Preparation Method of WC88%-12%Co Powder

The preparation of WC88%-12%Co powder, a tungsten carbide-based thermal spray powder, involves several key steps to ensure the desired properties and particle size distribution. This powder is widely used in various applications due to its excellent hardness, wear resistance, and thermal stability. Below is a detailed description of the preparation process.

1. Material Selection and Initial Mixing

The process begins with the selection of raw materials. For the preparation of WC88%-12%Co powder, 88 wt% tungsten carbide (WC) powder and 12 wt% cobalt (Co) powder are chosen as the primary components. These materials are known for their excellent mechanical properties, making them suitable for high-performance applications.

The tungsten carbide powder and cobalt powder are added to a ball mill. To facilitate the milling process, deionized water is introduced to control the solid content to 75%. The use of deionized water helps prevent contamination and ensures a uniform mixture. The wet milling process is carried out for 12 hours, allowing the powders to achieve a fine and homogeneous mixture.

2. Particle Size Reduction

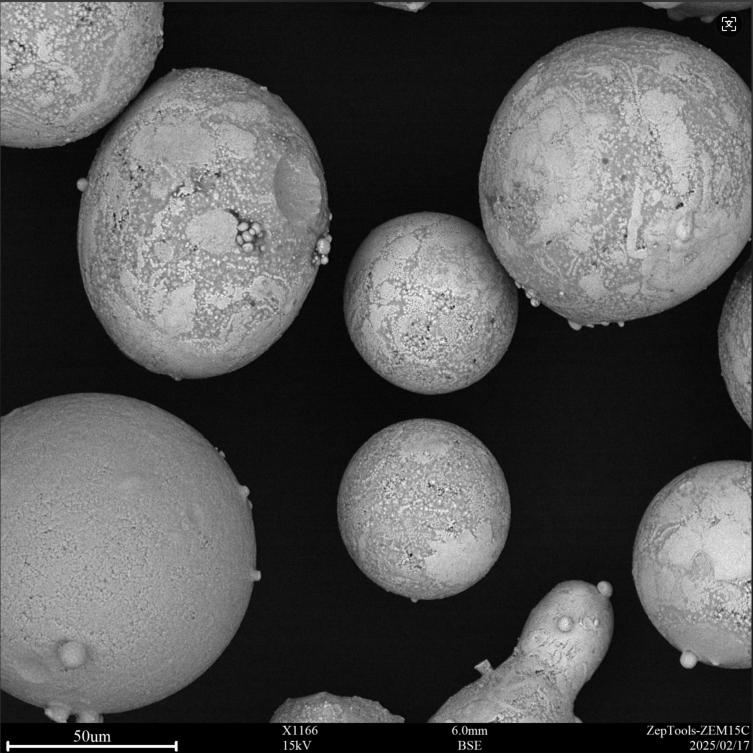

After the wet milling process, the average particle size of the mixed powder is reduced to approximately 0.1 to 10 micrometers. This fine particle size is crucial for achieving a uniform and dense final product. To further enhance the properties of the powder, 2 wt% polyethylene glycol (PEG) is added to the mixed powder. The PEG acts as a binder and helps improve the flowability of the powder during subsequent processing.

The mixture is stirred for 2 hours to ensure that the PEG is evenly distributed throughout the powder. This step is essential for achieving consistent properties in the final product.

3. Granulation

The next step involves granulating the mixed powder using a spray drying tower. The inlet temperature of the spray dryer is controlled at 260°C, while the outlet temperature is maintained at 110°C. This temperature control is critical to ensure that the powder is dried effectively without causing degradation of the materials.

