Stainless Powder has emerged as a versatile material for various innovative applications. Its fine particles provide unique properties that enhance performance in several industries. The lightweight nature of Stainless Powder makes it ideal for creating high-strength components. These characteristics enable advancements in manufacturing processes.

In recent years, many sectors have begun adopting Stainless Powder for additive manufacturing. This trend signifies a shift towards more efficient production methods. However, challenges remain in optimizing the properties of the powder. Achieving a consistent particle size can be tricky. The need for research is evident.

The exploration of Stainless Powder in niche applications shows promise. From aerospace to medical devices, its potential is vast. Yet, there is room for reflection on best practices. Understanding the limits of this material will ensure better integration into new technologies. Embracing such challenges can lead to groundbreaking innovations.

Stainless powder has gained popularity in various innovative applications. Its unique properties make it a sought-after material. Composed mainly of iron, chromium, and nickel, stainless powder boasts excellent corrosion resistance. This resistance allows it to thrive in challenging environments. Furthermore, the powder can withstand high temperatures, making it suitable for aerospace and automotive industries.

The particle size of stainless powder plays a critical role in its applications. Smaller particles often allow for better flowability and packing density. This can result in improved mechanical properties. However, one must be cautious when handling the powder, as inconsistent particle sizes can lead to unpredictable outcomes. Ensuring uniformity in the manufacturing process is essential.

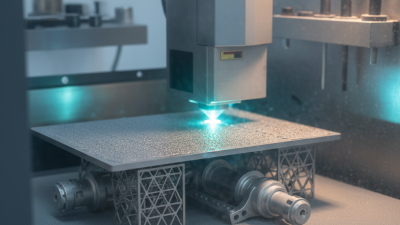

Stainless powder is also versatile in additive manufacturing. It can be used to create complex geometries that traditional methods struggle with. Yet, achieving optimal layer bonding can be challenging. The printing parameters require careful calibration. Mistakes can lead to structural weaknesses. Innovation comes with risks and the need for constant evaluation of processes.

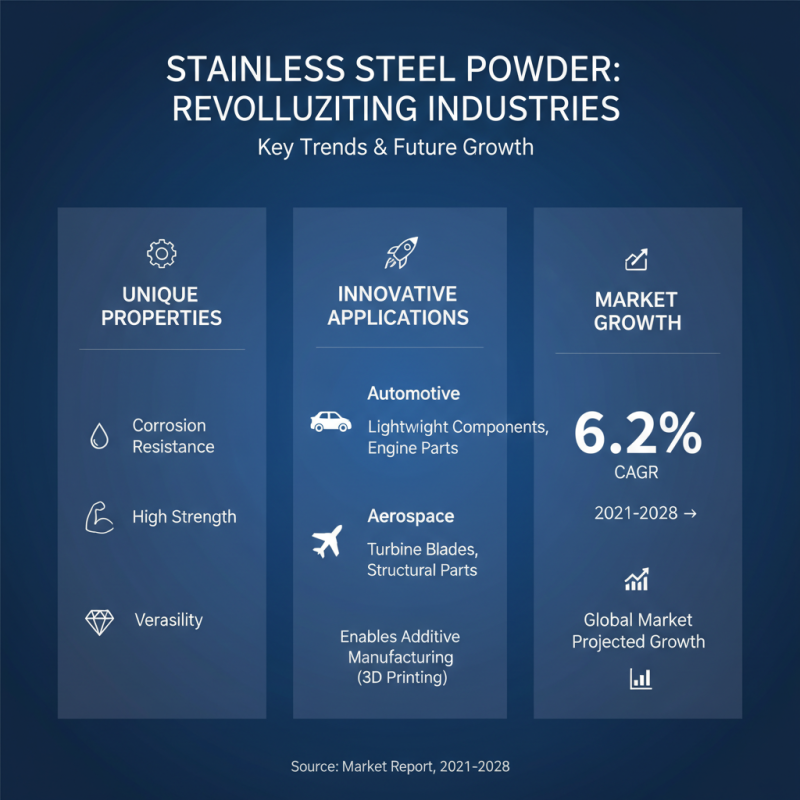

Stainless powder is revolutionizing various industries. Its unique properties enable innovative applications, especially in automotive and aerospace sectors. According to a market report, the global stainless powder market is projected to grow at a CAGR of 6.2% from 2021 to 2028. This growth indicates significant demand in advanced manufacturing techniques like additive manufacturing.

In the automotive industry, stainless powder is increasingly used for creating lightweight components. These components enhance fuel efficiency and performance. For example, using stainless powder in engine parts results in improved durability and reduced weight. However, the challenge lies in controlling the powder's particle size. Inconsistent sizes can lead to defects during the manufacturing process.

Similarly, the aerospace industry is exploring stainless powder for manufacturing complex structures. Advanced 3D printing techniques allow for precise designs with minimal waste. Yet, questions remain regarding the economic viability of large-scale production. High costs of stainless powder can limit its application. Balancing cost with performance is crucial for future innovations.

Stainless powder is gaining attention for its versatility. Processing this powder requires specific techniques to shape and manipulate it effectively. One popular technique is powder metallurgy, which combines metal powders using heat and pressure. This method achieves dense, durable components. However, achieving uniformity can be a challenge. Not every batch yields the same results, which can lead to inconsistencies.

