What is the most commonly used nickel-based self-fluxing alloy Ni60?

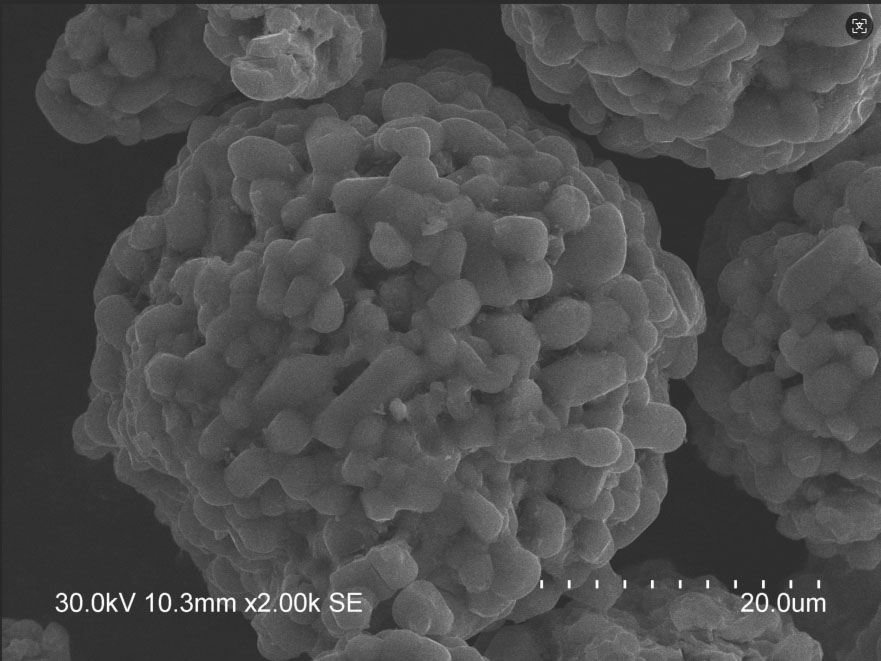

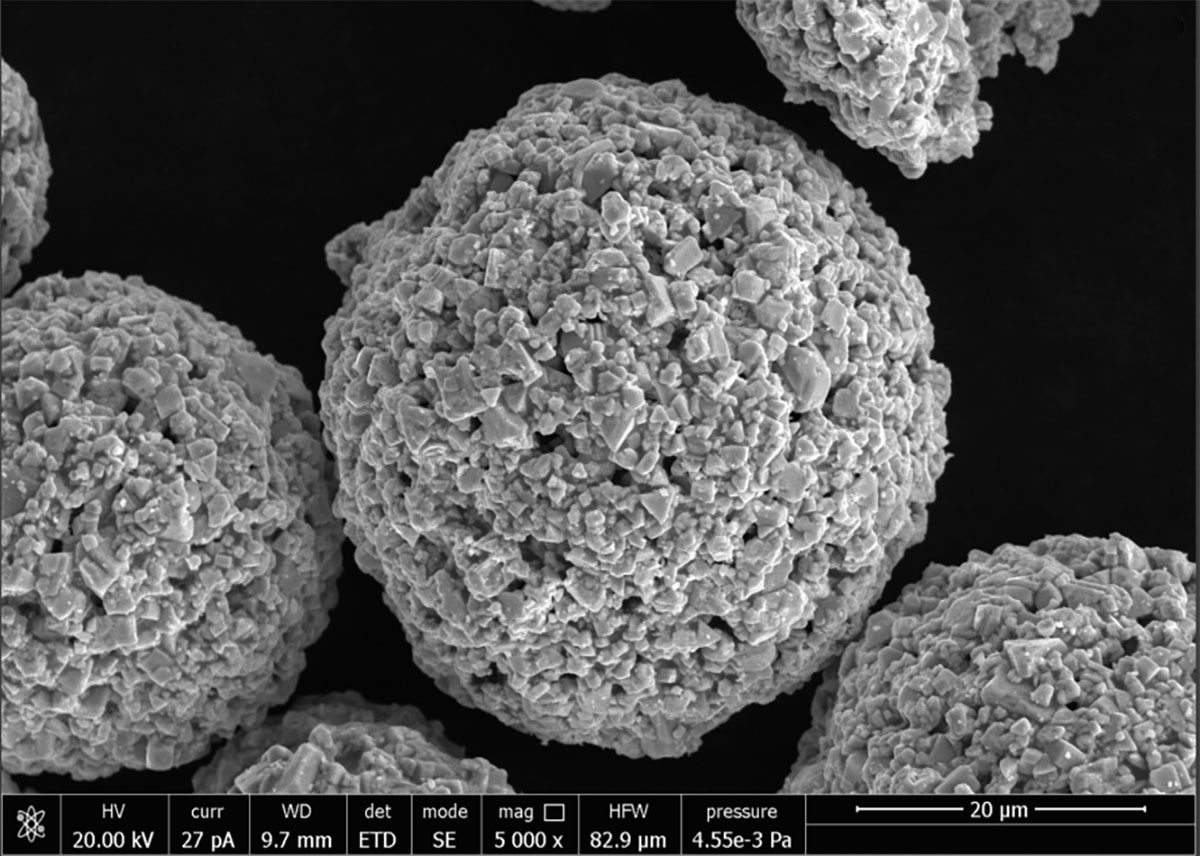

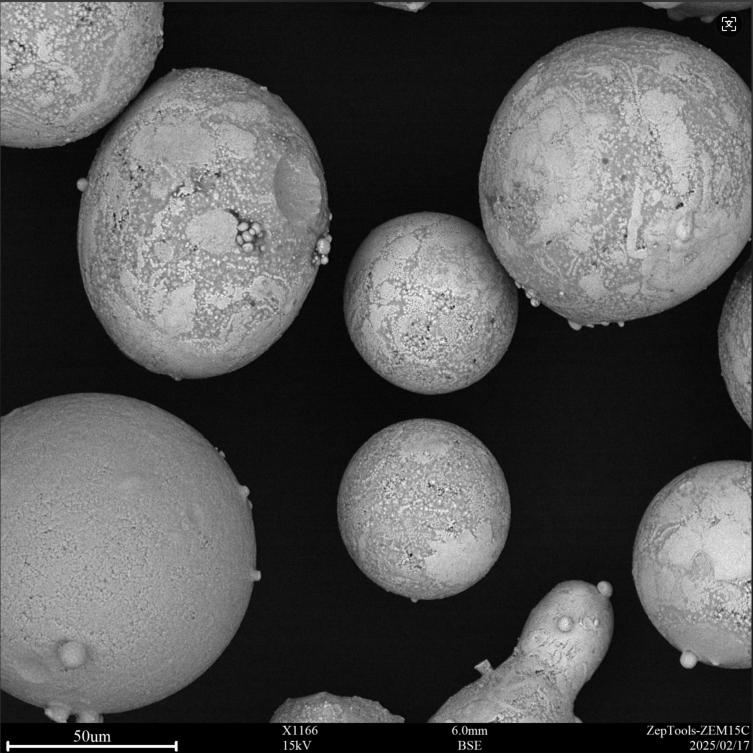

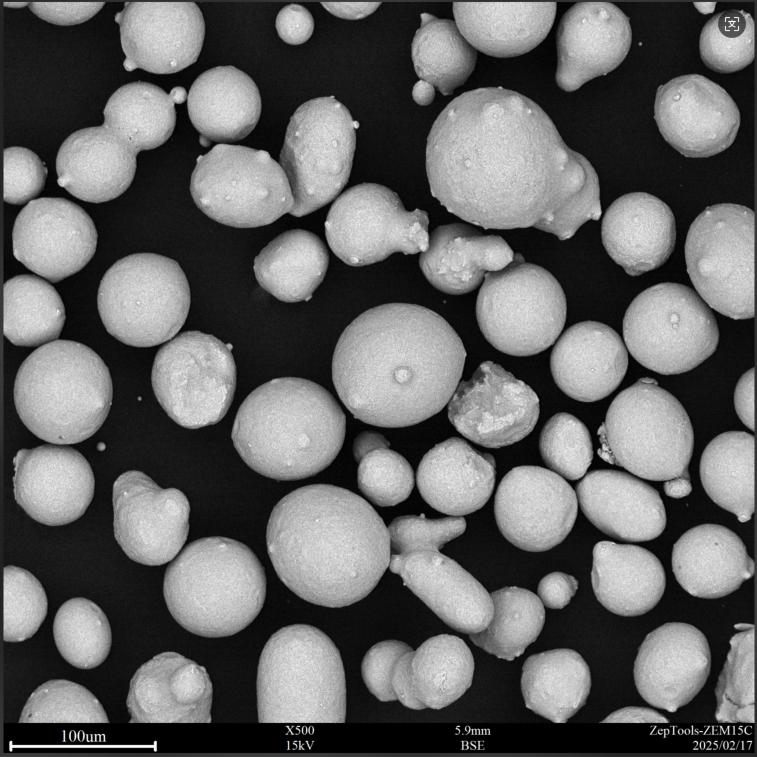

Ni60 is a high hardness (HRC 55-60) nickel-chromium-boron-silicon (NiCrBSi) self-fluxing alloy with excellent wear resistance, corrosion resistance and high temperature performance. Its typical composition is:

Nickel (Ni): matrix, providing toughness and corrosion resistance

Chromium (Cr) (15-20%): enhance oxidation resistance and corrosion resistance

Boron (B) (3-4.5%), Silicon (Si) (4-5.5%): reduce melting point, improve self-fluxing and hardness

Carbon (C) (0.7-1.0%): forms hard carbides and borides (such as Cr7C3, Ni3B) with chromium and boron to improve wear resistance

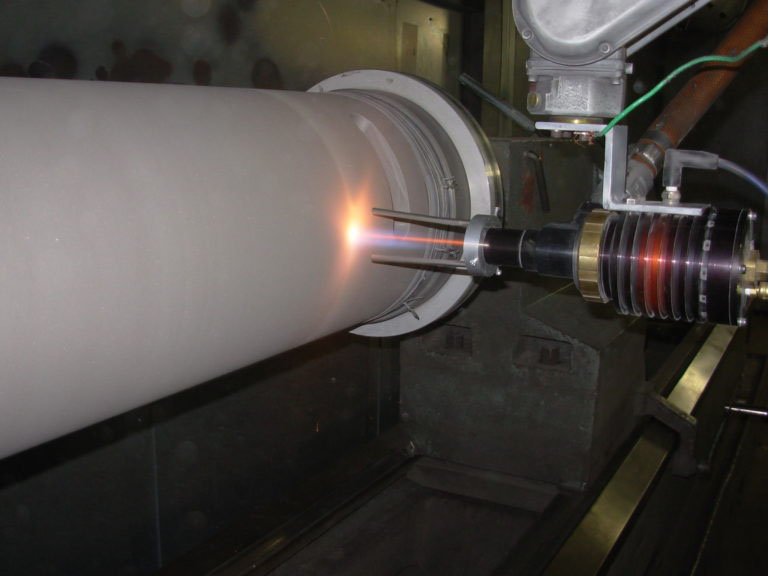

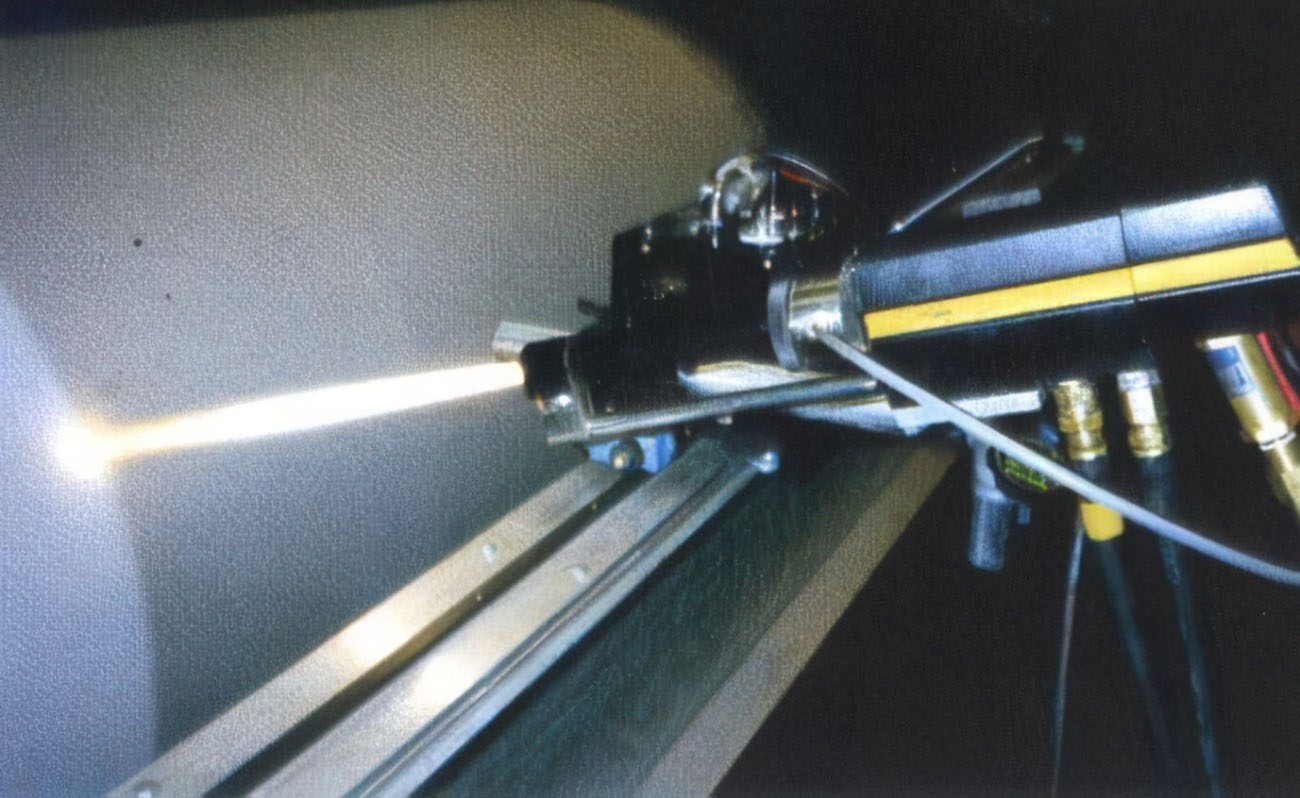

Main applications

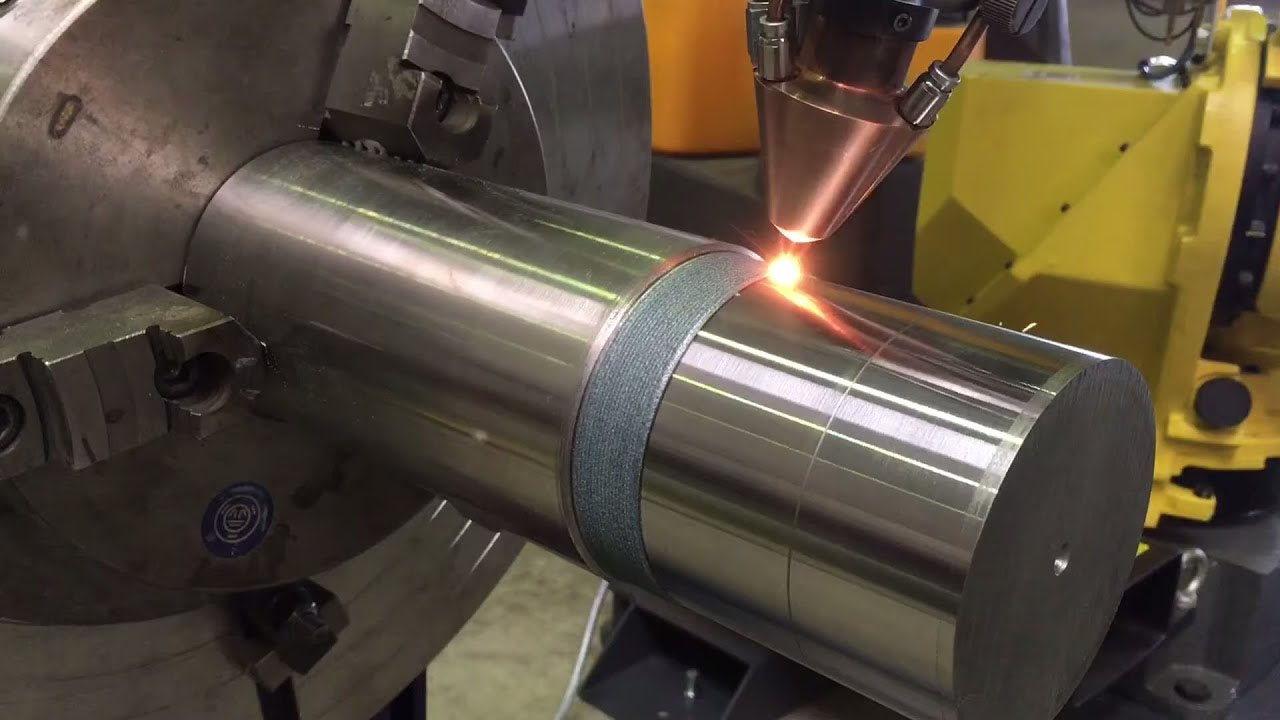

Wear-resistant parts: rollers, shafts, molds, gears, etc.