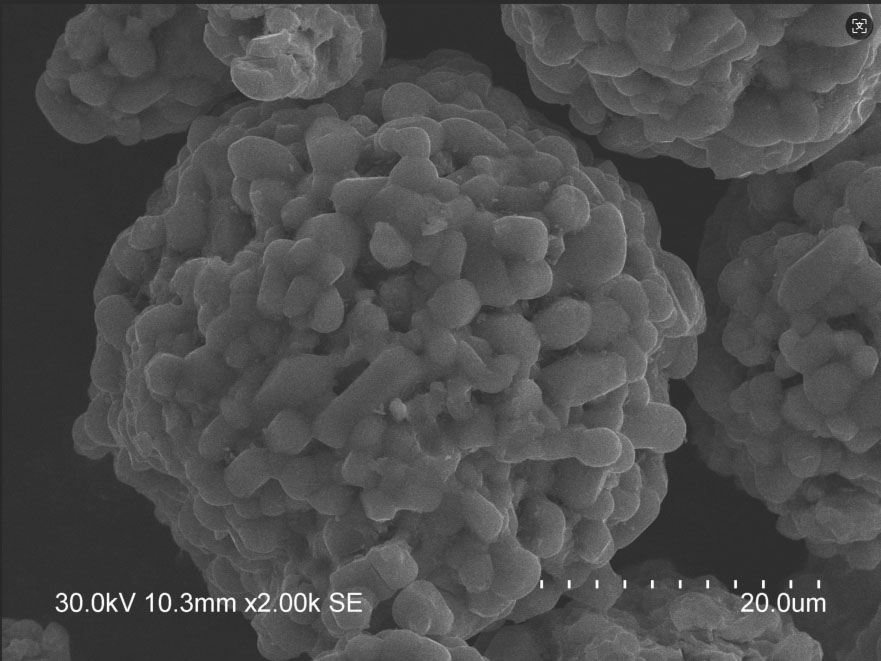

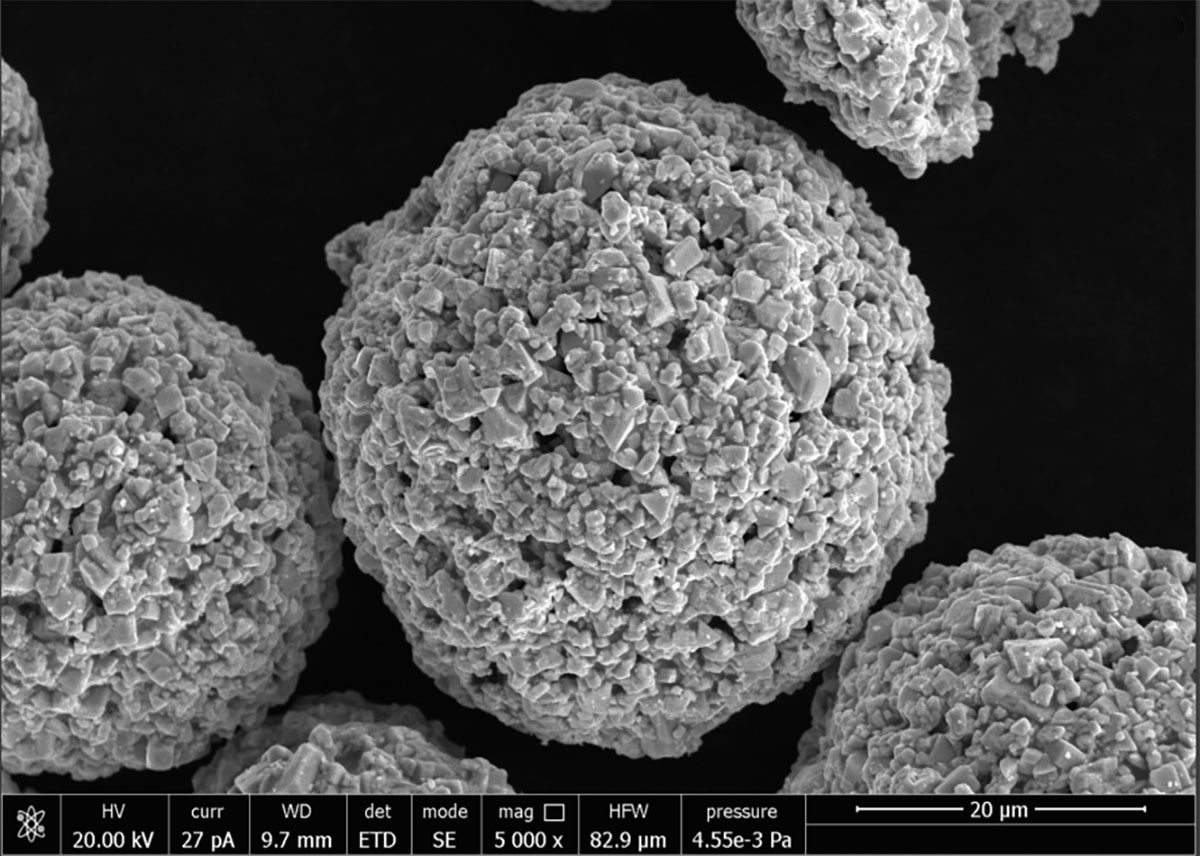

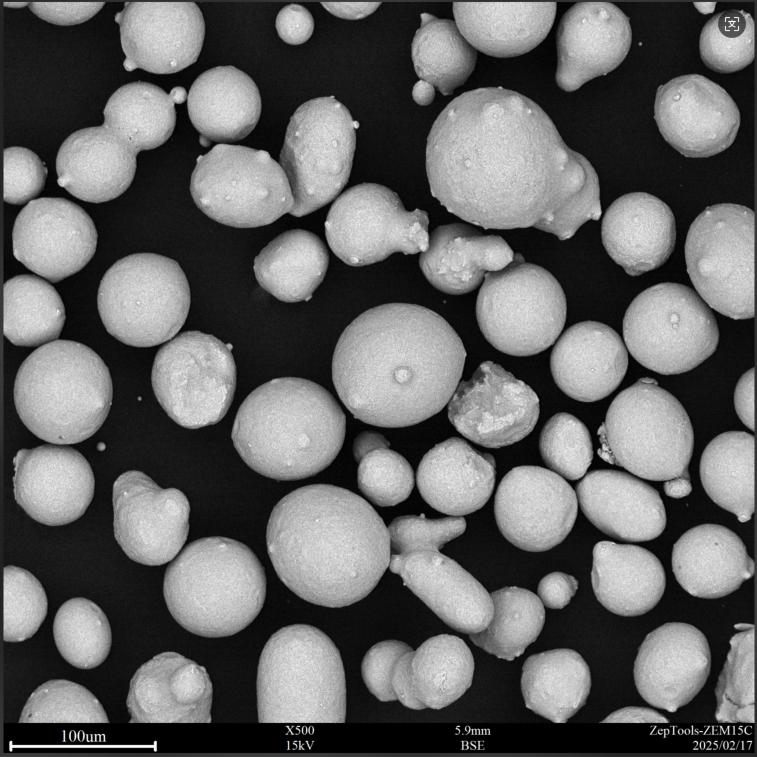

During the spray drying process, the liquid mixture is atomized into fine droplets, which are then dried rapidly as they pass through the hot air in the drying chamber. This results in the formation of granulated powder, which is easier to handle and process in subsequent steps.

4. Screening and Size Classification

Once the granulated powder is obtained, it is passed through a dual-layer vibrating screen with mesh sizes of 200 mesh and 900 mesh. This screening process separates the powder based on particle size, yielding a fraction with a particle size distribution of 15 to 75 micrometers.

The powder retained on the 200 mesh screen and the powder passing through the 900 mesh screen are both returned to the wet milling process. This recycling ensures that all particles are within the desired size range, contributing to the uniformity of the final product.

5. Debinding Process

The next step is the debinding process, where the granulated powder is subjected to thermal treatment in a tube furnace. The temperature is set at 800°C, and the duration is maintained for 4 hours. This step is crucial for removing the polyethylene glycol binder from the granulated powder.

During the debinding process, the PEG decomposes and evaporates, leaving behind a clean powder that is ready for sintering. This step is essential to ensure that the final product has the desired density and mechanical properties.

