What is nickel-chromium carbide?

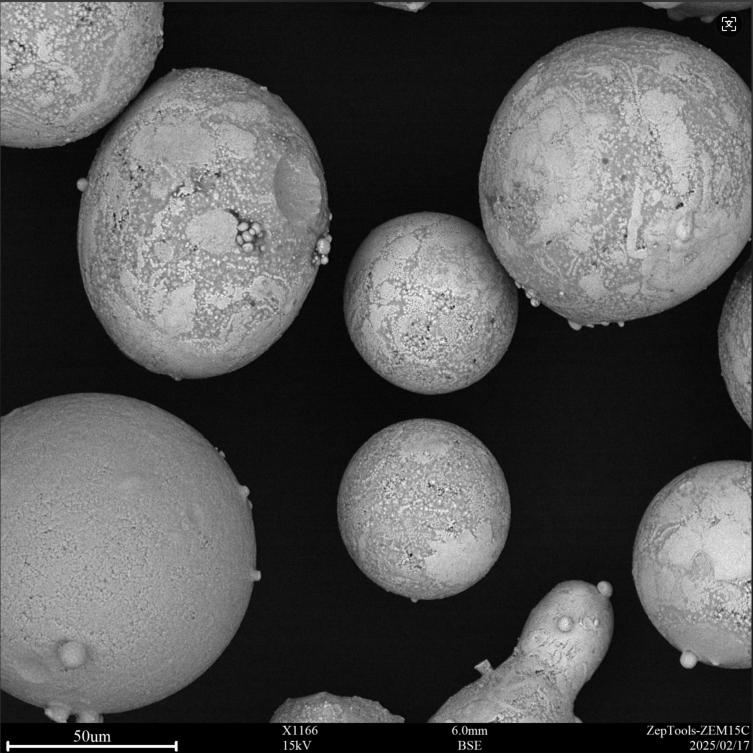

This material has three core characteristics:

- High temperature stability: It can still maintain hardness at 800-900℃, and its oxidation resistance is better than ordinary tungsten carbide

