010203

Ni60A a widely used nickel-based self-fluxing alloy with high hardness and corrosion resistance

Product introduction

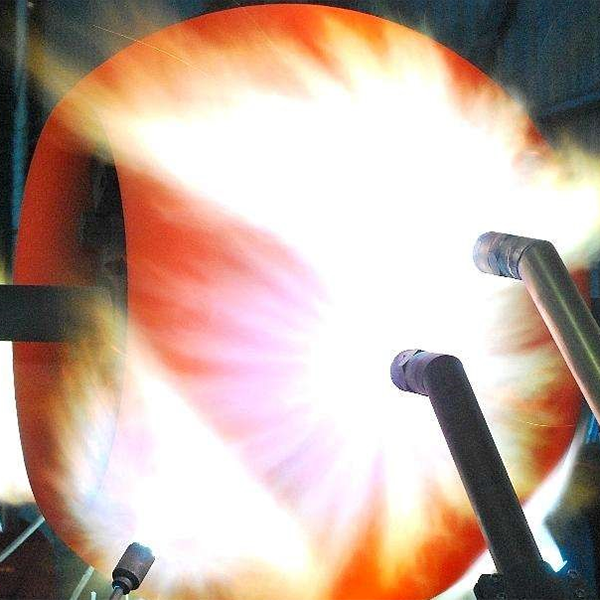

Application: Suitable for oxy-acetylene flame or plasma spray welding process, often used for corrosion resistance, wear resistance, especially resistance to sliding wear parts of the preventive protection and repair, such as wire drawing drum, CAM, plunger, rolling machine conveyor rolls.

Powder melting temperature :960-1040℃ spray welding layer hardness :HRC58-62 Note :1. Strictly follow the requirements of the oxy-acetylene flame or plasma spray welding process. 2. When using small and medium-sized spray welding guns, it is appropriate to choose a powder of 150 purpose, and when using large spray welding guns, choose a powder of 150/+320 purpose. 3. If the alloy powder has moisture absorption phenomenon, or the storage period is more than 3 months, it should be dry (120℃, 22 hours) before use.

