What are the applications of plasma surfacing nickel-based tungsten carbide?

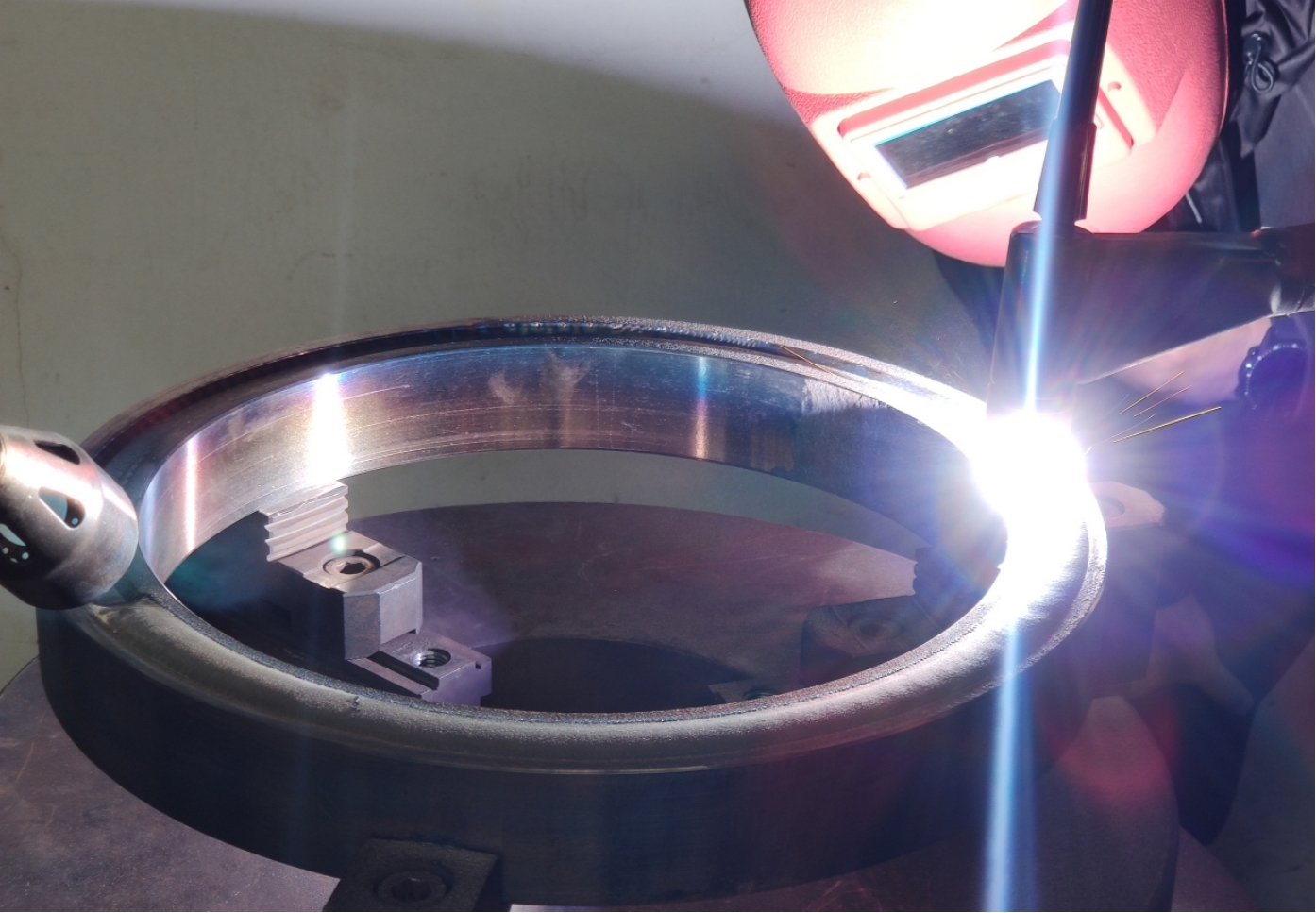

Plasma surfacing nickel-based tungsten carbide (Ni-WC) is widely used in key components in multiple industrial fields due to its comprehensive performance of high wear resistance, impact resistance and corrosion resistance. The following are its main application scenarios:

- Mining and engineering machinery

Crusher roller surface: resist high-intensity abrasive wear of ore and rock.

