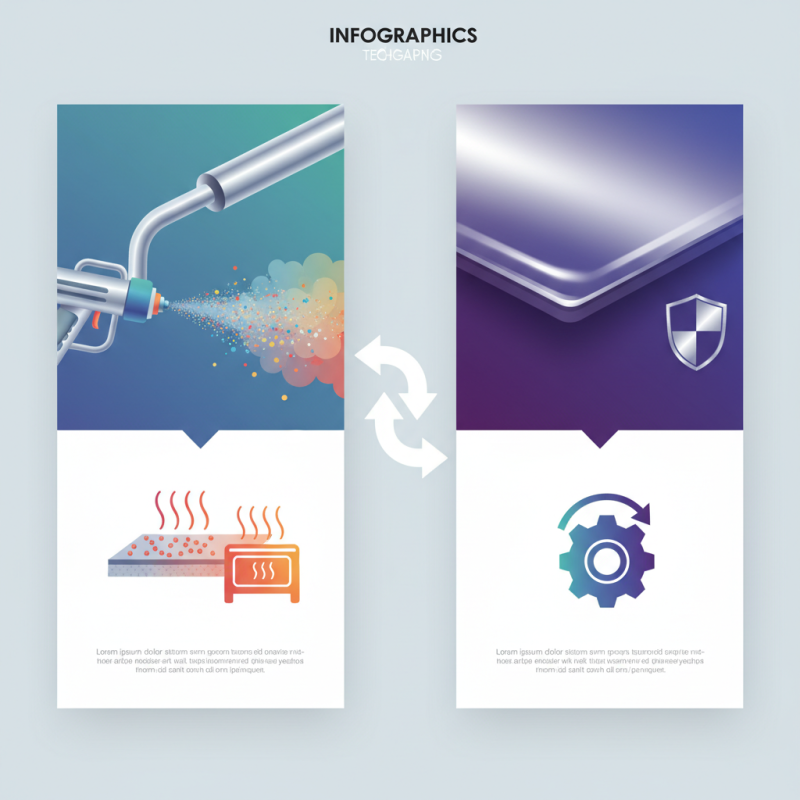

Powder coating involves applying dry powder to a surface, which is then cured under heat. This method is popular for its environmental benefits and resistance to chipping. However, despite its advantages, many still overlook its potential. The intricacies of application and adhesion can be daunting for newcomers. Achieving the desired results requires precision and technique.

Learning "Apa Itu Powder Coating" reveals both its promises and challenges. It's a subject that invites curiosity and caution alike. As more industries explore its use, the importance of grasping this technology becomes evident. Understanding the fundamentals can lead to innovative solutions and improvements in product longevity.

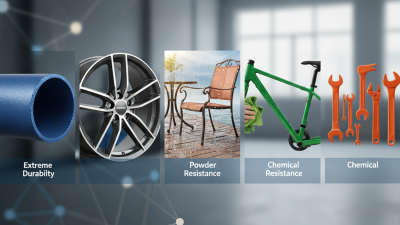

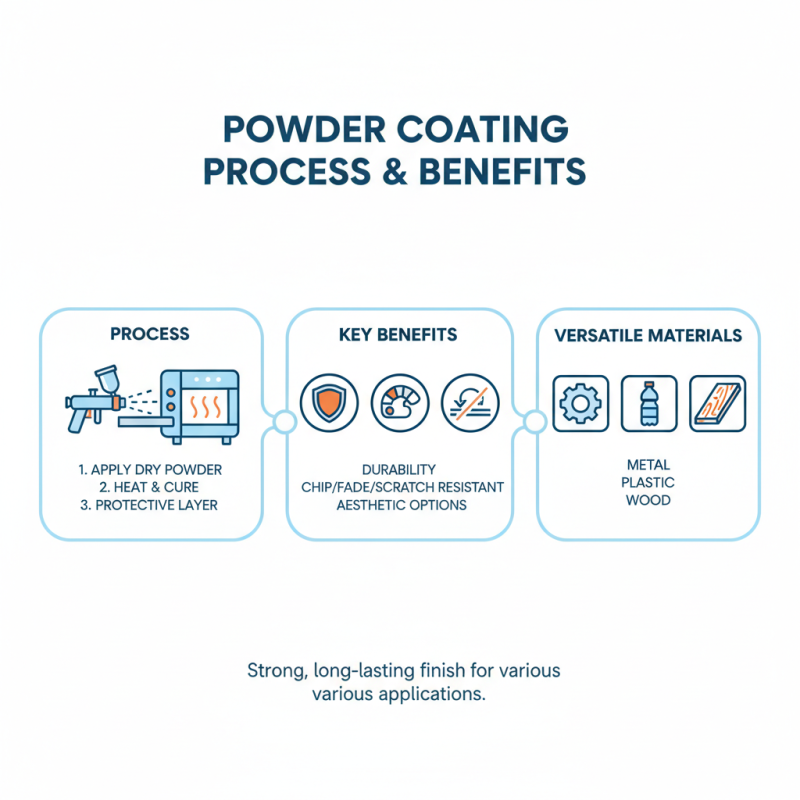

Powder coating is a unique finishing process that offers both durability and aesthetic appeal. It involves applying a dry powder to a surface, which is then heated to create a strong, protective layer. This method is popular in various industries due to its resistance to chipping, fading, and scratching. It can be applied to metal, plastic, and even wood surfaces, providing a versatile solution for many applications.

