WC-20CrC-7Ni Composite Material: An Overview

Today, we will explore a remarkable composite powder known as WC-20CrC-7Ni, which is composed of tungsten carbide (WC), chromium carbide (CrC), and nickel carbonyl. This composite material is designed to offer exceptional properties, including corrosion resistance, wear resistance, and high-temperature stability. The unique combination of these materials makes WC-20CrC-7Ni suitable for a wide range of applications, particularly in harsh environments.

1. Basic Parameters of WC-20CrC-7Ni

Chemical Composition:

Chromium (Cr): 17.5%

-Nickel (Ni): 7%

Carbon (C): 6.8%

Tungsten (W): Balance

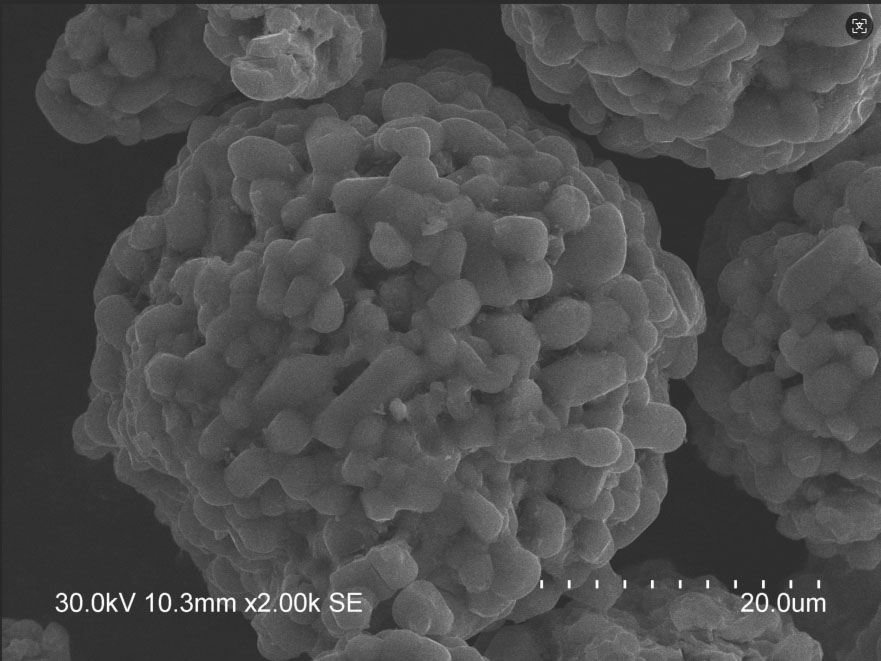

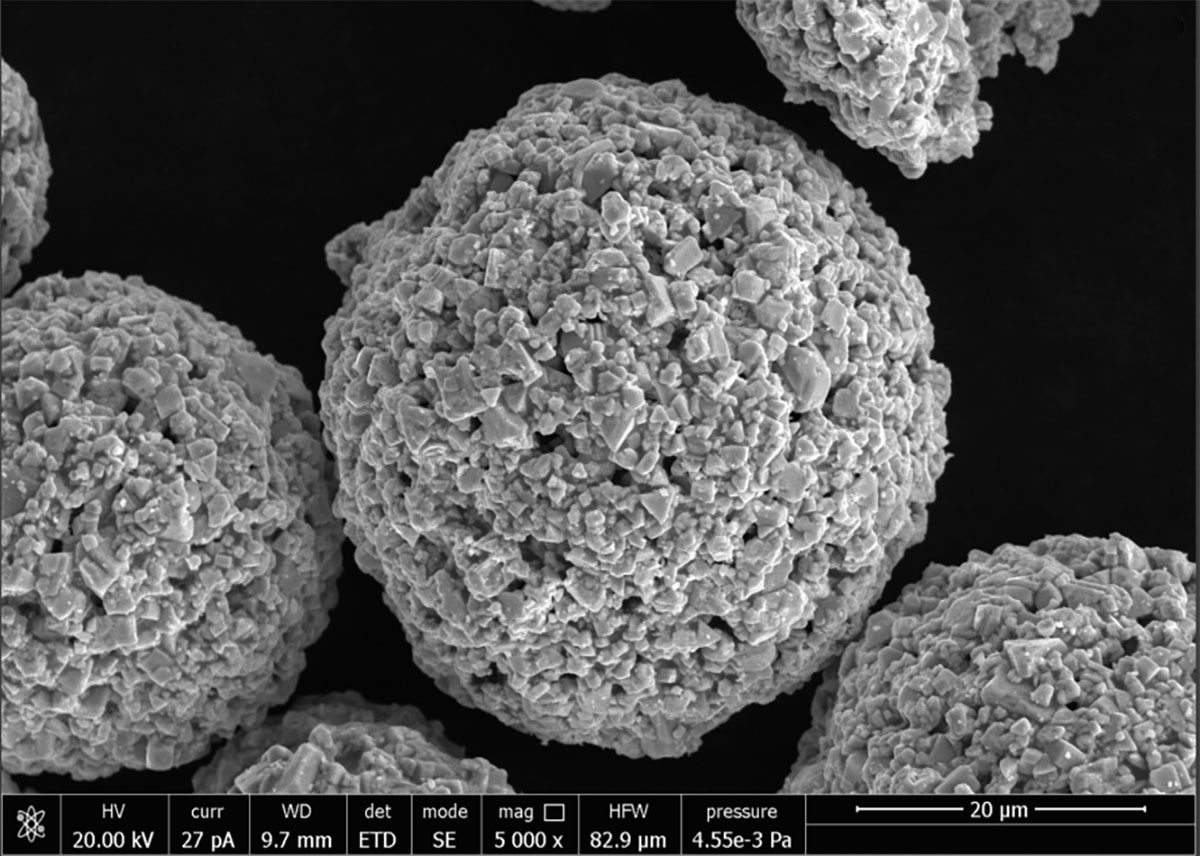

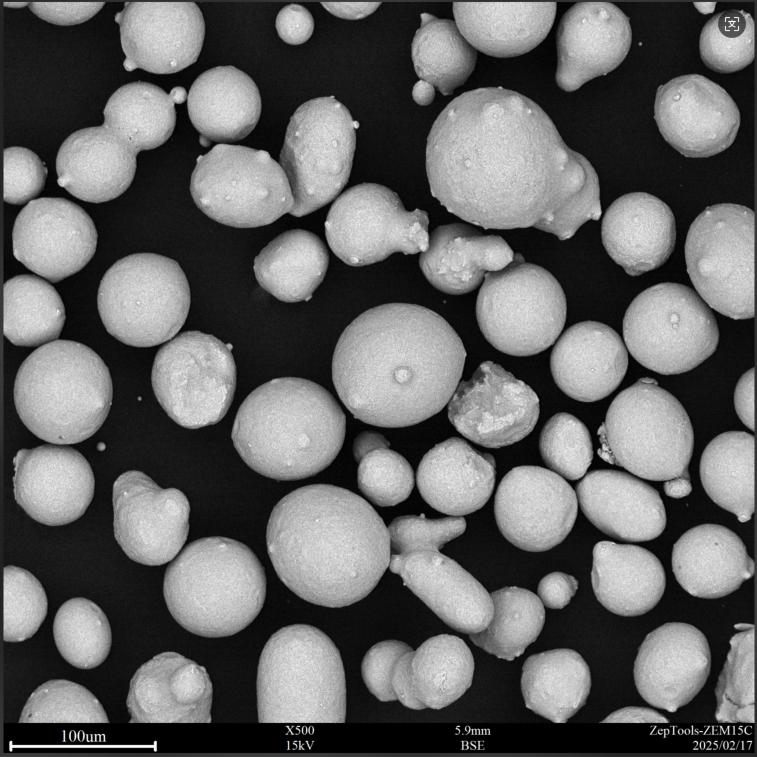

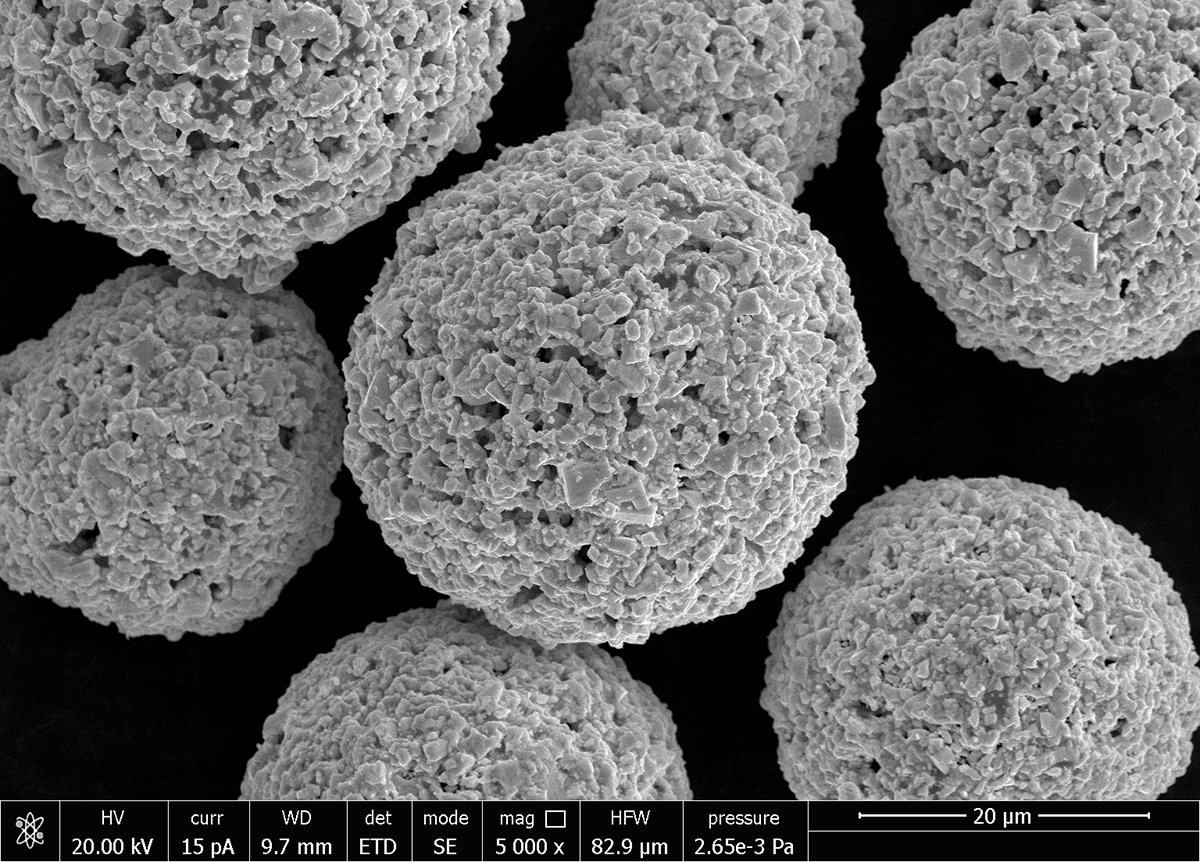

Production Process:

