Ni60CuMo is a better material than Ni60A

Ni60CuMo is a reinforced material improved by adding copper (Cu) and molybdenum (Mo) elements to the standard Ni60 (NiCrBSi) alloy, which mainly improves corrosion resistance, thermal conductivity and high temperature stability.

What are the applications of supersonic sprayed tungsten carbide coatings?

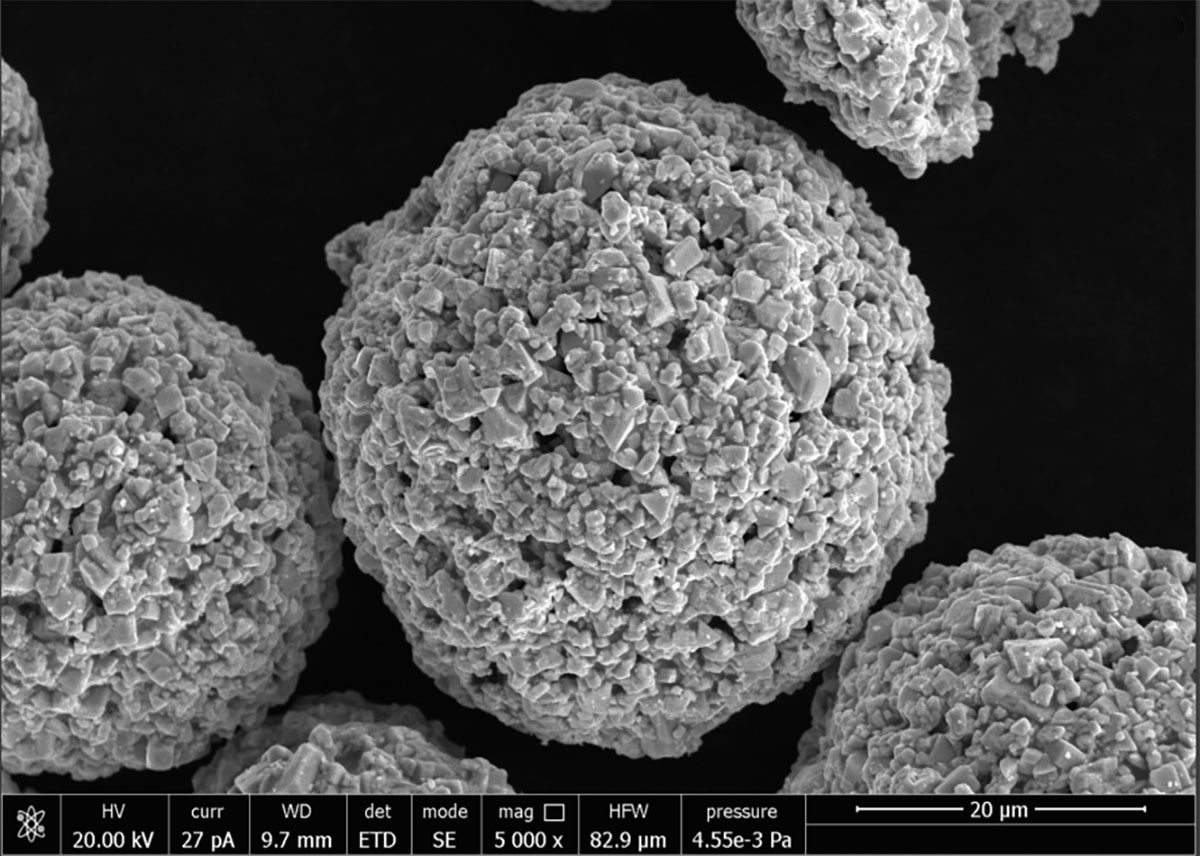

What is WC-10Co4Cr?

