Alloy Powders Suitable for Surfacing Glass Molds

|

Order |

Brand |

HRC Hardness |

Chemical Composition |

|

1 |

DG.Ni20AAA |

Around 25 |

C0.03,B0.7,Cr4.5,Si2.0,Fe0.1,Ni allowance. |

|

2 |

DG.Ni220M1 |

Around 25 |

C0.03,B1.0,Cr4.9,Si3.0,Fe2.4,Mn0.2,Ni allowance. |

|

3 |

DG.Ni22AAA |

Around 22 |

C0.2,B1.5,Cr0.1,Si2.8,Fe0.5,Mn0.5,Ni allowance. |

|

4 |

DG.Ni22M2 |

Around 22 |

C0.05,B0.8,Cr3.0,Si2.3,Ni allowance. |

|

5 |

DG.Ni30AAA |

Around 30 |

C0.15,B1.4,Cr2.5,Si2.6,Fe1.0,Mn0.3,Ni allowance. |

|

6 |

DG.Ni31M |

Around 30 |

C0.05,B1.0,Cr3.5,Si3.1,Fe3.0,Mn0.4,Ni allowance. |

|

7 |

DG.Ni35AAA |

Around 35 |

C0.2,B1.6,Si3.2,Cr4.0,Si2.6,Fe1.4,Mn0.1,Mo0.1,Ni allowance. |

|

8 |

DG.Ni37AAA |

Around 37 |

C0.15,B1.4,Si2.6,Cr4.5,Si2.6,Ni allowance. |

|

9 |

DG.Ni40AAA |

Around 40 |

C0.3,B1.7,Si3.5,Cr7.5,Si2.6,Fe2.3,Mn0.1,Mn0.1,Ni allowance. |

|

10 |

DG.Ni43AAA |

Around 43 |

C0.2,B1.0,Si3.0,Cr5.0,Si2.6,Fe0.5,Mn0.5,Mn3.0,Ni allowance. |

Glass mold welding powder from Chengdu Daguang Thermal Spraying Materials Co., Ltd.