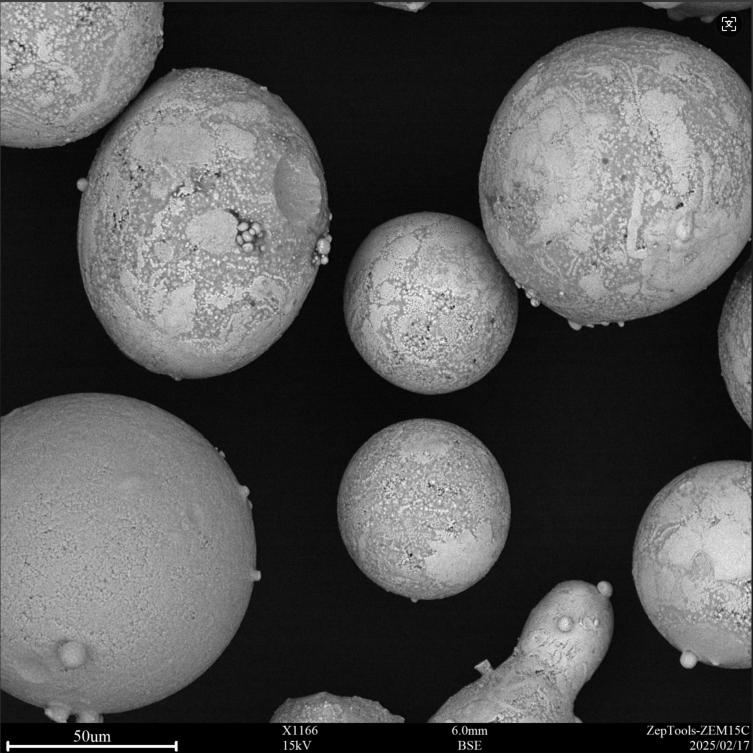

- The material is produced through a process known as agglomerated sintering, which enhances the properties of the composite by ensuring a uniform distribution of the components.

Hardness:

- The hardness of the coatings produced from WC-20CrC-7Ni ranges from HV950 to HV1350, making it suitable for applications requiring high wear resistance.