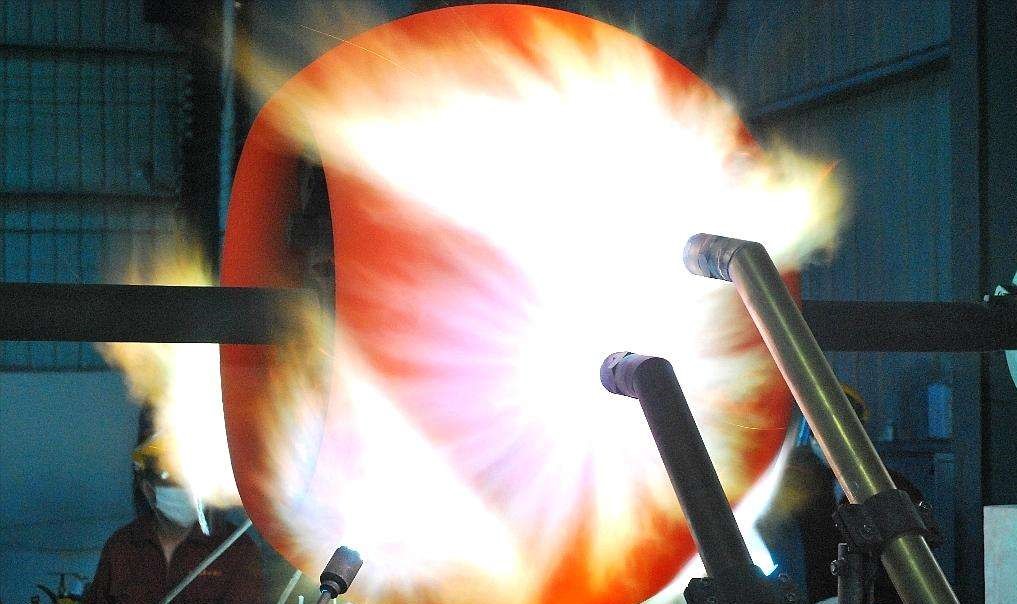

Characteristics of Supersonic Sprayed Tungsten Carbide

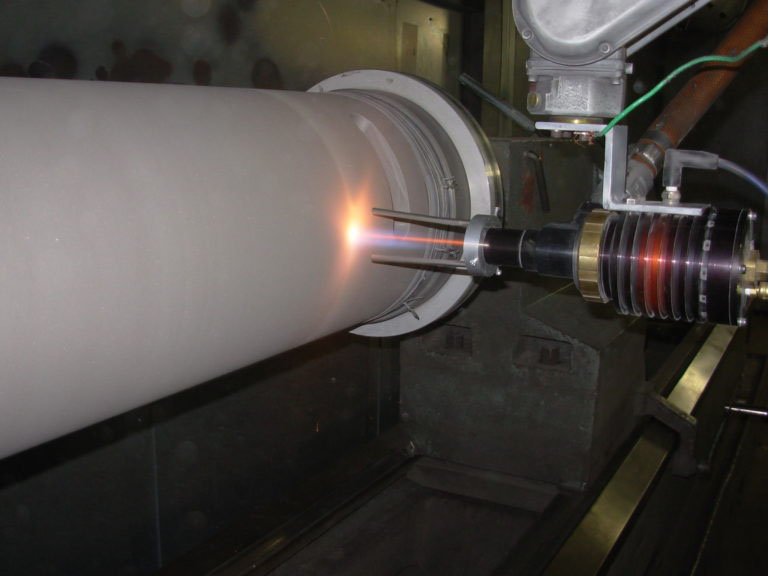

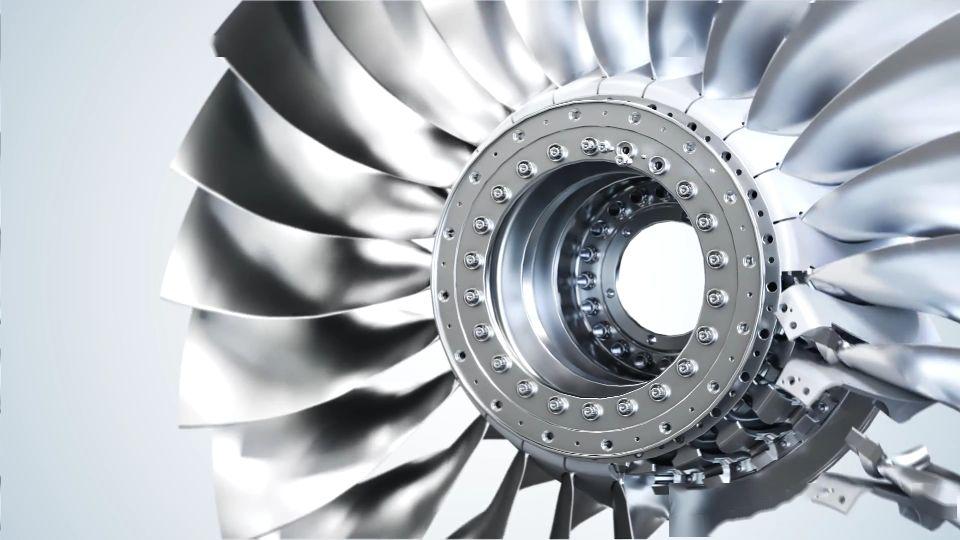

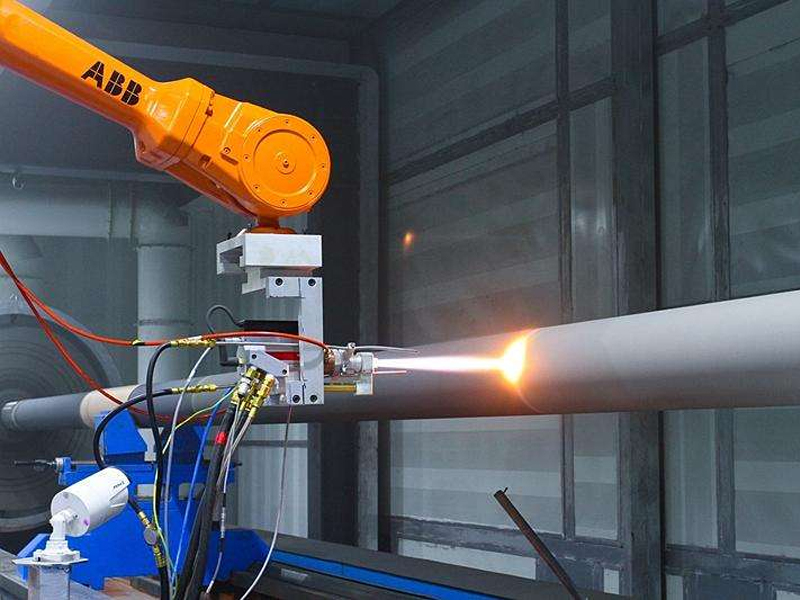

Supersonic flame spraying is an advanced thermal spraying technology that has gained significant attention in the field of materials surface treatment. This technique is particularly effective for creating coatings that require high wear resistance and corrosion resistance.

WC-20CrC-7Ni Composite Material: An Overview

Today, we will explore a remarkable composite powder known as WC-20CrC-7Ni, which is composed of tungsten carbide (WC), chromium carbide (CrC), and nickel carbonyl. This composite material is designed to offer exceptional properties, including corrosion resistance, wear resistance, and high-temperature stability.

Hastelloy C276: The Premier Alloy for Acid Corrosion Resistance

Hastelloy C276 is renowned for its exceptional resistance to corrosion, particularly in harsh environments involving high concentrations of chloride solutions and hot sulfuric acid. This nickel-based alloy is a preferred choice in various industries due to its remarkable properties, making it one of the most effective materials for combating acid corrosion. In this article, we will delve into the chemical composition, performance characteristics, and applications of Hastelloy C276.