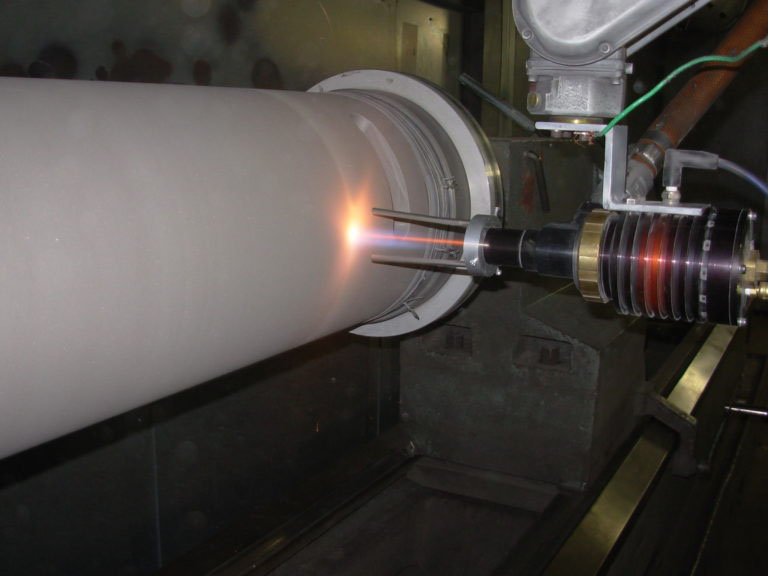

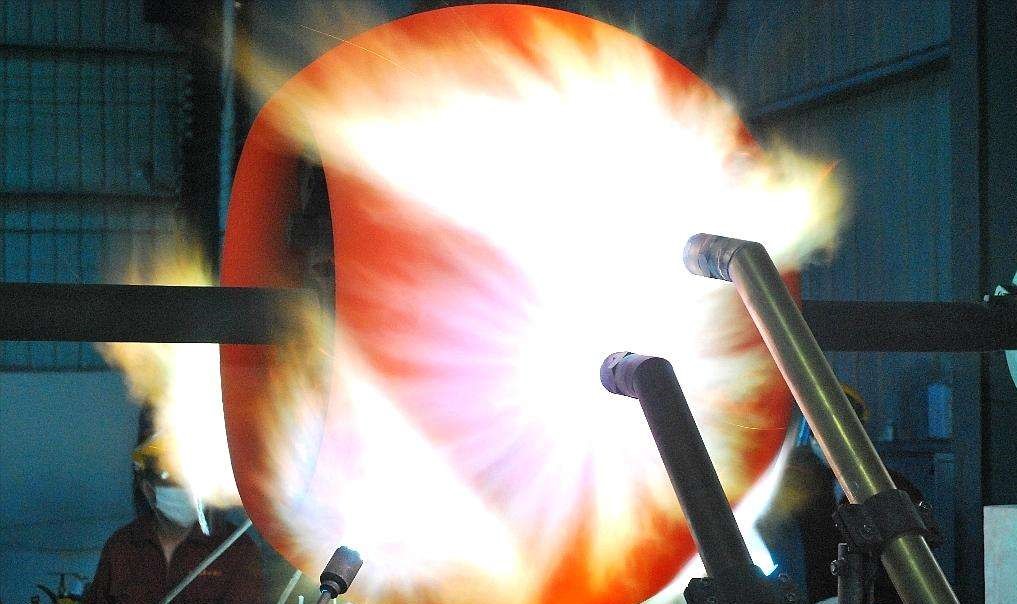

6. Sintering

After debinding, the powder is subjected to rapid sintering in a vertical high-temperature sintering furnace. The powder is allowed to fall freely through the heating and cooling zones, ensuring uniform heating and cooling. The feeding method for the powder is through a vibrating screen, and nitrogen gas is used as a protective atmosphere during the sintering process.

The sintering temperature is set at 1250°C, and the duration is controlled at 0.4 seconds. This rapid sintering process allows for the formation of a dense and strong sintered body while minimizing the risk of oxidation and contamination.

7. Particle Size Classification

Once the sintering process is complete, the sintered powder is subjected to air flow classification to separate particles within the desired size range of 15 to 45 micrometers. This classification step ensures that the final product meets the specifications required for thermal spraying applications.