During the powder coating process, the powder must be evenly distributed to ensure a uniform finish. This can be tricky. If the application is not precise, it may lead to uneven surfaces or visible imperfections. The curing phase, where the coated item is heated, is equally critical. If the temperature isn’t controlled properly, issues like bubbling or inadequate adhesion can arise. It’s essential to observe and refine this process for the best results.

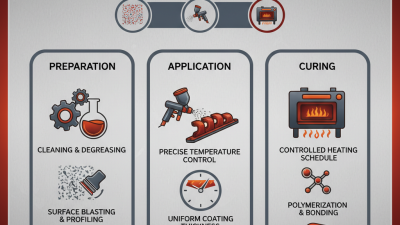

Not all individuals are aware of the importance of surface preparation before coating. Any dirt or grease can compromise the final outcome. Taking the time to clean and prepare the surface properly is crucial. It's a step often overlooked but vital for achieving a lasting effect. The balance between efficiency and quality demands constant reflection and adjustment.

Powder coating is a technique with roots that trace back to the 1950s. Initially developed as an alternative to liquid paint, it aimed to improve durability and finish. Over the years, advancements have refined the process, leading to better adhesion and color retention. Today, powder coating is widely used in various industries, including automotive and furniture.

Despite its benefits, powder coating has faced challenges. Early formulas lacked versatility, limiting applications. As technology evolved, the introduction of thermosetting and thermoplastic powders transformed the industry. These advancements opened new opportunities for customization and design. However, mistakes still happen. Uneven application or improper curing can ruin a project. Learning from these errors is essential for improvement.

Tips: Always prepare surfaces well before coating. A clean surface ensures better adhesion. Experiment with different powders to find the best match for your needs. Don’t rush the curing process. Allow adequate time for the coating to set, ensuring optimal results.

Powder coating has gained popularity due to its many advantages over traditional painting methods. One significant benefit is durability. Powder-coated surfaces resist chipping, scratching, and fading better than painted ones. This can be especially useful for outdoor furniture or equipment. The toughness of powder coating makes it a reliable choice for various applications.

Another key advantage is the environmental impact. Powder coating releases fewer volatile organic compounds (VOCs) compared to traditional paints. This helps minimize air pollution and is better for health. Additionally, the process produces minimal waste, making it a more sustainable option. It's essential to consider cost-effectiveness as well. While the initial investment may be higher, the long-term savings on maintenance and replacement can be significant.

However, not everything is perfect. The curing process requires specific temperatures, which might not be feasible for all users. It can also be challenging to achieve certain finishes or textures. Sometimes, the color selection may be limited compared to traditional paint. Reflecting on these limitations can help users make informed decisions about their coating options.

Powder coating is a popular finishing process. It involves several distinct steps that are crucial for achieving a durable finish. Understanding these steps can help you appreciate this method even more.

The process begins with surface preparation. It’s essential to clean the item thoroughly. Any dirt or grease can affect the final coat. Sometimes, this step is rushed, leading to unsatisfactory results. After cleaning, the item is pre-treated. This can include applying a chemical solution or using abrasive materials to enhance adhesion.

Next comes the actual application of the powder. The powder is electrostatically charged and sprayed onto the surface. The coating layer should be even, but imperfections can happen. Overlap or thin spots may occur if not careful. Finally, the coated item is cured in an oven. This step helps the powder to melt and adhere properly. However, temperature inconsistencies can lead to a lackluster finish. Understanding these nuances in the powder coating process can provide better insights into its overall effectiveness.

Powder coating is a versatile finishing process used across various industries. It involves applying dry paint particles to materials, which are then cured under heat. This method creates a durable and attractive finish. Many sectors benefit from this technology, including automotive, furniture, and construction.

In the automotive industry, powder coating provides a protective layer. It resists scratches and corrosion, prolonging the life of car components. Similarly, the furniture industry uses powder coating for its aesthetic appeal and durability. Customized colors and textures enhance furniture designs, making them more appealing to consumers.

**Tips:** When choosing powder coating, consider the environment. Opt for eco-friendly options to reduce your footprint. Yet, some may not be as durable as conventional coatings. Understand your specific needs before selecting a product. Always ensure thorough surface preparation for the best results. Proper cleaning can prevent imperfections in the finish.

| Industry | Common Applications | Benefits of Powder Coating |

|---|---|---|

| Automotive | Wheels, chassis, and bumpers | Durability, resistance to corrosion |

| Aerospace | Aircraft components, landing gear | Lightweight, heat resistance |

| Appliances | Refrigerators, ovens, and washers | Smooth finish, scratch resistance |

| Furniture | Outdoor furniture, metal tables | UV protection, color retention |

| Construction | Windows, railings, and doors | Weather resistance, aesthetic appeal |

| Electronics | Casing for devices, circuit boards | Electrically insulating, protective layer |