Hastelloy C276: The Premier Alloy for Acid Corrosion Resistance

Hastelloy C276 is renowned for its exceptional resistance to corrosion, particularly in harsh environments involving high concentrations of chloride solutions and hot sulfuric acid. This nickel-based alloy is a preferred choice in various industries due to its remarkable properties, making it one of the most effective materials for combating acid corrosion. In this article, we will delve into the chemical composition, performance characteristics, and applications of Hastelloy C276.

1. Chemical Composition

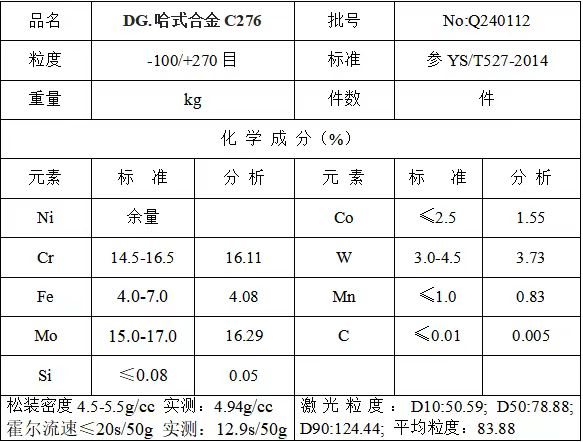

The effectiveness of Hastelloy C276 in resisting corrosion can be attributed to its unique chemical composition, which includes:

Nickel (Ni): Comprising over 57% of the alloy, nickel is a metal known for its excellent corrosion resistance. It provides the alloy with its overall stability and enhances its ability to withstand corrosive environments.

Chromium (Cr): The chromium content ranges from 14.5% to 16.5%. Chromium plays a crucial role in forming a dense oxide layer on the surface of the alloy, which significantly enhances its oxidation resistance and corrosion resistance. This oxide layer helps maintain the stability of the weld in oxidative environments.

Molybdenum (Mo): With a content of 15% to 17%, molybdenum effectively increases the alloy's resistance to corrosive ions, particularly chloride ions. This makes Hastelloy C276 particularly suitable for environments containing chlorides, which are known to cause pitting and stress corrosion cracking.

Tungsten (W): The addition of tungsten (3.5%) further enhances the alloy's corrosion resistance. Tungsten contributes to the overall strength and stability of the alloy.

Iron (Fe): Iron is present at about 4.5%, and cobalt (Co) is included at 1.5%. These elements help adjust the strength of the alloy without significantly compromising its corrosion resistance.

Carbon (C) and Silicon (Si): The contents of carbon and silicon are kept extremely low to minimize any adverse effects on the alloy's corrosion resistance.

This carefully balanced composition allows Hastelloy C276 to excel in environments that would typically degrade other materials.