The resulting WC88%-12%Co powder exhibits excellent properties, making it suitable for various thermal spray processes. The typical particle sizes available include 5-30 micrometers, 10-38 micrometers, 15-45 micrometers, and 45-75 micrometers. Custom particle size distributions can also be provided based on specific customer requirements.

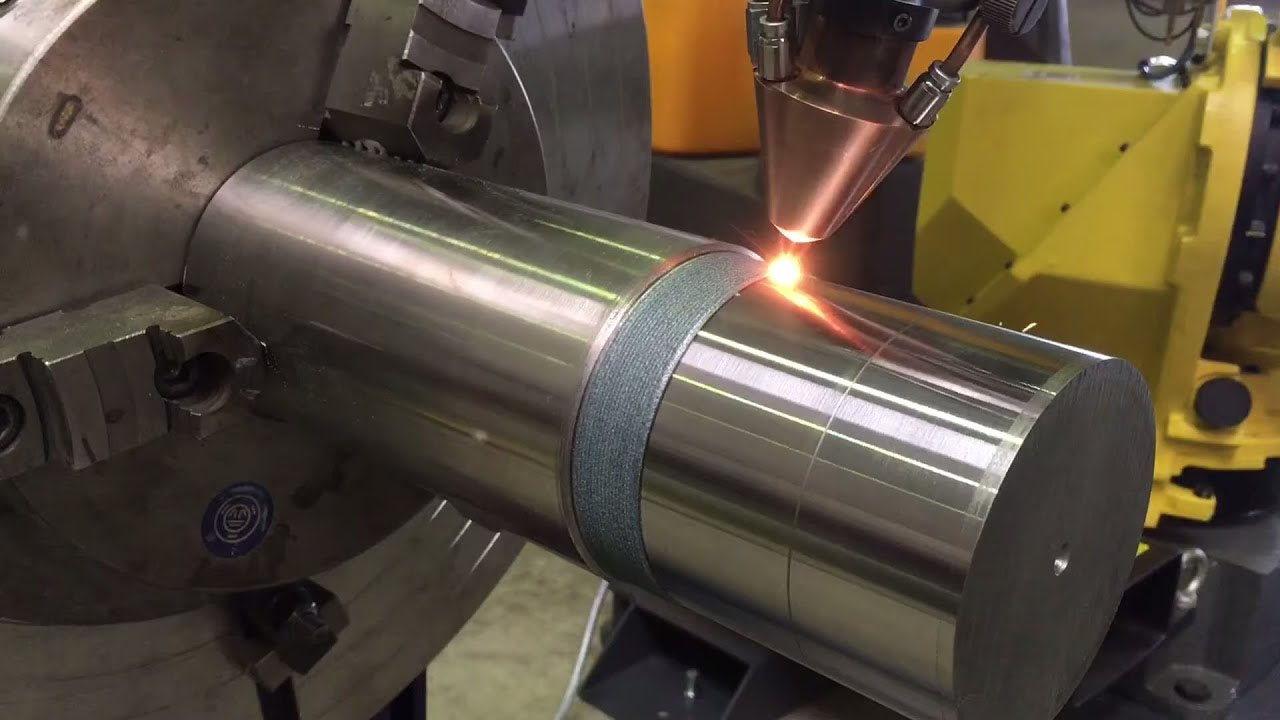

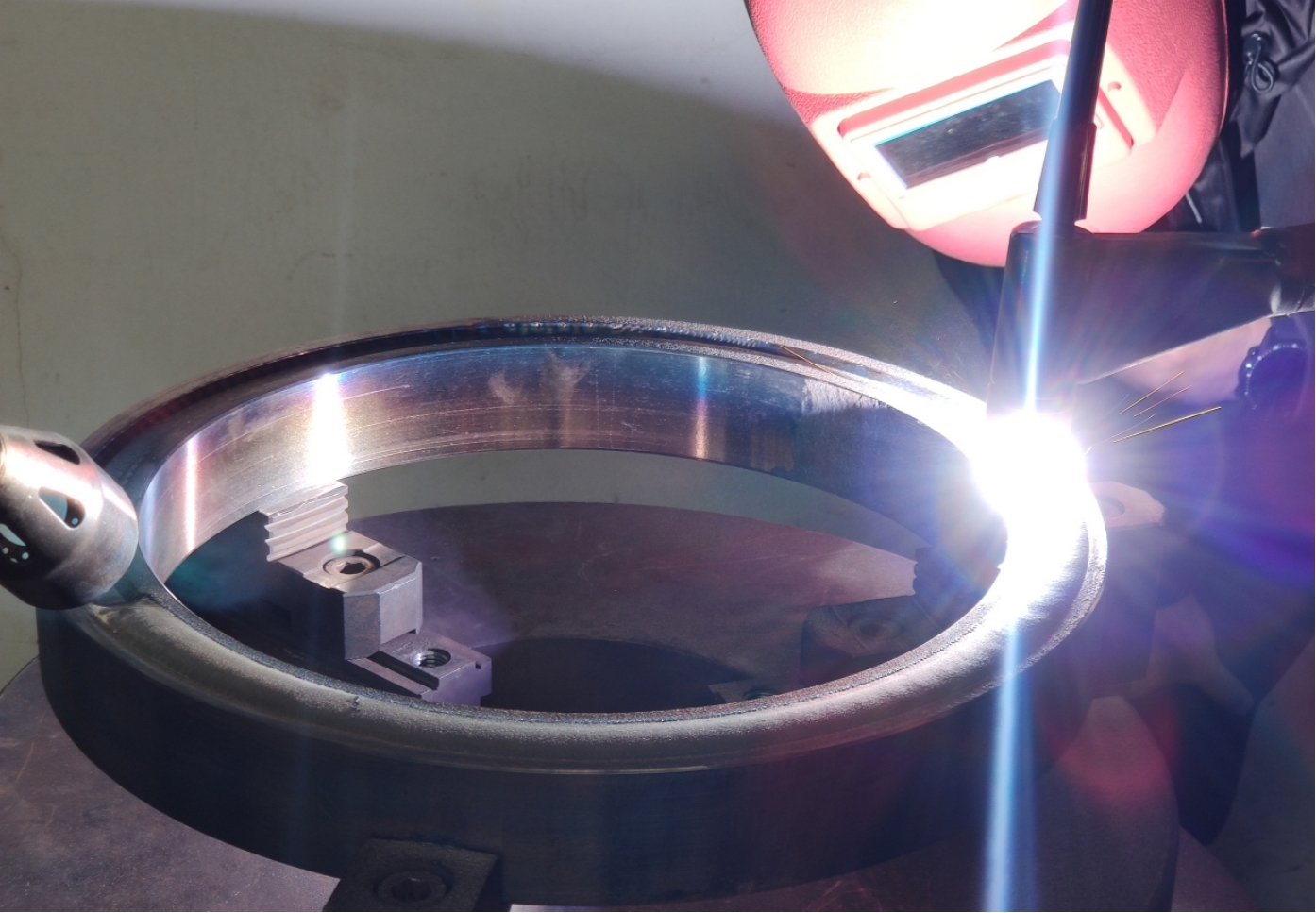

8. Thermal Spray Applications

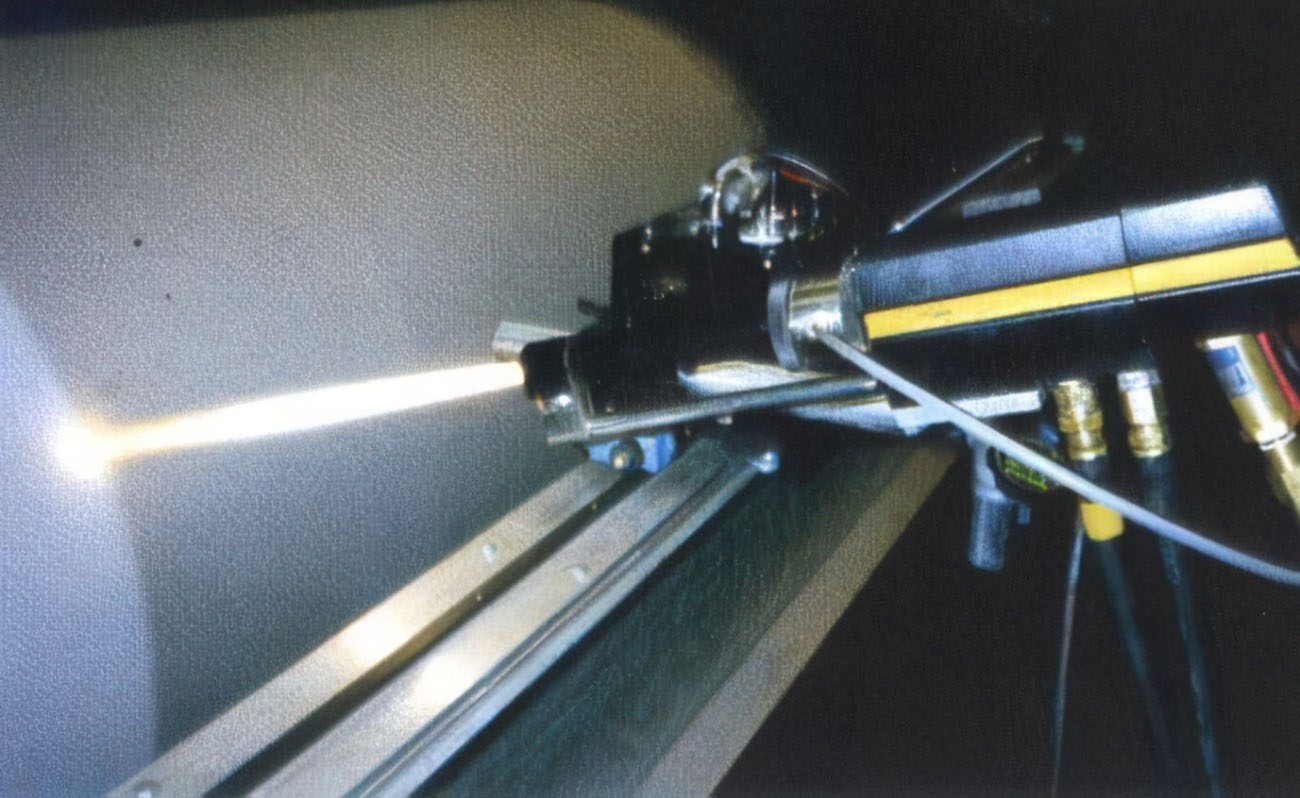

The WC88%-12%Co powder is primarily used in thermal spray applications, with common processing methods including high-velocity oxygen fuel (HVOF), high-velocity air fuel (HVAF), and plasma spraying. The coatings produced from this powder exhibit remarkable hardness, typically ranging from 1000 to 1400 HV.

The coatings made from WC88%-12%Co powder can withstand working environment temperatures of up to 500°C, making them suitable for high-temperature applications. The coatings also possess several significant advantages, including:

1. Excellent Wear Resistance: The high hardness of the tungsten carbide provides outstanding wear resistance, making the coatings ideal for applications involving abrasive wear.

2. High Bonding Strength: The metallurgical bonding between the coating and the substrate ensures high adhesion strength, which is critical for the longevity of the coating.

3. Outstanding Sliding Wear Resistance: The coatings exhibit excellent performance against sliding wear, making them suitable for components subjected to friction.

4. Wide Range of Applications: The WC88%-12%Co coatings are widely used in various industries, including manufacturing wear-resistant parts, valve seats, rollers, compressor blades, and other components that require enhanced durability.

Conclusion

The preparation of WC88%-12%Co powder involves a series of well-controlled processes, including mixing, milling, granulation, debinding, sintering, and classification. The resulting powder exhibits excellent properties that make it suitable for thermal spray applications, providing high-performance coatings with outstanding wear resistance and thermal stability. As industries continue to demand materials that can withstand harsh operating conditions, the importance of high-quality tungsten carbide-based powders like WC88%-12%Co will only continue to grow.