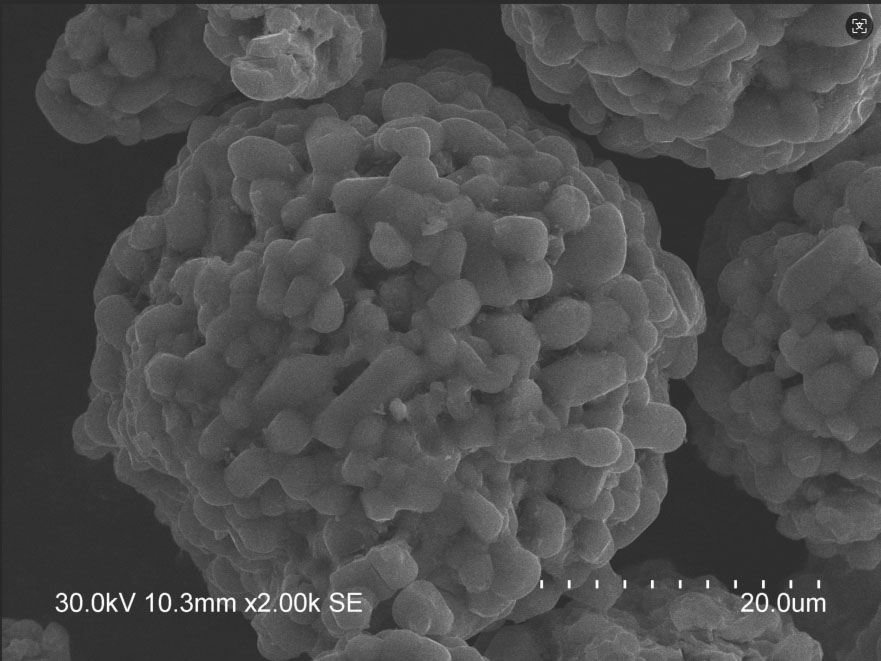

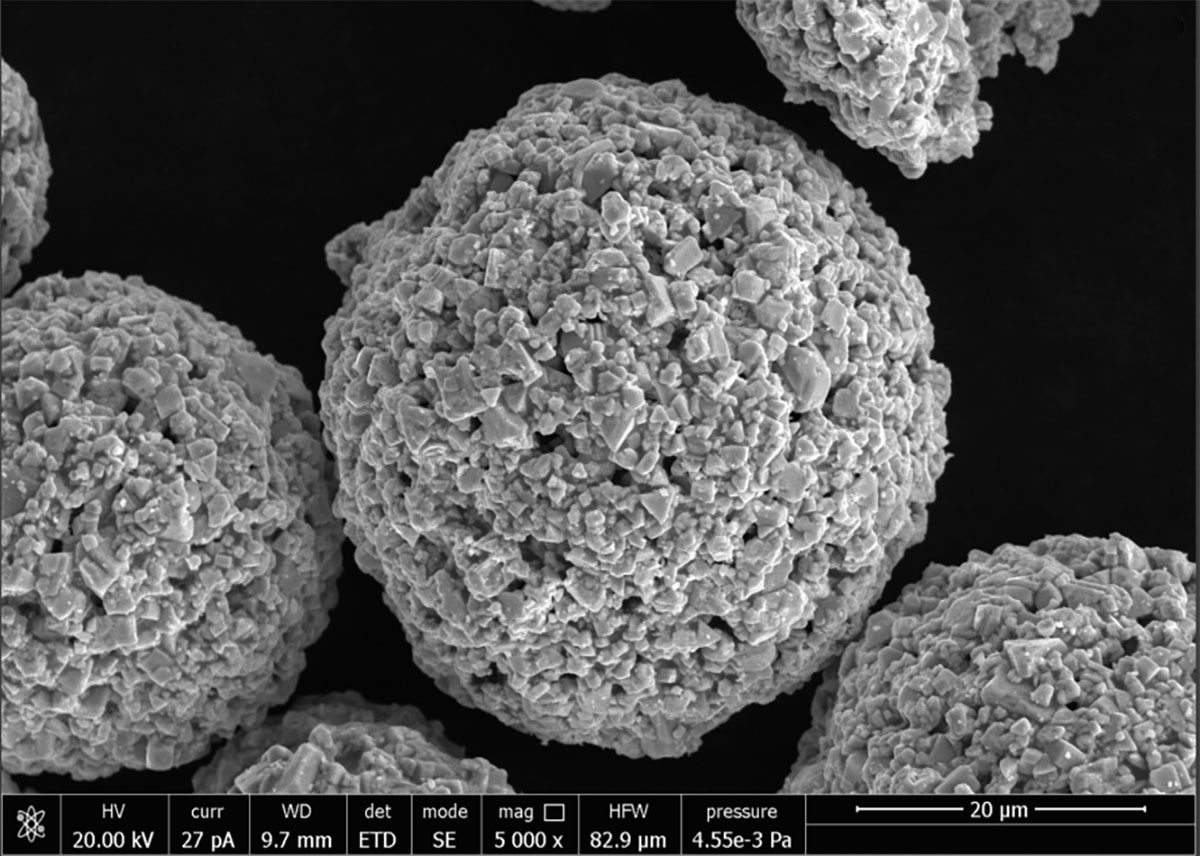

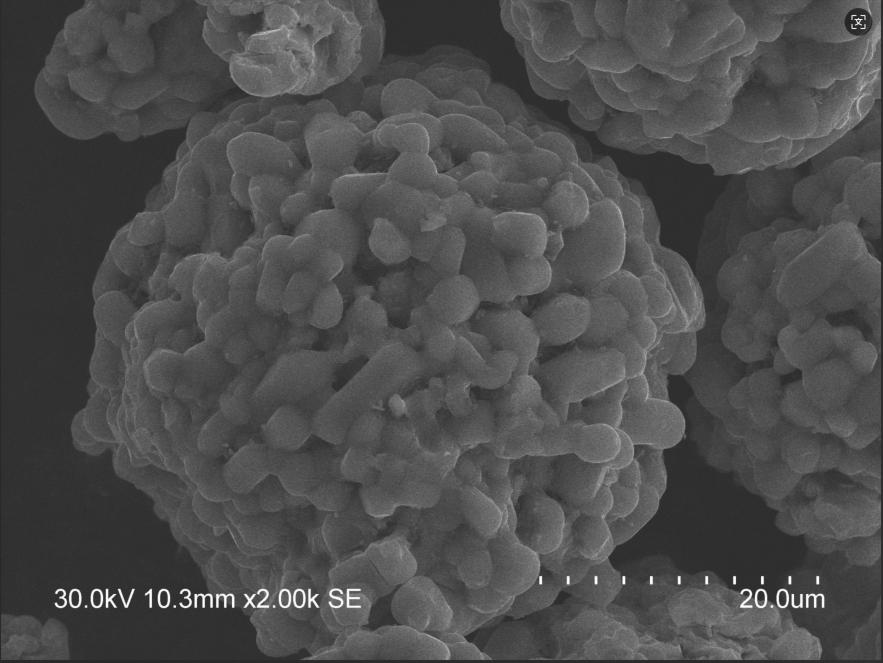

- Wear and corrosion resistance: The hardness of chromium carbide reaches HV1400-1600, and the nickel-chromium matrix provides good corrosion resistance

- Thermal shock resistance: The thermal expansion coefficient is similar to that of steel, and it is not easy to peel off under high temperature conditions

