What are the main applications of nickel-based self-fluxing alloy welding layers?

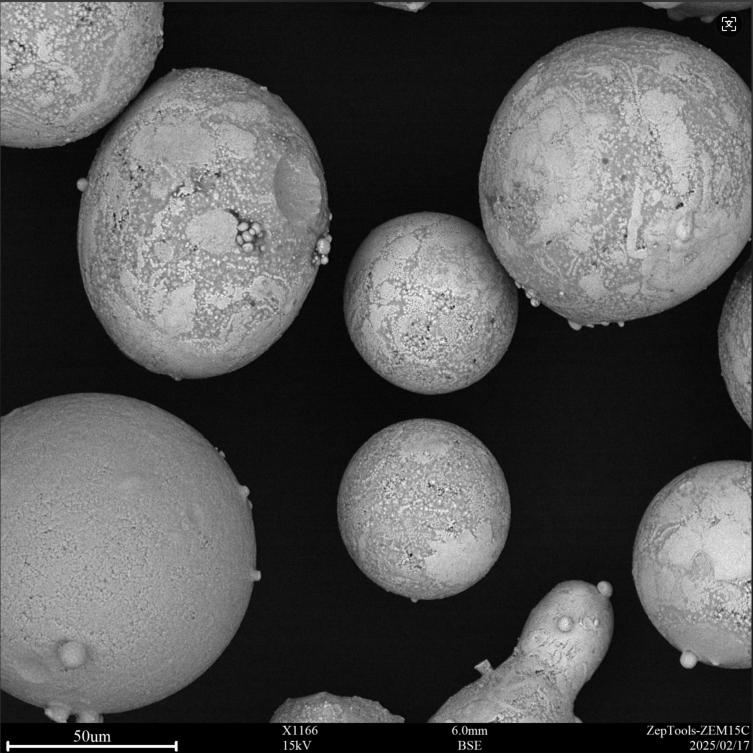

Nickel-based self-fluxing alloy welding layers (such as NiCrBSi series) are widely used in key components that require surface strengthening due to their excellent wear resistance, corrosion resistance and high temperature performance. The following are the main application areas:

- Petrochemical equipment

Valve sealing surface: Improve corrosion resistance and erosion resistance, and extend service life.

Pump body, impeller: Prevent acid, alkali medium and particle wear.

Reaction kettle stirring shaft: Reduce chemical corrosion and mechanical wear.

- Energy and power industry

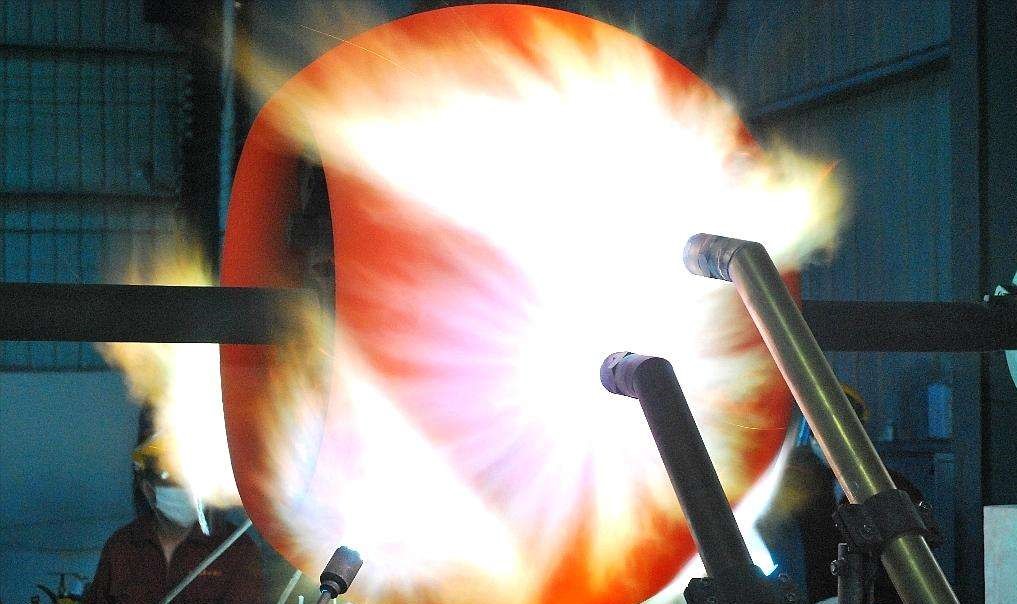

Gas turbine blades: Enhance resistance to high-temperature oxidation and thermal fatigue.

