Laser cladding nickel-based high-temperature alloy Inconel625

Inconel 625 material introduction

1. Basic composition

Inconel 625 is a nickel-chromium-molybdenum-niobium (Ni-Cr-Mo-Nb) high-temperature alloy, the specific composition is:

Nickel (Ni): ≥58% (matrix, providing high temperature strength and corrosion resistance)

Chromium (Cr): 20-23% (anti-oxidation and corrosion resistance)

Molybdenum (Mo): 8-10% (enhanced resistance to pitting and crevice corrosion)

Niobium (Nb): 3-4% (synergistic strengthening with molybdenum to prevent intergranular corrosion)

Iron (Fe): ≤5% (impurity control)

2. Core performance

High temperature resistance: long-term use temperature can reach 980℃, short-term use temperature can reach 1150℃

Corrosion resistance: resistant to seawater, chlorides, acidic media (such as sulfuric acid, hydrochloric acid)

High strength: room temperature tensile strength ≥830MPa, still maintain good mechanical properties at high temperature

Anti-oxidation: Excellent performance in high-temperature oxidation and sulfidation environments

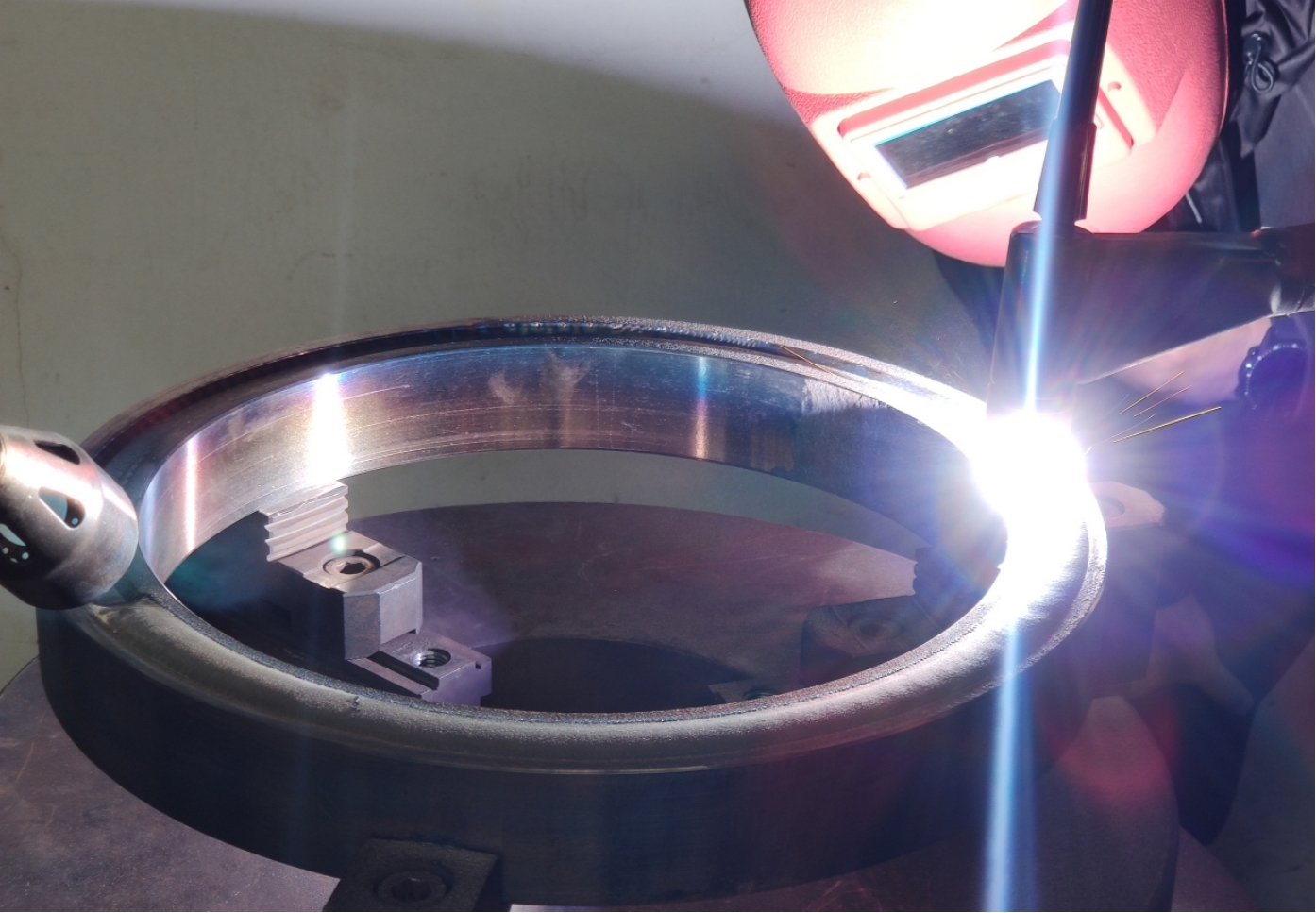

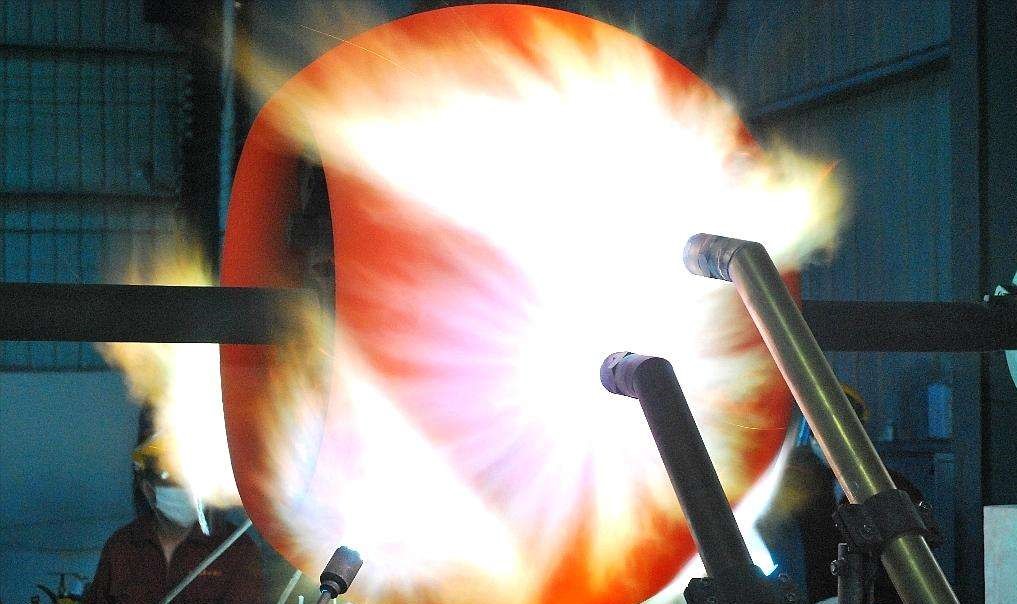

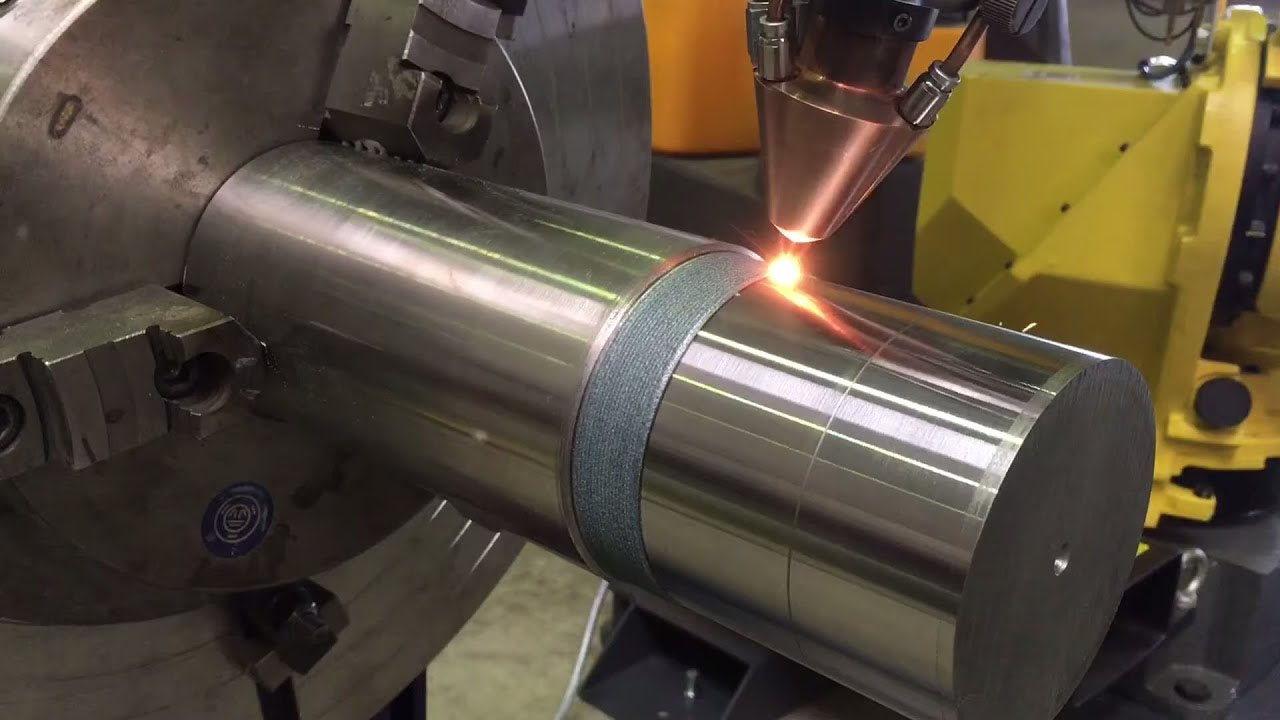

Laser cladding processing Inconel 625

1. Process characteristics

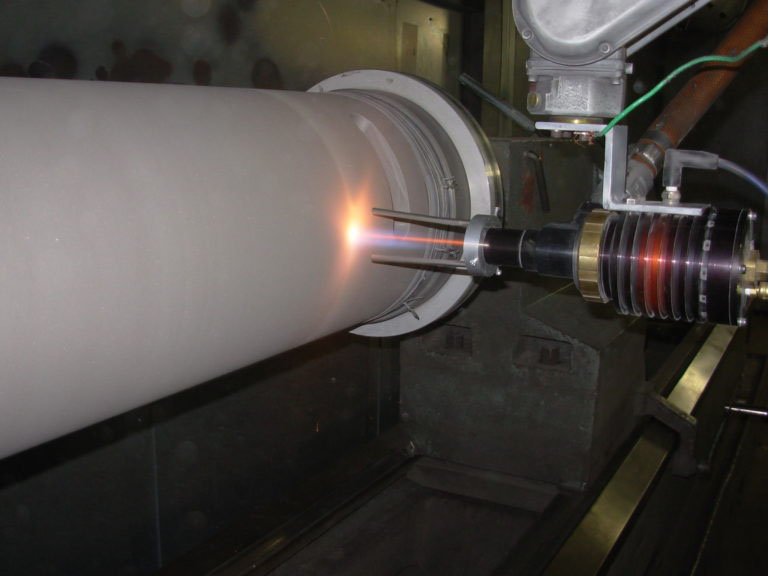

