What is nickel-based tungsten carbide?

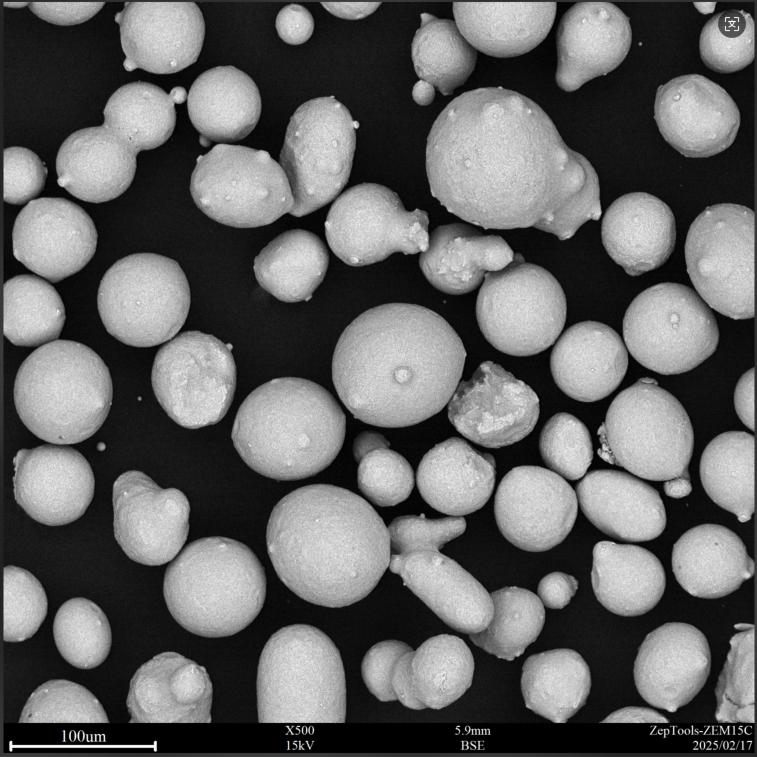

Nickel-based tungsten carbide is a composite material composed of a nickel-based self-fluxing alloy (such as Ni60) as a bonding phase and tungsten carbide (WC) hard particles. It is characterized by the toughness and self-fluxing properties of nickel-based alloys and the high wear resistance of tungsten carbide.

- Material composition

Nickel-based alloy (such as Ni60): As a bonding phase, it provides corrosion resistance and high temperature performance.

Tungsten carbide (WC): Hardness ≥ HV2000, usually accounting for 30%-60% (adjusted according to wear resistance requirements).

- Core characteristics

Ultra-high wear resistance: WC particles significantly improve the ability to resist abrasive wear, and the wear resistance is 3-5 times higher than that of pure nickel-based alloys.

High temperature resistance: Nickel-based alloys remain stable below 600°C, and WC is not easily oxidized at high temperatures (better than chromium carbide).

Good toughness: nickel matrix buffers impact and prevents WC particles from peeling off.

- Typical applications

Mining machinery: crusher roller surface, excavator tooth tip.

Oil drilling: drill collar, stabilizer.

Metallurgical industry: rolling mill guide plate, feed roller.

Agricultural machinery: rotary tiller, harvester blade.

Preparation process points

- Mixing method:

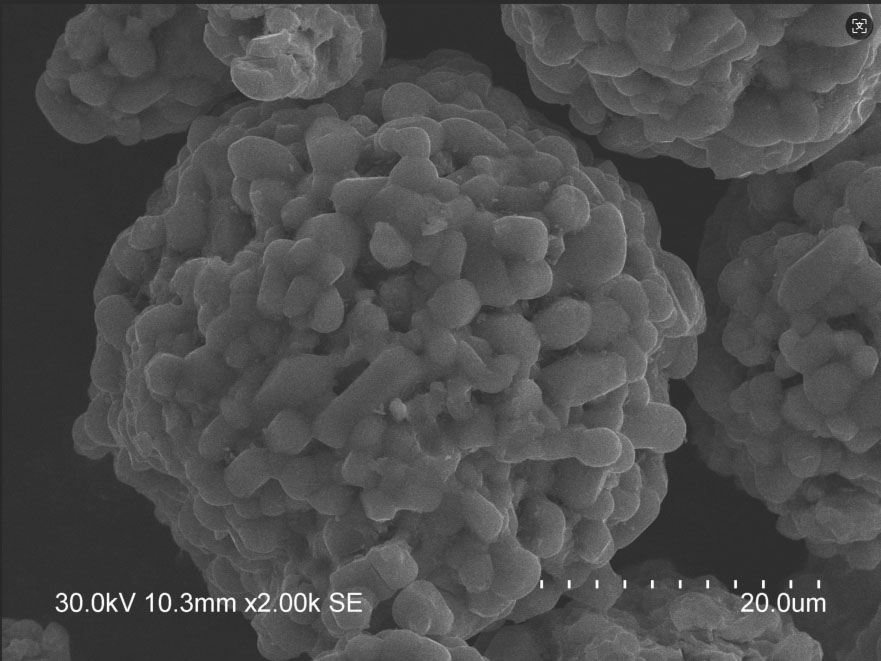

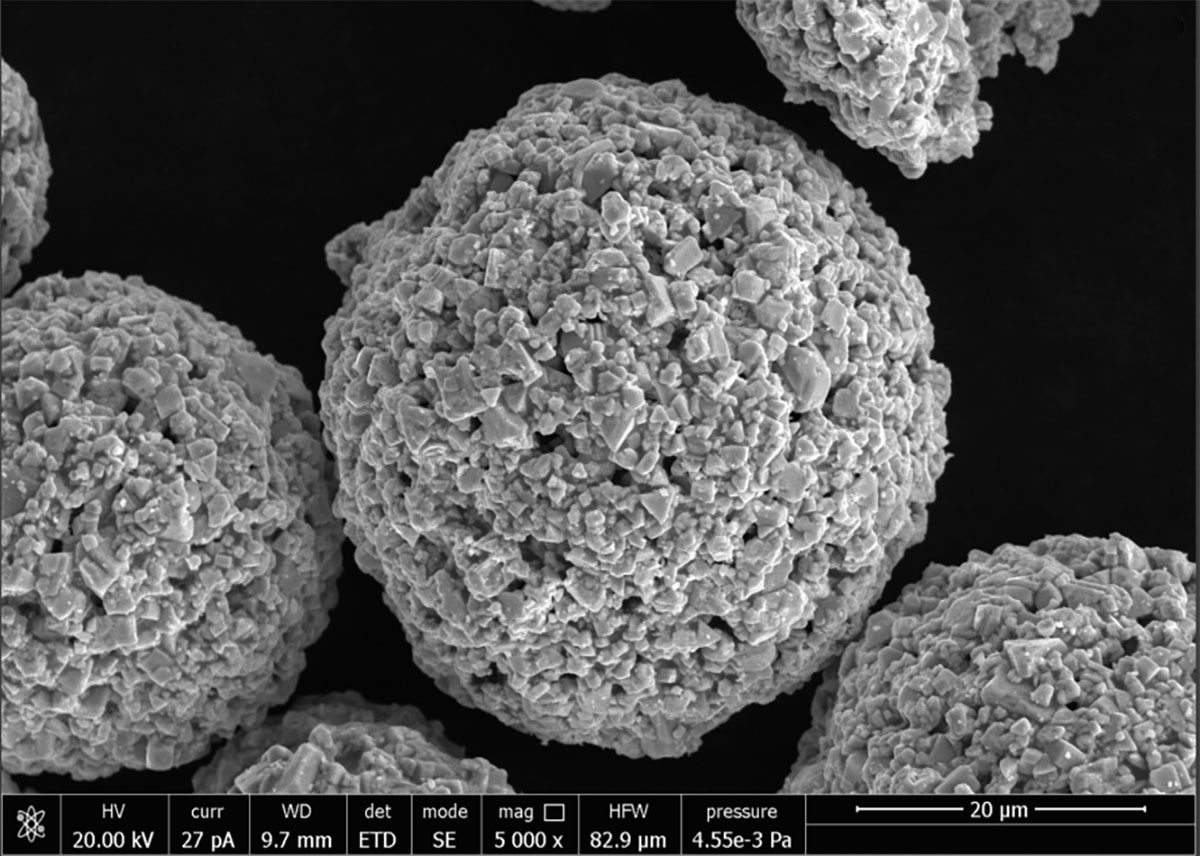

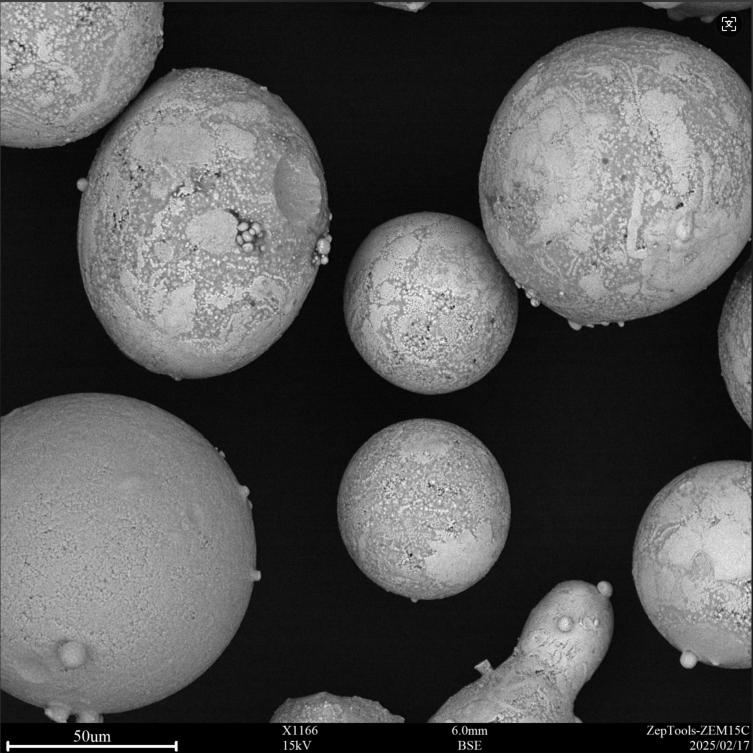

Mechanical mixing: nickel-based powder and WC powder are directly mixed (low cost, but WC is unevenly distributed).

Coated powder: WC particle surface is pre-plated with nickel to improve the bonding strength with the matrix (excellent performance, high price).

- Common processing technology:

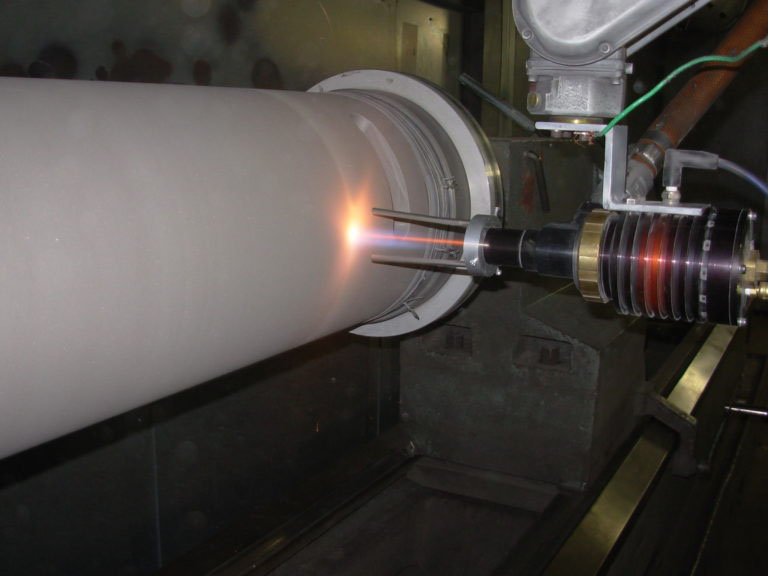

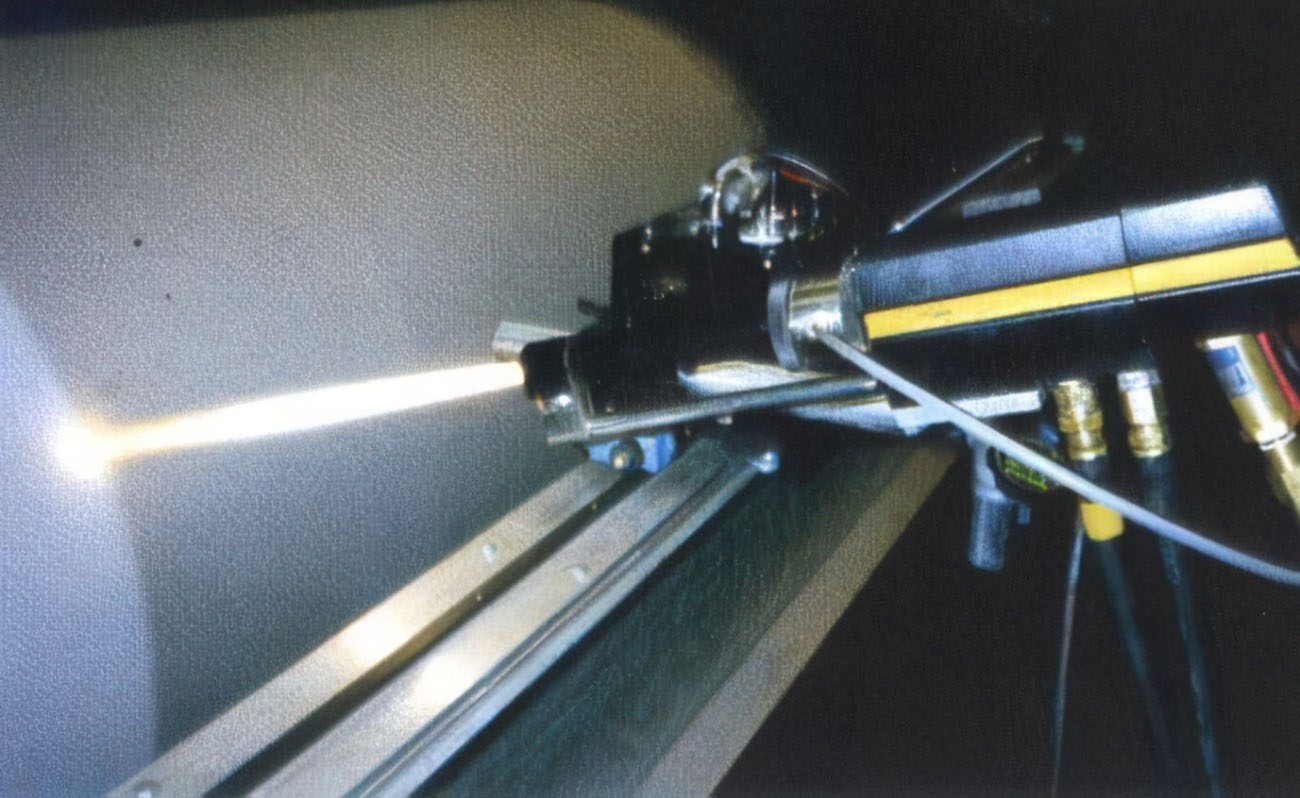

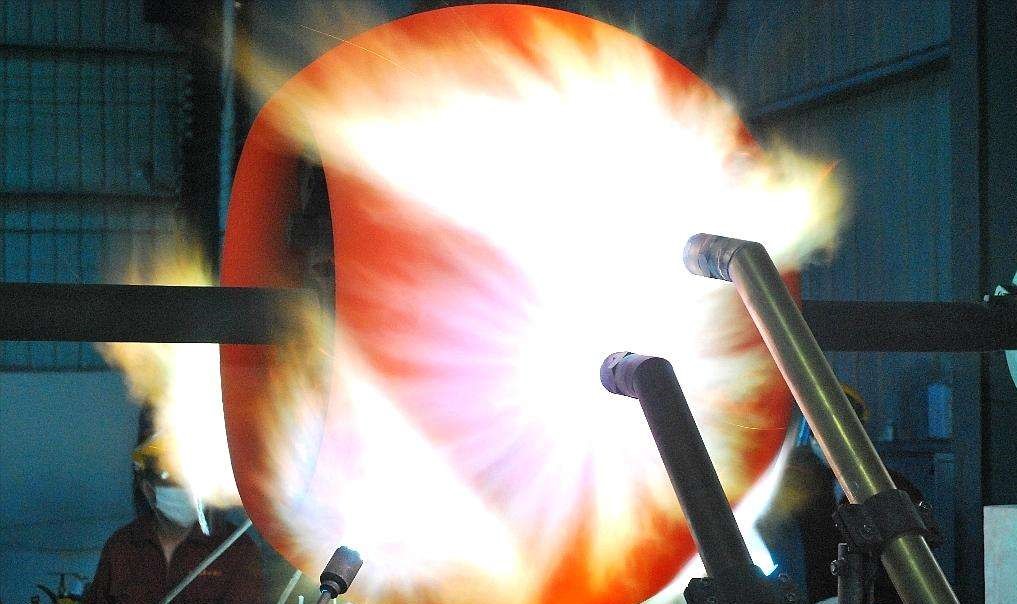

Oxyacetylene spray welding: suitable for on-site maintenance, but the flame temperature needs to be controlled (to avoid WC decomposition into W2C).