Boiler tube wall: Prevent high-temperature sulfur corrosion and fly ash wear.

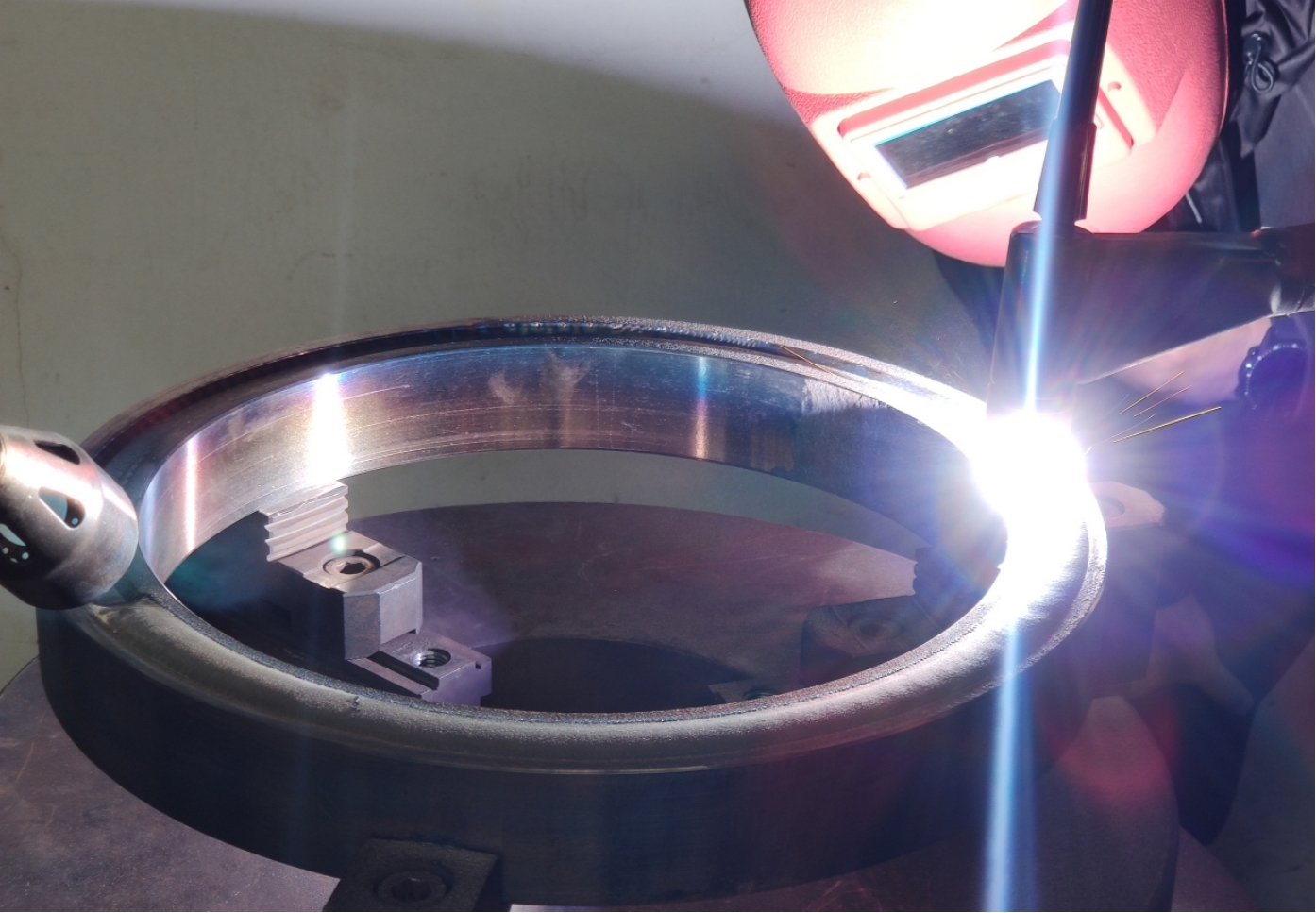

Turbine sealing ring: Improve wear resistance and air tightness.

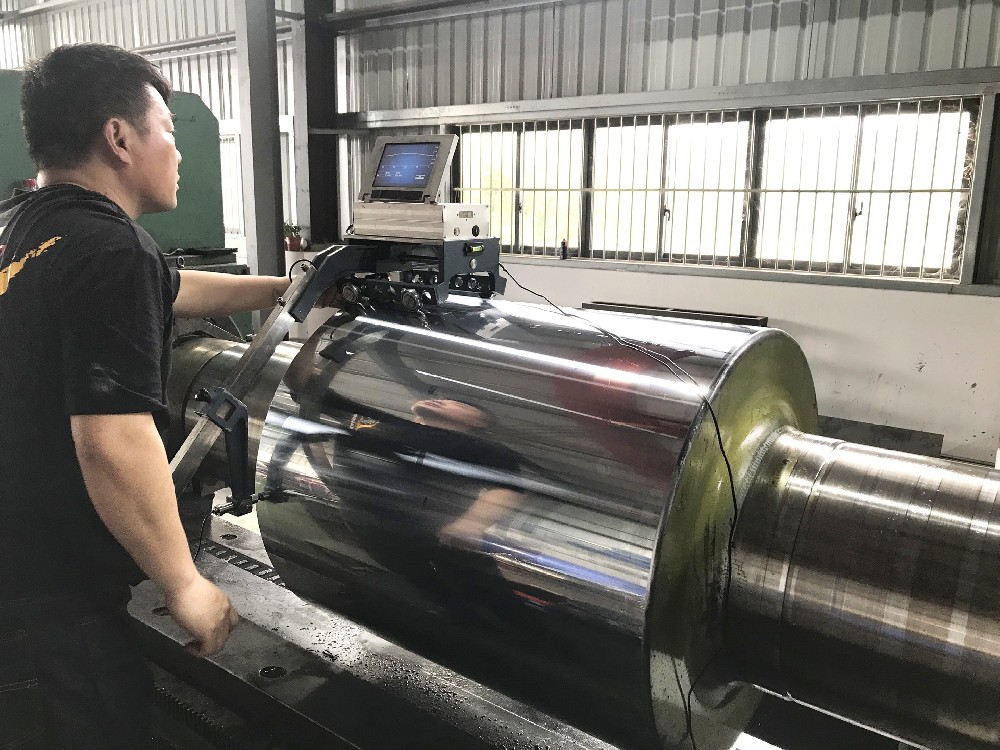

- Metallurgy and mining machinery

Roller repair: Restore worn surface and improve wear resistance.

Crusher roller surface: Resist ore impact and wear.

Blast furnace charge bell: Reduce high-temperature material erosion loss.

- Automobile and shipbuilding

Engine exhaust valve: Enhance high temperature corrosion resistance and ablation resistance.

Ship propeller shaft: Prevent seawater corrosion and cavitation.

- Industrial equipment maintenance

Mold repair: such as injection molds and die-casting molds, restore size and increase life.