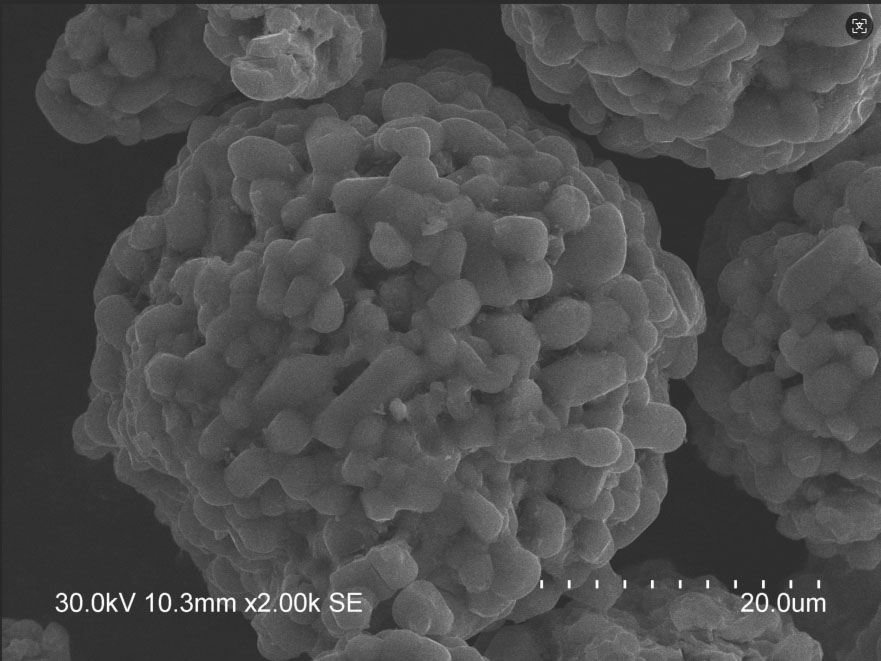

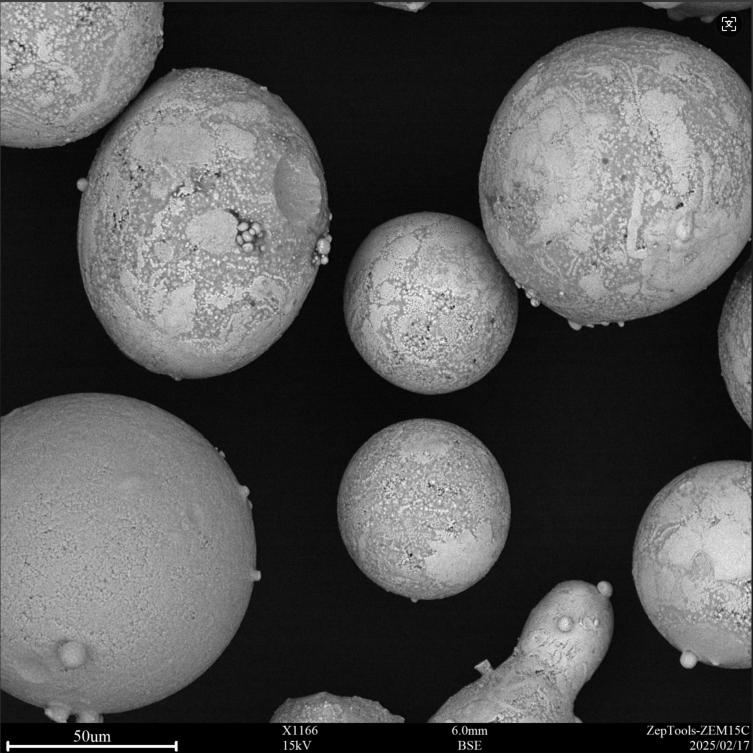

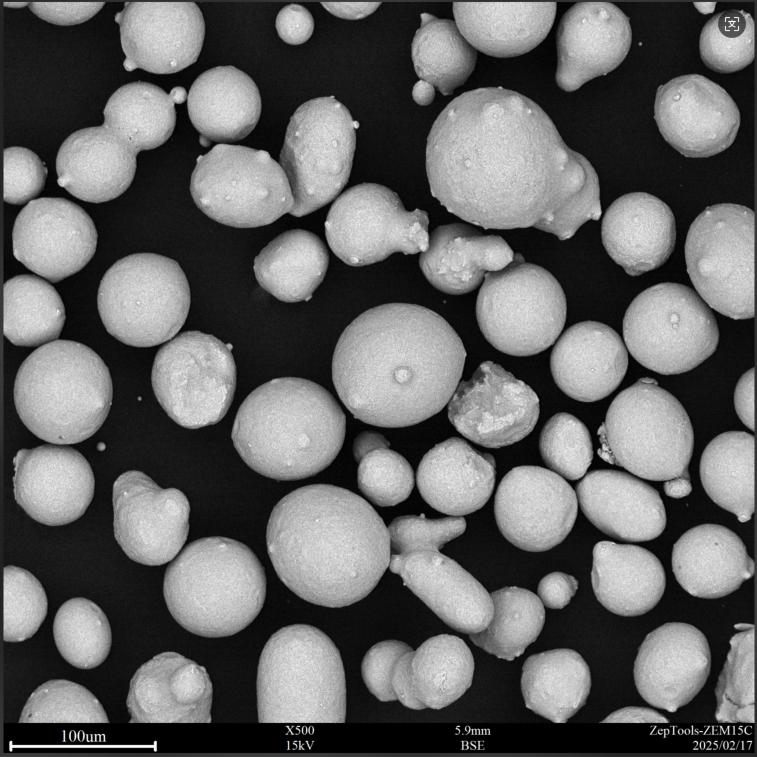

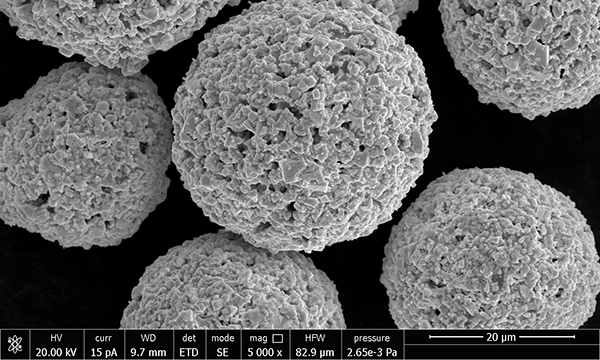

Do You Know What the Primer of Ceramic Powder is?

As we all know, ceramic materials are widely used. Due to its excellent high-temperature resistance and heat-resistant corrosion effect, ceramic materials are a commonly used thermal barrier coating material, which is often used in the preparation of various aero engine coatings and various thermal barrier coatings that need to work in a high temperature environment.

Alloy Powders Suitable for Surfacing Glass Molds

Glass mold welding powder from Chengdu Daguang Thermal Spraying Materials Co., Ltd.

In modern manufacturing, glass mold welding technology plays a vital role. Chengdu Daguang Thermal Spraying Materials Co., Ltd. is committed to providing customers with high-quality glass mold welding powder to meet different processing needs.