DG.Ni60A chemical composition: Ni 0.9C 4.3Si 3.3B 4.2Fe 16.3Cr

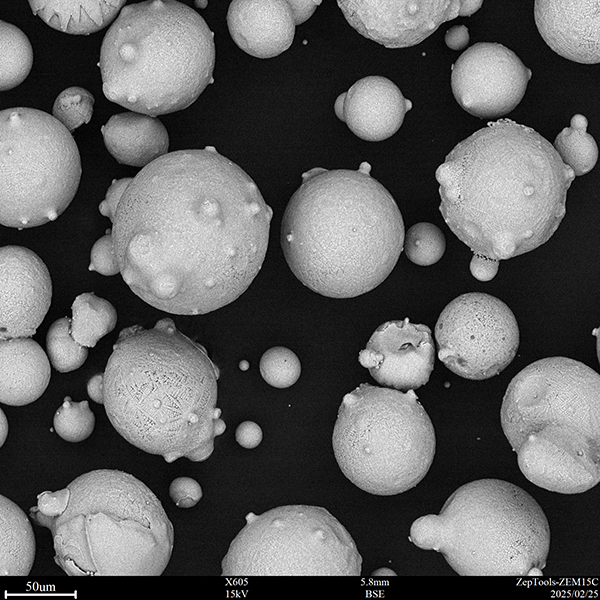

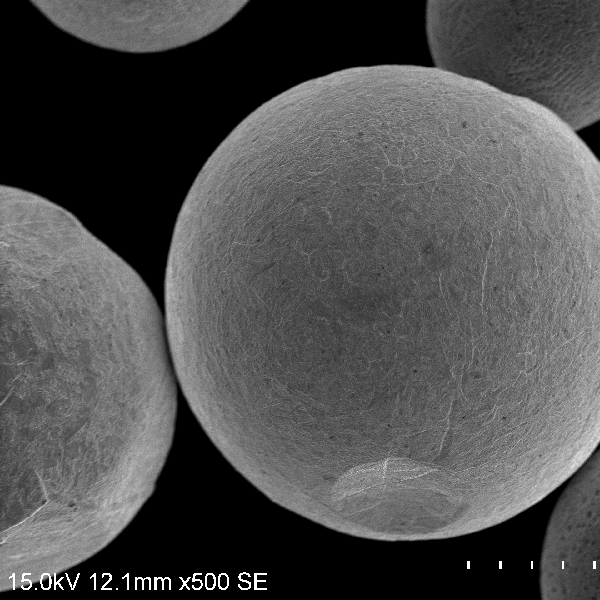

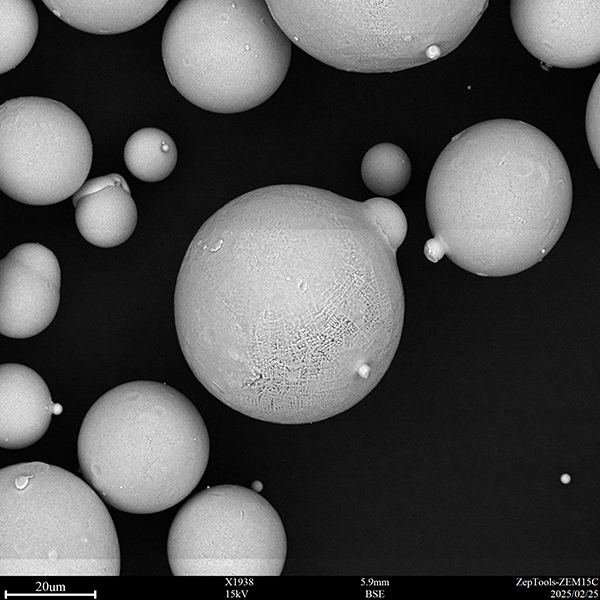

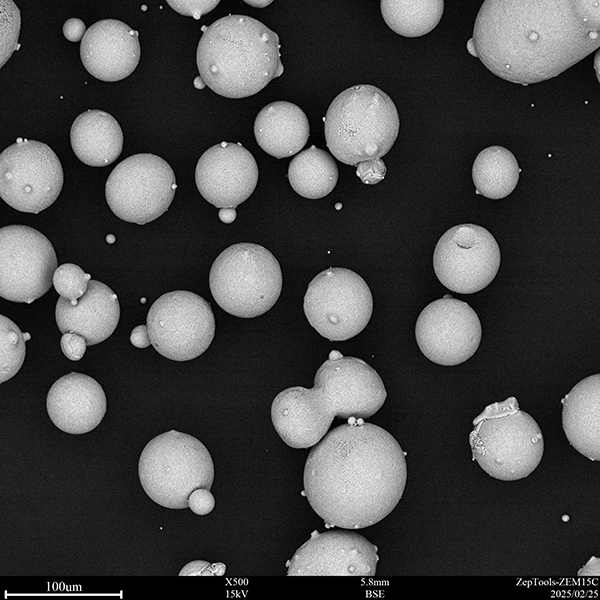

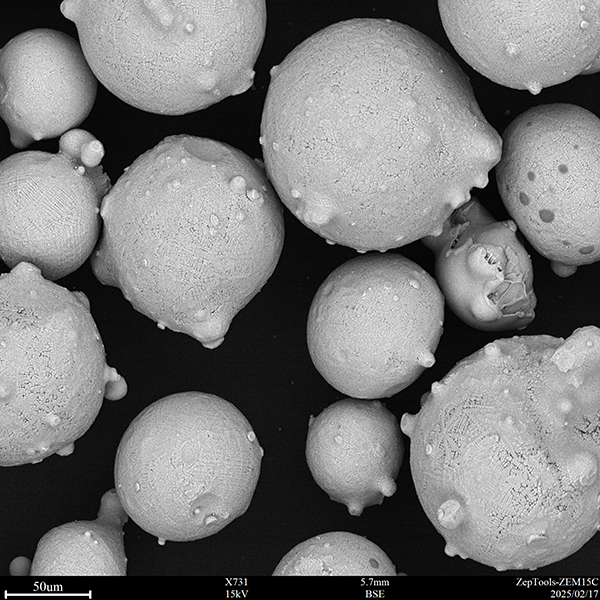

