Do You Know What the Primer of Ceramic Powder is?

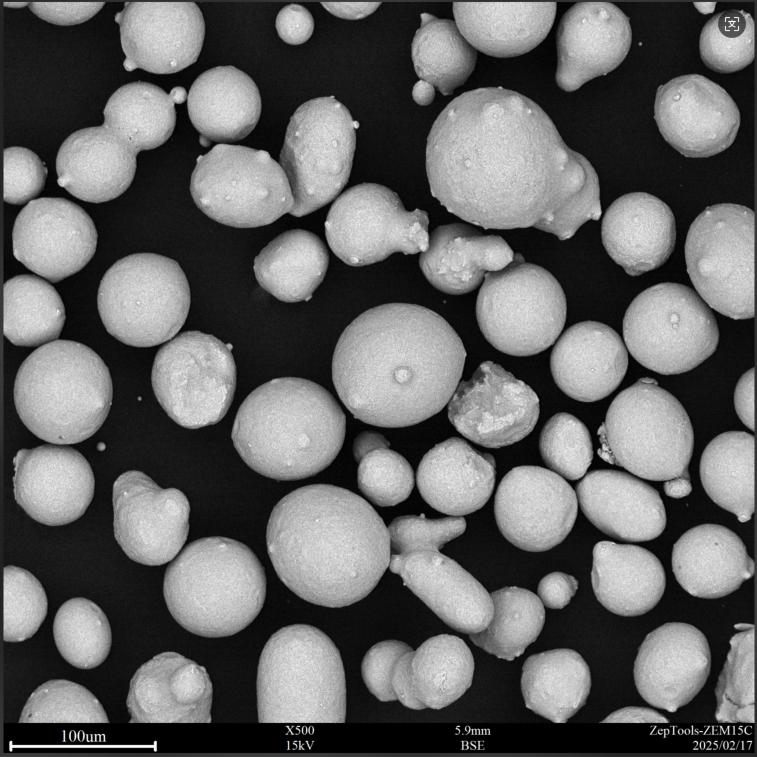

As we all know, ceramic materials are widely used. Due to its excellent high-temperature resistance and heat-resistant corrosion effect, ceramic materials are a commonly used thermal barrier coating material, which is often used in the preparation of various aero engine coatings and various thermal barrier coatings that need to work in a high temperature environment. Due to the large difference in the coefficient of thermal expansion between ceramic materials and steel substrates, ceramic materials are widely used in the preparation of thermal barrier coatings. Spraying ceramic material directly on the substrate, its adhesion rate or bonding effect is not ideal, so it is necessary to spray a layer of ceramic material primer before spraying ceramic material;

Chengdu Da light thermal spraying Materials Co., Ltd. mainly produces the following types of primer powder:

1.Ni80%Cr20% : that is, nickel-chromium alloy powder, which is often used for plasma spraying targets, and can also be used for bonding layers of chromium oxide and zirconia materials;

The operating temperature is up to 980 degrees Celsius

2.NiCrAl: Cr20%, Al1-5%, Ni allowance, transition layer of ceramic powder, high temperature oxidation resistance

In the high temperature environment of 1000 degrees Celsius, the oxidation weight gained 6.25mg·cm-2 for 200h, and the oxidation kinetic behavior followed the parabolic law.

Reference: Non-ferrous Metal Science and Engineering, Volume 6, Issue 4, August 2015, "High Temperature oxidation behavior of Nickel-chromium aluminum alloy"

3.NiCrAlY: Cr20%, Al5%, Y1%, Ni residual, that is, nickelchromium aluminum yttrium alloy powder, this powder for ceramic substrate resistance to high temperature performance than Ni20Cr, NiCrAl are better, metal Al at high temperature generated alumina is very dense, and chromium oxide together to form a double protective barrier to avoid matrix culture, plus metal Y contributed to this process. So NiCr AlY is particularly suitable for zirconia and other high temperature ceramic coating substrate.

In the high temperature environment of 1000 degrees Celsius, the weight gain of 200h was 5.24mg·cm-2, and the oxidation kinetic behavior followed the parabolic law.

China Steel Research Technology Group Co., LTD., Beijing 100081, China "Study on High Temperature Oxidation Resistance of MCrAlY Coating"

4.NiCrCoAlY, commonly used as a transition layer for ceramic materials such as zirconia,

The above is the primer produced by our company, which can be prepared by plasma spraying and supersonic spraying.