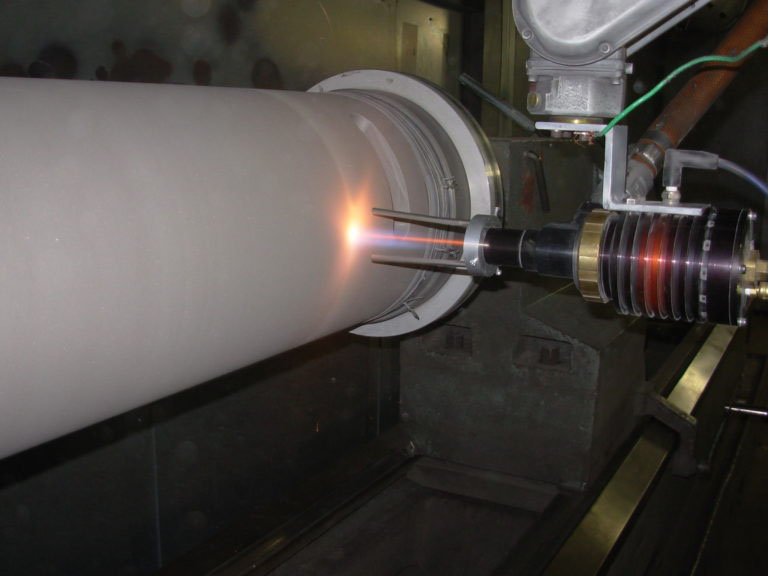

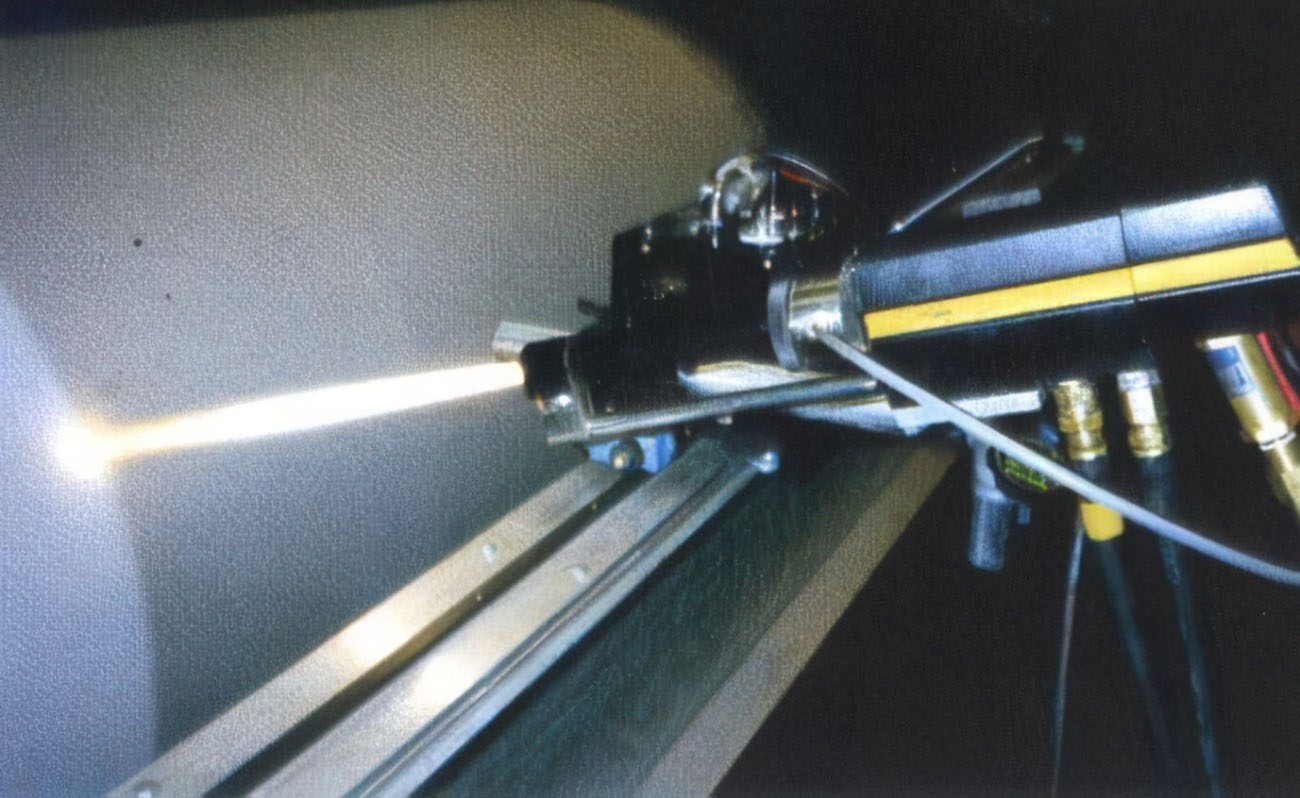

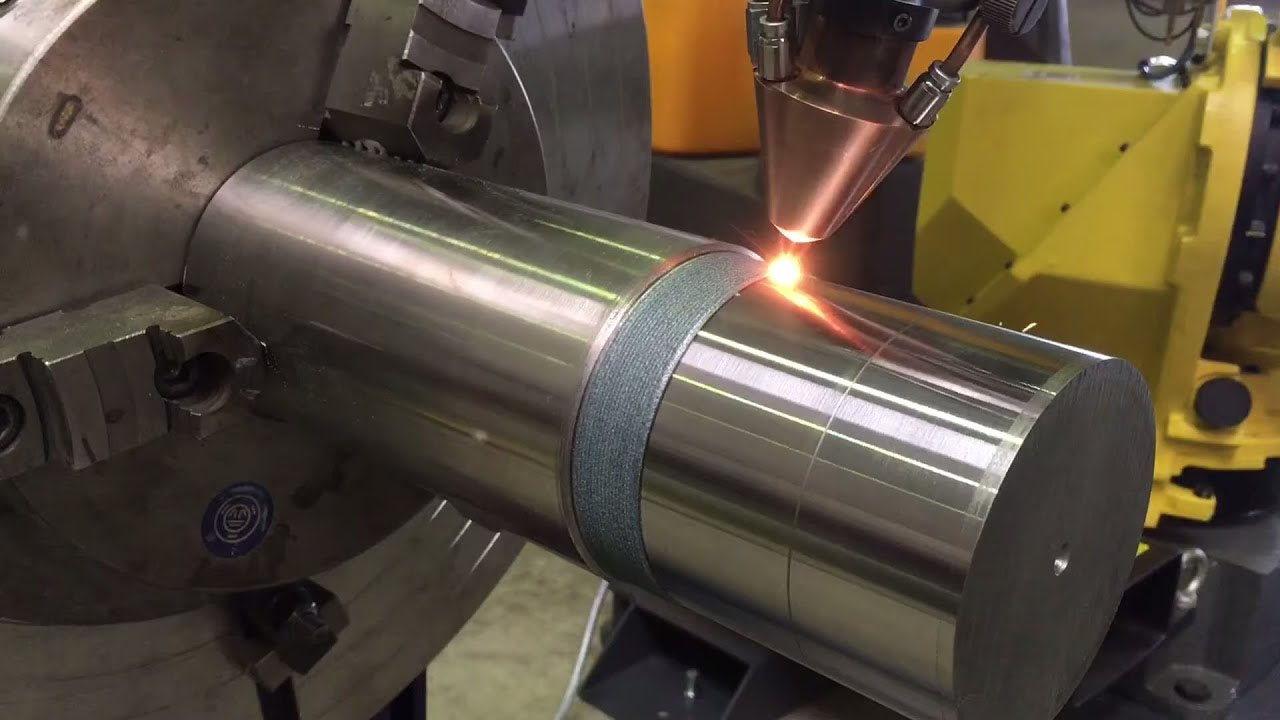