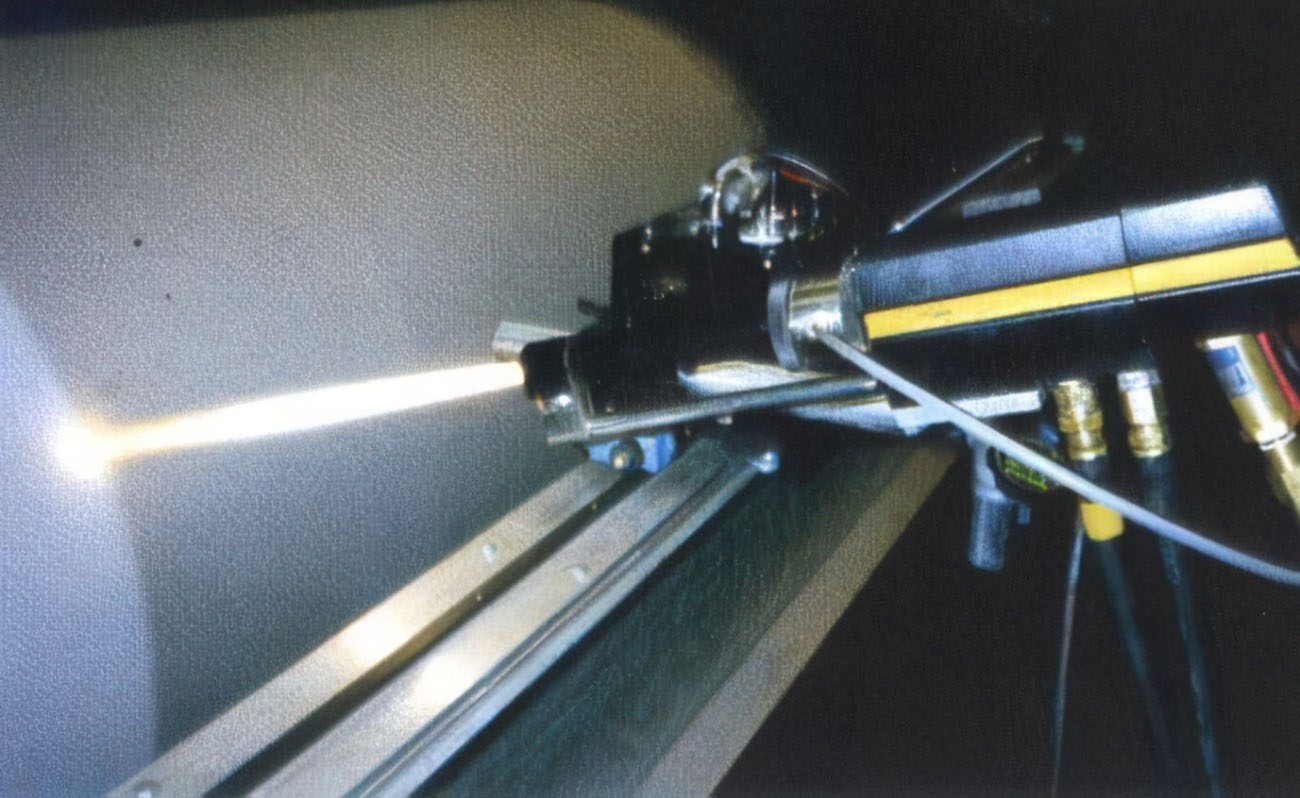

Laser cladding melts Inconel 625 powder through a high-energy laser beam to form a metallurgical bonding layer on the surface of the substrate, which has the following advantages:

Low heat input: Reduce substrate deformation and heat-affected zone

High bonding strength: Metallurgical bonding, bonding force ≥400MPa

Precision control: The thickness of the cladding layer is adjustable from 0.2-3mm, suitable for high-precision repair

2. Typical applications

Aerospace: Turbine blade tip repair, combustion chamber component strengthening

Energy and power: High temperature resistant coating of gas turbine blades, sealing surface of nuclear power valves

Petrochemical: Corrosion and wear resistant repair of pump shafts and valve stems

Marine engineering: Seawater pump housing, propeller shaft anti-corrosion coating

3. Process parameter control

Laser power: 1000-3000W (adjusted according to cladding thickness)

Scanning speed: 5-20mm/s (too low speed will cause overheating, too high speed will cause unfused)

Powder feeding amount: 10-30g/min (matching with laser power)

Shielding gas: argon (purity ≥99.99%), to prevent oxidation

4. Common problems and countermeasures

Cracks: preheat the substrate to 300-400℃ (especially for high carbon steel substrate)

