Co12 Cobalt-Based Alloy: High-Temperature and High-Pressure Wear Resistance Solution

Chemical Composition and Element Functions

Core Performance Advantages

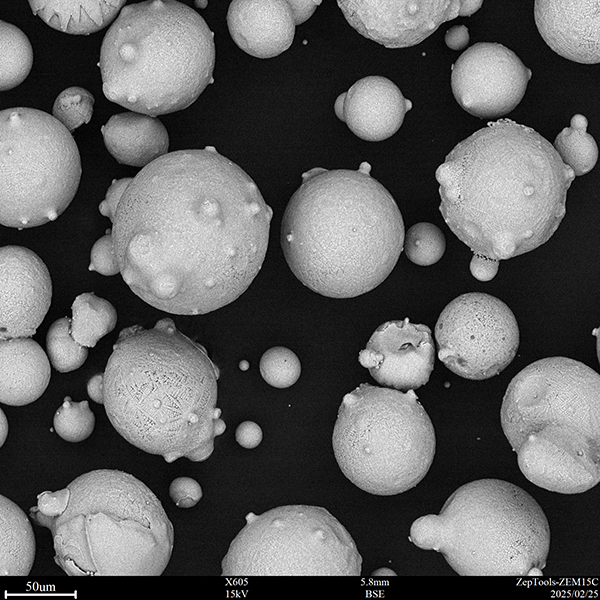

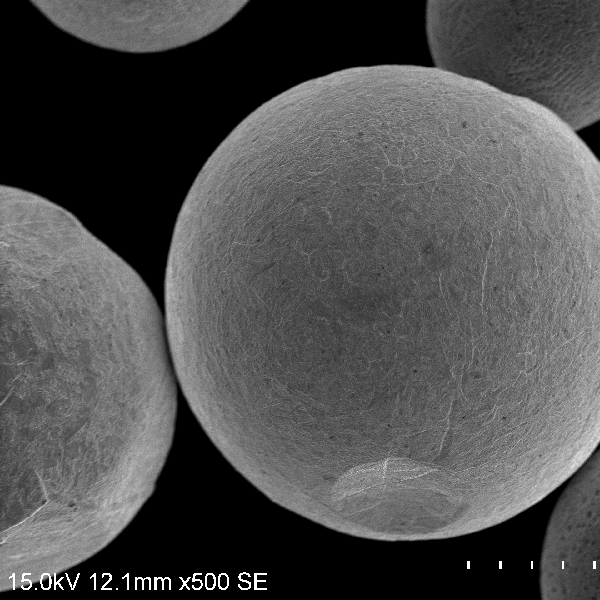

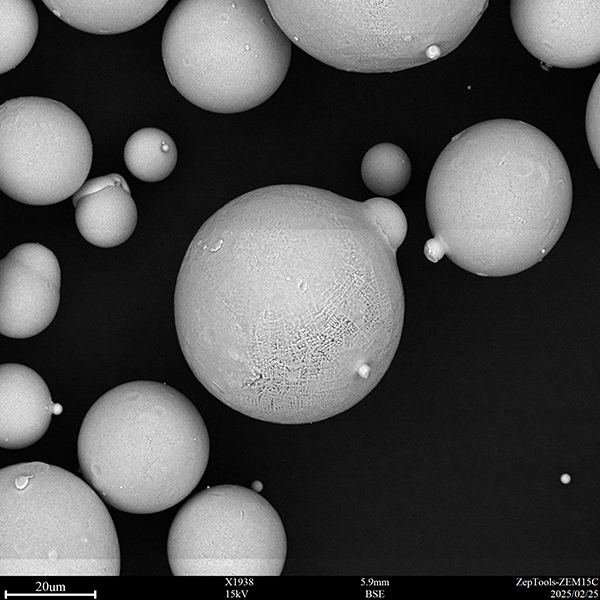

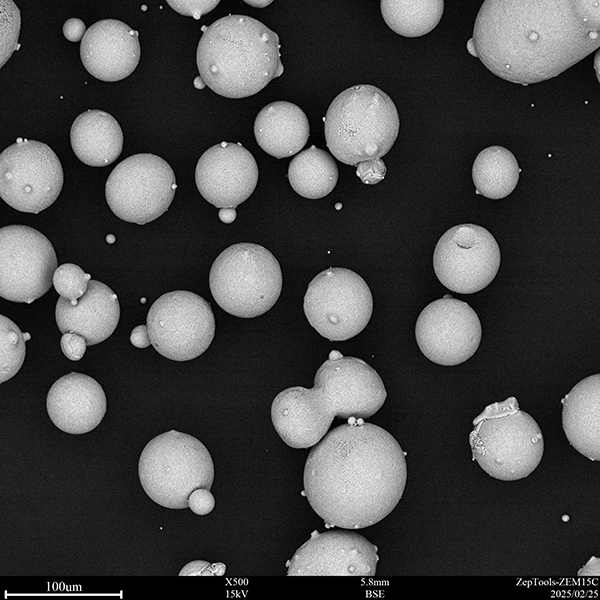

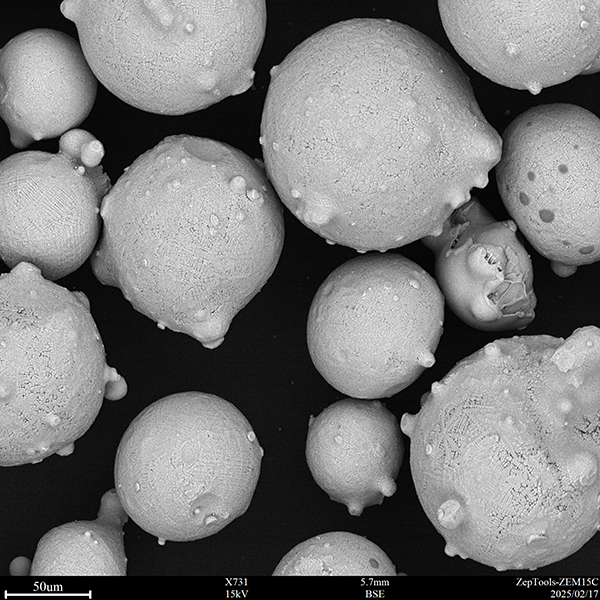

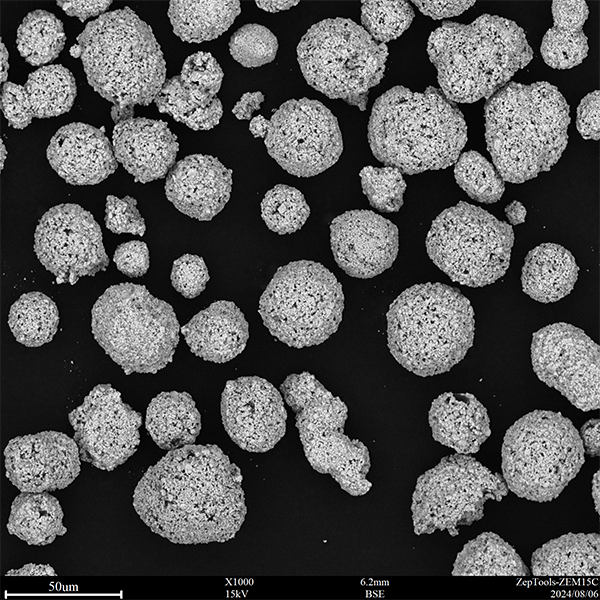

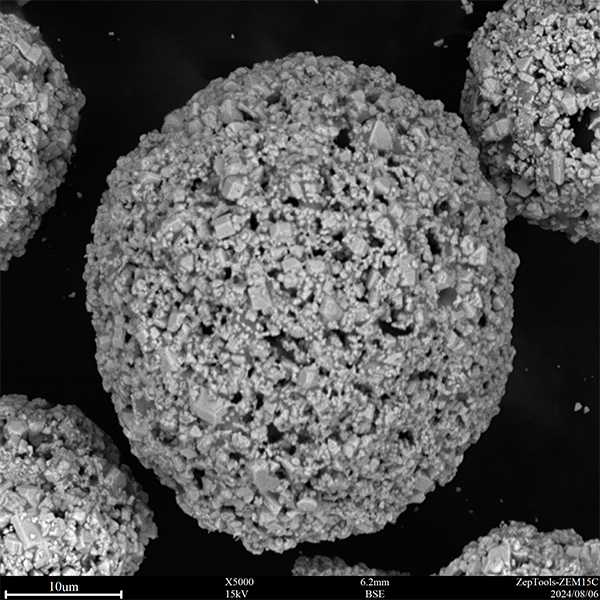

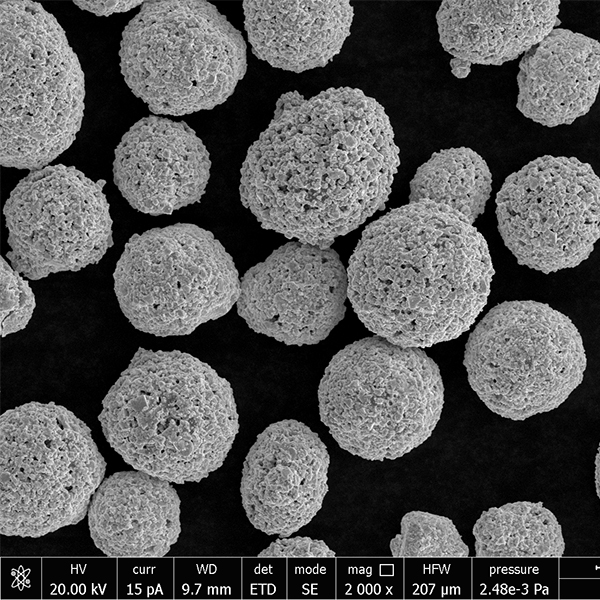

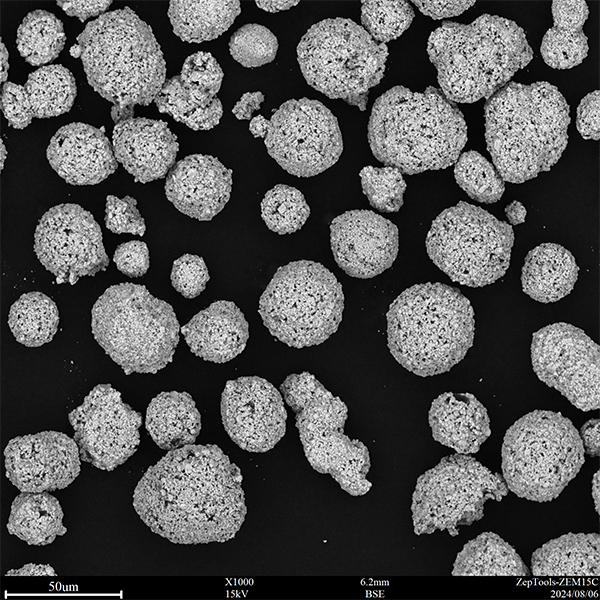