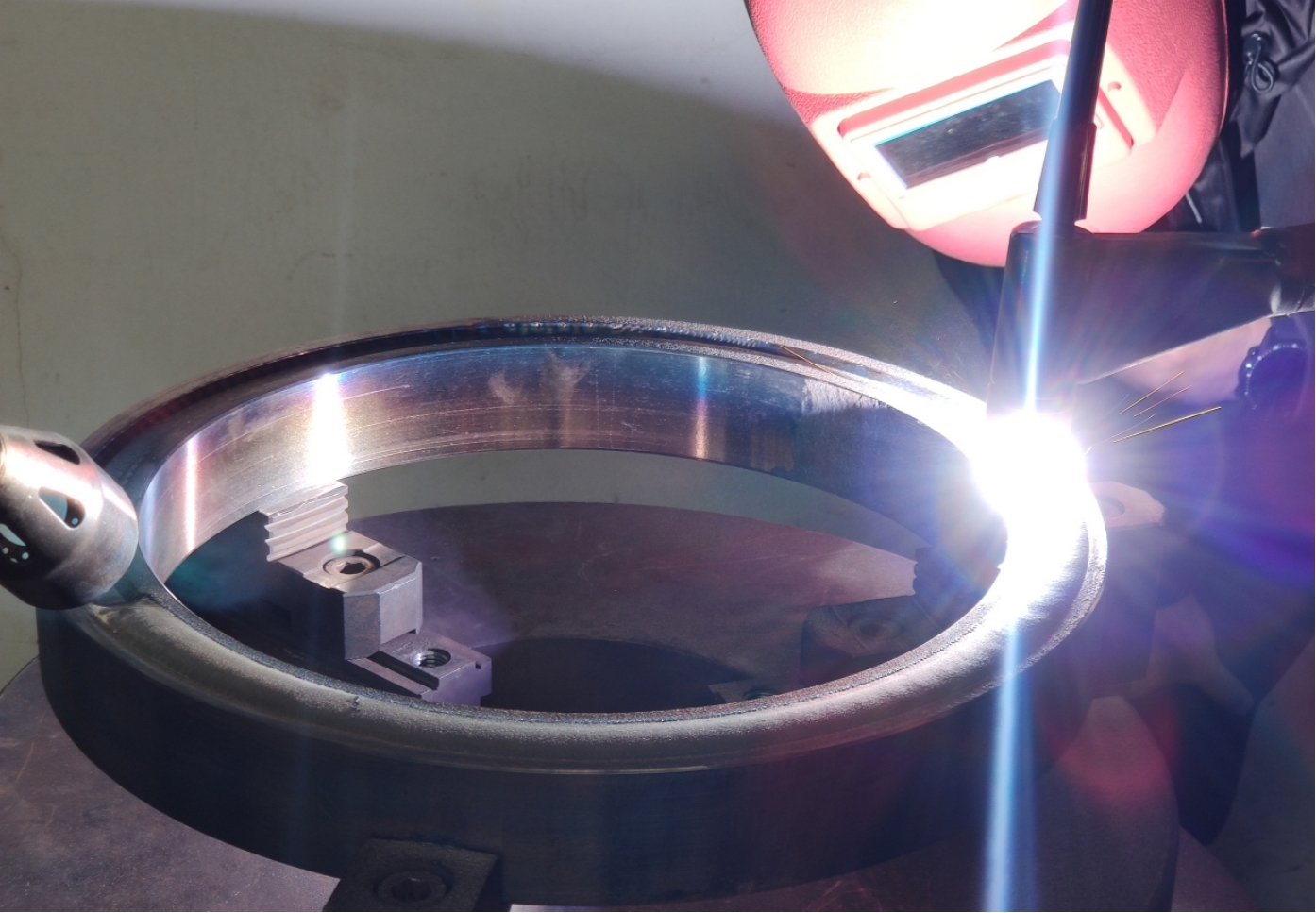

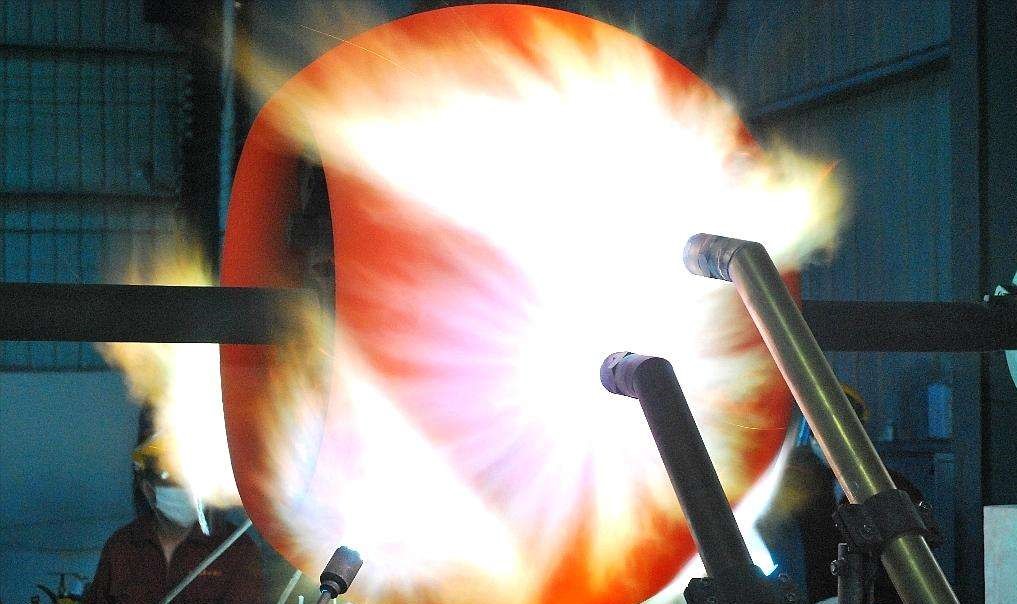

Suitable Thermal Spray Processes:

- The composite can be processed using various thermal spray techniques, including High-Velocity Air Fuel (HVAF), High-Velocity Oxygen Fuel (HVOF), and Atmospheric Plasma Spraying (APS).