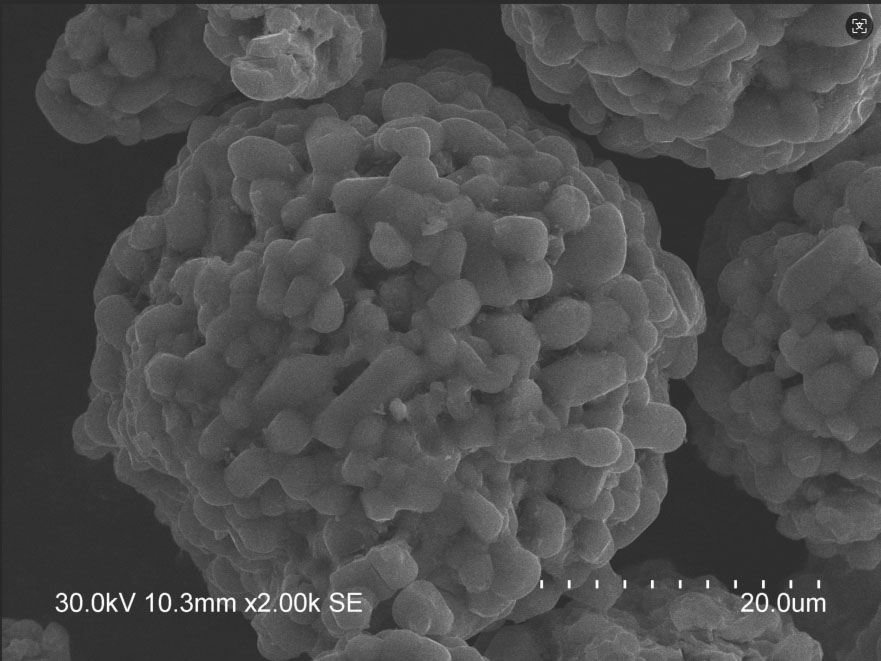

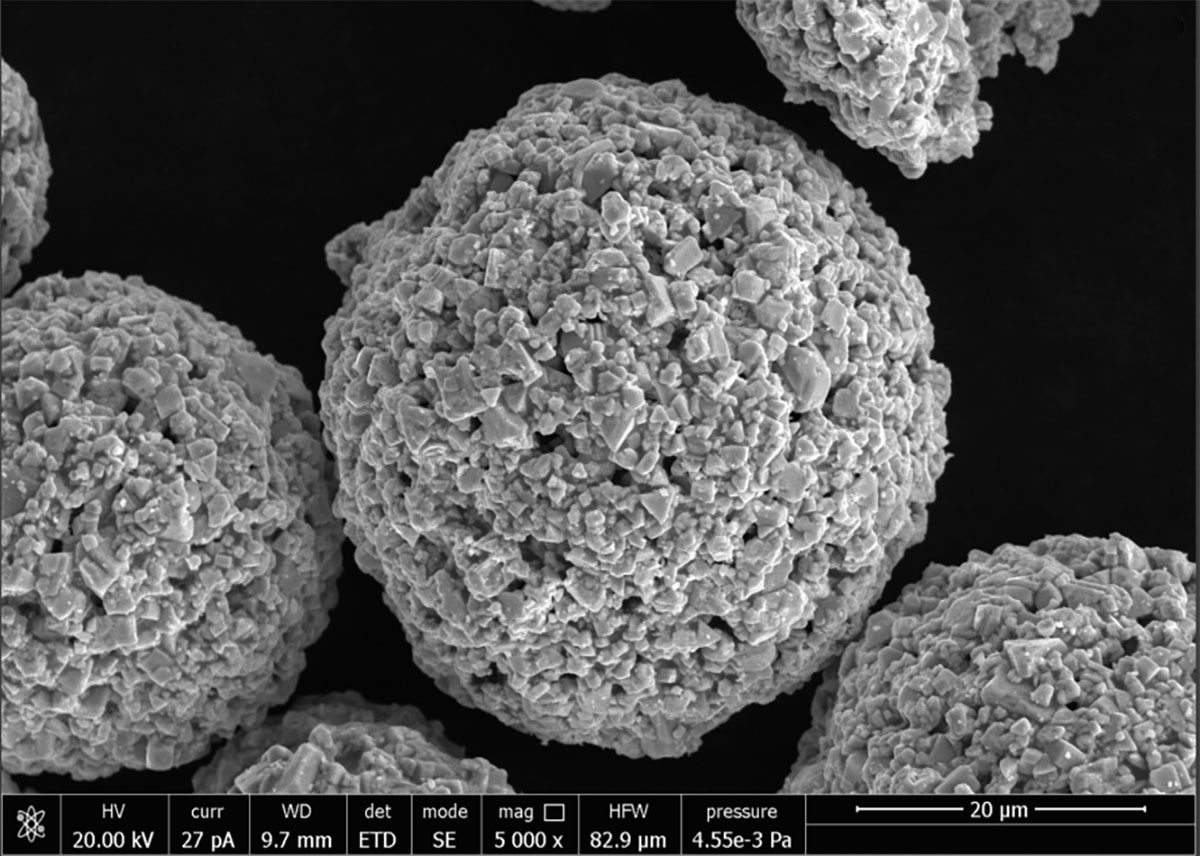

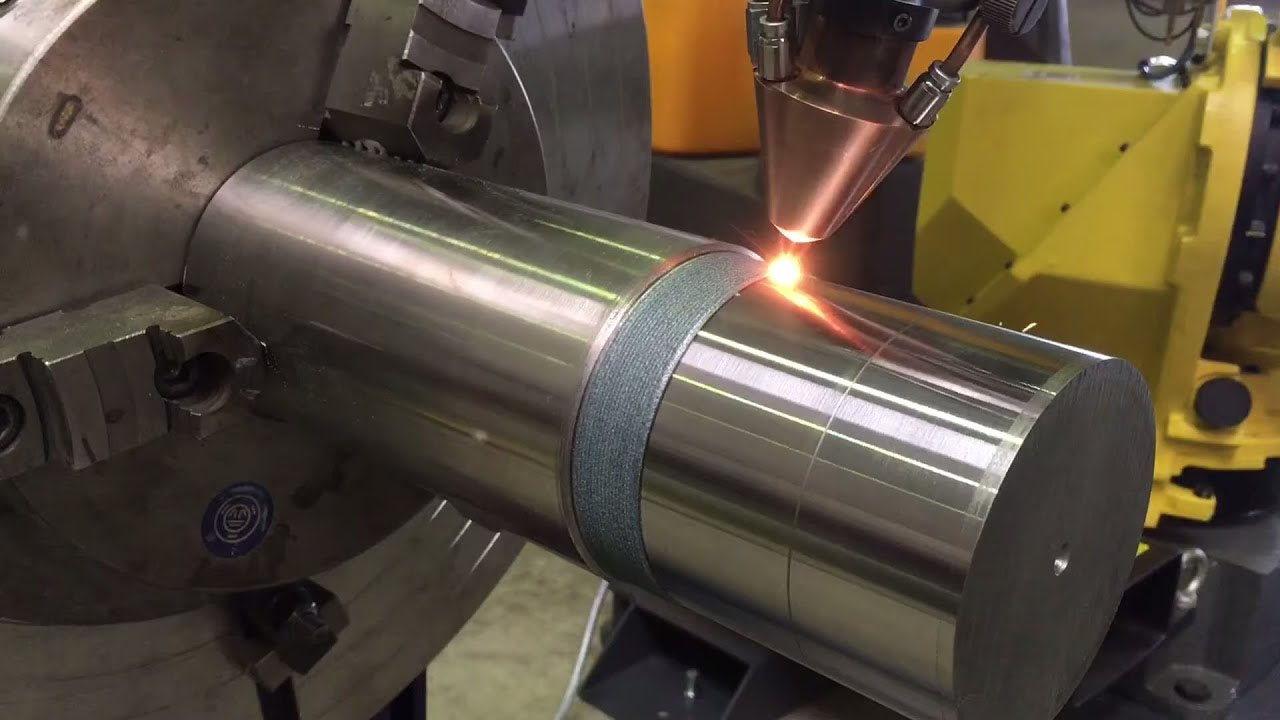

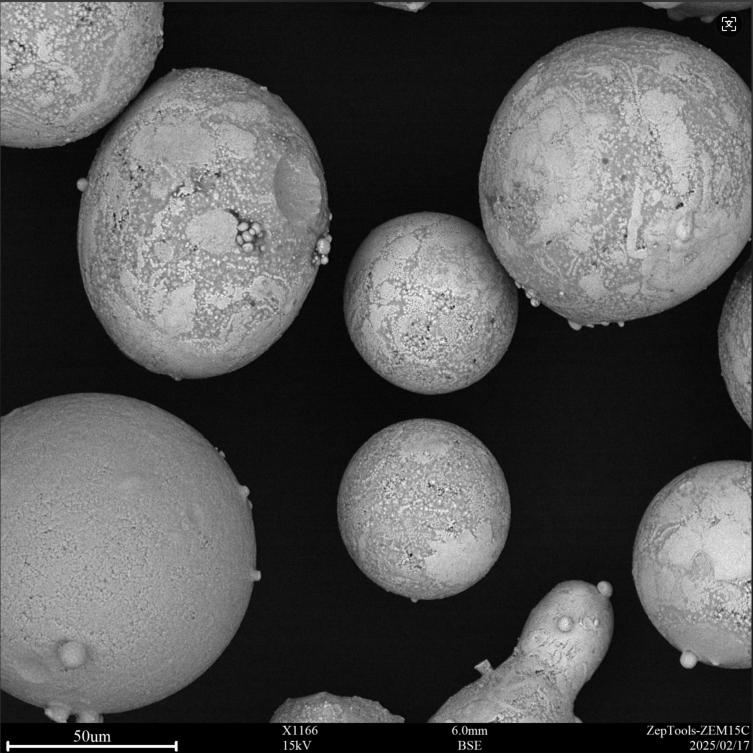

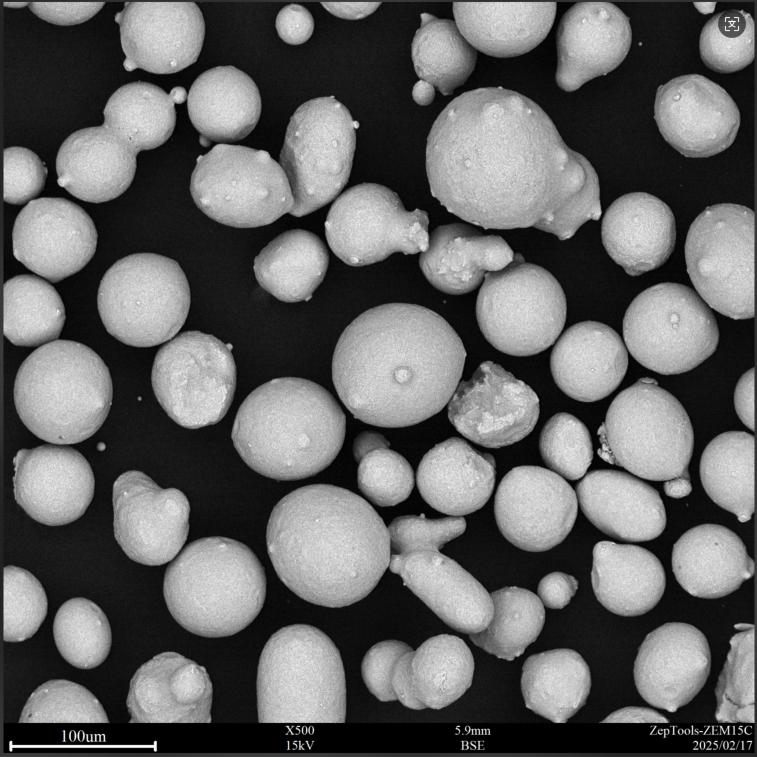

In modern manufacturing, glass mold welding technology plays a vital role. Chengdu Daguang Thermal Spraying Materials Co., Ltd. is committed to providing customers with high-quality glass mold welding powder to meet different processing needs. Our welding powder adopts advanced gas atomization production technology to ensure that the powder has a more rounded spherical shape and better fluidity, thereby improving welding efficiency and quality.

