Ni60CuMo is a better material than Ni60A

Ni60CuMo is a reinforced material improved by adding copper (Cu) and molybdenum (Mo) elements to the standard Ni60 (NiCrBSi) alloy, which mainly improves corrosion resistance, thermal conductivity and high temperature stability.

1. Material composition and strengthening mechanism

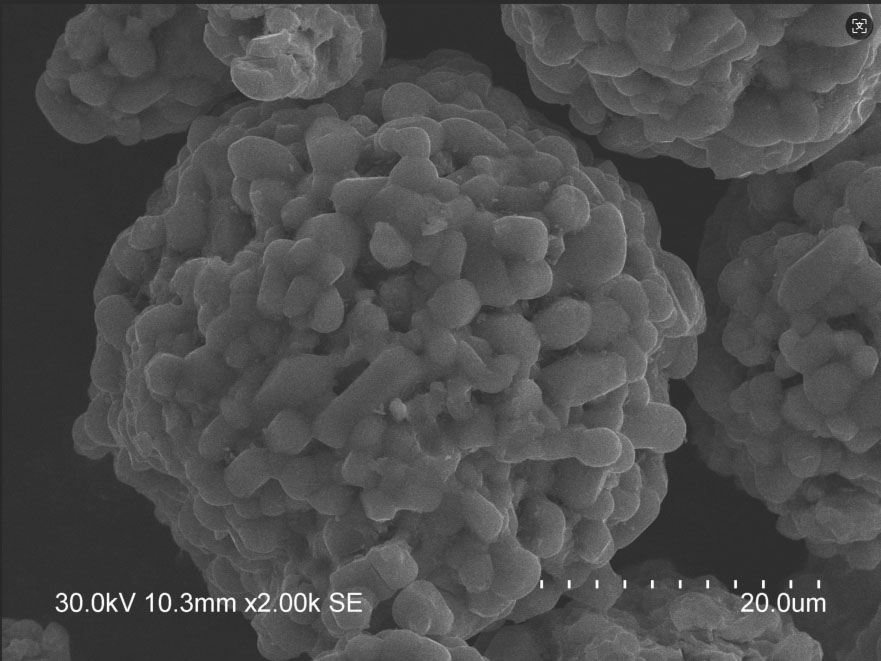

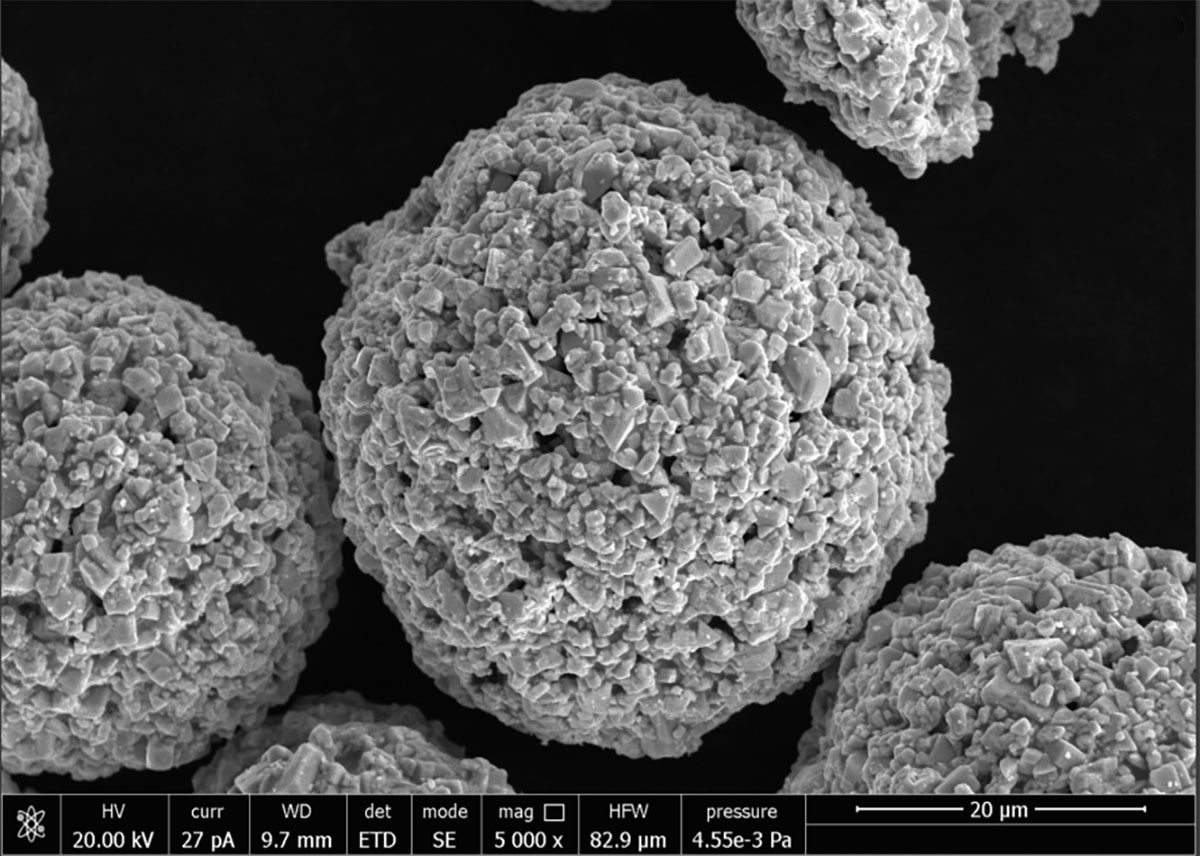

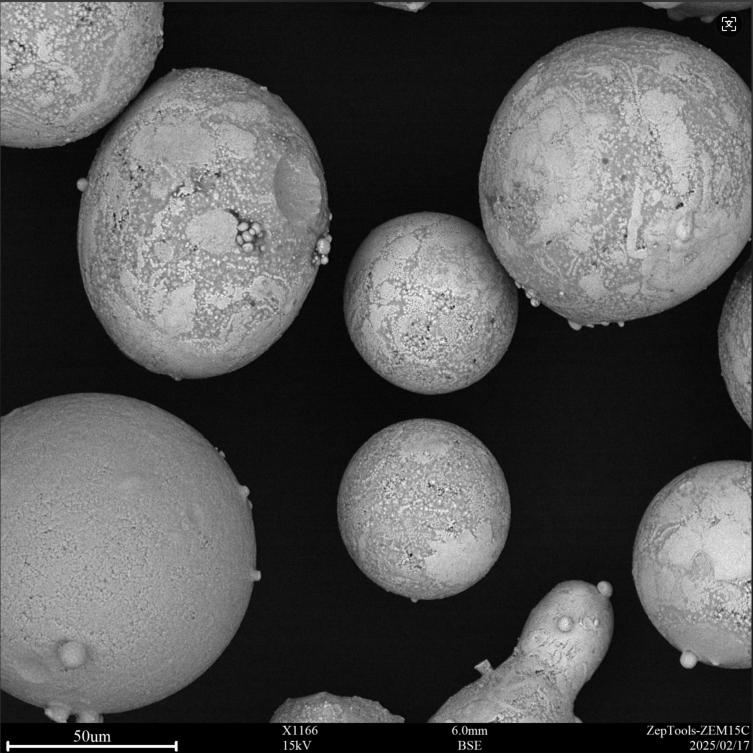

Basic composition: mainly nickel (Ni), chromium (Cr) 15-20%, boron (B) 3-4.5%, silicon (Si) 4-5.5% (same as Ni60).

Key added elements:

Copper (Cu) (5-10%): improve thermal conductivity and enhance resistance to non-oxidizing acid (such as sulfuric acid, hydrochloric acid) corrosion.

Molybdenum (Mo) (2-5%): improve high temperature strength, resistance to pitting and chloride ion stress corrosion (especially suitable for chemical and marine environments).

2. Performance advantages (compared with Ni60)

Corrosion resistance: It performs better in acidic and seawater media, for example, the corrosion resistance to sulfuric acid is improved by more than 30%.

High temperature performance: The addition of molybdenum enhances the red hardness and can work for a long time below 700℃ (Ni60 is usually limited to 600℃).

Wear resistance: It retains the high hardness of Ni60 (HRC 55-60), and at the same time, due to the lubrication of copper, the friction reduction performance is slightly better.