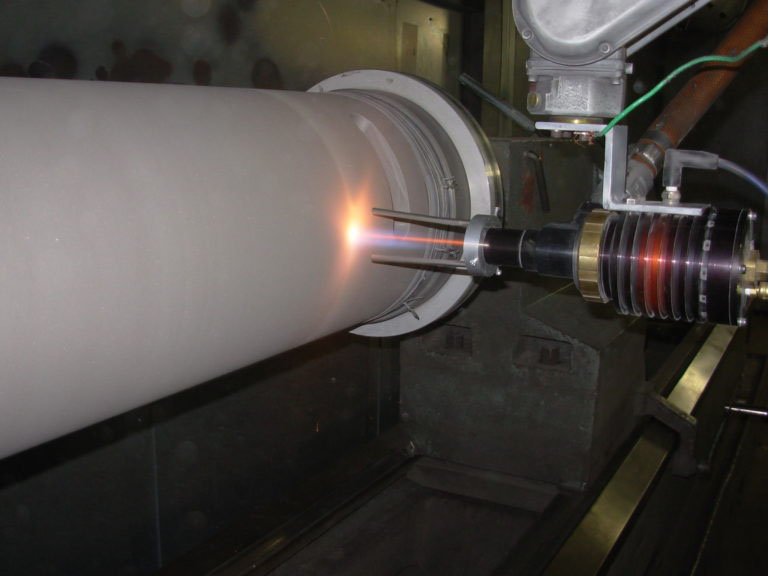

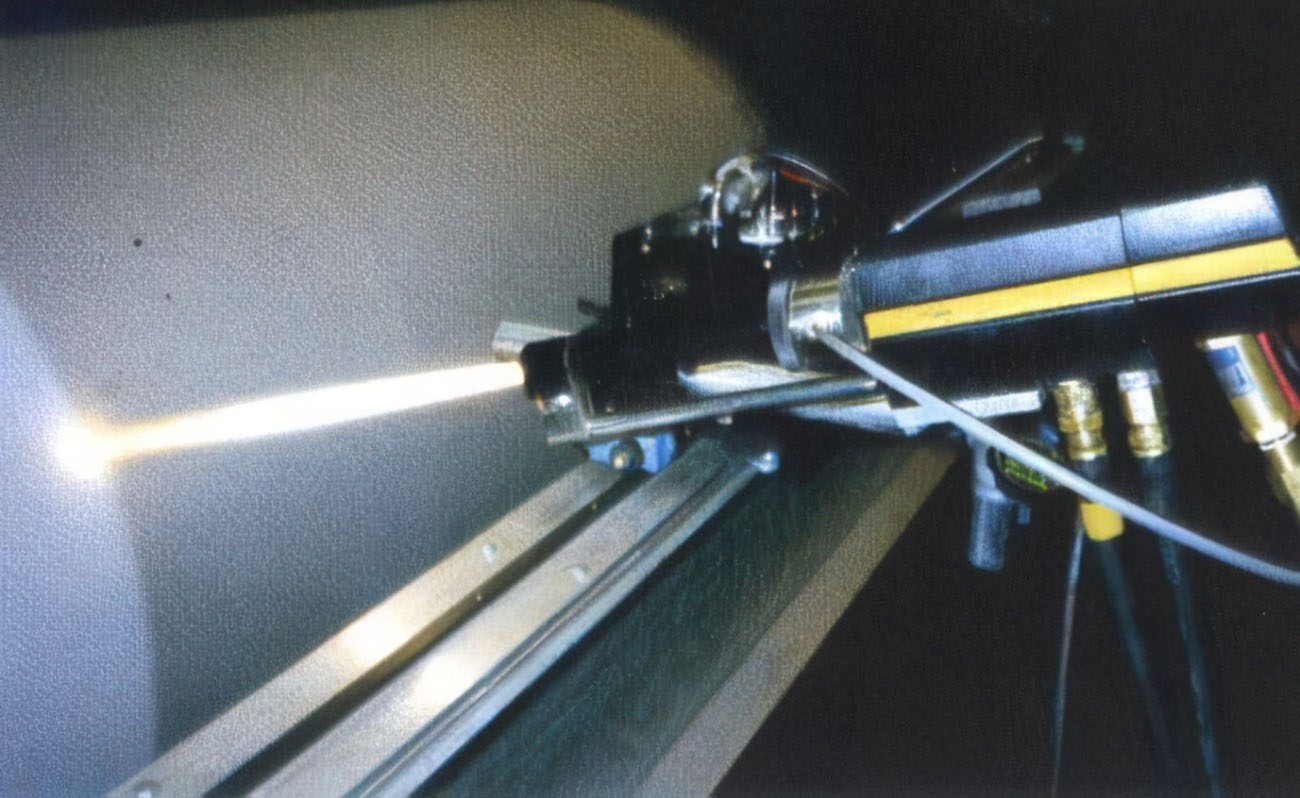

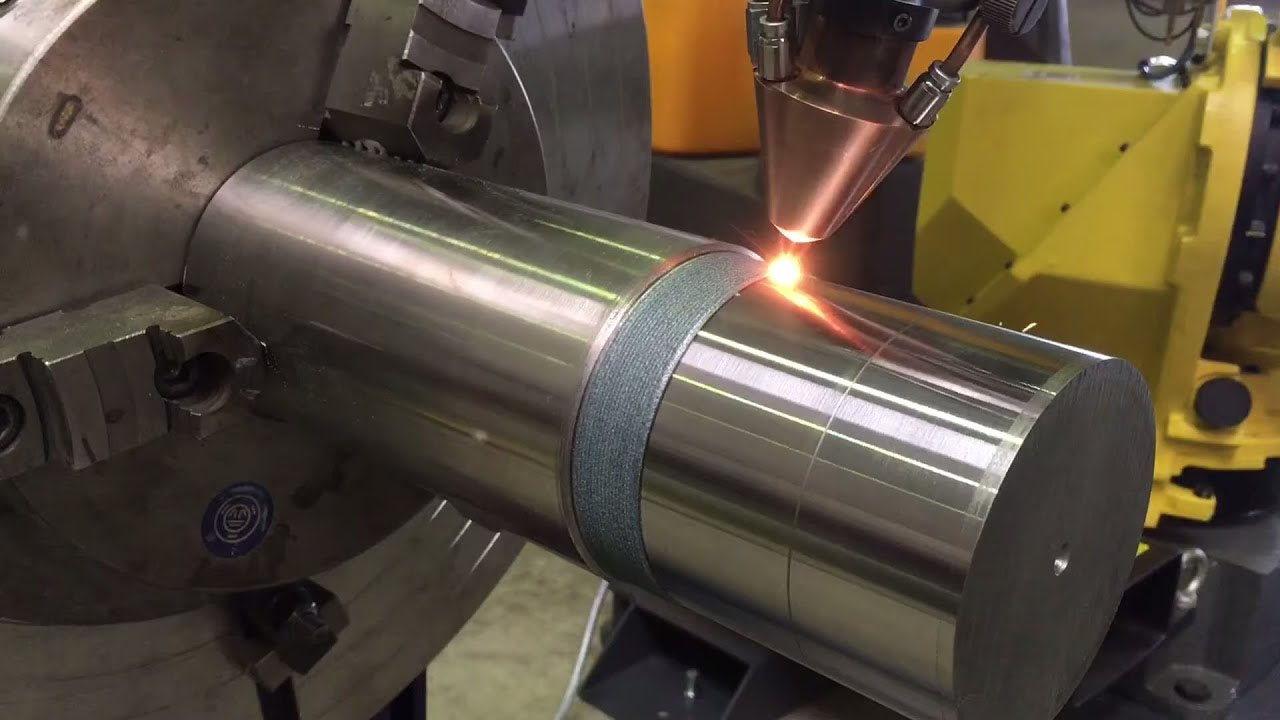

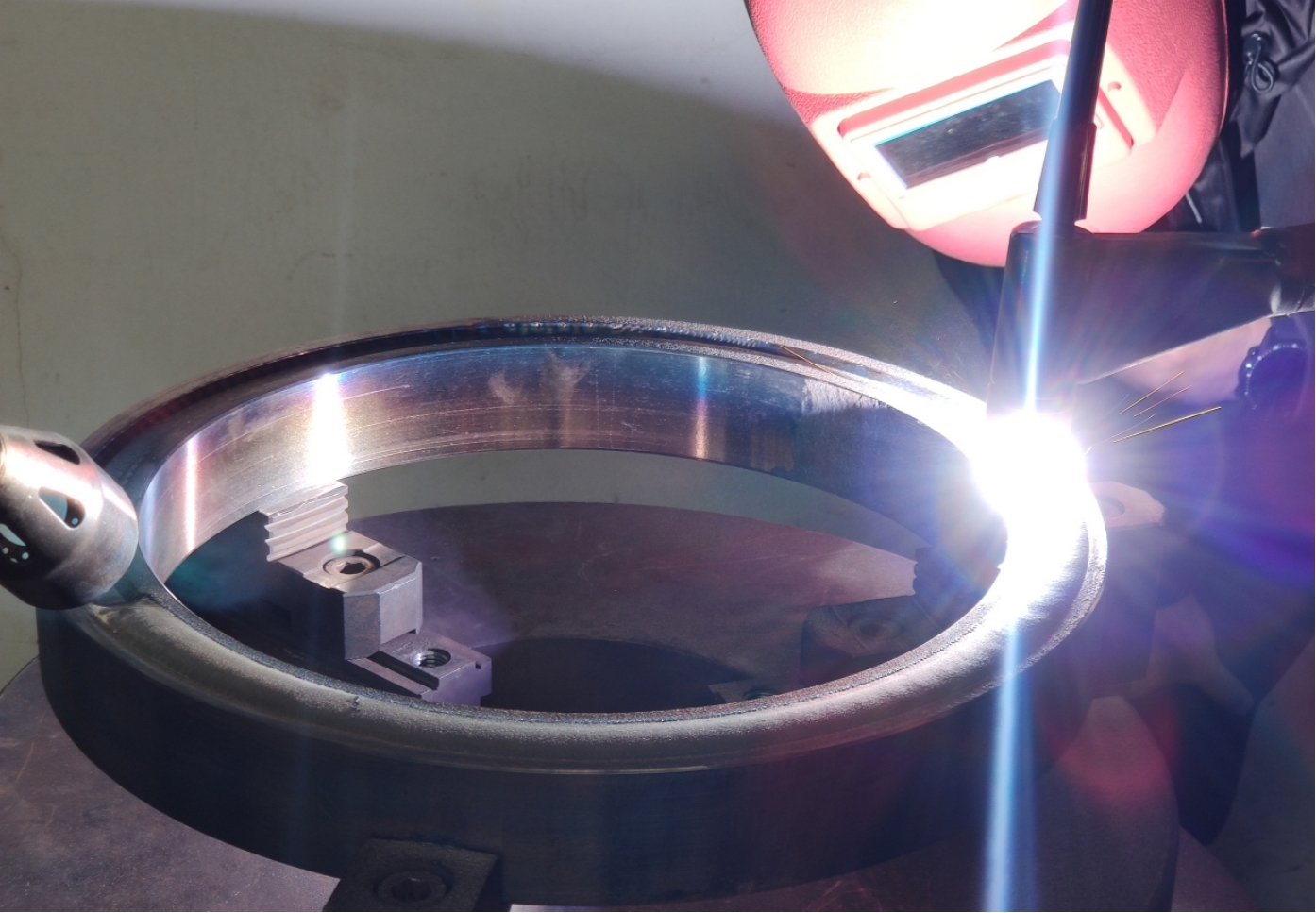

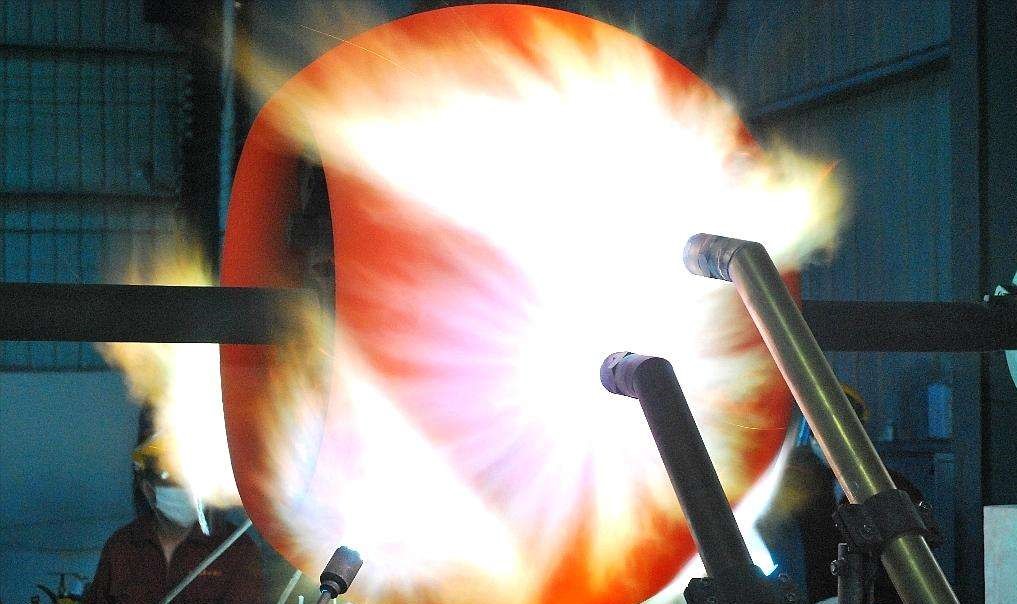

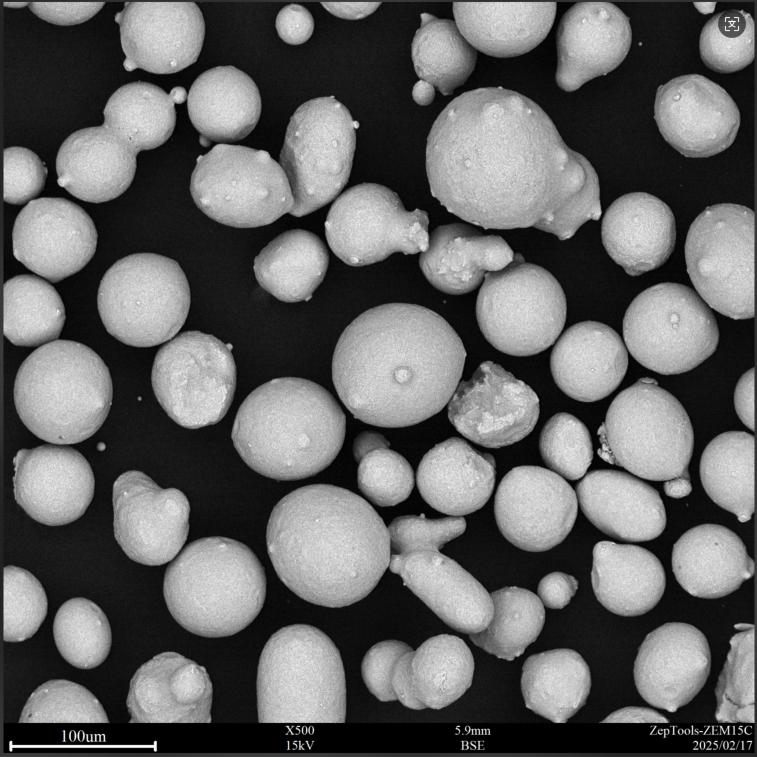

In industry, the coating is mainly prepared by supersonic flame spraying (HVOF) or plasma spraying process, which is widely used in:

High temperature corrosion resistance of boiler tubes in thermal power plants

Protection of hot end components of aviation engines

Corrosion and wear resistant components of chemical equipment

High temperature wear resistant parts in the metallurgical industry, etc.

Compared with tungsten carbide coating, it has a longer service life in high temperature oxidation environment, but its wear resistance at room temperature is slightly inferior to that of tungsten carbide materials. When selecting materials, it is necessary to weigh the specific working temperature, corrosive medium and other conditions.