Ceramic powder primer and its application

Ceramic materials are widely used in high-tech fields such as aviation, aerospace, and automobiles due to their excellent high-temperature and corrosion resistance, especially thermal barrier coating materials in high-temperature environments. With the continuous advancement of science and technology, the application scope of ceramic materials is also expanding. However, due to the large difference in thermal expansion coefficient between ceramic materials and steel substrates, spraying ceramic materials directly on the substrate often leads to insufficient adhesion and even peeling. Therefore, it is particularly important to use ceramic primer powder for pretreatment before spraying ceramic materials.

1. The necessity of ceramic primer

The main function of ceramic primer is to improve the adhesion between the ceramic coating and the substrate and improve the overall performance of the coating. Primer is usually made of metal alloy powder, which can form a good bonding layer at high temperature to ensure the stability and durability of the ceramic coating. The choice of primer directly affects the performance of the coating, so it is very important to understand the different types of primer and their characteristics.

2. Primer products of Chengdu Daguang Thermal Spraying Materials Co., Ltd.

Chengdu Daguang Thermal Spraying Materials Co., Ltd. focuses on the research and development and production of high-performance primers. Its main products include the following:

Ni80%Cr20% (nickel-chromium alloy powder)

This powder is often used as a plasma spray target and can also be used as a bonding layer for chromium oxide and zirconium oxide materials. The operating temperature of Ni80%Cr20% powder is as high as 980 degrees Celsius, and it can maintain good performance in high temperature environments. Its excellent high temperature resistance makes it an ideal choice for ceramic primers, which can effectively improve the adhesion of ceramic coatings.

NiCrAl (nickel-chromium-aluminum alloy powder)

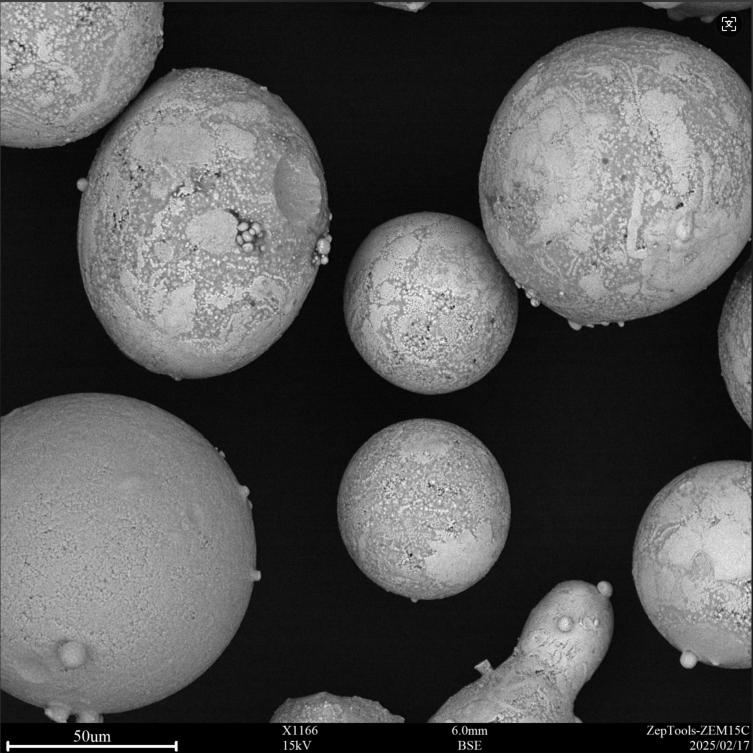

NiCrAl powder is composed of Cr20%, Al1-5%, and Ni balance. It is mainly used as the transition layer of ceramic powder and has the ability to resist high temperature oxidation. In a high temperature environment of 1000 degrees Celsius, after 200 hours of oxidation test, its oxidation weight gain is 6.25mg·cm-2, and the oxidation kinetic behavior obeys the parabolic law. The superior performance of this powder makes it widely used in high temperature environments.

NiCrAlY (nickel-chromium-aluminum-yttrium alloy powder)

The composition of NiCrAlY powder is Cr20%, Al5%, Y1%, and Ni as the balance. Its high temperature resistance is better than Ni20Cr and NiCrAl. The alumina generated by metal aluminum at high temperature is very dense, and together with chromium oxide, it forms a double protective barrier to prevent matrix oxidation. After 200 hours of high temperature oxidation test, its oxidation weight gain is 5.24mg·cm-2, and the oxidation kinetic behavior also obeys the parabolic law. NiCrAlY is particularly suitable for the primer of high temperature ceramic coatings such as zirconium oxide, which can effectively improve the durability and stability of the coating.