3. Typical application scenarios

Chemical equipment:

Sulfuric acid pump impeller, hydrochloric acid reactor stirring shaft.

Petrochemical industry valve sealing surface (resistant to sulfide corrosion).

Marine engineering:

Seawater desalination pump parts, marine propeller sleeves.

Energy field:

Geothermal well drilling tools (resistant to high temperature brine corrosion).

Nozzles for desulfurization systems in coal-fired power plants.

Special wear-resistant parts:

Copper alloy roll repair (due to the addition of Cu, the difference in thermal expansion with the copper matrix is reduced).

4. Key points of processing technology

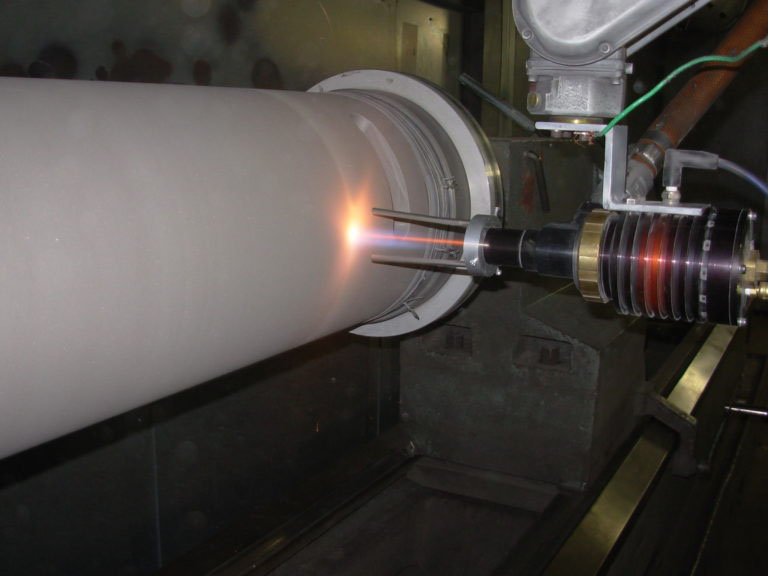

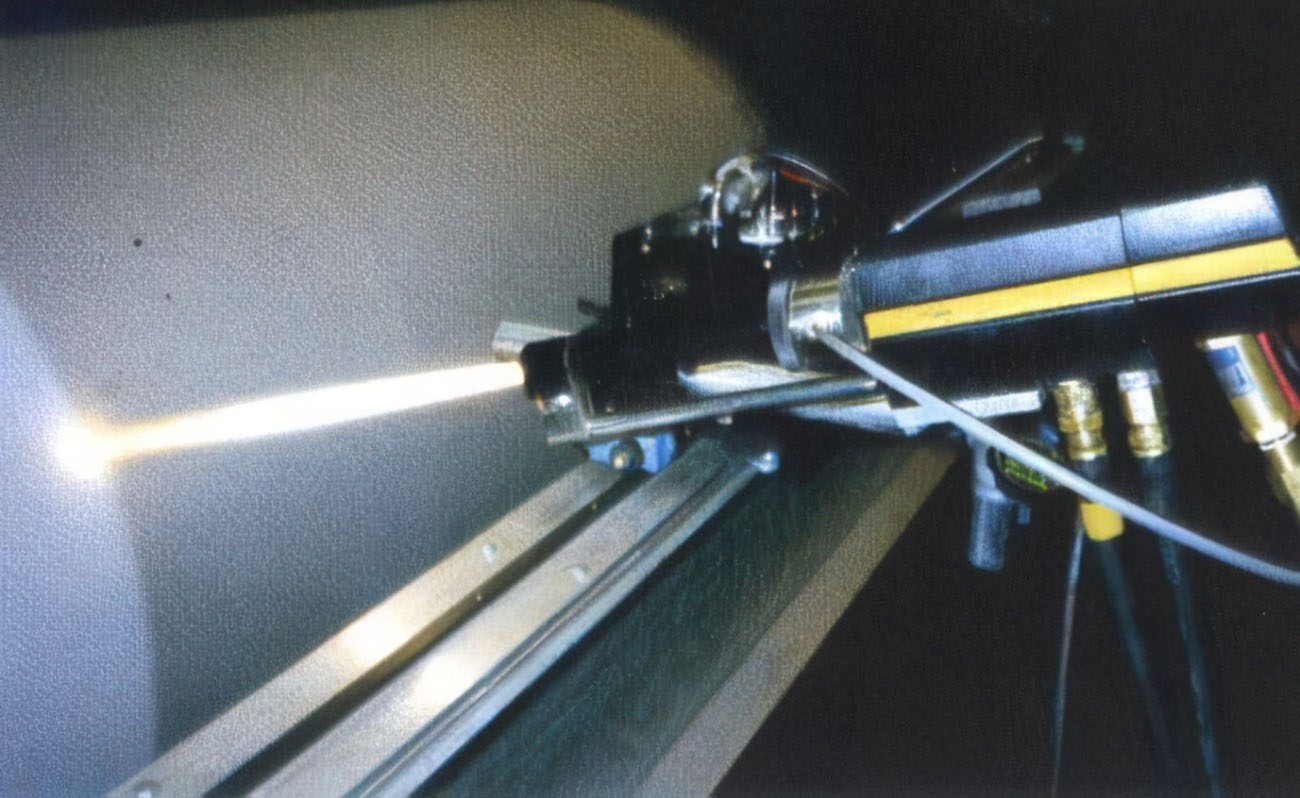

