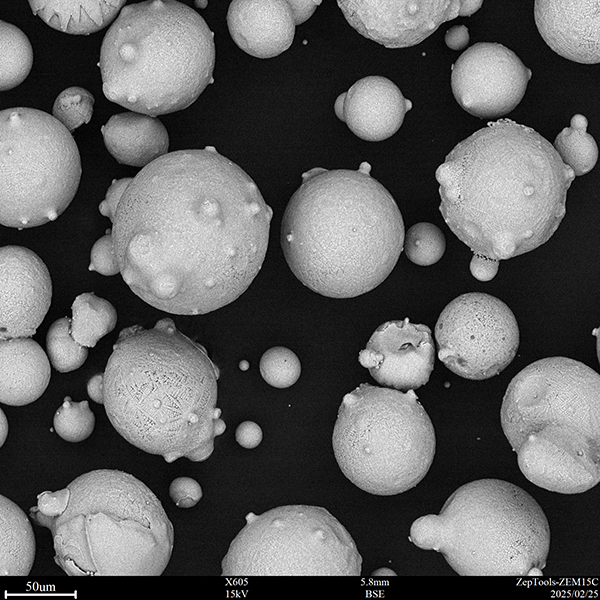

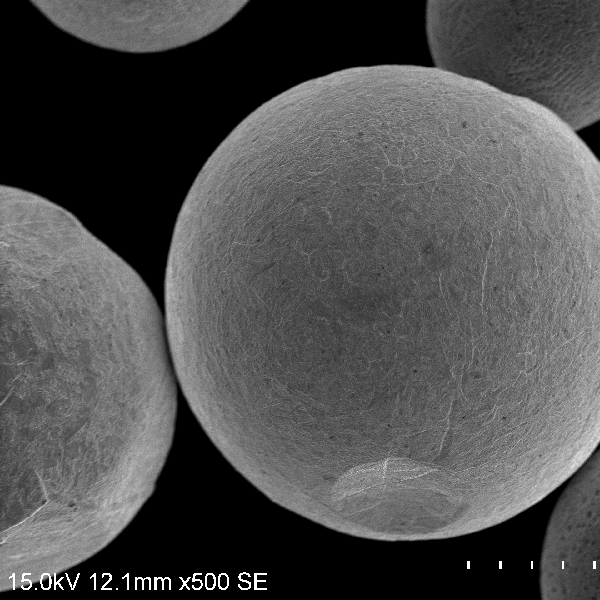

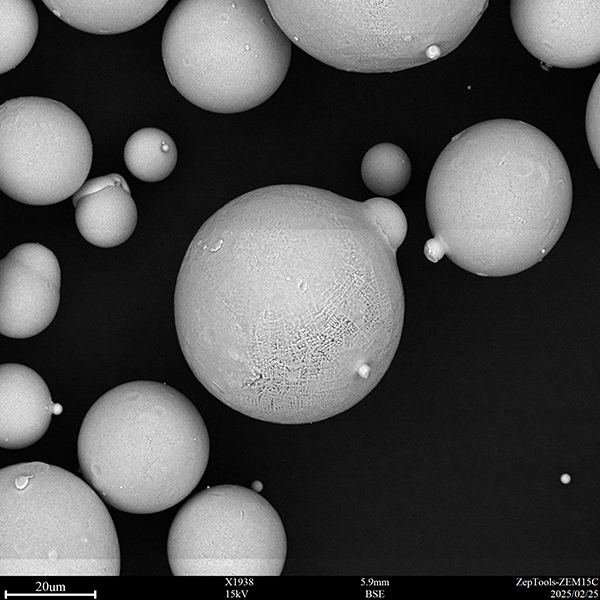