NiCrCoAlY (nickel chromium cobalt aluminum yttrium alloy powder)

This powder is often used as a transition layer for ceramic materials such as zirconium oxide, and has good high temperature resistance and oxidation resistance. The unique composition of NiCrCoAlY enables it to effectively prevent substrate oxidation in high temperature environments, ensuring the adhesion and stability of the ceramic coating.

3. Spraying process of primer

The primer powder of Chengdu Daguang Thermal Spraying Material Co., Ltd. can be used for coating preparation through two main spraying methods: plasma spraying and supersonic spraying.

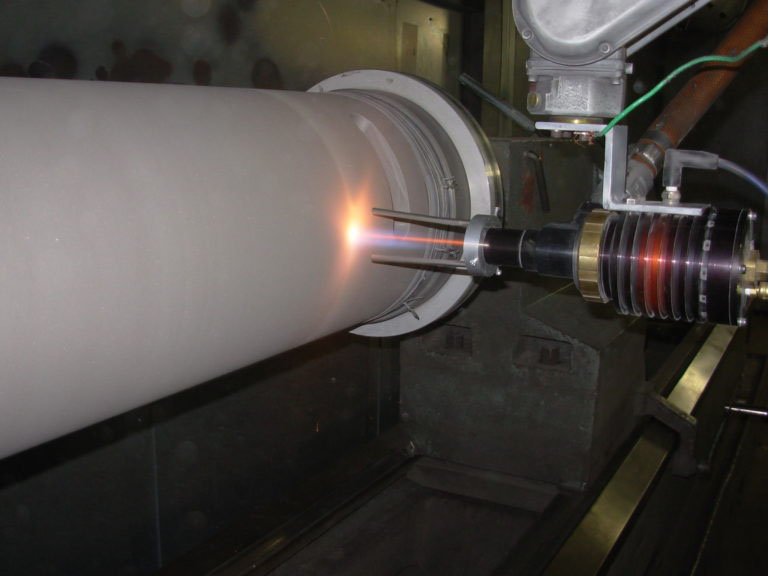

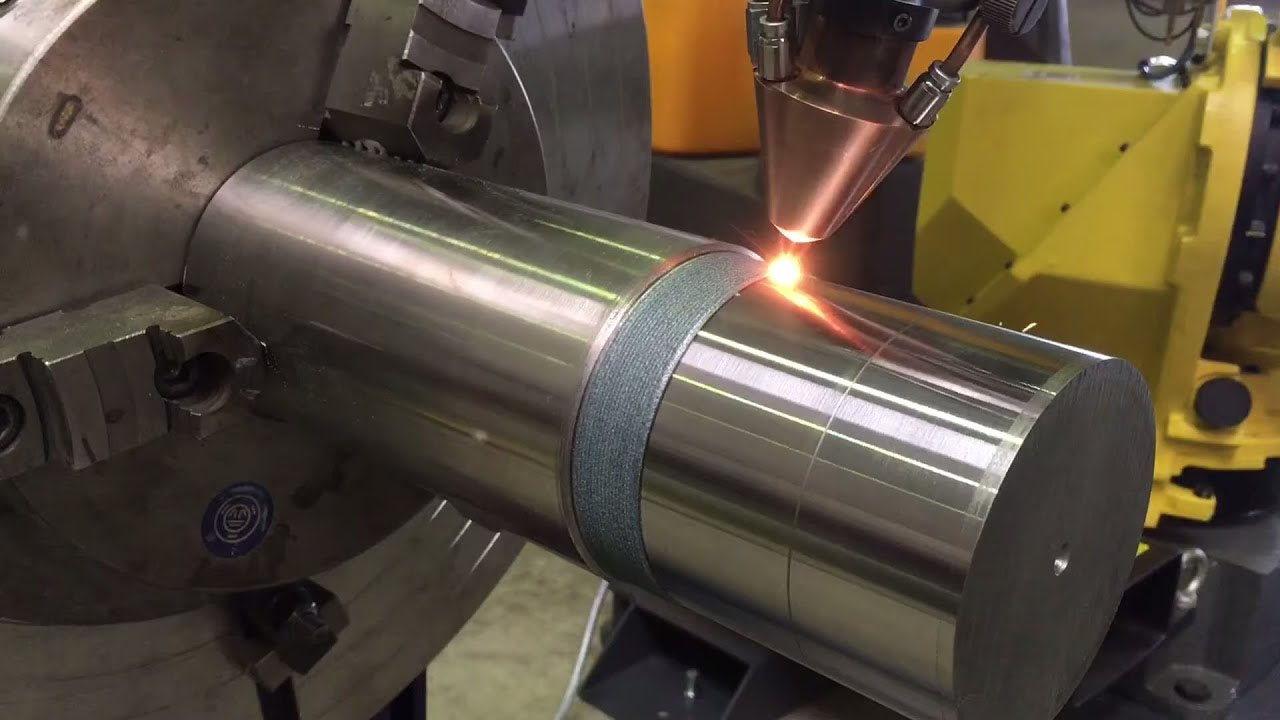

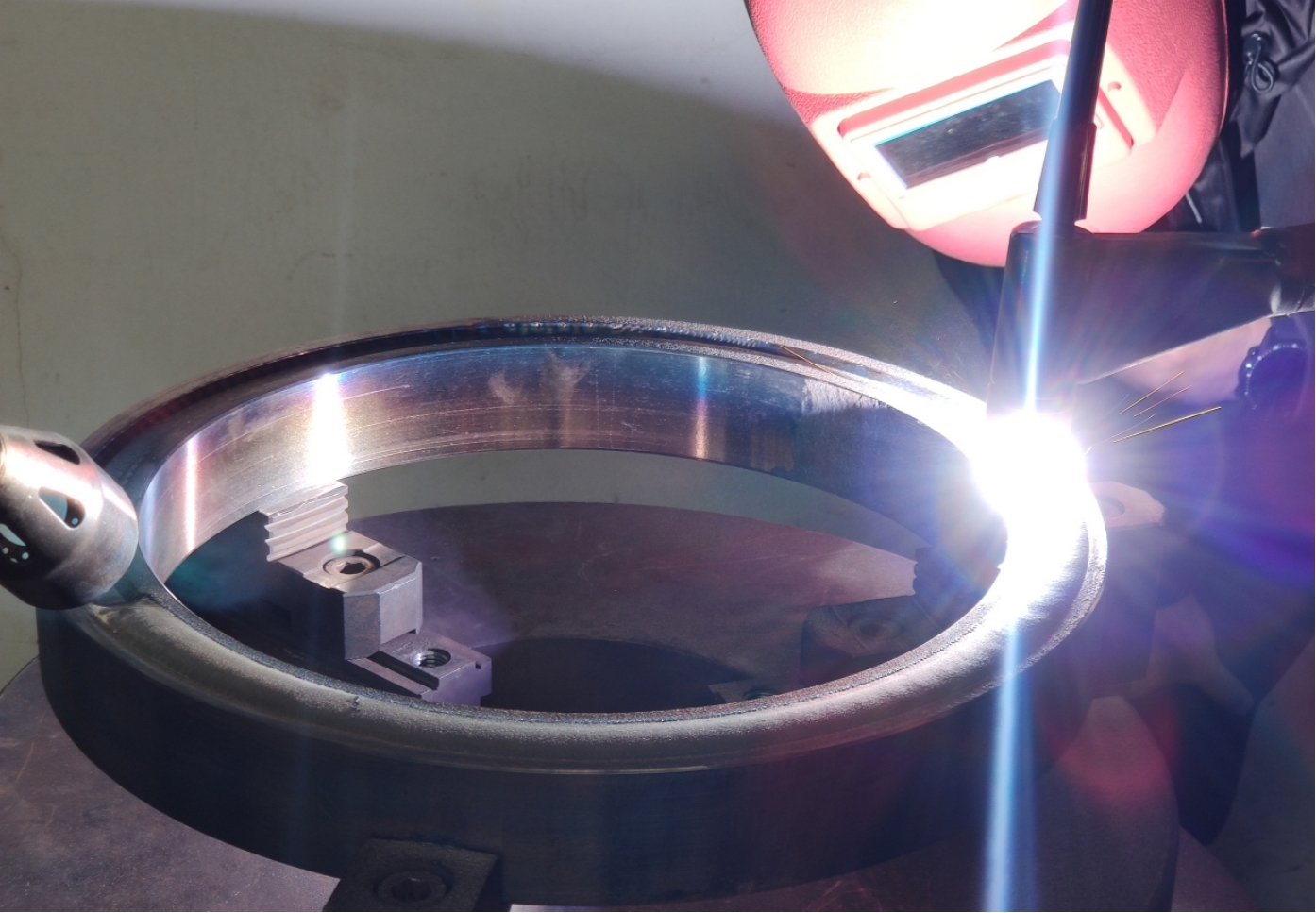

Plasma spraying

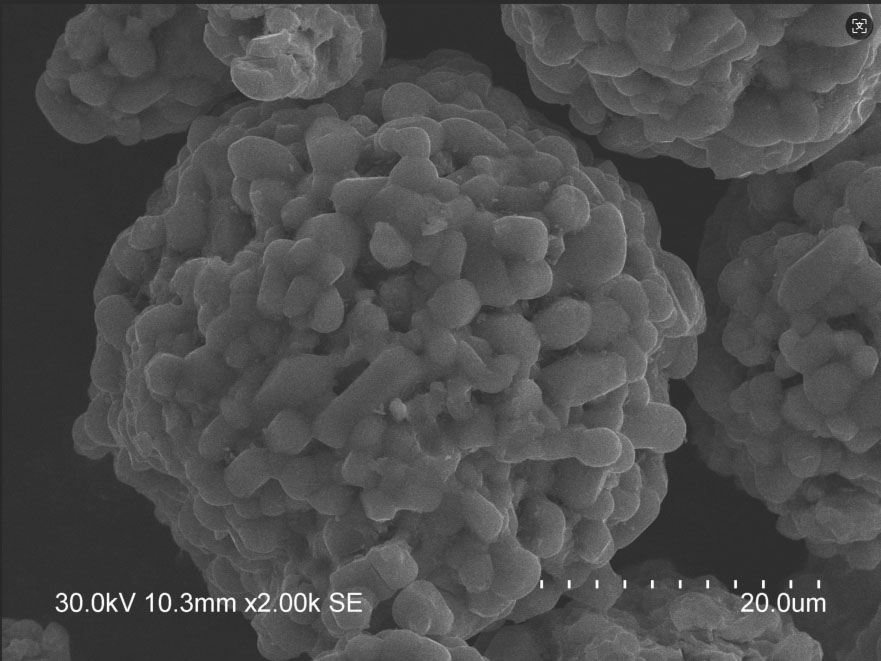

Plasma spraying is a high energy density spraying technology that can melt powder at high temperature and spray it onto the substrate surface. This process is suitable for coating preparation of various metal and ceramic materials and can form a dense and uniform coating. The advantage of plasma spraying is that it can complete the coating preparation in a shorter time and the coating has higher adhesion and wear resistance.