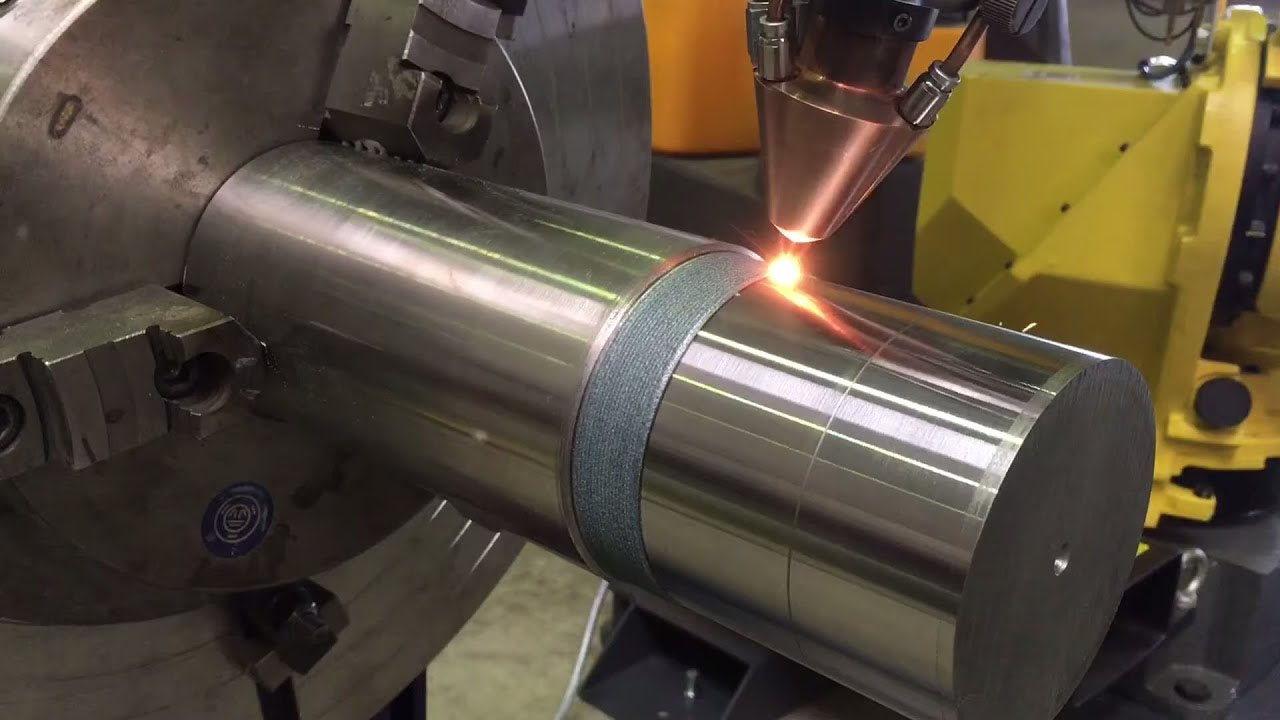

Shaft parts: Repair worn journals to avoid overall replacement.

- Other special applications

Nuclear industry components: Partially resistant to radiation corrosion environment.

Food machinery (models that meet hygiene standards): Reduce corrosion and adhesion.