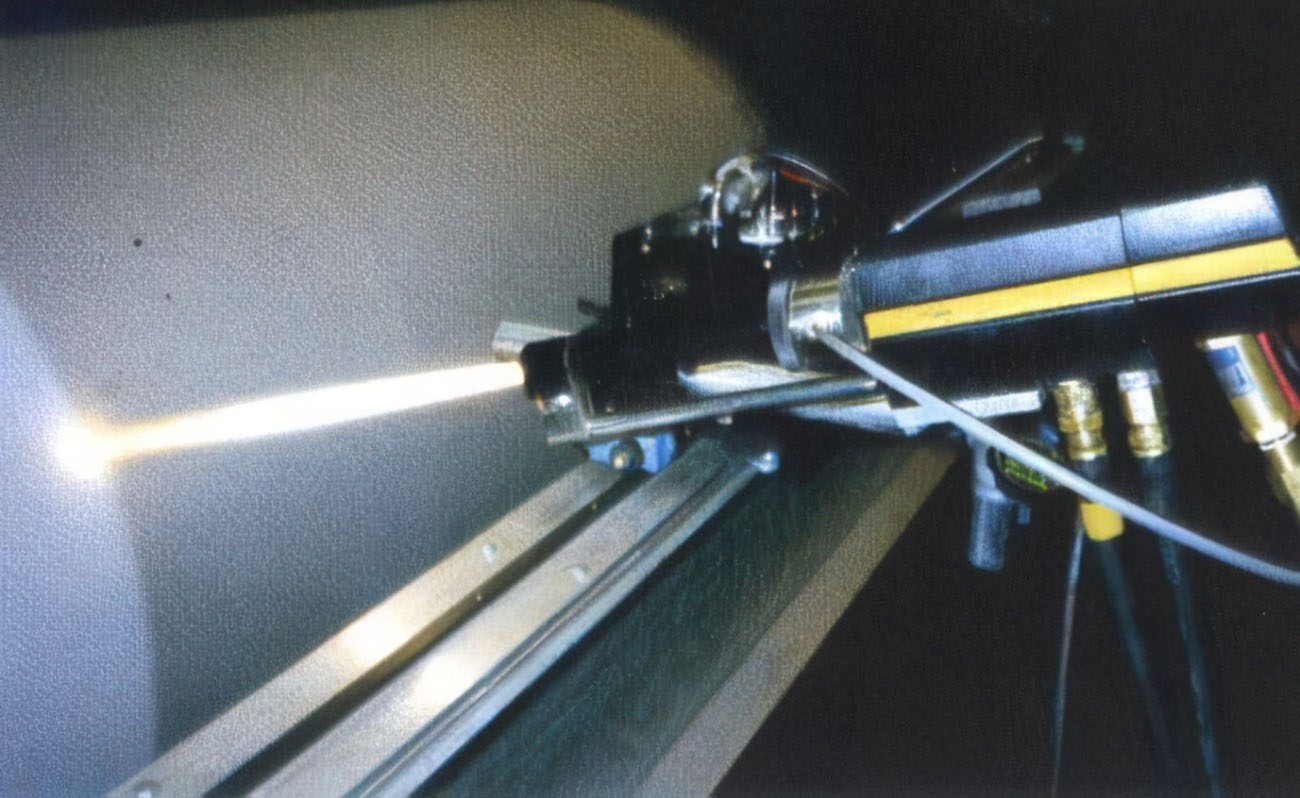

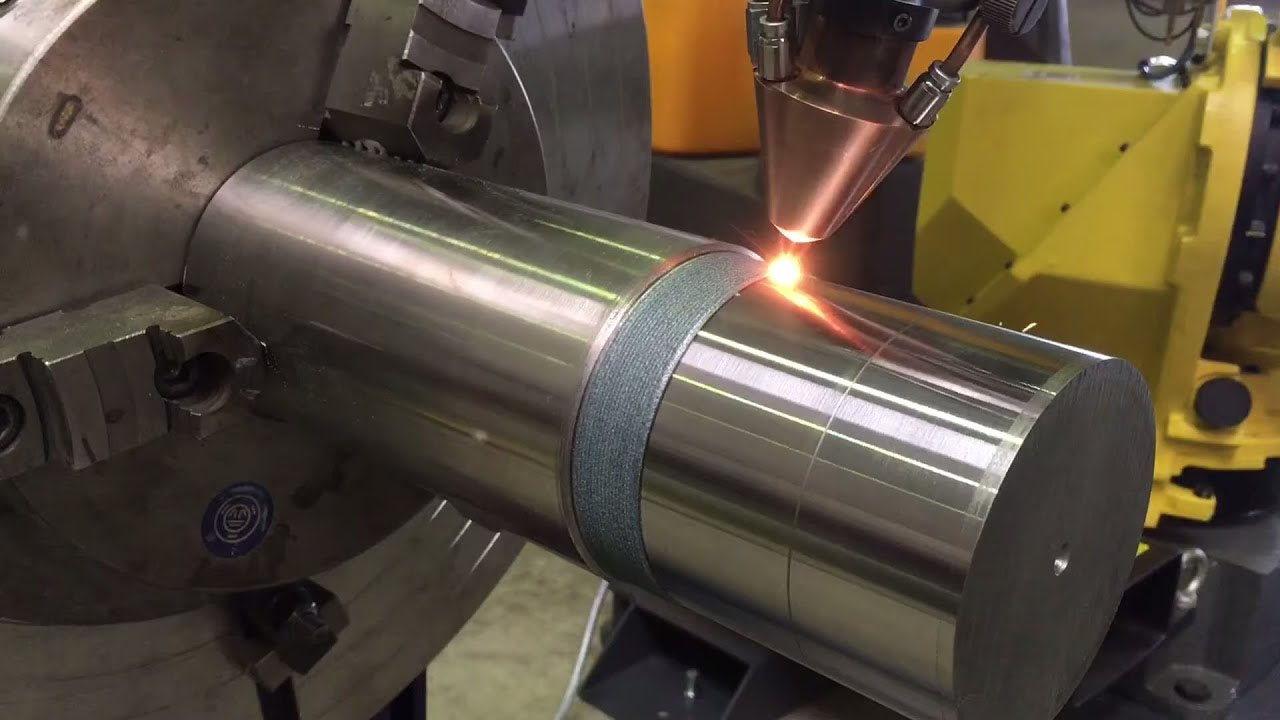

Processing Characteristics and Applications of Laser Cladding

Laser Cladding: Processing Characteristics and Applications

Laser cladding technology is an advanced surface treatment technique widely used for the repair and enhancement of metal materials. Its core principle involves utilizing the high energy density of lasers to melt powder materials and bond them with the substrate, thereby forming a cladding layer with excellent properties.

