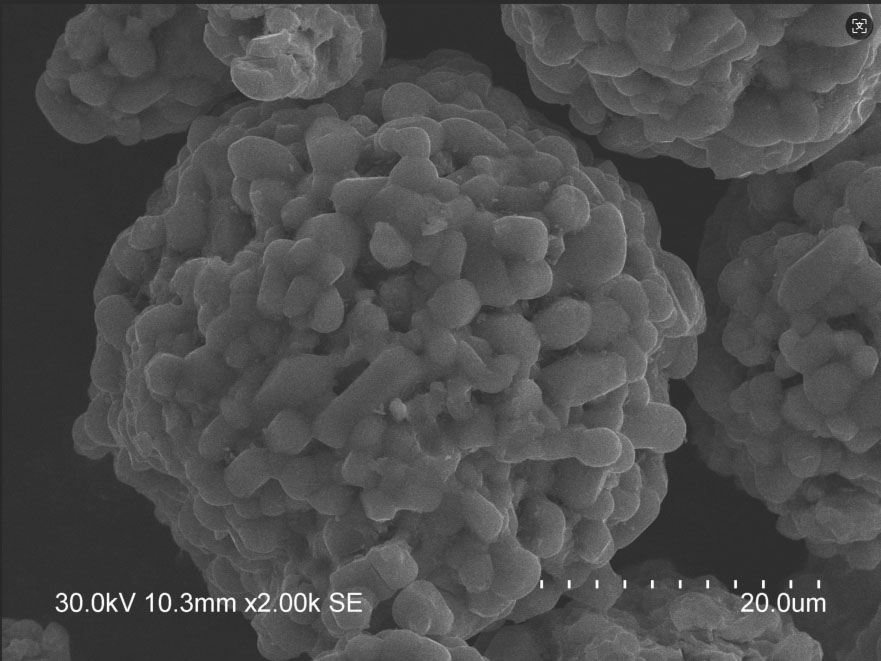

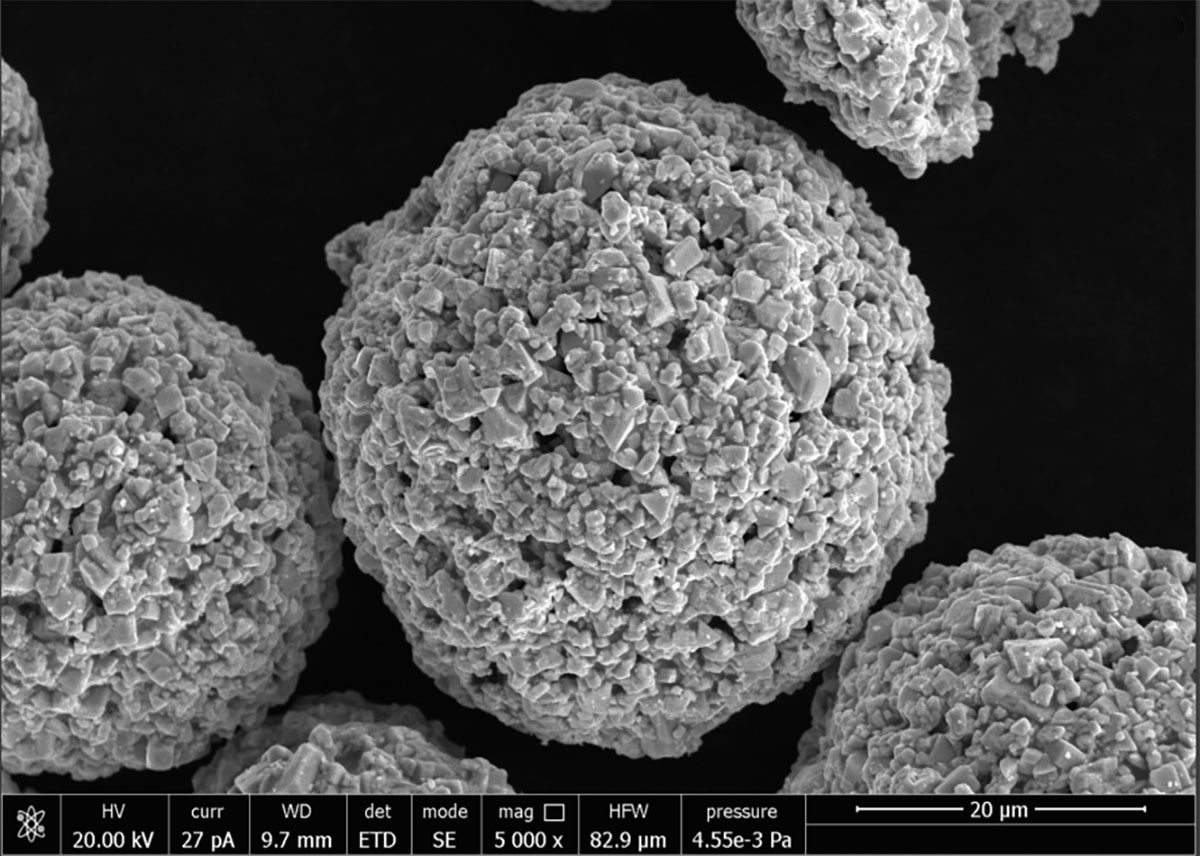

What is WC-10Co4Cr?