I. Classification of welding powder

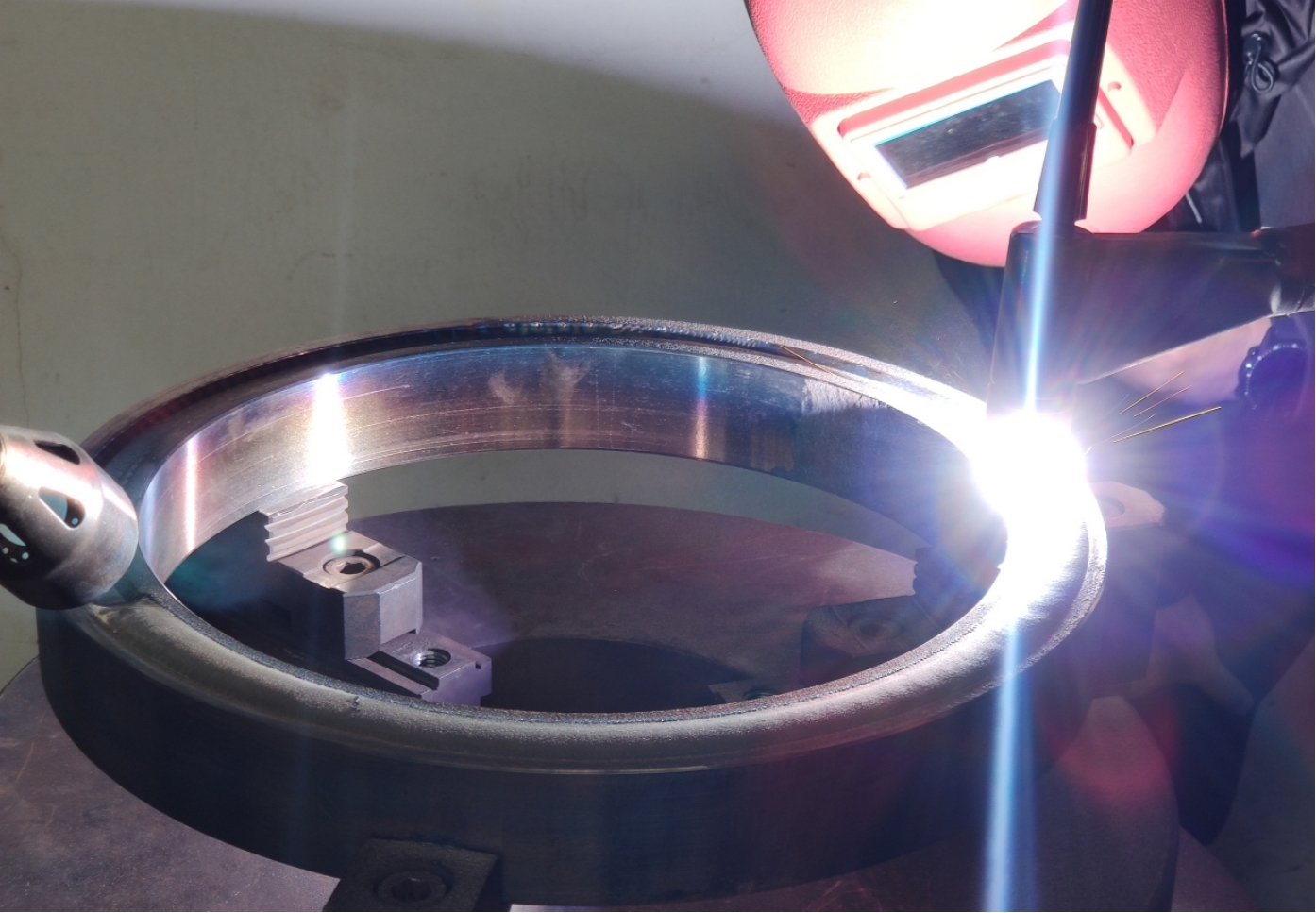

According to different processing methods, our glass mold welding powder is mainly divided into two categories: oxyacetylene welding powder and plasma welding powder. These two kinds of welding powder each have their own unique advantages and are suitable for different welding scenarios.