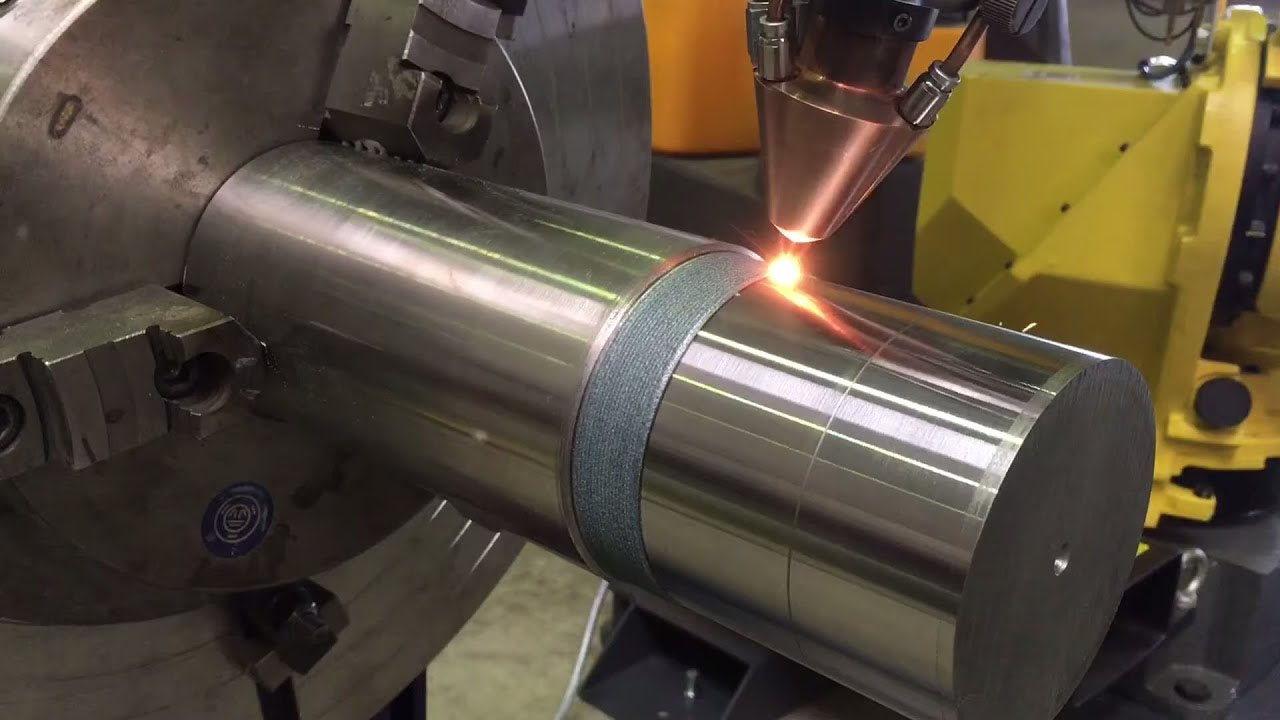

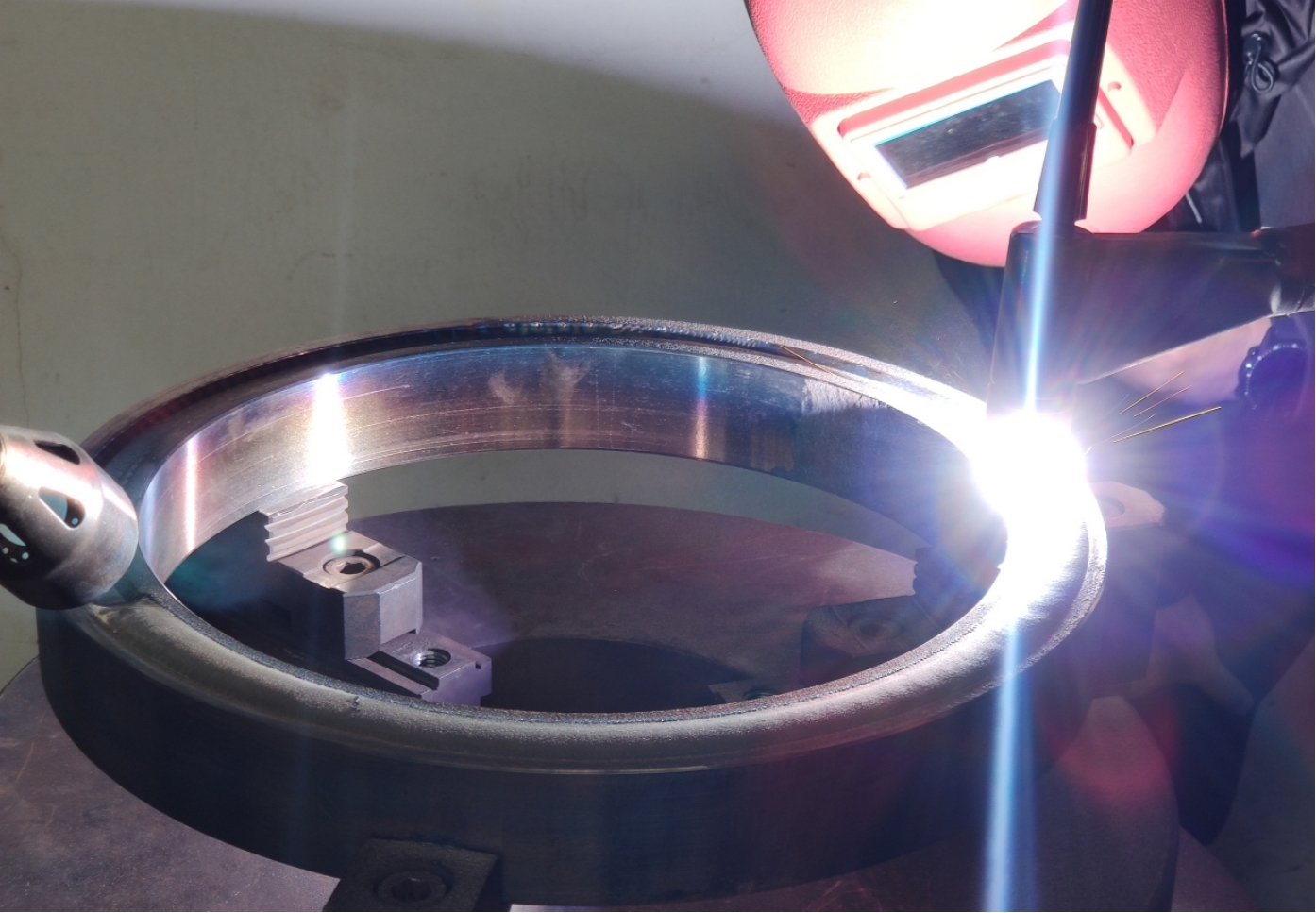

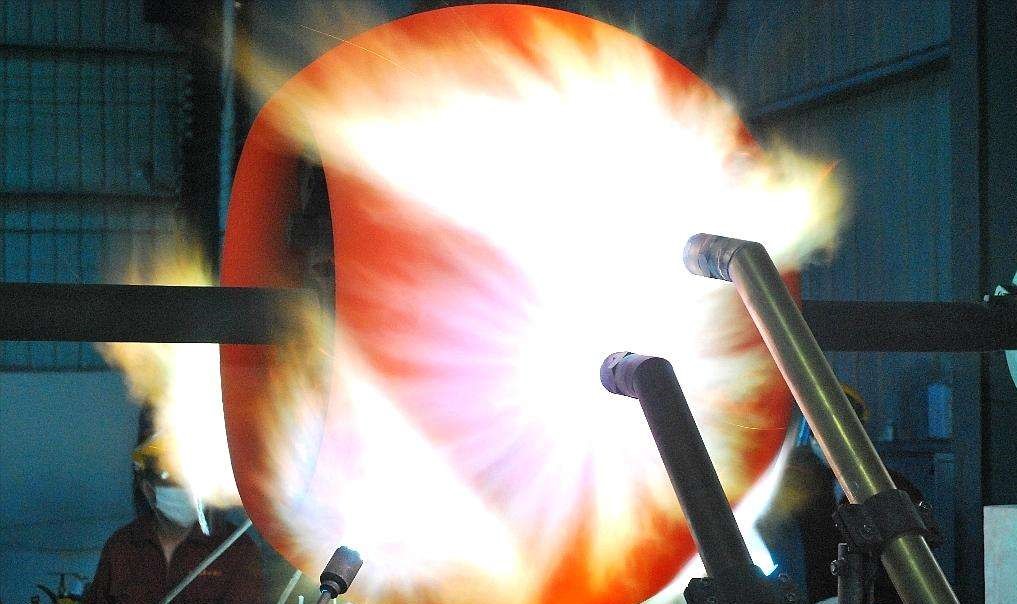

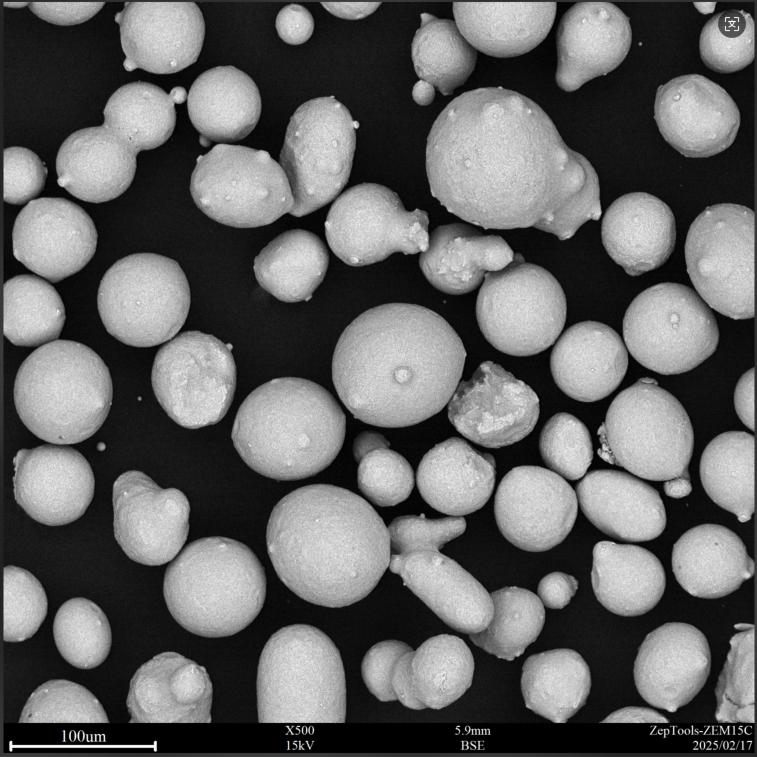

Recommended process: plasma surfacing or laser cladding (oxyacetylene spray welding is prone to Cu oxidation).

Parameter control:

Preheating temperature: 200-350℃ (high molybdenum content requires higher preheating to prevent cracking).

Interlayer temperature: ≤150℃ to avoid segregation of copper elements.

Post-treatment: 600-650℃ tempering can reduce residual stress and improve toughness.

Ni60CuMo is an upgraded version of Ni60, especially suitable for harsh working conditions where corrosion and wear coexist, but the cost is about 20-30% higher than Ni60.