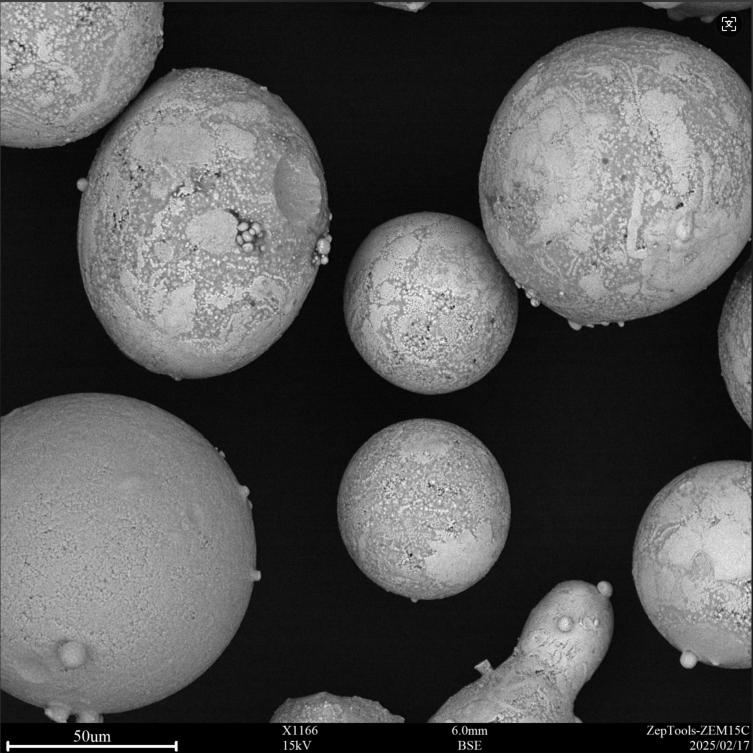

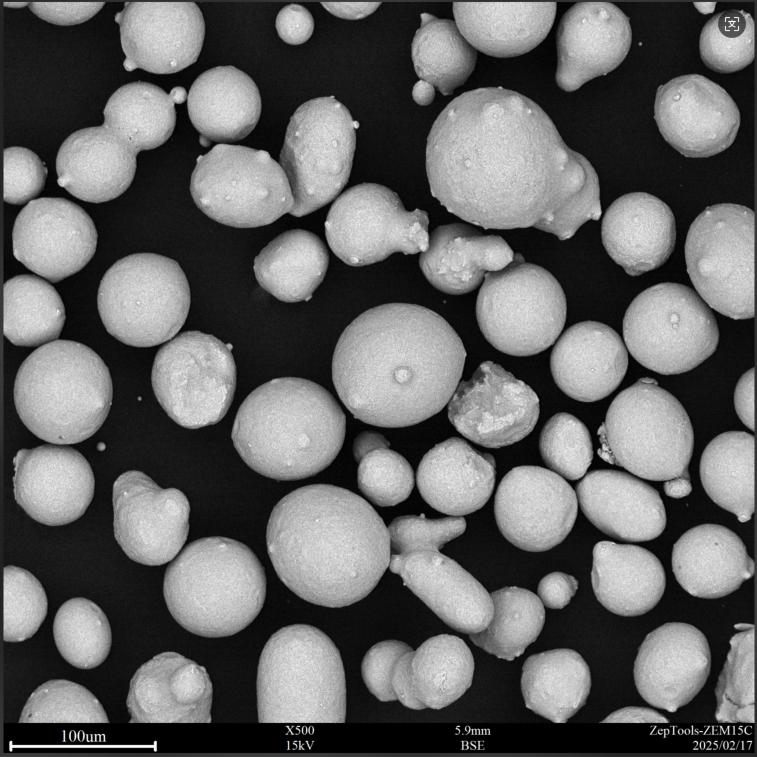

WC-10Co4Cr is a tungsten carbide-based composite powder material consisting of a tungsten carbide (WC) hard phase and a cobalt-chromium (Co-Cr) metal bonding phase. The numbers indicate the composition ratio: 10% cobalt (Co), 4% chromium (Cr), and the rest is tungsten carbide. This combination gives the coating high hardness, wear resistance, and corrosion resistance.