2. Performance Characteristics of Welded Layers

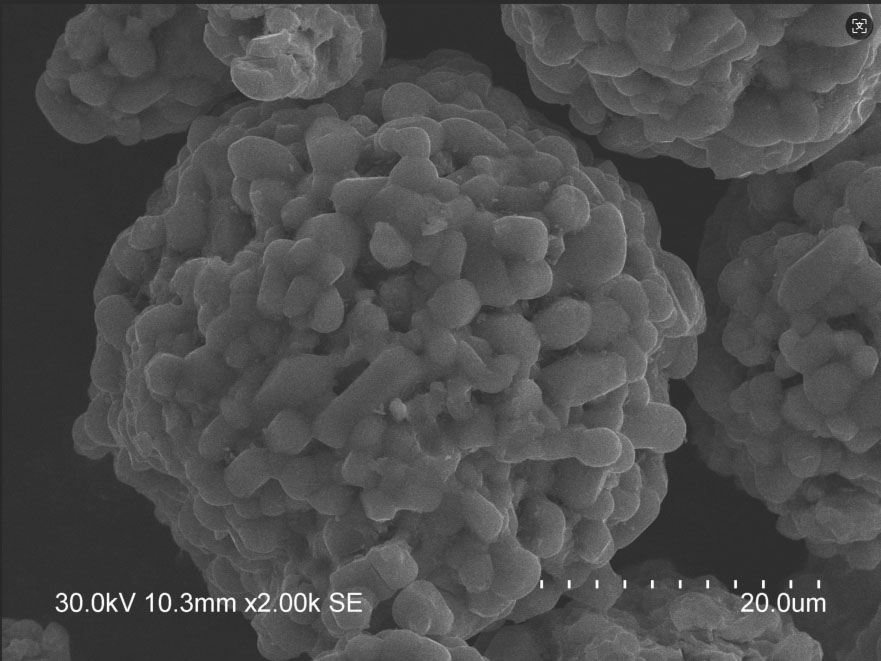

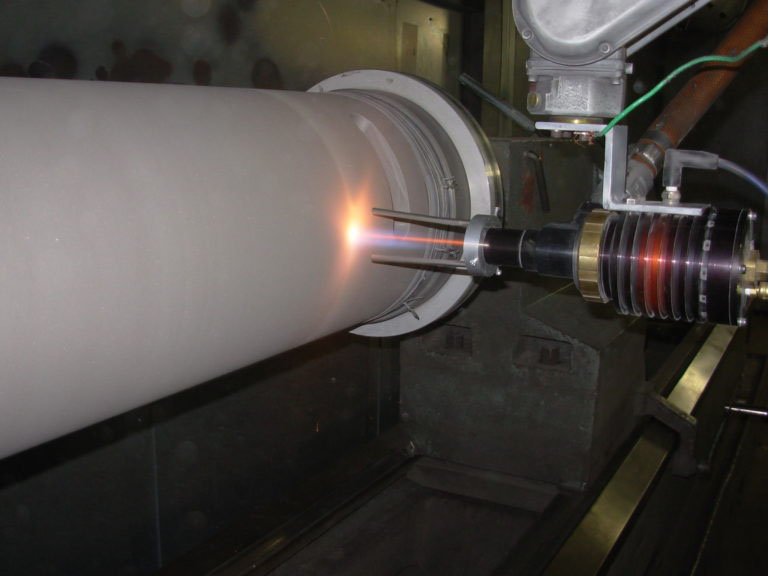

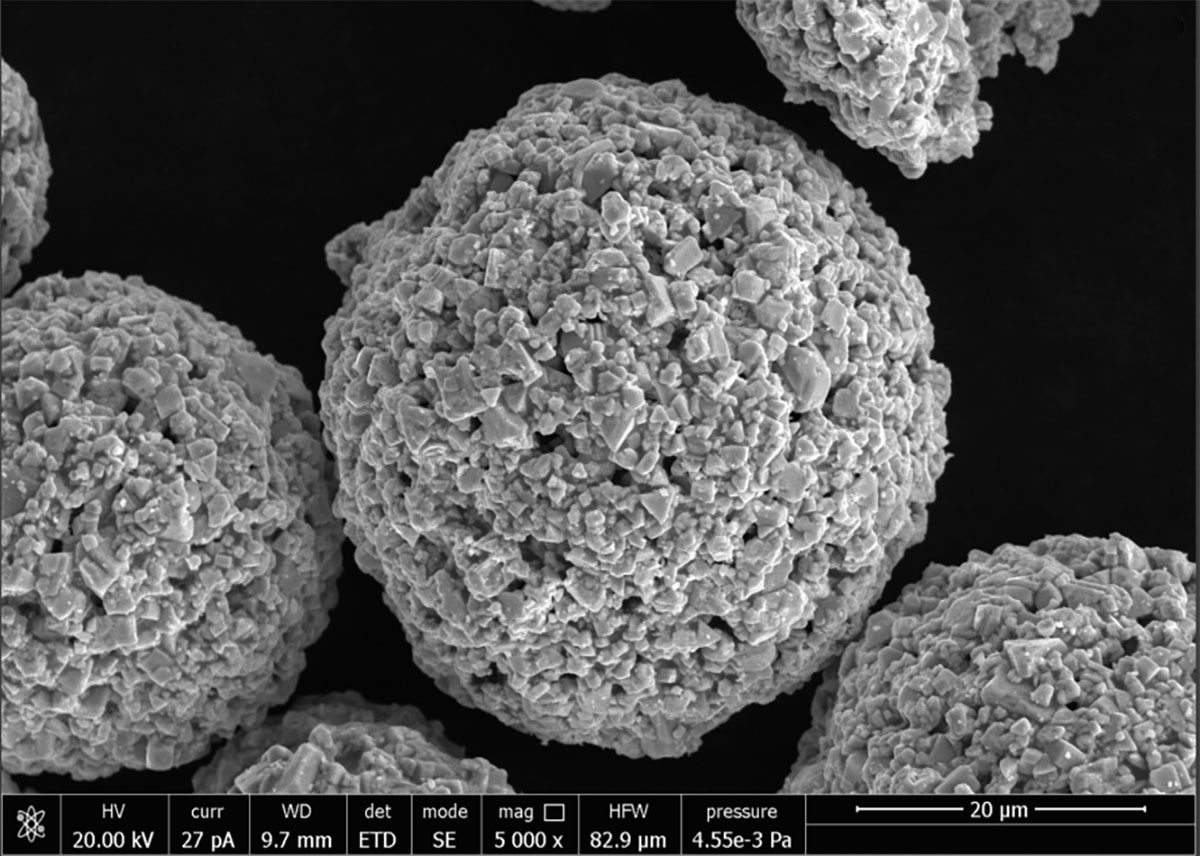

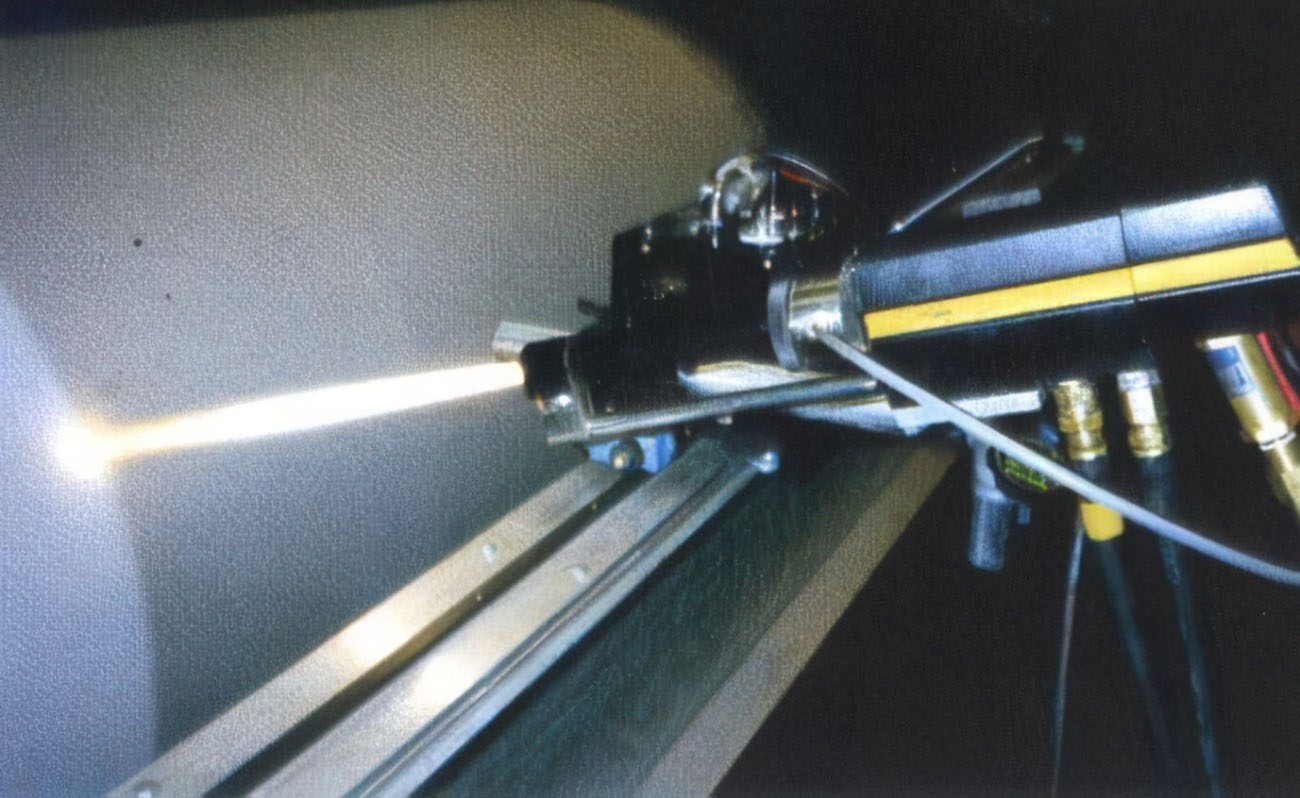

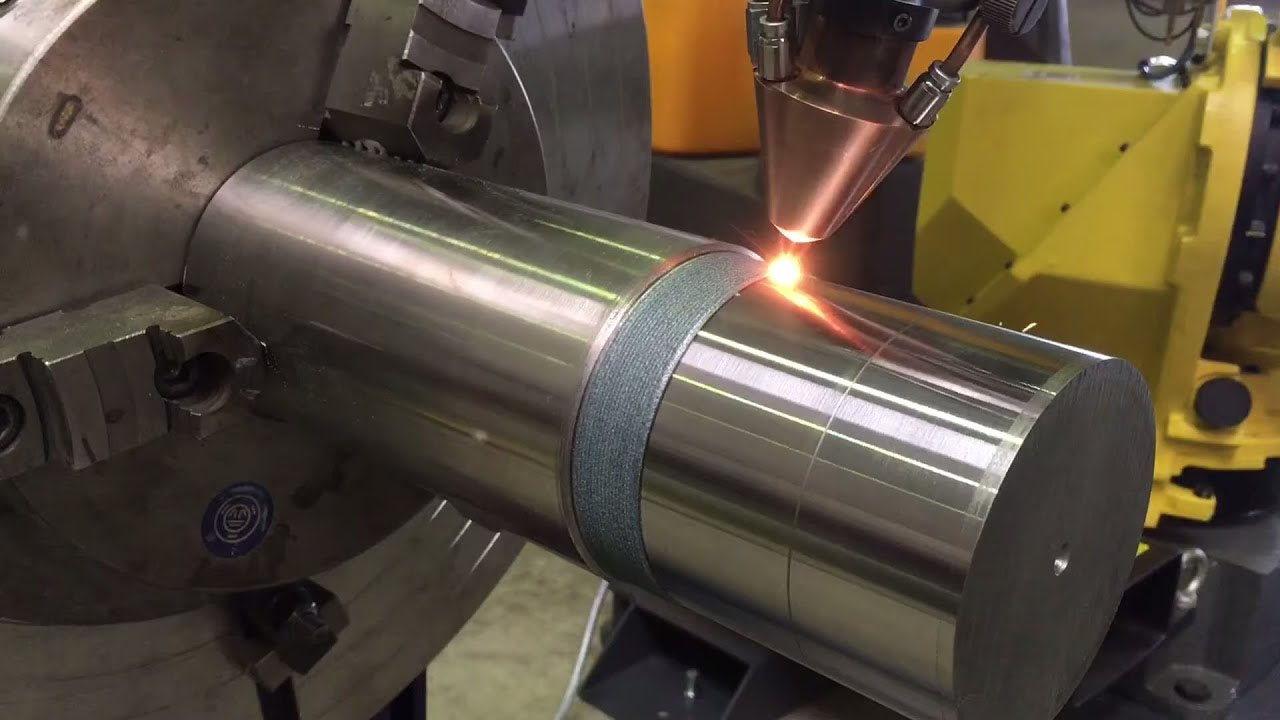

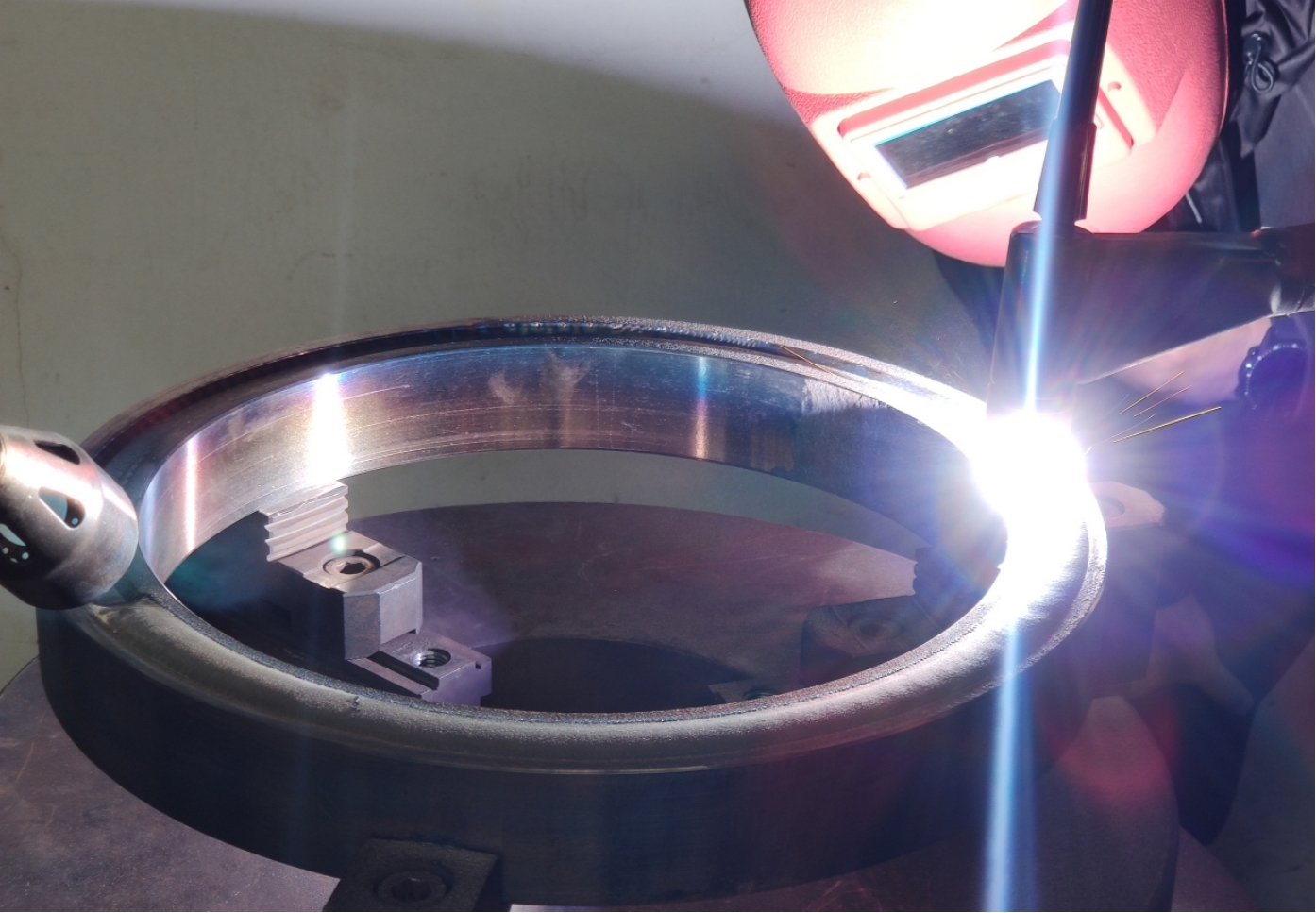

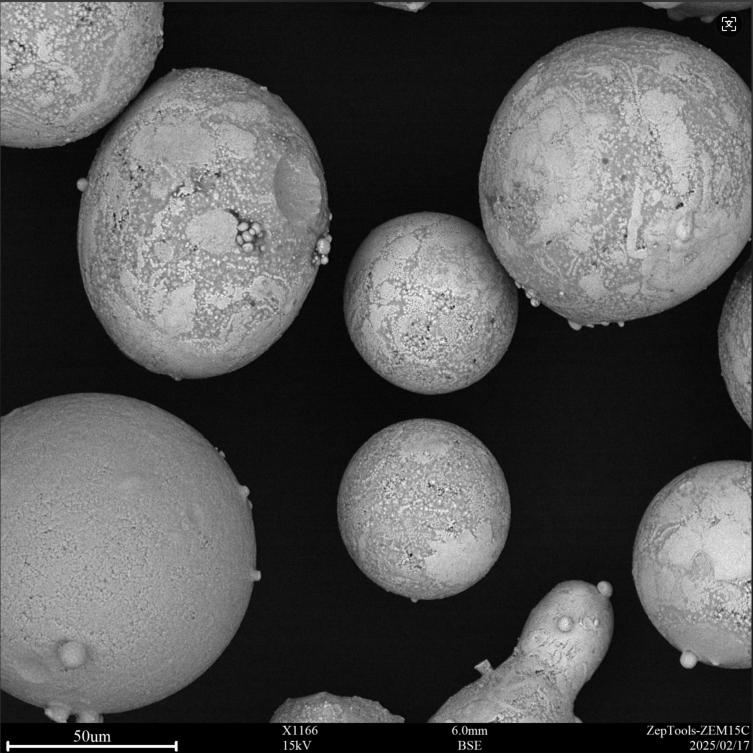

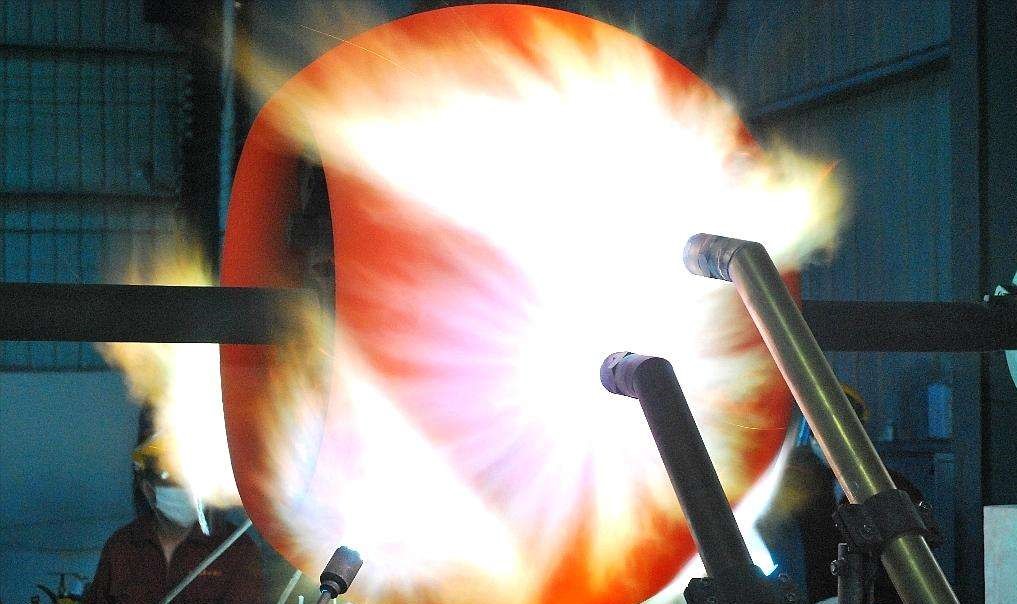