Excavator bucket teeth: enhance impact resistance and wear resistance when excavating hard rock and sand.

Shovel blades and bulldozers: used for ore loading and earthwork operations to extend service life.

- Oil and gas drilling

Drill collars and centralizers: prevent wear of underground rock cuttings and sand particles.

Downhole tools (such as stabilizers and reamer): improve durability in sandy and highly abrasive formations.

Valve sealing surface: resistant to erosion by high-pressure sand-containing fluids.

- Metallurgy and rolling equipment

Rolling mill guide plate: resist friction and scale wear of high-temperature steel billets.

Continuous casting machine crystallizer: reduce high-temperature molten steel erosion loss.

Hot shear tool: maintain edge hardness at high temperature.

- Power and energy

Gas turbine blades: resist erosion by high-temperature gas particles (WC content needs to be controlled to prevent oxidation).

Boiler coal nozzle: resist erosion by coal particles.

- Agricultural machinery

Rotary tiller blades, harvester blades: deal with abrasive wear of soil and straw.

Feed crusher hammer: resist impact wear of grain and hard feed.

- Other industrial fields

Cement industry: crusher hammer, powder selector blade.

Ship propeller shaft: resist seawater corrosion and cavitation (need to be matched with corrosion-resistant nickel-based alloy).

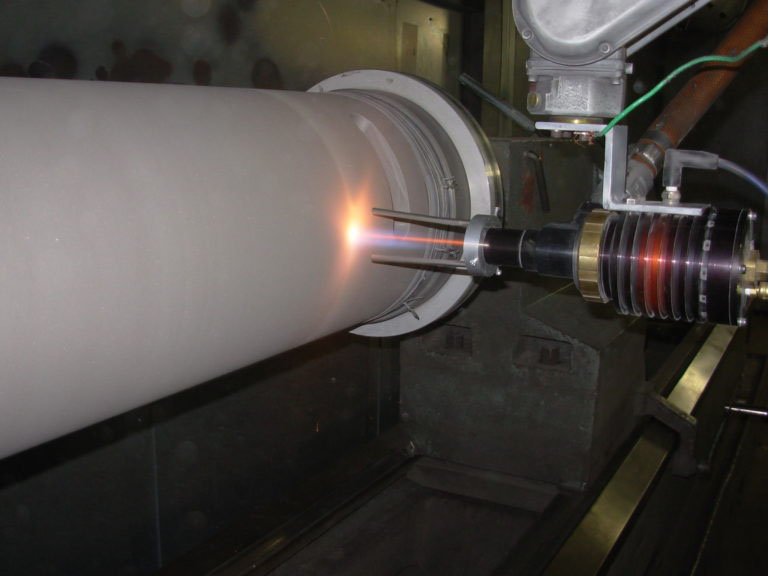

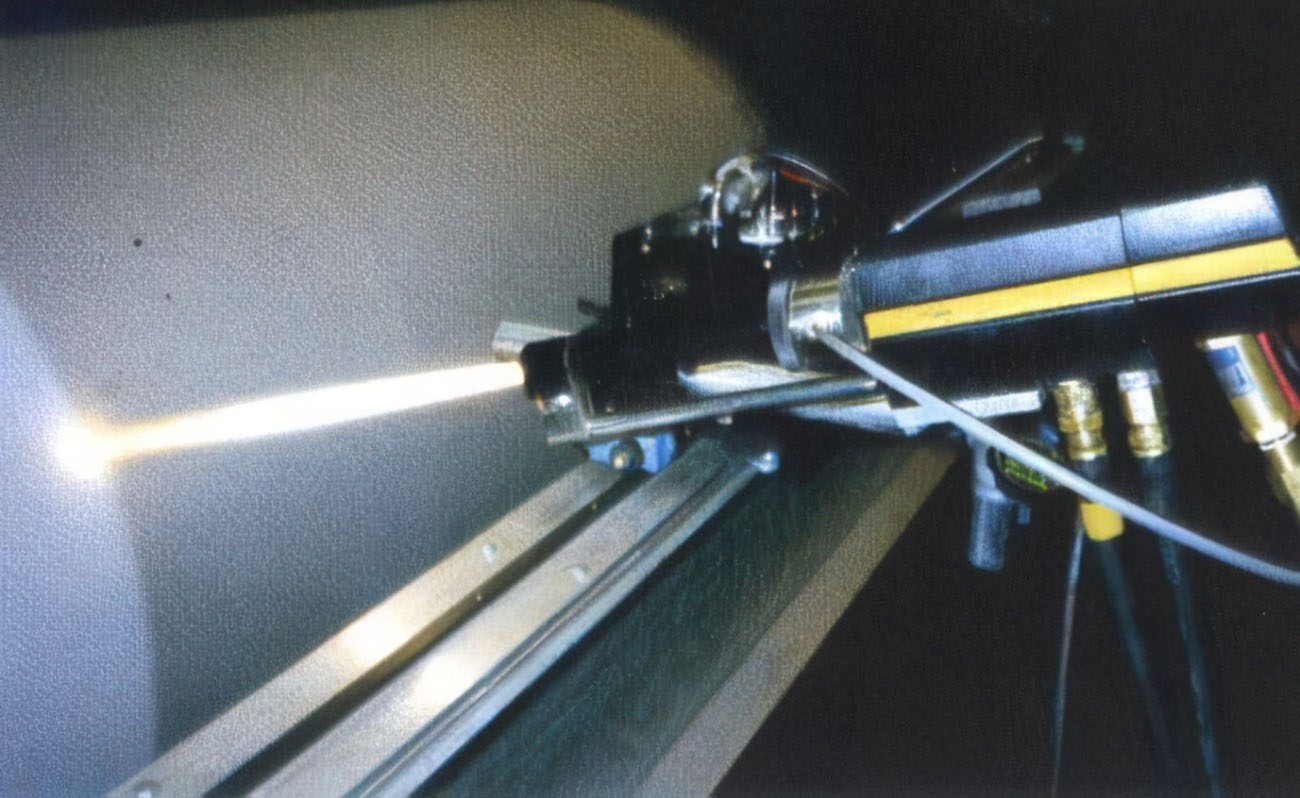

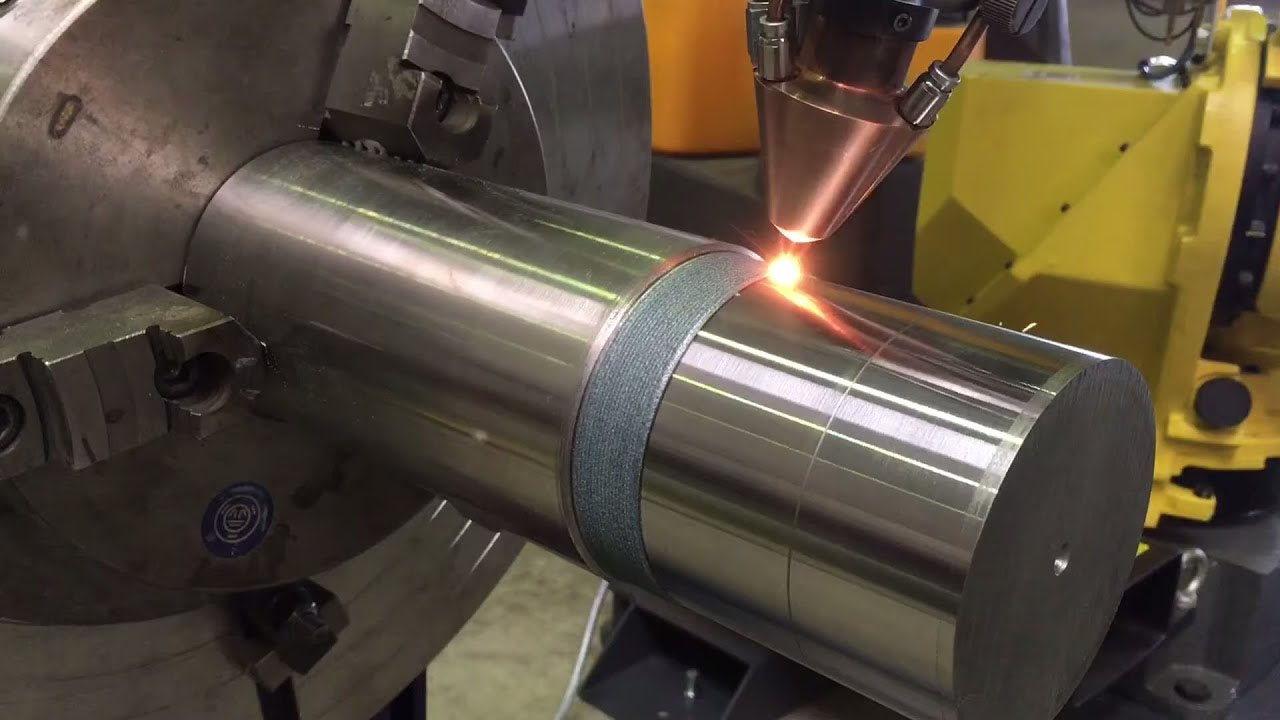

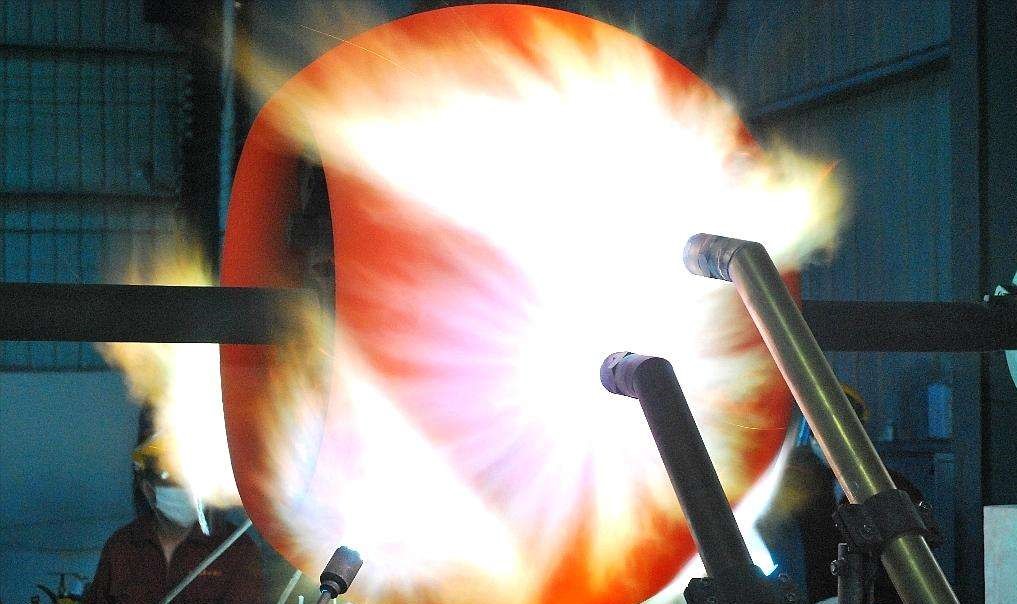

Process advantages and precautions

1.Advantages:

- High bonding strength (high plasma arc temperature, sufficient metallurgical bonding).

- Less decomposition of WC (compared with oxyacetylene spray welding, it is easier to retain the original hardness of WC).