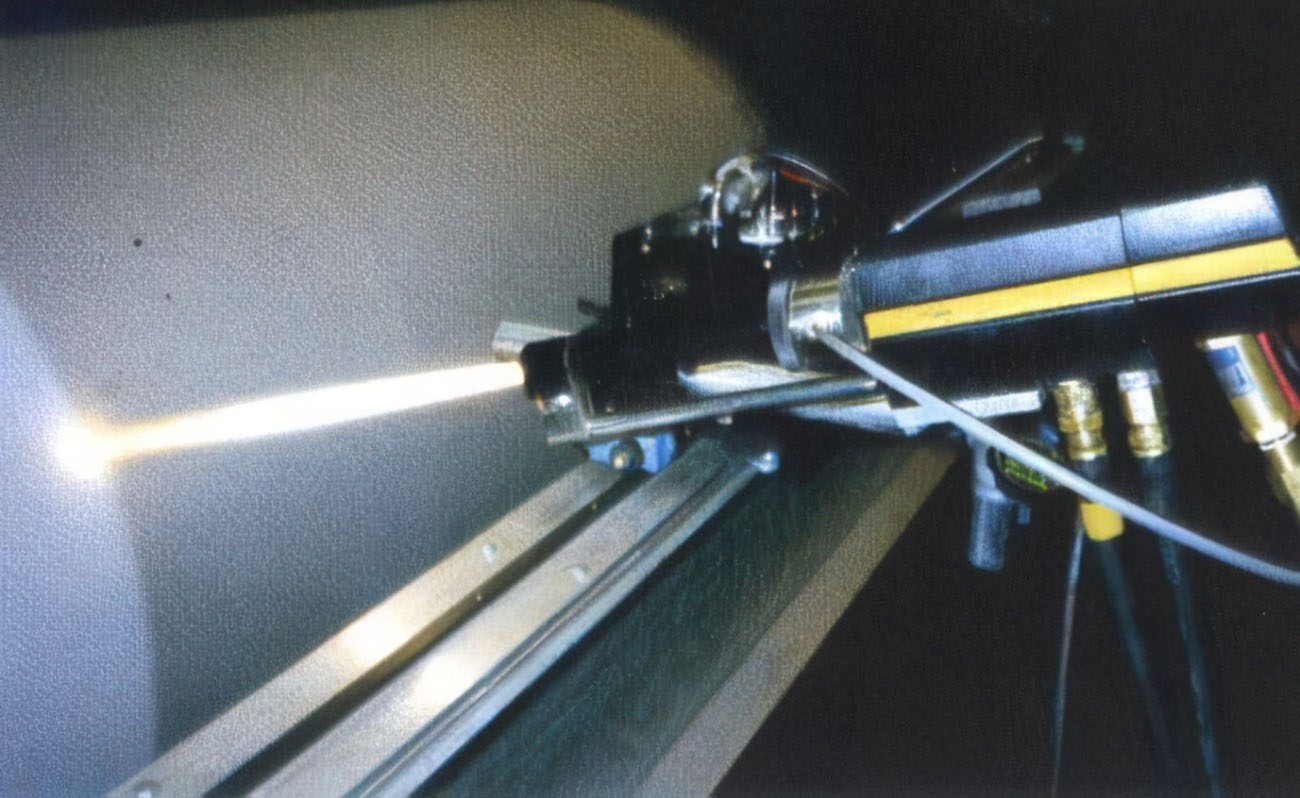

Oxyacetylene welding powder

Oxyacetylene welding is a traditional welding method, which is widely used in welding various metal materials. Our oxyacetylene welding powder has good melting point and fluidity, which can form a uniform weld during welding and ensure the welding quality. This welding powder is suitable for large-area welding, especially in welding occasions that require lower hardness. For example, when welding large surfaces, welding powder with an HRC hardness of about 20-25 can effectively meet the needs.

