What are the applications of supersonic sprayed tungsten carbide coatings?

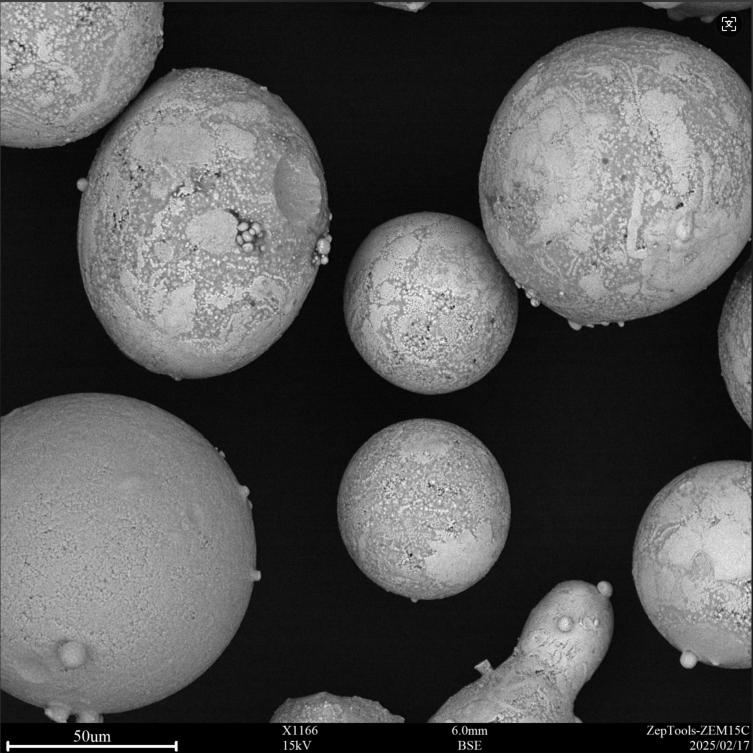

Supersonic sprayed tungsten carbide coatings (such as WC-10Co4Cr, WC-17Co, etc.) are widely used in the protection of key components under harsh working conditions due to their high hardness, wear resistance and corrosion resistance. The following are the main application areas:

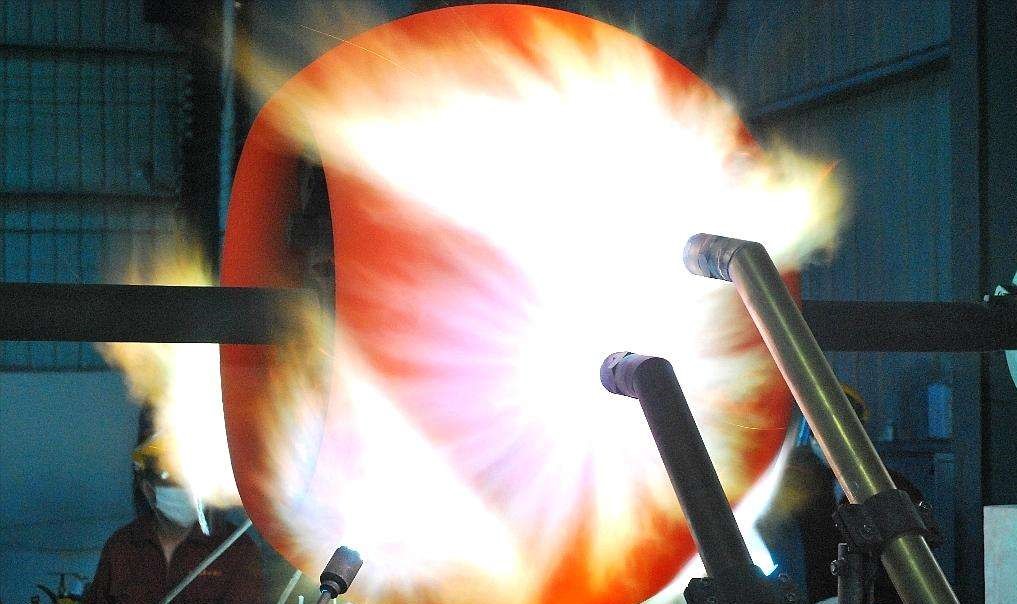

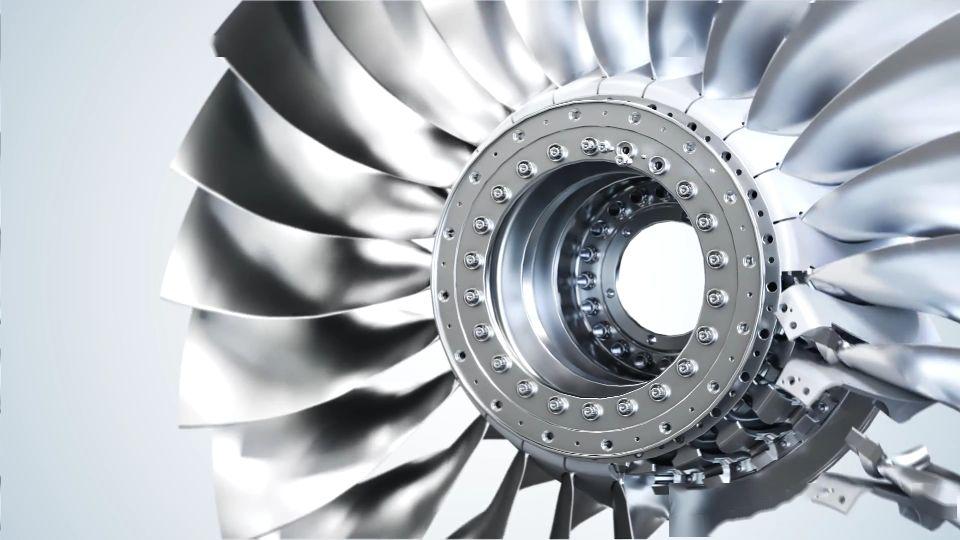

1. Aerospace

Aerospace engine components: turbine blades, compressor shafts, gears, etc., to improve wear resistance.

Landing gear components: reduce runway friction and particle erosion.

2. Energy and power

Turbine blades: resist sediment erosion and cavitation.

Gas turbine components: such as gas turbine blades, enhance high temperature wear resistance.

Nuclear power valves: prevent corrosion and particle wear.

3. Petroleum and chemical

Drilling tools: drill pipes, pump valves, etc., to extend the life in sandy and highly corrosive media.