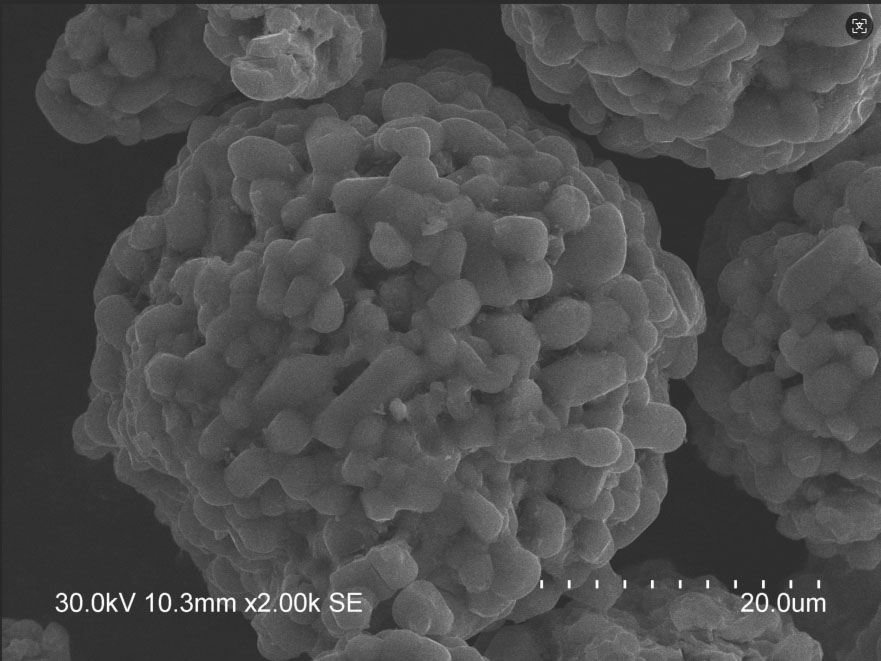

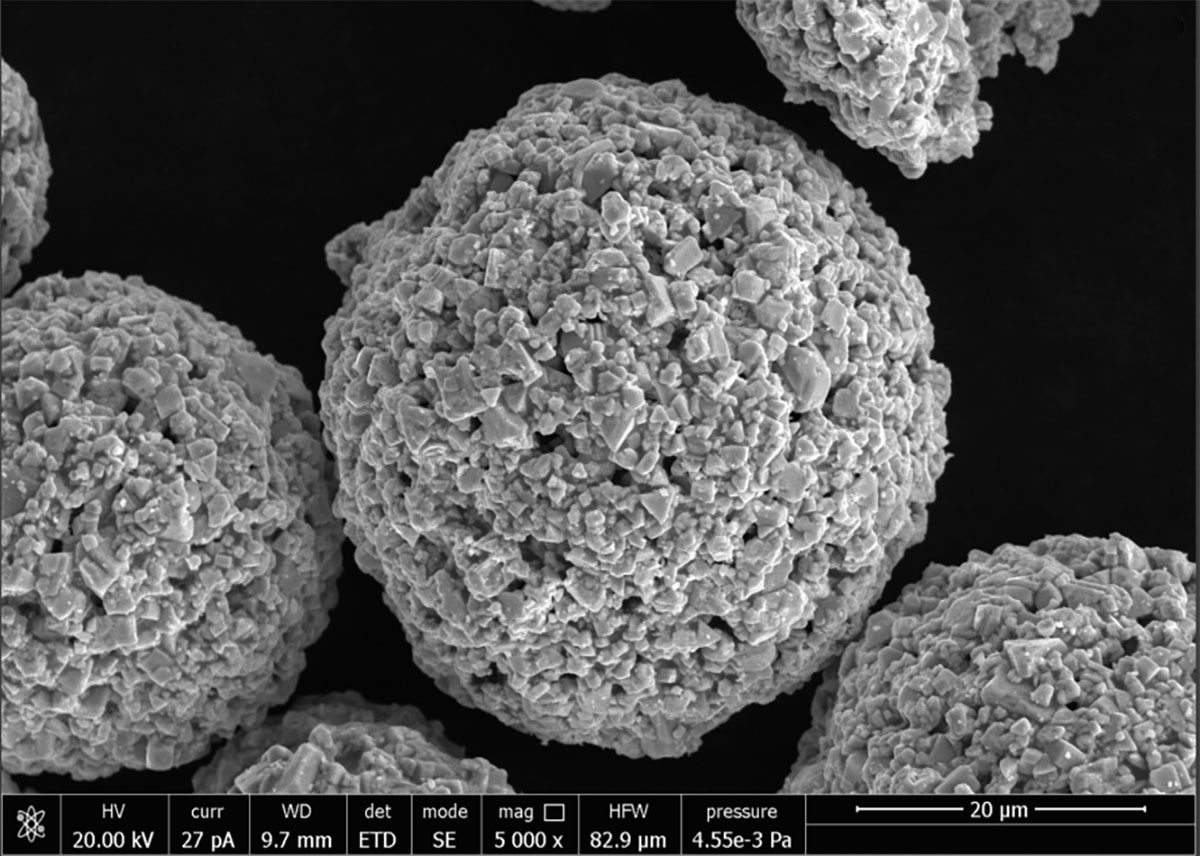

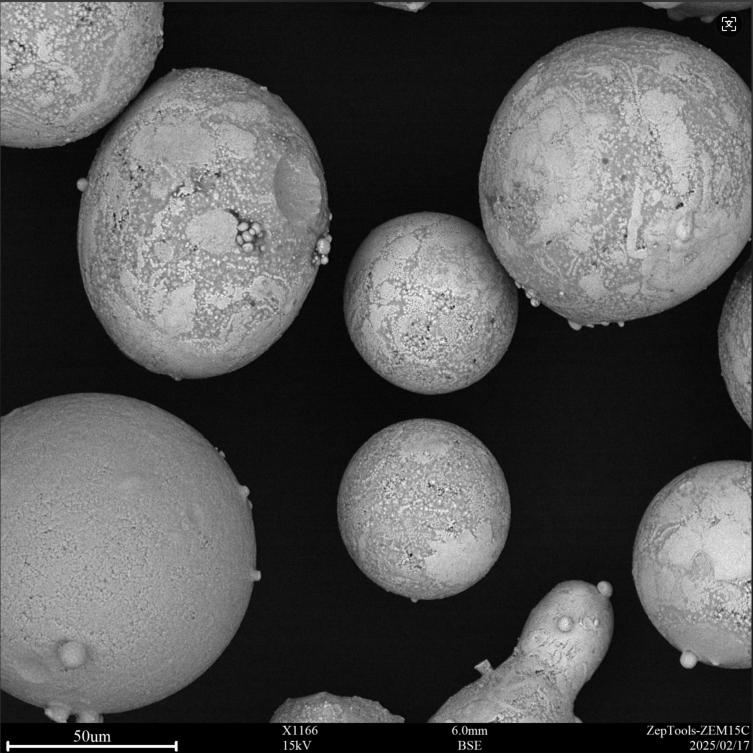

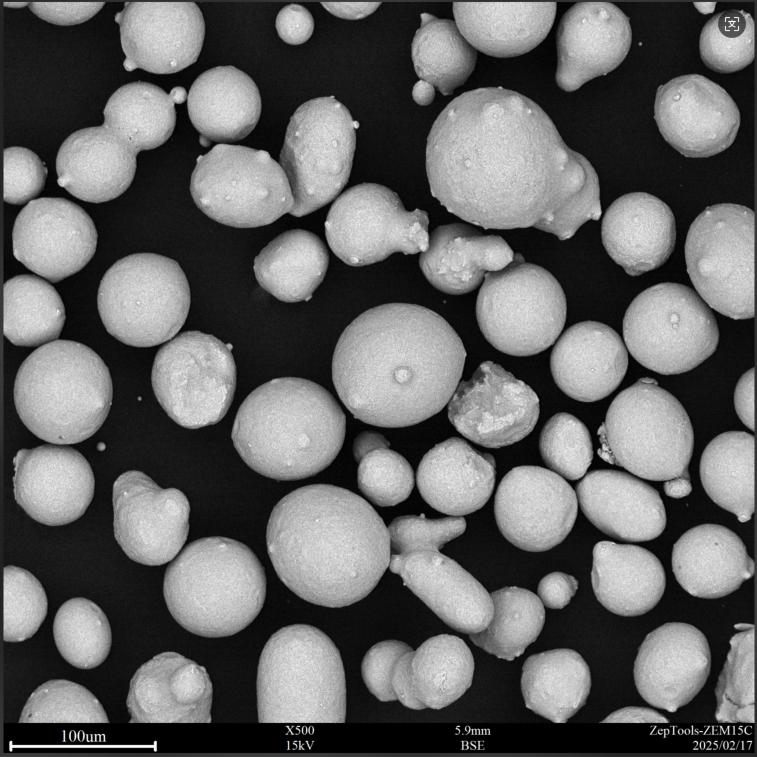

Porosity: optimize powder feeding uniformity and avoid powder moisture

Residual stress: 600-800℃ stress relief annealing after cladding

Laser cladding Inconel 625 is suitable for precision repair and strengthening of high value-added components, but parameters need to be strictly optimized to ensure quality.