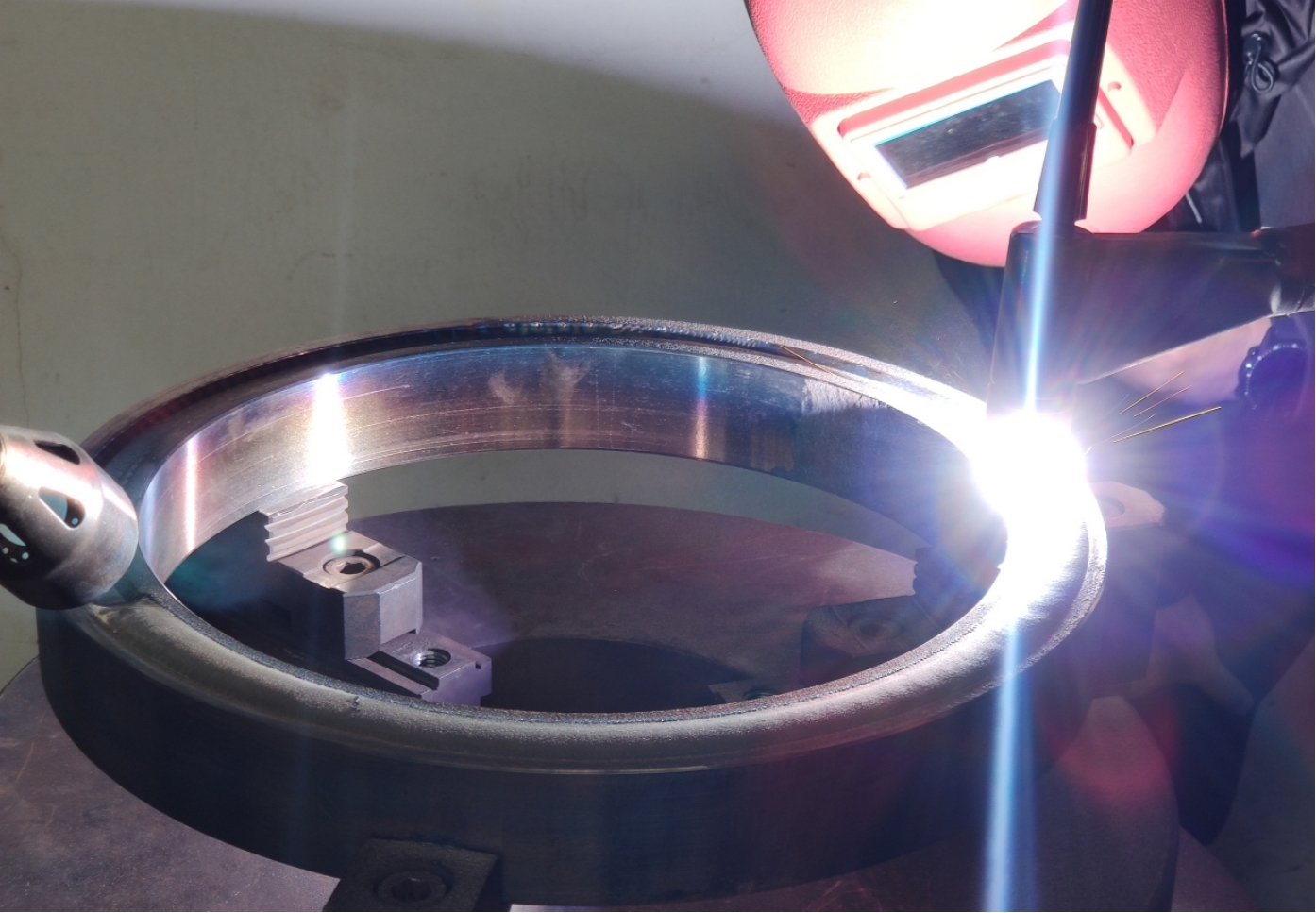

Corrosion-resistant environment: chemical valves, pump bodies, agitators

High temperature conditions: boiler sealing surfaces, exhaust valves