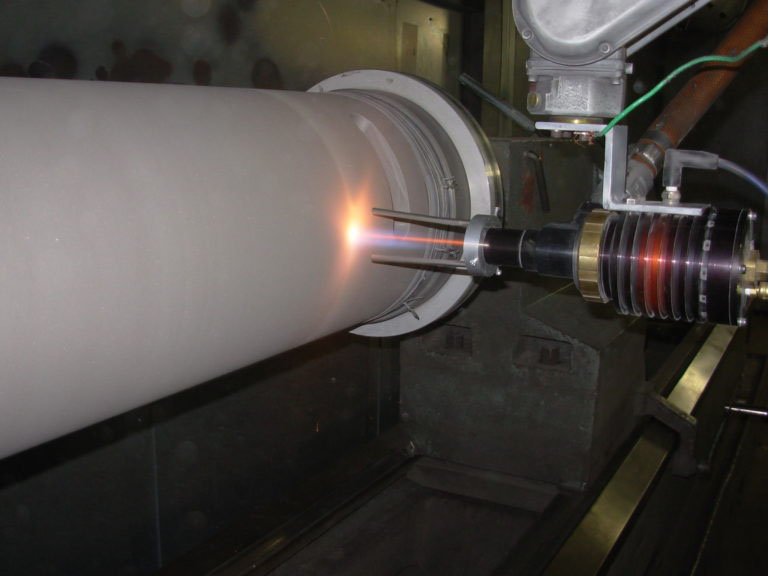

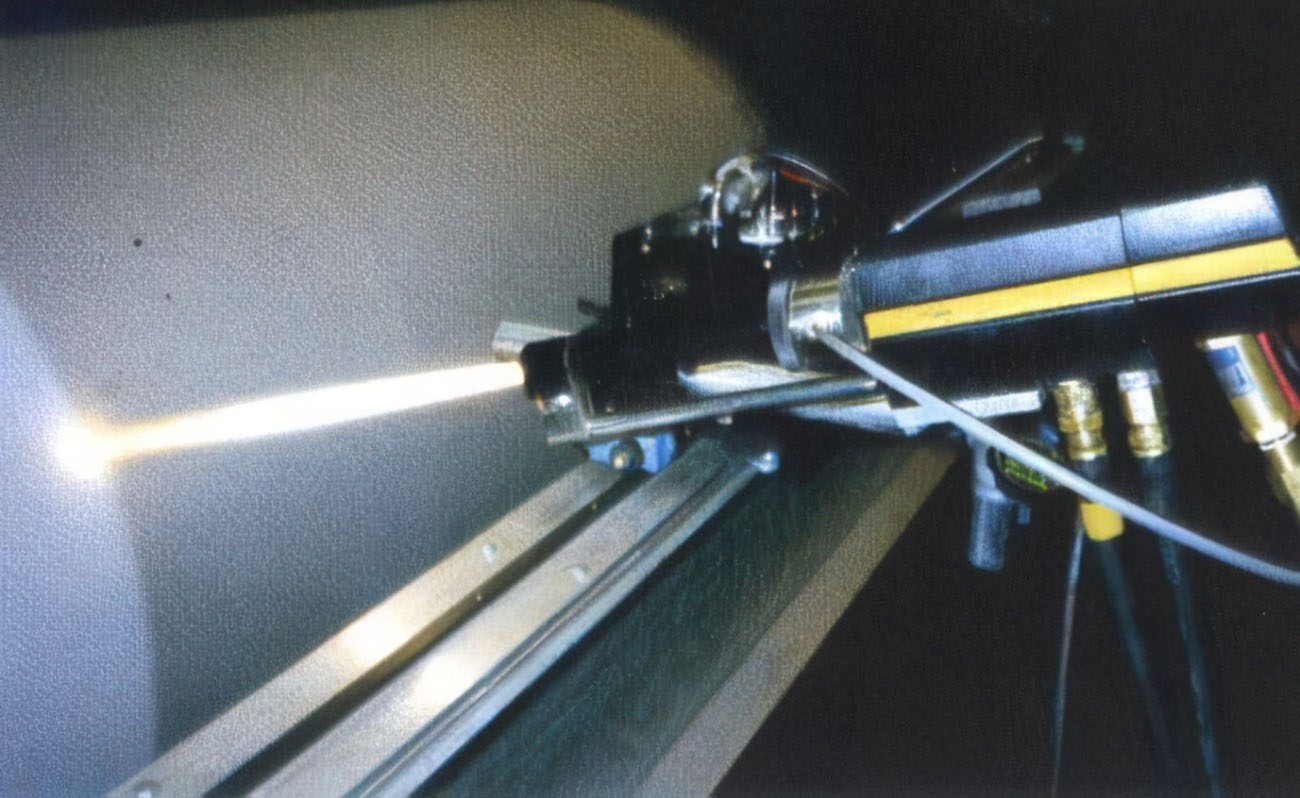

This type of weld layer usually uses oxyacetylene flame spray welding, plasma spray welding or laser cladding process, which is suitable for working conditions requiring high bonding strength, high temperature resistance or chemical corrosion resistance.