An alternative technique is additive manufacturing, particularly 3D printing. This method allows for complex geometries that traditional methods cannot replicate. The ability to create intricate designs can reduce material waste. Yet, the precision required can be daunting. Fine-tuning the printer settings is crucial, and a small error can affect the end product.

Another approach involves sintering, where stainless powder is heated to just below its melting point. This process fuses particles together. It creates a strong bond between them, but controlling the temperature is critical. Too high or too low can compromise the material’s integrity. Experimentation is often necessary, and results can vary. This unpredictability requires careful monitoring and adjustments throughout the process.

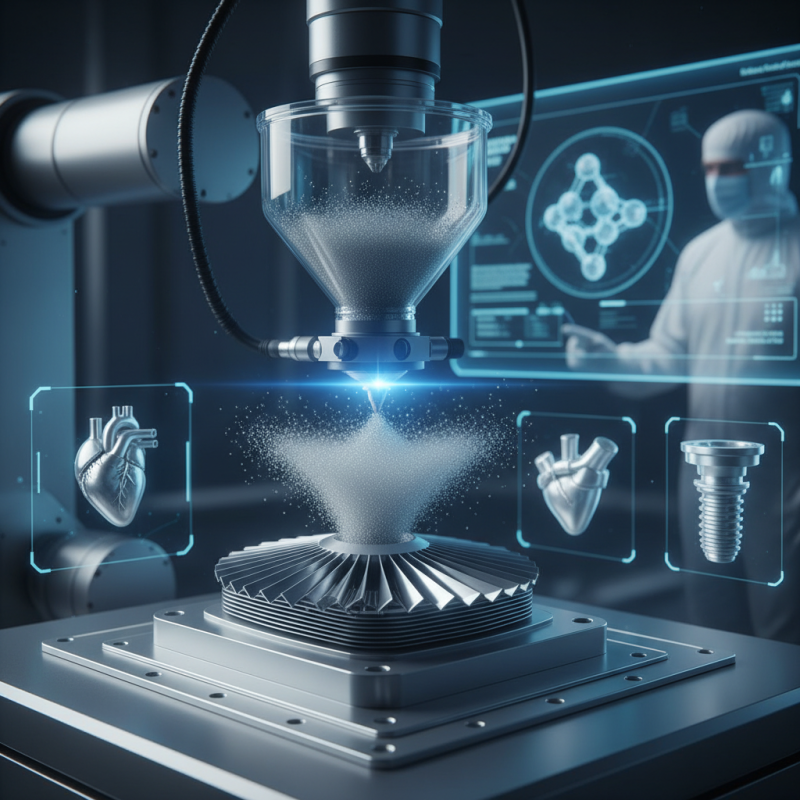

Stainless powder is revolutionizing additive manufacturing. Its unique properties enhance durability and performance in various applications. According to a recent report by MarketsandMarkets, the global stainless steel powder market is projected to reach $1.12 billion by 2027, indicating significant growth in this sector.

Additive manufacturing techniques, like 3D printing, benefit from stainless powder's high tensile strength. Manufacturers can create complex geometries that were previously impossible with traditional methods. For instance, aerospace components made from stainless powder exhibit excellent fatigue resistance. However, optimizing the powder's particle size and flow characteristics is still a challenge for many producers.

Another innovative application includes medical devices. Stainless powder can be used to create custom implants tailored to patient needs. A study by Wohlers Associates noted that medical applications will drive up to 25% of the 3D printing market by 2024. Yet, the industry must address issues like biocompatibility and regulatory compliance. These factors can hinder the adoption of stainless powder in some medical applications.

| Application Area | Type of Stainless Powder | Process Used | Benefits | Challenges |

|---|---|---|---|---|

| Aerospace Components | 316L Stainless Steel | Selective Laser Melting | High strength-to-weight ratio, Corrosion resistance | Cost of raw materials, Complex geometries |

| Medical Devices | 304L Stainless Steel | Binder Jetting | Biocompatible, Customization | Regulatory approvals, Post-processing requirements |

| Automotive Parts | 430 Stainless Steel | Fused Deposition Modeling | Durable, Lightweight structures | Material adhesion issues, Finishing requirements |

| Consumer Goods | 17-4 PH Stainless Steel | Electron Beam Melting | Aesthetic appeal, High hardness | Complexity in production, Time-consuming |

| Industrial Applications | Inconel 625 Powder | Laser Metal Deposition | High-temperature resistance, Strong fusion quality | High cost, Process monitoring needed |

Stainless powder is gaining traction in various innovative applications. Its unique properties allow for advancements in industries like healthcare and automotive. Researchers are exploring its potential for additive manufacturing, which can revolutionize component production. However, challenges remain. The purity of stainless powder can affect performance, leading to inconsistencies in final products.

Tips: Emphasize quality control in sourcing. Always test for impurities before use.

In healthcare, stainless powder is used to create implants and instruments. Enhancing biocompatibility is a crucial area of research. Innovations in surface treatments are vital for improving adherence in biological environments. Yet, understanding body reactions to new materials is still incomplete.

Tips: Engage with biomedical engineers to discuss material performance. Consider using simulations to predict outcomes.

Automotive manufacturers are also experimenting with stainless powder for lightweight components. This can improve fuel efficiency. The challenge lies in balancing strength and weight. Future research must focus on optimizing alloys to meet safety standards while being eco-friendly.

Tips: Collaborate with material scientists for better formulations. Think about long-term sustainability in designs.