Bonding Strength:

- The coating produced from WC-20CrC-7Ni exhibits a bonding strength greater than 70 MPa, ensuring a strong adhesion to the substrate.

Deposition Efficiency:

- The deposition efficiency of the powder ranges from 40% to 60%, which is a critical factor in determining the effectiveness of the thermal spray process.

Common Particle Sizes:

- The typical particle sizes available for WC-20CrC-7Ni include 5-30 µm, 10-38 µm, 15-45 µm, and 45-75 µm. Custom particle size distributions can also be provided based on specific requirements.

2. Special Properties of WC-20CrC-7Ni

WC-20CrC-7Ni exhibits several unique properties that set it apart from other composite materials, particularly WC-Co powders. Here are some of the standout features:

1. Enhanced Corrosion Resistance:

Compared to traditional WC-Co thermal spray powders, WC-20CrC-7Ni demonstrates superior corrosion resistance. The presence of chromium carbide and nickel enhances the material's ability to withstand corrosive environments, making it suitable for applications in chemical processing and other industries where exposure to acids and bases is common.

2. Densely Packed Coatings:

The coatings produced from WC-20CrC-7Ni are known for their density and compactness. This dense structure contributes to excellent oxidation resistance, allowing the coatings to perform well in high-temperature environments. The coatings can effectively resist abrasive wear and corrosion wear, making them ideal for demanding applications.

3. Performance in Acidic and Alkaline Environments:

Components coated with WC-20CrC-7Ni can be used in environments with low concentrations of acids and bases at temperatures up to 200°C. This property is particularly beneficial in industries such as pulp and paper, where equipment is often exposed to corrosive chemicals.

4. High-Temperature Stability:

The coatings made from WC-20CrC-7Ni can withstand working temperatures of up to 700°C. This high-temperature resistance allows the material to be used in applications where thermal stability is critical, such as in gas turbines and other high-heat environments.

5. Versatile Applications:

WC-20CrC-7Ni is commonly used in various industrial applications, including:

- Paper Industry: Coatings for paper rollers that require high wear resistance and corrosion protection.

- Valves and Valve Seats: The material is ideal for ball valves and valve plates, where durability and resistance to wear and corrosion are essential.

- Mining and Construction: Components exposed to abrasive materials benefit from the wear-resistant properties of WC-20CrC-7Ni coatings.

3. Applications of WC-20CrC-7Ni

The unique properties of WC-20CrC-7Ni make it suitable for a wide range of applications across various industries:

Chemical Processing: The ability to withstand corrosive environments makes WC-20CrC-7Ni an excellent choice for components in chemical reactors, pipelines, and storage tanks.

Oil and Gas Industry: The material's resistance to wear and corrosion is beneficial for equipment used in oil extraction and refining processes.

Aerospace: In aerospace applications, where materials are subjected to extreme conditions, WC-20CrC-7Ni coatings can enhance the performance and longevity of critical components.

Automotive: The automotive industry can utilize WC-20CrC-7Ni for parts that require high wear resistance, such as engine components and transmission parts.

Food Processing: The corrosion resistance of WC-20CrC-7Ni makes it suitable for equipment used in food processing, where hygiene and durability are paramount.

4. Conclusion

WC-20CrC-7Ni is a versatile composite material that combines the benefits of tungsten carbide, chromium carbide, and nickel to create a product that excels in wear resistance, corrosion resistance, and high-temperature stability. Its unique properties make it suitable for a wide range of applications across various industries, from chemical processing to aerospace.

As industries continue to seek materials that can withstand harsh environments while maintaining performance, WC-20CrC-7Ni stands out as a reliable solution. Its ability to be processed using advanced thermal spray techniques further enhances its applicability, making it a valuable material for manufacturers and engineers looking to improve the durability and longevity of their products. Whether in the paper industry, oil and gas sector, or aerospace applications, WC-20CrC-7Ni is poised to meet the challenges of modern manufacturing and engineering.