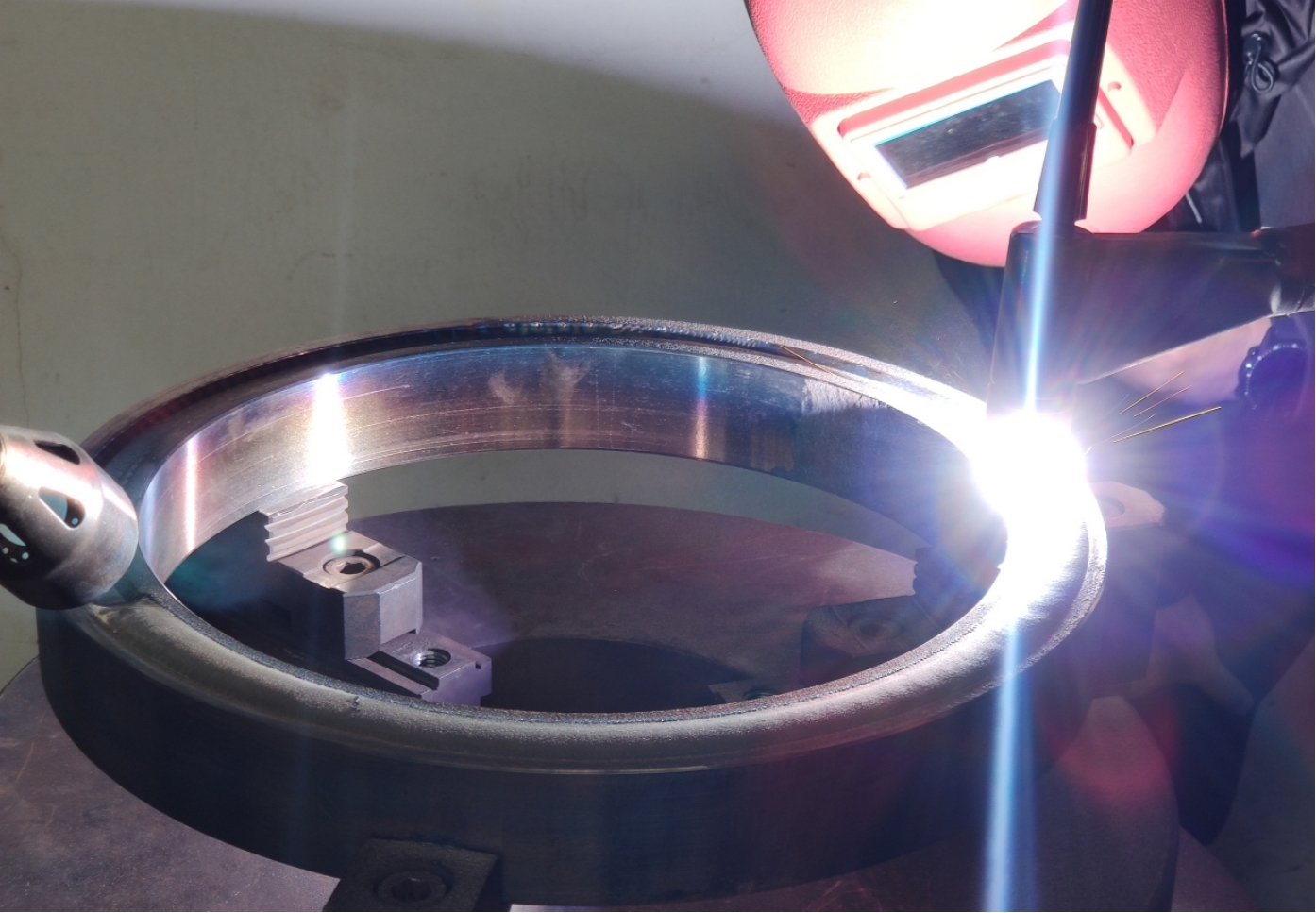

Chemical pump seal rings: reduce chemical media and particle wear.

4. Shipbuilding and marine engineering

Propeller shaft: prevent seawater corrosion and cavitation.

Seawater pump parts: improve salt spray and wear resistance.

5. Industrial machinery

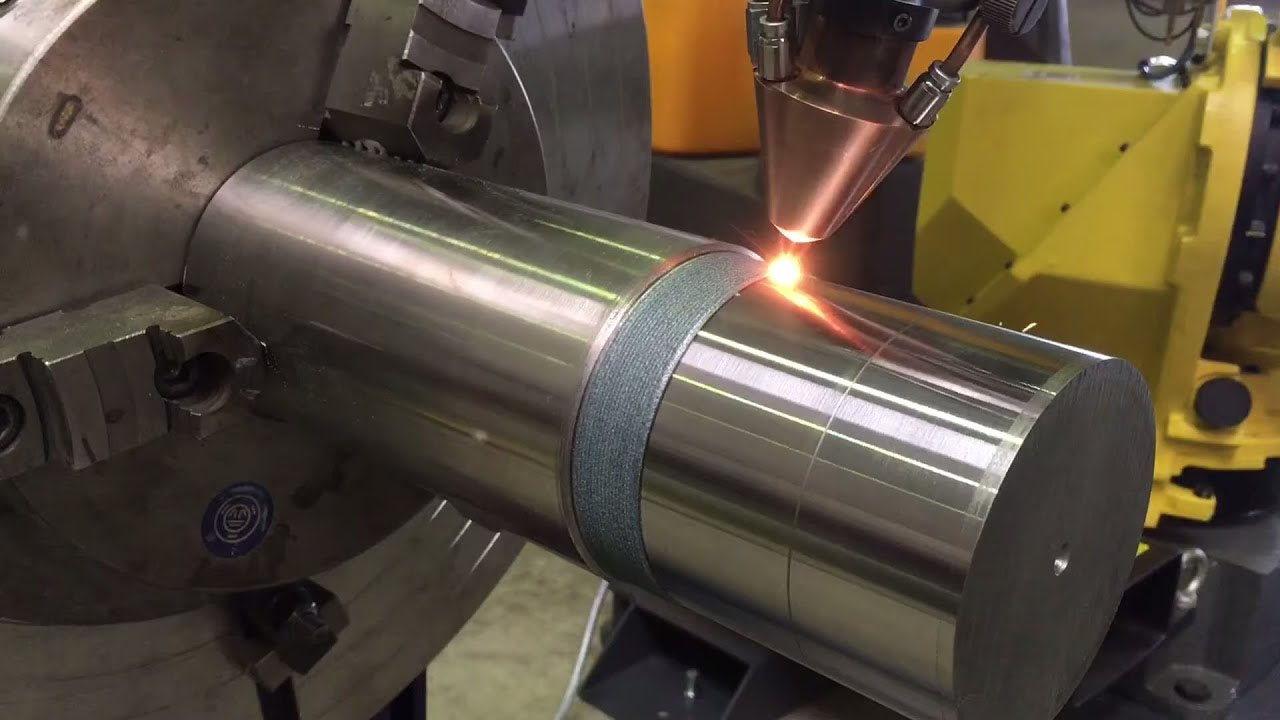

Hydraulic piston rod: reduce seal wear and prevent rust.

Rollers and molds: improve wear resistance and extend service life.

Textile machinery guide wheel: reduce fiber friction loss.

6. Automobile and rail transportation

Engine valve stem: reduce friction and high-temperature oxidation.

Rail transportation brake parts: improve wear resistance.

7. Other special applications

Barrels and gun barrels (military): enhance ablation and wear resistance.

3D printing parts repair: restore the size and performance of worn parts.

Supersonic spraying of tungsten carbide coating can significantly extend the life of components. It is suitable for high wear, high corrosion or high temperature environments and is an important surface strengthening technology in the industrial field.