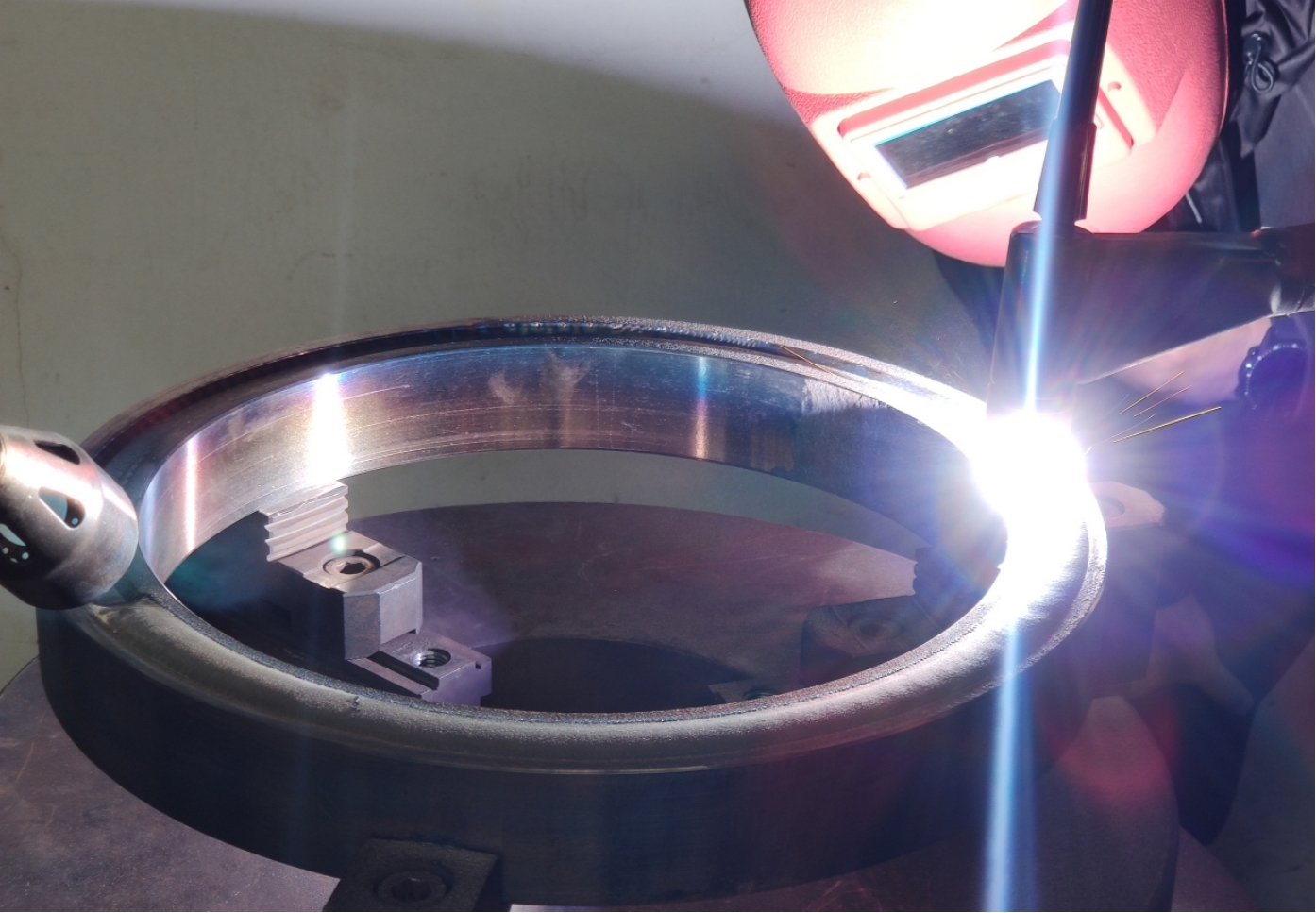

Plasma Cladding Technology: Principles and Applications

Plasma cladding technology began to be applied in industrial settings in the 1960s. It utilizes the tungsten electrode of a welding torch as the negative electrode and the substrate as the positive electrode, generating plasma between them to produce heat.