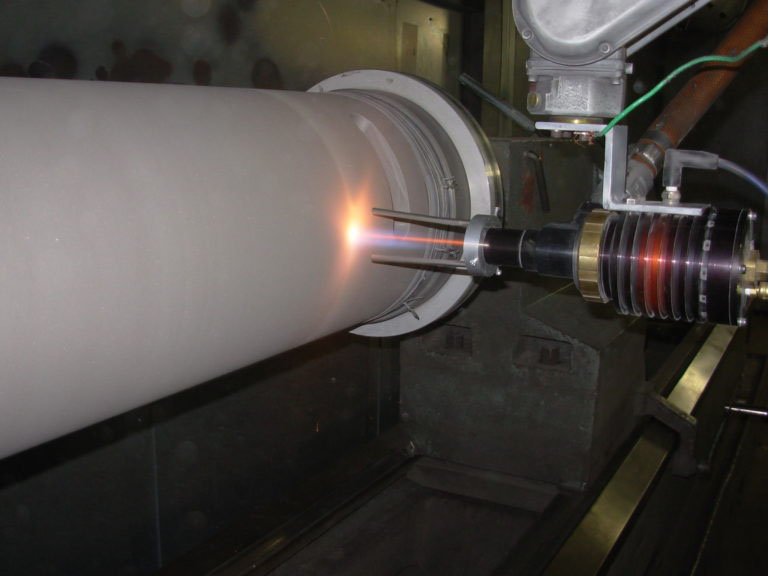

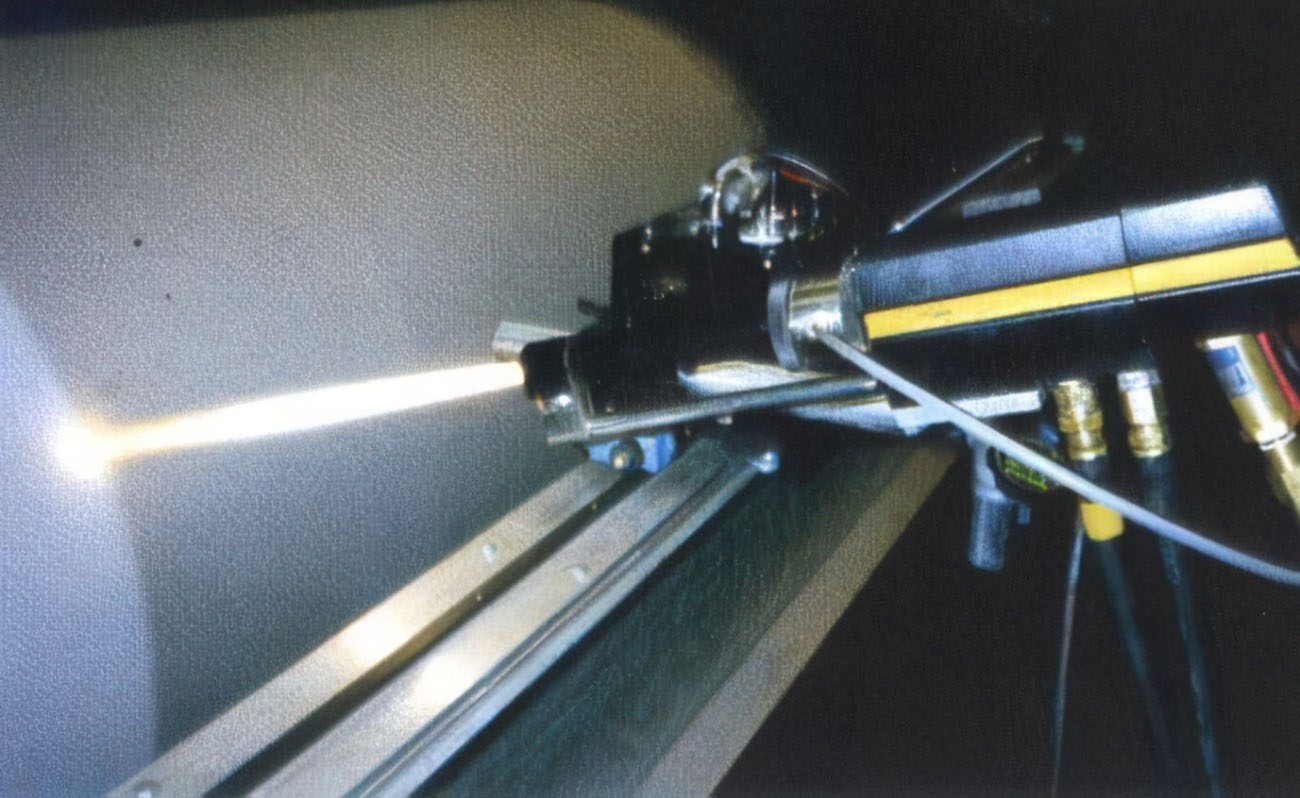

Application characteristics of supersonic spraying technology

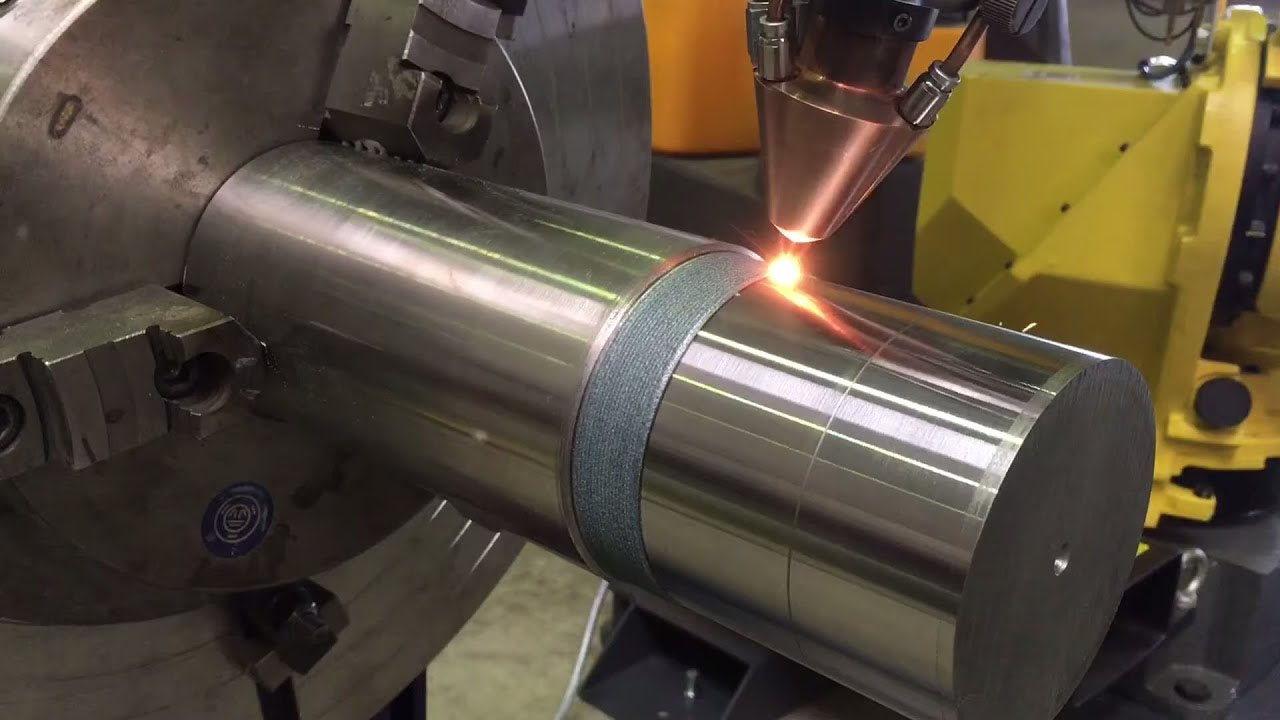

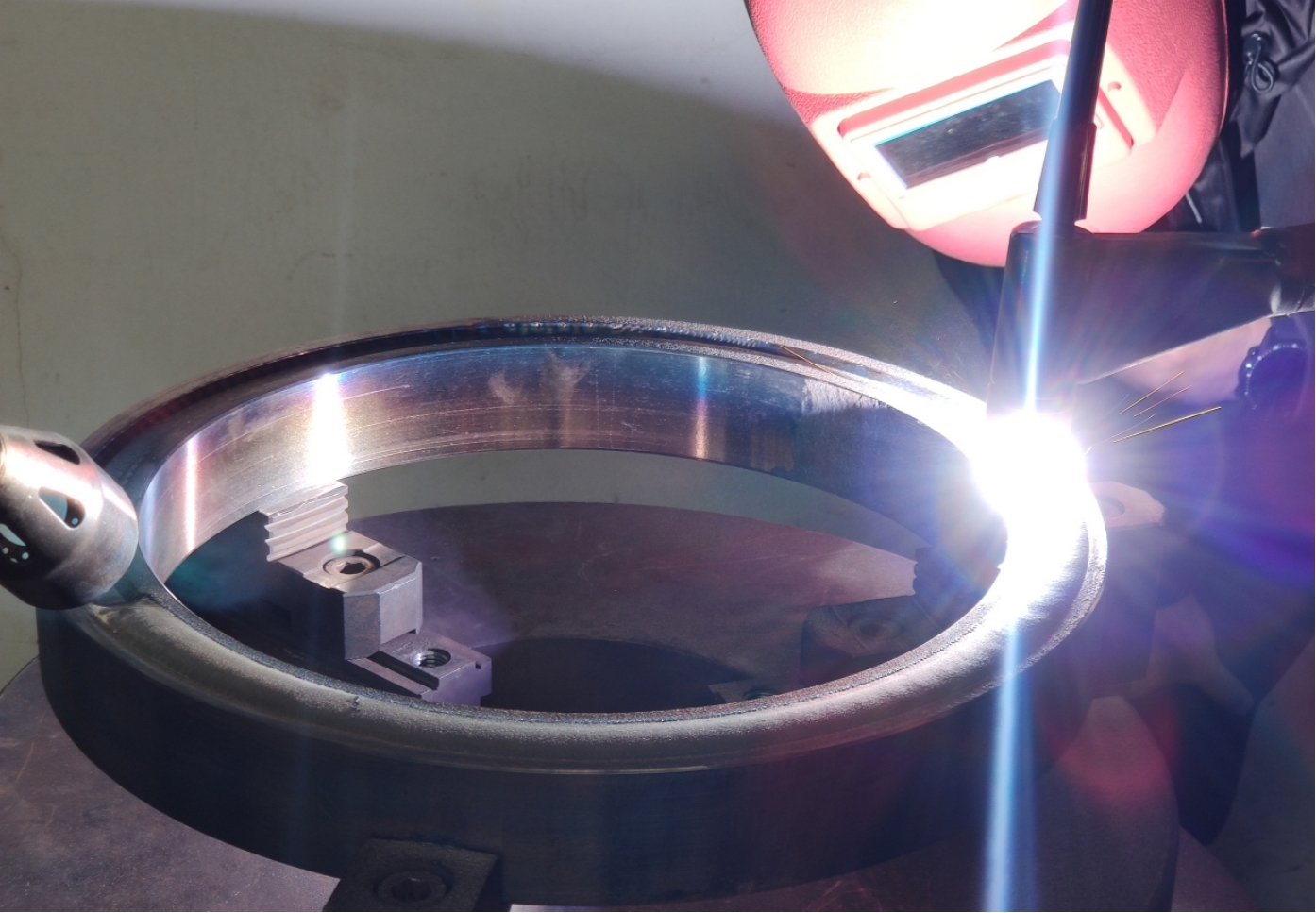

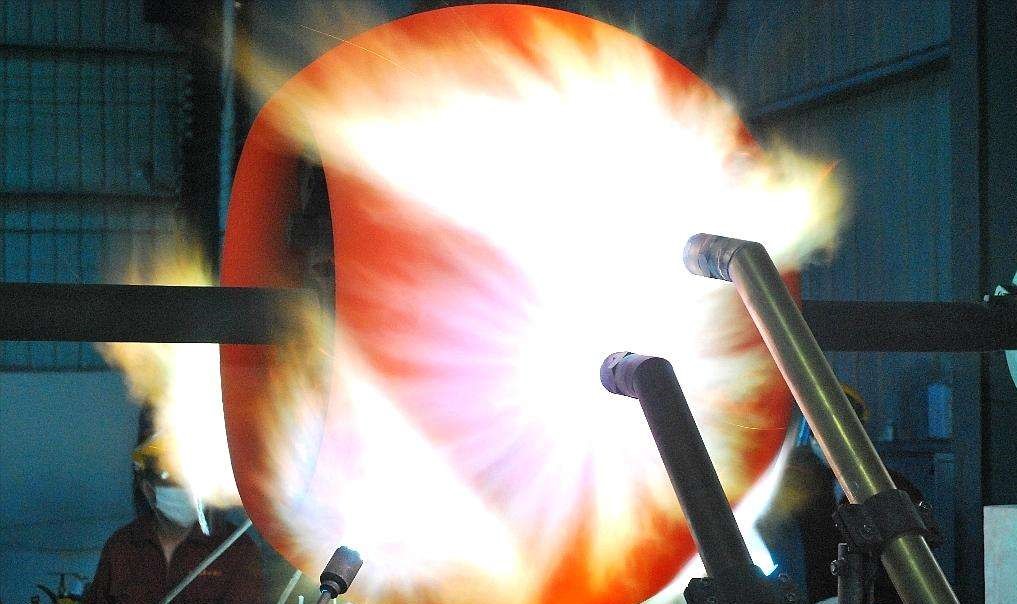

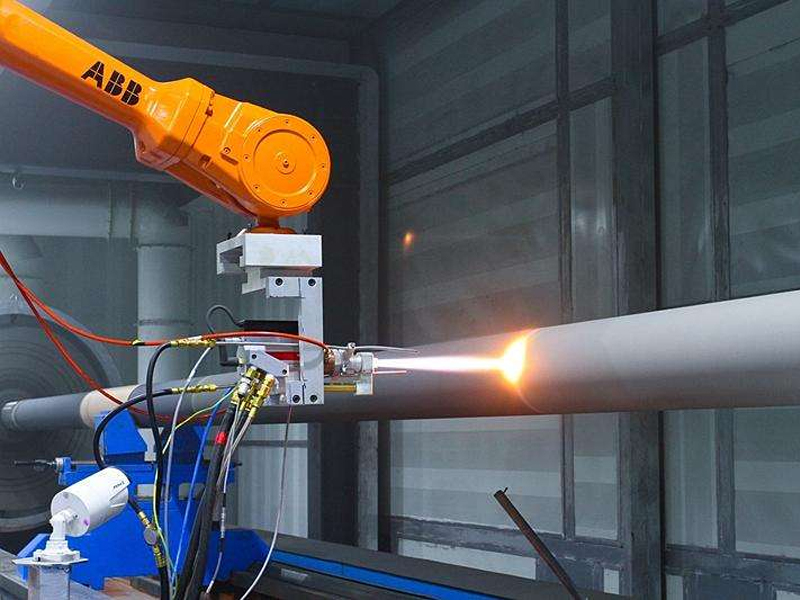

Supersonic spraying (such as HVOF or HVAF) accelerates WC-10Co4Cr powder to supersonic speed through high-temperature and high-speed airflow, and impacts the substrate to form a dense coating. Its advantages include:

- High bonding strength: particles impact at high speed to form mechanical bonding and partial metallurgical bonding.

- Low porosity (usually <1%): the coating is dense and has excellent permeability resistance.

- Low temperature process (relative to plasma spraying): reduce thermal deformation of the substrate and decomposition of tungsten carbide.

Typical application areas

- Wear-resistant parts:

- Aircraft engine blades, turbine shafts

- Hydraulic piston rods, coal mine hydraulic supports

- Papermaking drying rollers, pump mechanical seals

- Corrosion-resistant environments:

- Marine equipment (such as ship shafting, valves)

- Chemical pump bodies, nuclear power components

- Combined protection:

- Working conditions that are subject to wear and corrosion at the same time (such as offshore drilling equipment)

Process considerations

- Spraying parameters (such as temperature and speed) must be controlled to avoid decarburization of tungsten carbide to form brittle W2C.

- Substrate pretreatment (sandblasting, cleaning) has a significant effect on bonding strength.

This type of coating can extend the life of key components by 3-8 times and is suitable for surface protection needs under harsh working conditions.