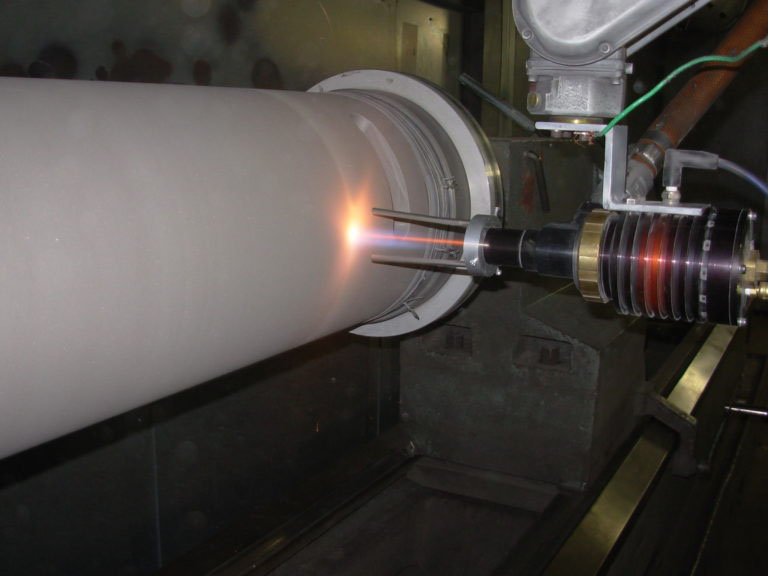

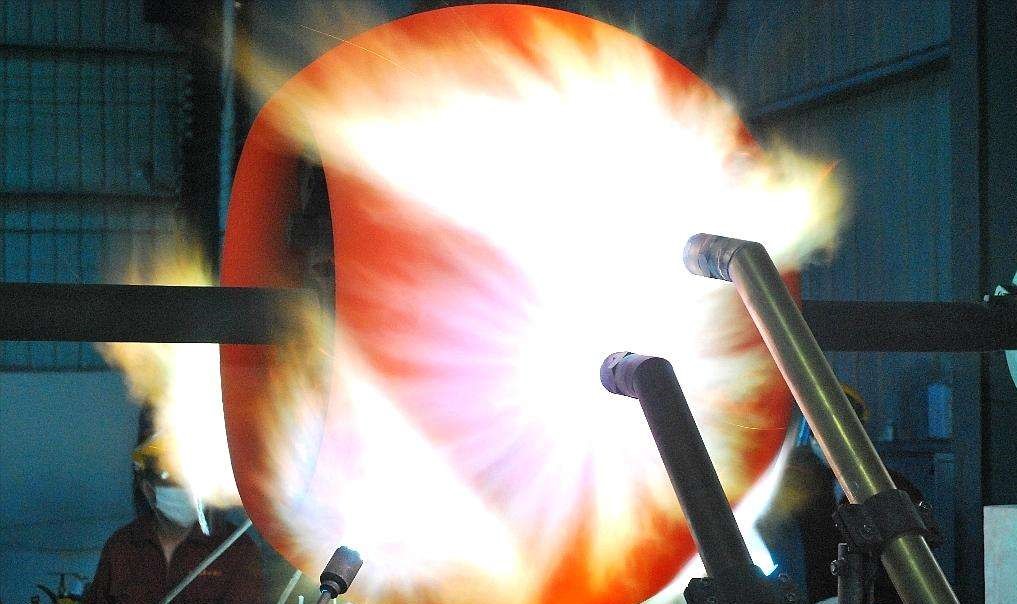

Plasma welding powder

Plasma welding is an efficient and precise welding technology suitable for applications with high welding quality requirements. Our plasma welding powder can melt quickly at high temperatures to form a high-strength and tough weld, suitable for welding parts that require high hardness, such as punches. The welding powder we produce with an HRC hardness of about 40-43 can meet the requirements of high strength and high wear resistance.

II. Hardness and performance of solder powder

The glass mold solder powder we produce has a wide range of hardness, ranging from HRC20 to HRC43, which can meet the needs of different customers. The choice of hardness directly affects the performance of the finished product after welding, so we strictly control the composition and process of the powder during the production process to ensure the quality of each batch of solder powder.

Advantages of low hardness solder powder

Low hardness welding powder (HRC20-25) has good ductility and is suitable for large-area welding. After welding, the weld has strong toughness and impact resistance, which can effectively prevent the weld from cracking and deformation. In addition, low hardness welding powder will not have defects such as pinholes and bubbles after fine grinding, ensuring the smoothness and beauty of the welding surface.

Advantages of high hardness solder powder

High hardness welding powder (HRC40-43) is suitable for welding parts that require high wear resistance, such as punches and molds. The weld formed by this welding powder after welding has extremely high hardness and wear resistance, can withstand greater impact and wear, and extend the service life of the mold.

III. Production process

Our glass mold solder powder adopts the gas atomization production process, the advantage of this process is that it can effectively control the particle size and shape of the powder. The gas atomization technology sprays the molten metal and quickly cools it to form a spherical powder, ensuring the fluidity and uniformity of the powder. This production process not only improves the quality of the solder powder, but also reduces the production cost, allowing us to provide customers with high-quality solder powder at a more competitive price.

IV. Quality Control

At Chengdu Daguang Thermal Spraying Materials Co., Ltd., we always put product quality first. Each batch of solder powder undergoes strict quality testing before leaving the factory, including particle size analysis, hardness test, and chemical composition analysis. We have a professional technical team to ensure that each test meets national and industry standards. Through strict quality control, our solder powder has won a good reputation in the market and has been recognized by many customers.

V. Customer Service

We know that high-quality products are inseparable from high-quality services. Chengdu Daguang Thermal Spraying Materials Co., Ltd. always adheres to the customer-centric service concept and is committed to providing customers with a full range of technical support and services. Whether it is product selection, technical consultation, or after-sales service, our professional team will respond in a timely manner to ensure that customers have no worries during use.

VI. Market Prospects

With the continuous development of the manufacturing industry, the market demand for glass mold solder powder is also growing. Especially in the automotive, electronics, home appliance and other industries, the demand for high-performance solder powder is increasing. Chengdu Daguang Thermal Spraying Materials Co., Ltd. will continue to increase R&D investment and continuously launch new products to meet the diverse needs of the market.

VII. Summary

Chengdu Daguang Thermal Spraying Materials Co., Ltd. has become a leading enterprise in the field of glass mold solder powder with advanced production technology, strict quality control and excellent customer service. We will continue to uphold the concept of innovation, quality and service, provide customers with better products and services, and help customers achieve greater success in the fierce market competition. No matter what type of glass mold solder powder you need, we can provide you with the most suitable solution. Looking forward to working with you to create a better future!