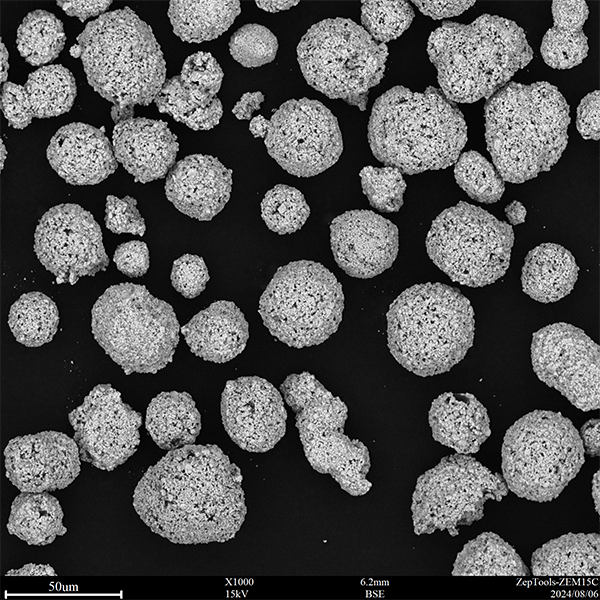

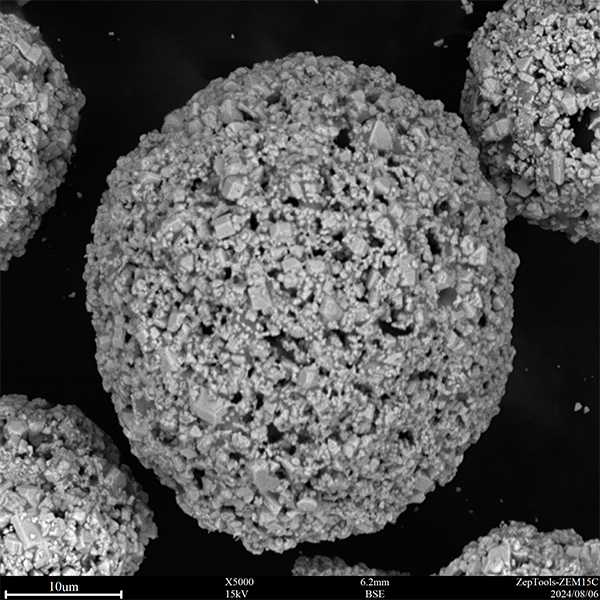

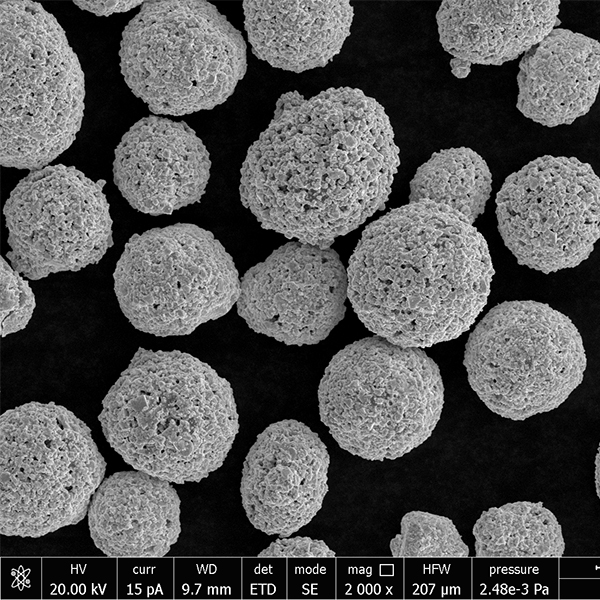

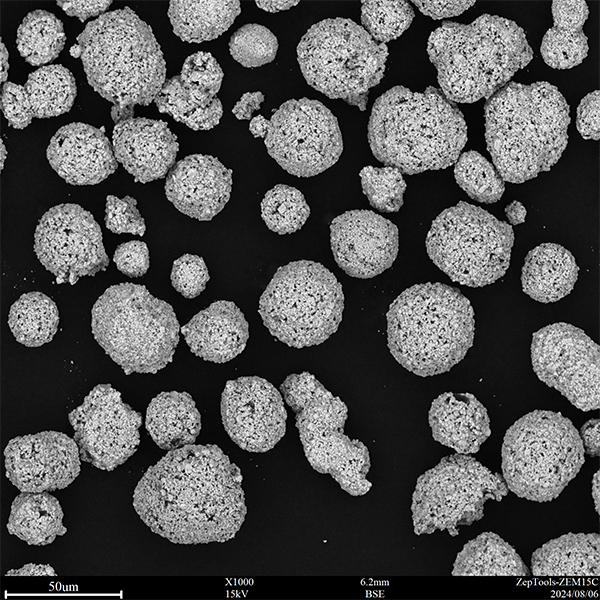

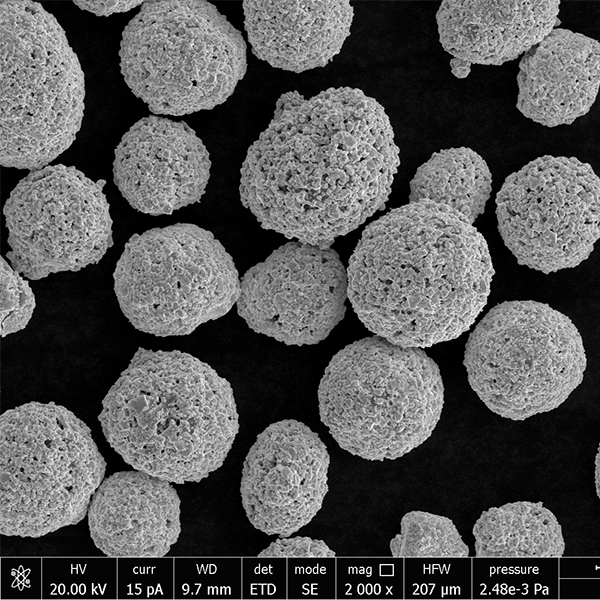

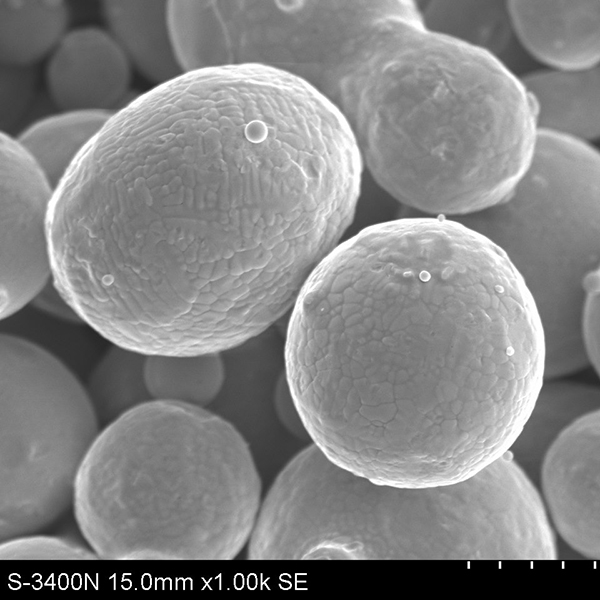

Production process: water atomization, gas atomization

Typical coating process: oxygen acetylene flame spraying, oxygen acetylene flame spraying, plasma spraying, plasma surfacing, supersonic spraying

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.