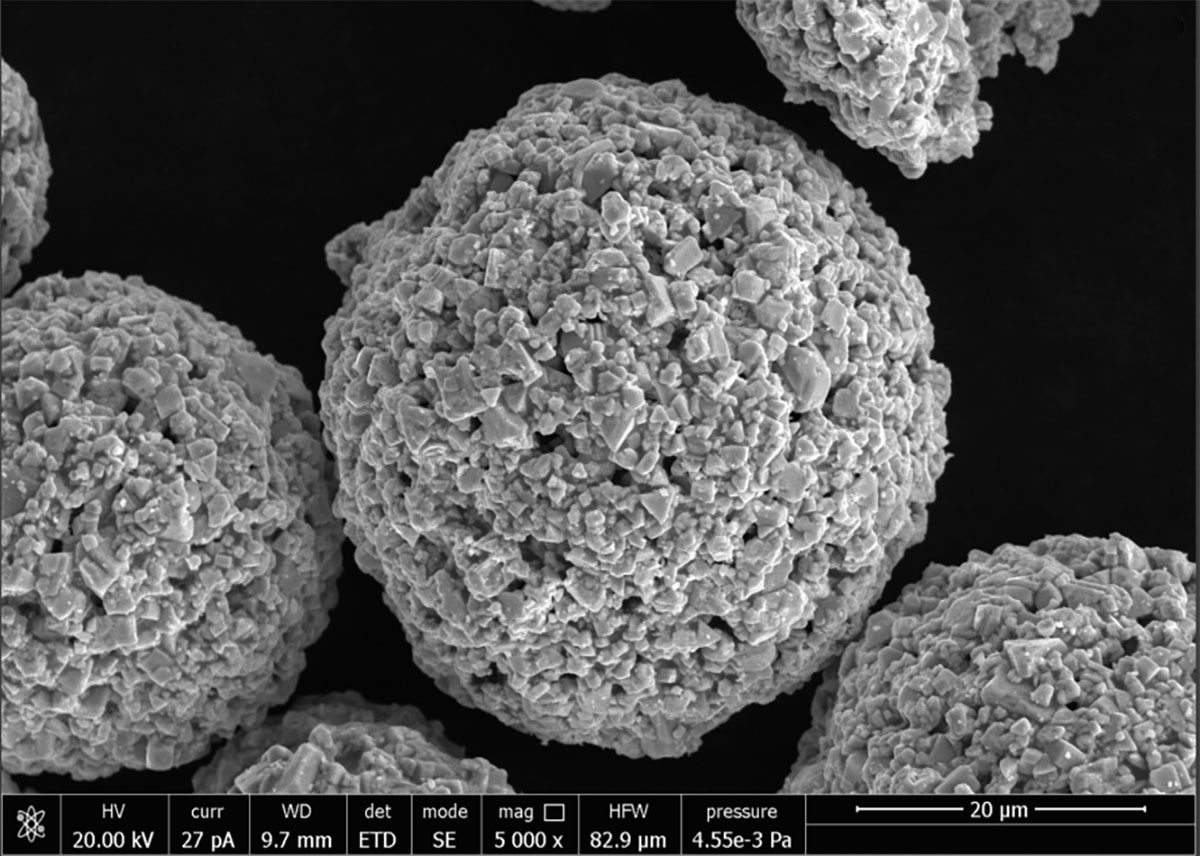

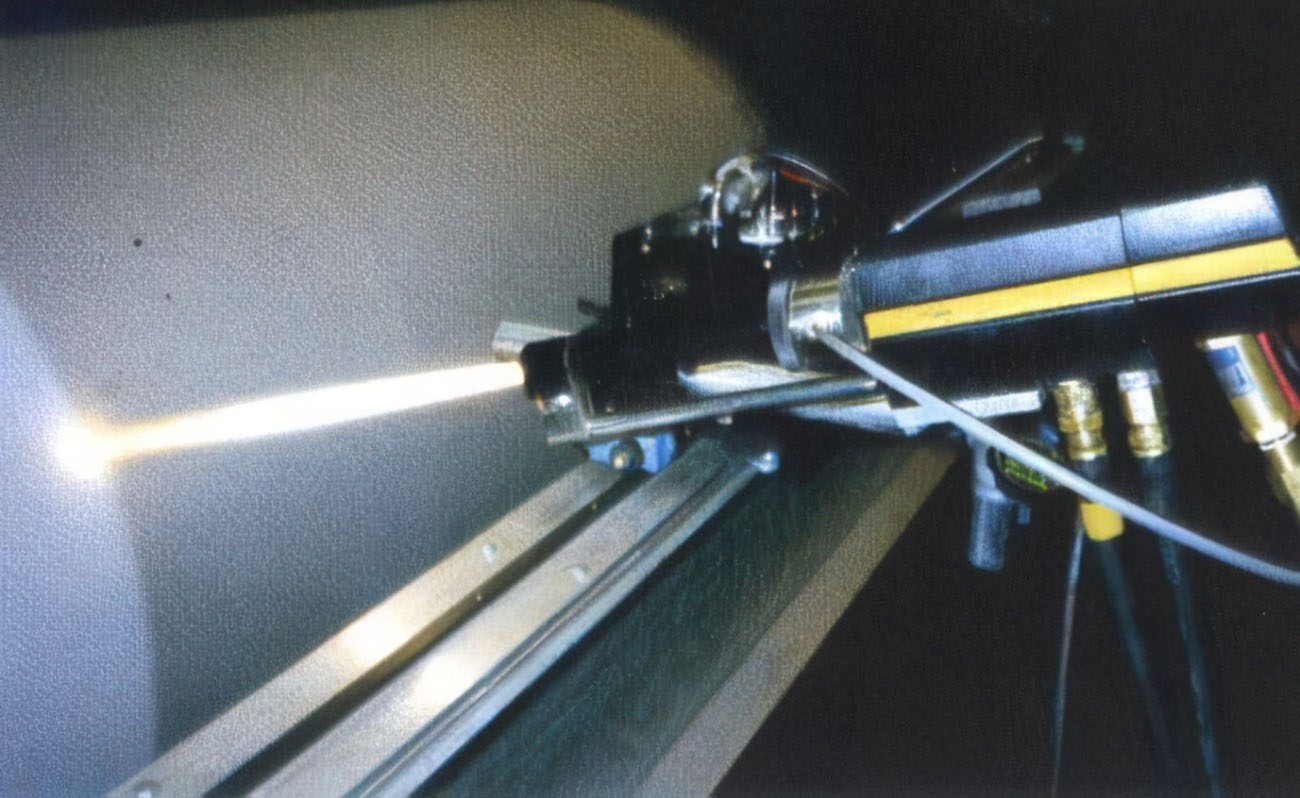

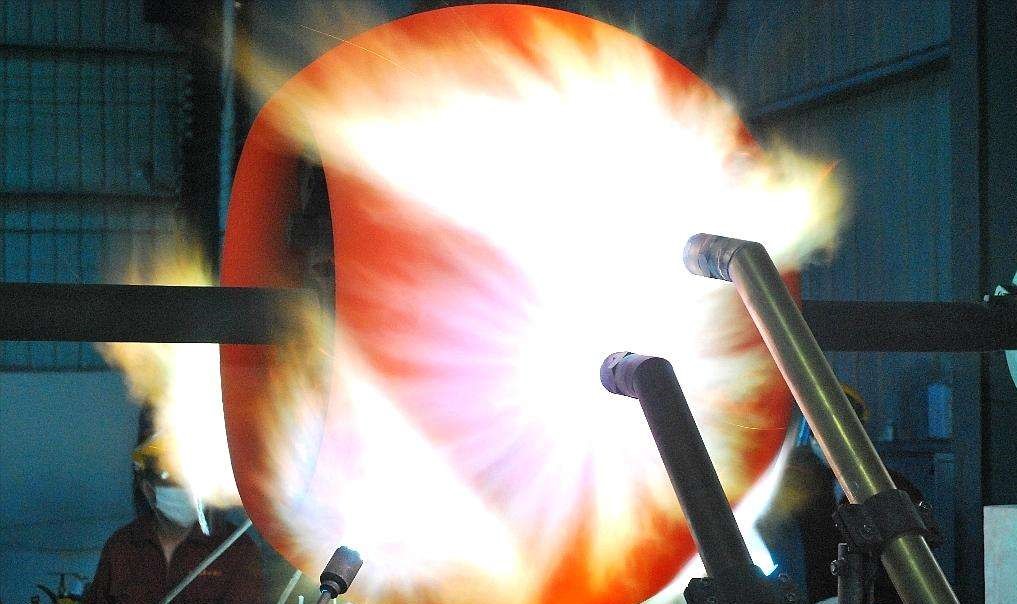

Supersonic spraying

Supersonic spraying is an emerging spraying technology that accelerates powder to a very high speed through supersonic airflow, causing it to produce strong plastic deformation when it hits the substrate, thereby forming a dense coating. This process has low heat input and can effectively avoid thermal damage to the substrate, and is suitable for applications with high requirements for coating quality.

4. Application fields of ceramic primer

Ceramic primer is widely used in aerospace, automotive, energy and other fields. In aircraft engines, ceramic coating can effectively protect engine components from high temperature and corrosion, improving engine performance and life. In automobile manufacturing, ceramic coating is used to protect high-temperature components such as engine components and exhaust systems, improving their durability and reliability. In addition, ceramic primer is also used in high-temperature equipment in the energy field, such as gas turbines, nuclear reactors, etc., to ensure the stable operation of equipment under extreme conditions.

5. Summary

Chengdu Daguang Thermal Spraying Materials Co., Ltd. is committed to providing customers with high-performance ceramic primers with advanced production technology and rich product lines. Our primers not only have excellent high temperature resistance and antioxidant capabilities, but also effectively improve the adhesion and stability of ceramic coatings. With the continuous advancement of technology, we will continue to increase investment in research and development, launch more high-performance products that meet market demand, and provide customers with better services. No matter what type of ceramic primer you need, we can provide you with the most suitable solution, and look forward to working with you to create a better future!