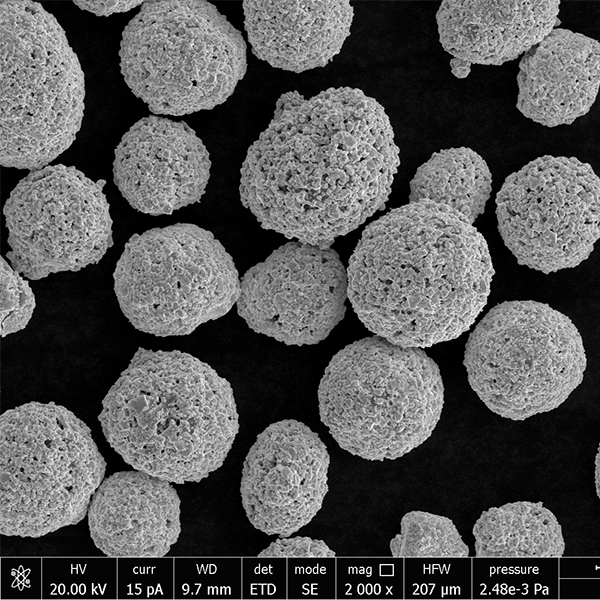

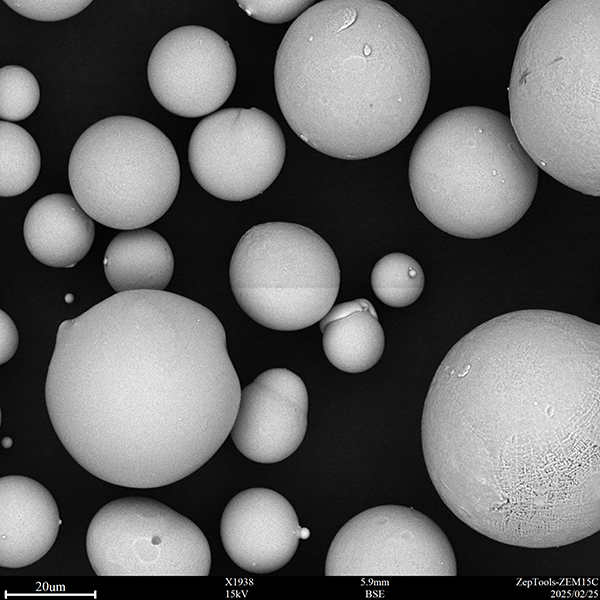

Production Process

Typical Applications

Considerations

· Processing Challenges: High hardness necessitates the use of carbide tools or laser cutting; welding is difficult and requires brazing or explosive bonding.

· Environmental Limits: Avoid exposure to HF or strong reducing environments; high carbon may reduce impact resistance.

· Alternatives: For higher toughness, consider Co10 or nickel-based alloys (e.g., Inconel 625); for extreme corrosion resistance, Stellite12 or Hastelloy C-series may be preferable.

Conclusion

Co12 cobalt-based alloy excels in scenarios requiring ultra-high hardness, thermal stability, and wear resistance under extreme conditions. Its gas atomization process ensures high-density, consistent performance, making it ideal for applications in energy,化工, aerospace, and heavy industry. While costly and challenging to process, Co12 offers unmatched durability for high-stress environments where traditional steels or lower-alloy materials fail.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.