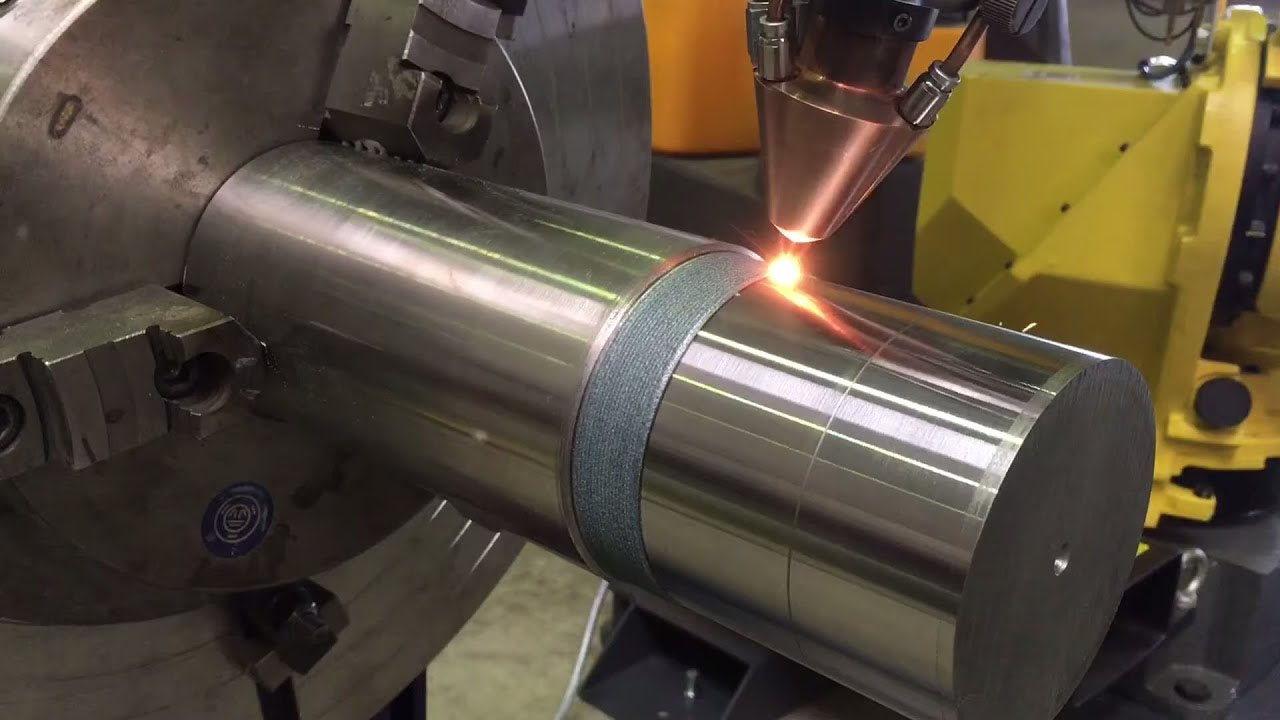

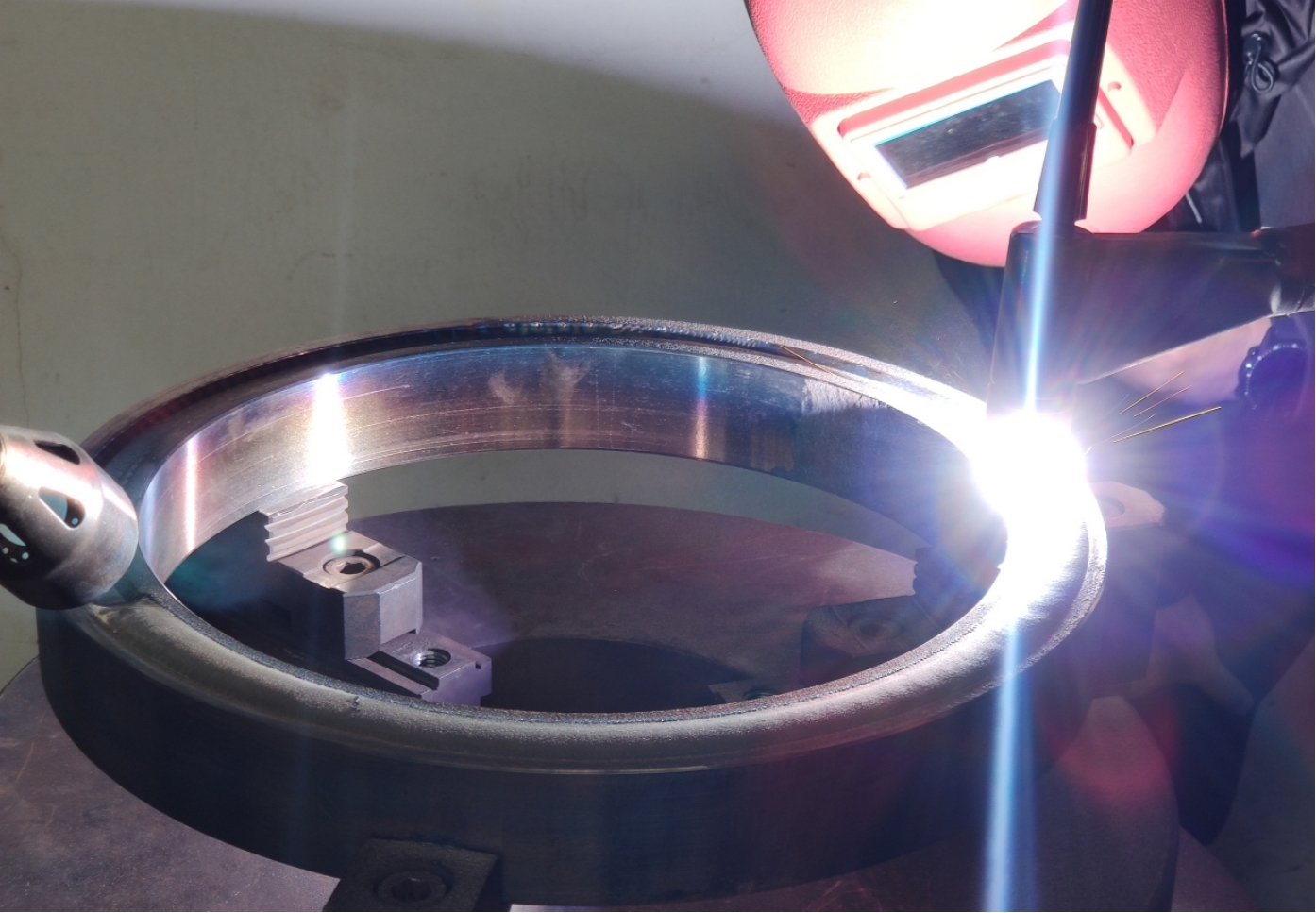

Plasma surfacing/laser cladding: concentrated energy, less WC decomposition, suitable for high-precision parts.

- Notes:

Upper limit of WC content: more than 60% will easily lead to increased brittleness of the coating.

Process matching: high-temperature processes (such as plasma) require coarse-grained WC (to avoid complete melting).

Nickel-based tungsten carbide composite materials are ideal for extreme wear conditions, especially for scenarios that require both impact resistance and wear resistance.