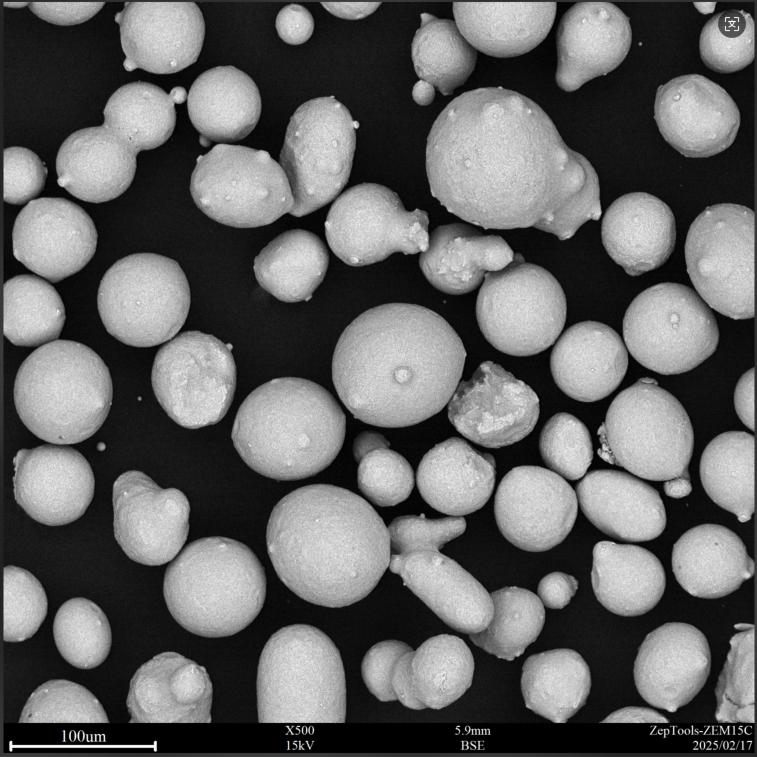

Hastelloy C276 is often processed using advanced techniques such as laser cladding, high-velocity oxygen fuel (HVOF) spraying, or plasma spraying. The melting point of this alloy is approximately 1325-1370°C, which makes it unsuitable for processes like spray welding that operate at lower temperatures. The performance characteristics of welded layers made from Hastelloy C276 include:

1. Exceptional Corrosion Resistance**: The alloy can withstand exposure to wet chlorine, various oxidizing chlorides, and chloride salt solutions. It exhibits remarkable resistance to high concentrations of chloride solutions, such as ferric chloride and cupric chloride. Additionally, Hastelloy C276 performs well in various concentrations of sulfuric acid, particularly in hot concentrated sulfuric acid environments. It is also resistant to hydrochloric acid, hydrofluoric acid, phosphoric acid, and various organic acids.

2. Good High-Temperature Stability**: With a melting point of around 1325-1370°C, Hastelloy C276 maintains its integrity and performance in high-temperature applications, making it suitable for long-term use in extreme conditions.

3. Excellent Toughness and Ductility**: The alloy's microstructure features a face-centered cubic lattice, which contributes to its toughness and ductility. This structure allows the material to adapt to various complex processing and operational conditions without compromising its performance.

3. Major Applications

Hastelloy C276 is widely used across several industries due to its outstanding properties. Some of the primary application areas include:

Chemical and Petrochemical Industries: Hastelloy C276 is extensively used in components and catalytic systems that come into contact with chlorinated organic compounds. It is commonly found in flue gas desulfurization systems, reaction vessels, pipelines, and heat exchangers, where it provides reliable performance in corrosive environments.