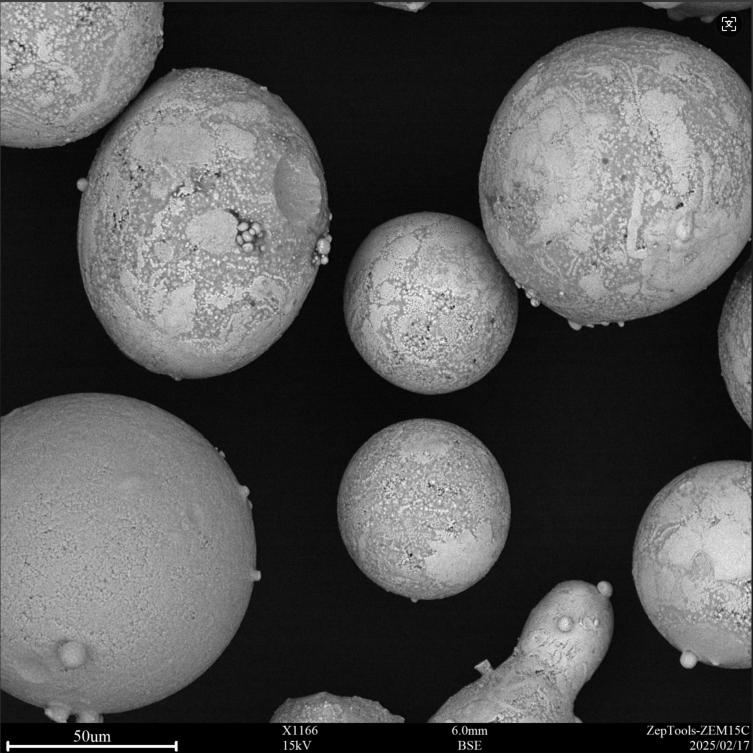

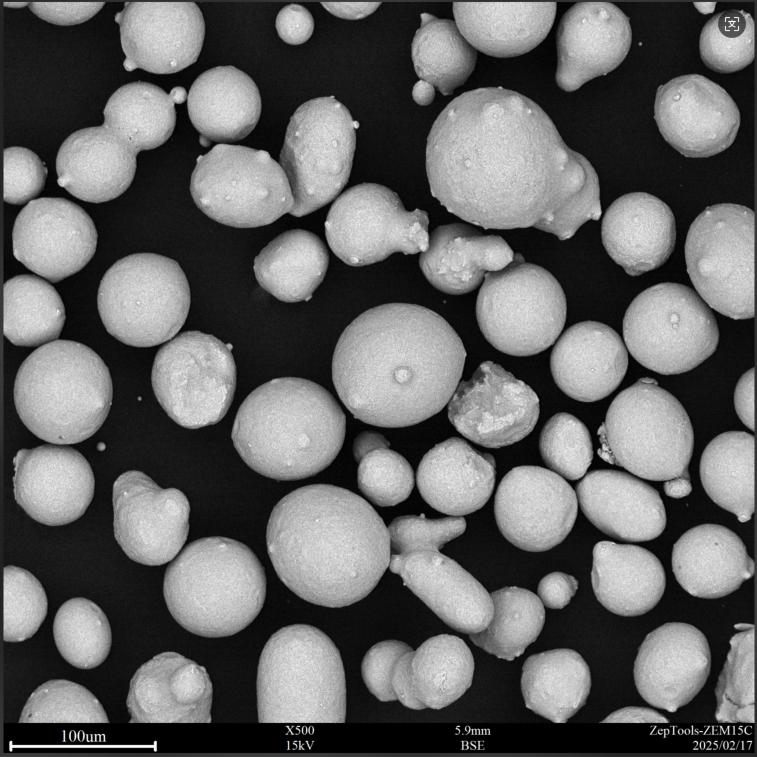

2.Key control:

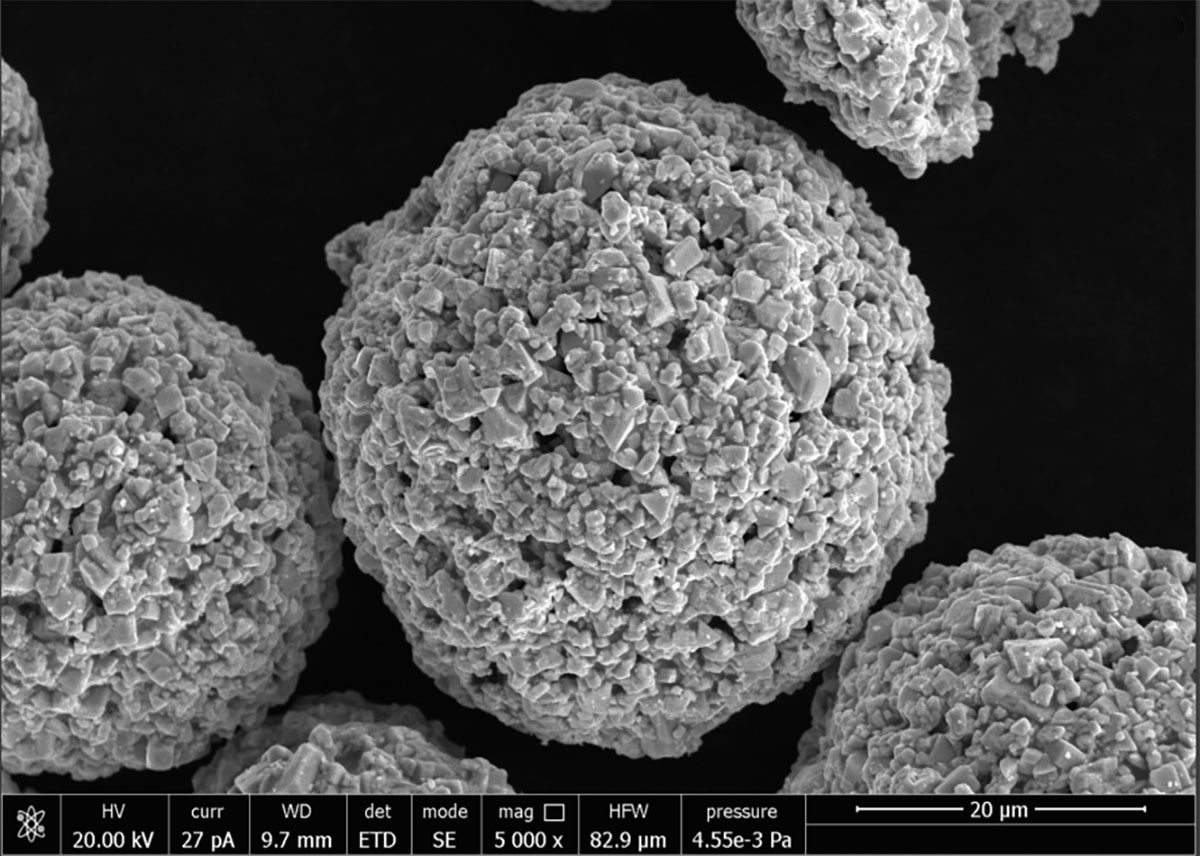

WC ratio: usually 30%-50%, too high will easily lead to brittle cracking of the coating.

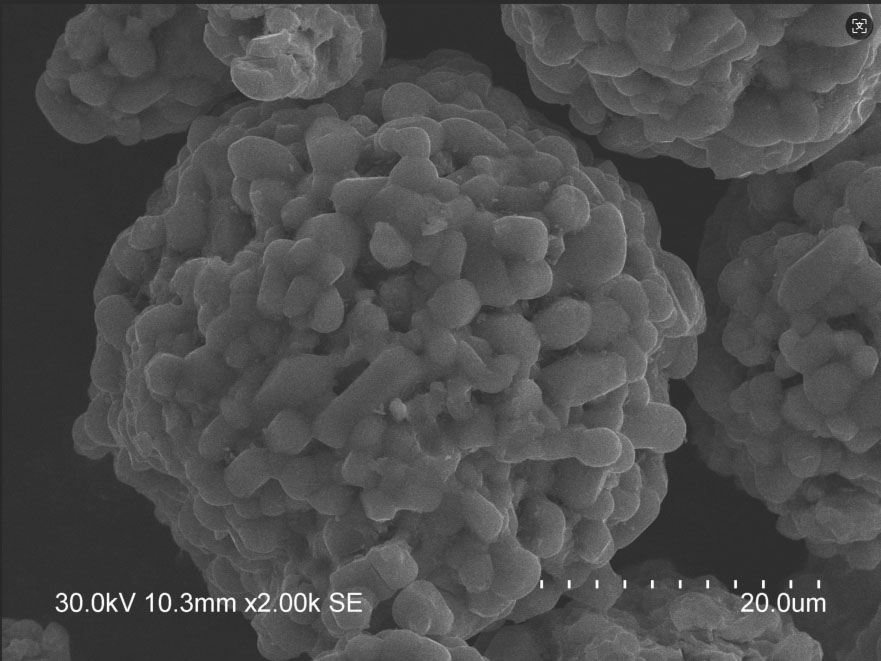

Powder particle size: WC particles should be selected to be 40-150μm, too fine will easily melt and fail.

Substrate preheating: medium and high carbon steel or cast iron needs to be preheated to 200-300℃ to prevent cracking.

This technology is particularly suitable for high-value parts that require local strengthening, which can significantly reduce the cost of frequent replacement.