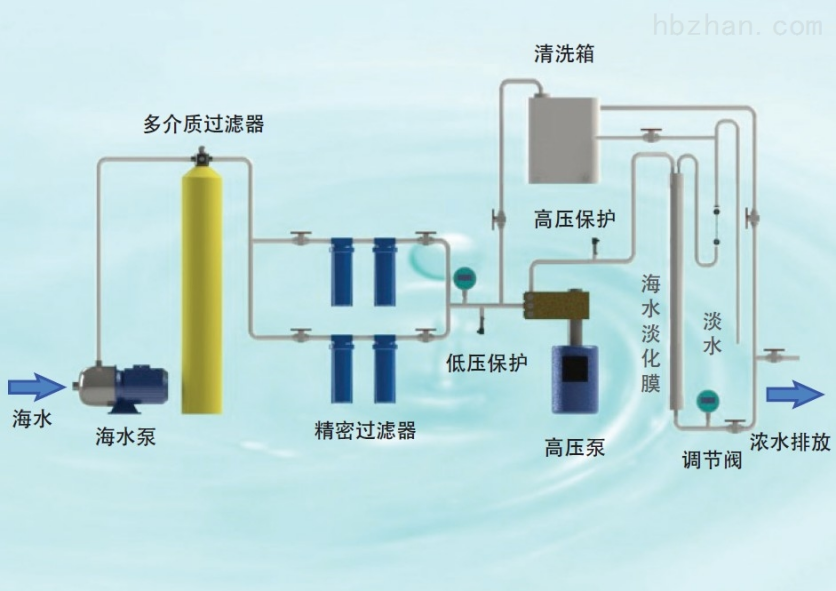

Marine Engineering: The alloy is suitable for equipment and structures in seawater environments, such as offshore platforms and seawater desalination plants. Its resistance to pitting and crevice corrosion makes it ideal for marine applications.

Pulp and Paper Industry: Hastelloy C276 is utilized in cooking and bleaching vessels, where it is exposed to aggressive chemicals and high temperatures. Its durability ensures the longevity of equipment in this demanding environment.

Aerospace Industry: The alloy is also used in aerospace applications, particularly in components that require high corrosion resistance and thermal stability. Hastelloy C276 is employed in various parts of aircraft engines and other critical systems.

Pharmaceutical and Food Processing: In industries where hygiene and corrosion resistance are paramount, Hastelloy C276 is used in equipment that processes chemicals and food products. Its ability to withstand aggressive cleaning agents and high temperatures makes it a preferred choice.

4. Advantages of Hastelloy C276

The use of Hastelloy C276 offers several advantages, making it a top choice for applications requiring high corrosion resistance:

Versatility: The alloy's ability to resist a wide range of corrosive environments makes it suitable for various applications across multiple industries.

Longevity: Components made from Hastelloy C276 tend to have a longer service life due to their resistance to corrosion and high-temperature stability, reducing the need for frequent replacements.

Cost-Effectiveness: While Hastelloy C276 may have a higher initial cost compared to other materials, its durability and performance can lead to significant cost savings over time by minimizing maintenance and replacement expenses.

Ease of Fabrication: The alloy can be easily fabricated and welded using standard techniques, allowing for flexibility in design and manufacturing processes.

5. Conclusion

Hastelloy C276 stands out as one of the most effective materials for resisting acid corrosion, particularly in environments involving high concentrations of chlorides and aggressive acids. Its unique chemical composition, combined with its exceptional performance characteristics, makes it a preferred choice in various industries, including chemical processing, marine engineering, aerospace, and more.

As industries continue to face challenges related to corrosion and material degradation, the demand for high-performance alloys like Hastelloy C276 is expected to grow. Its ability to withstand harsh conditions while maintaining structural integrity positions it as a critical material for ensuring the reliability and longevity of equipment in demanding applications. Whether in chemical reactors, offshore platforms, or aerospace components, Hastelloy C276 remains a trusted solution for engineers and manufacturers seeking to enhance performance and durability in corrosive environments.