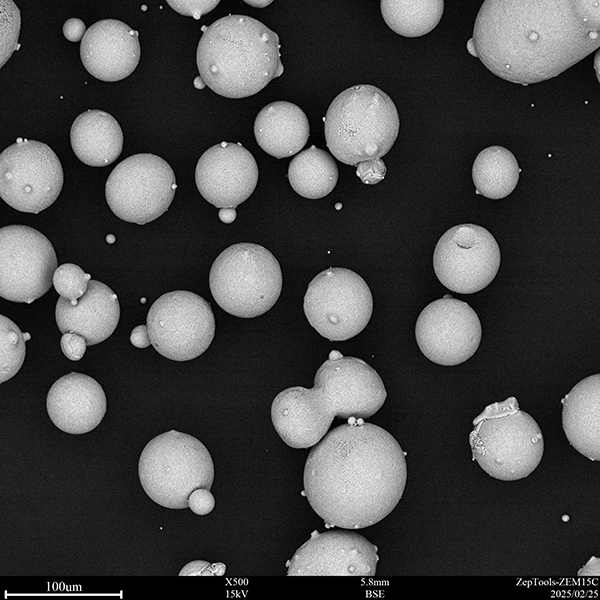

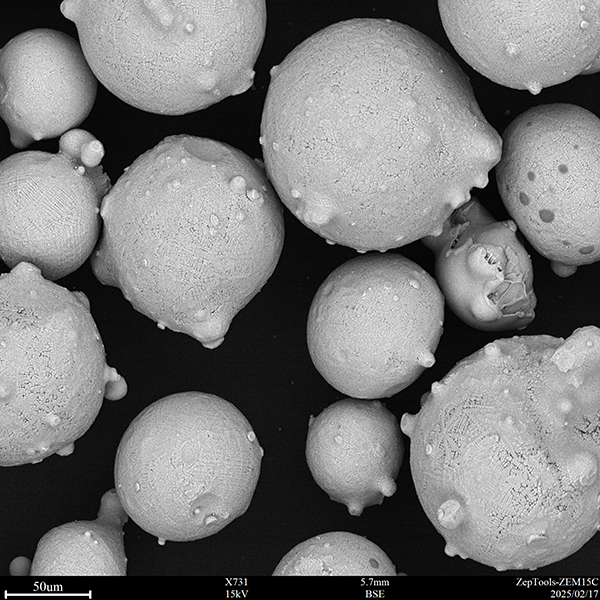

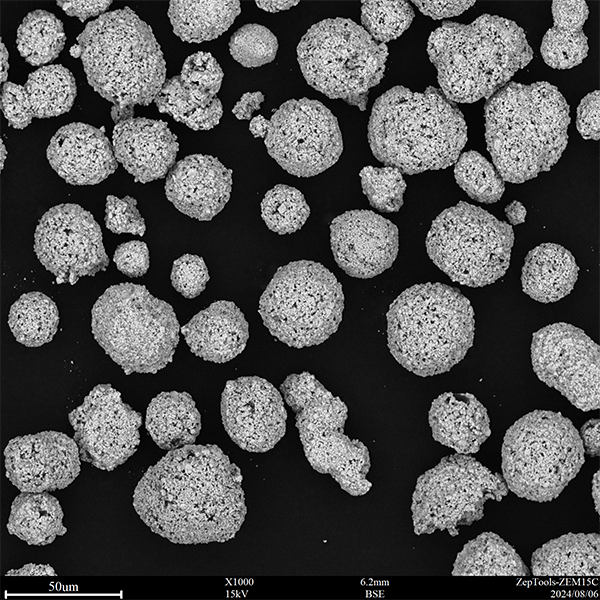

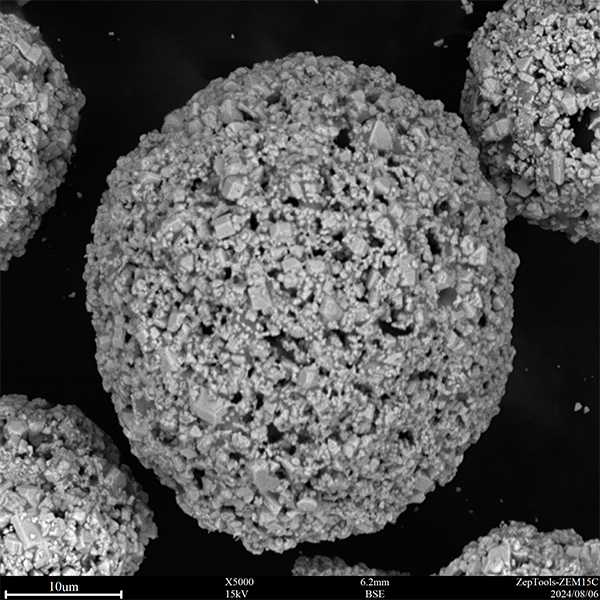

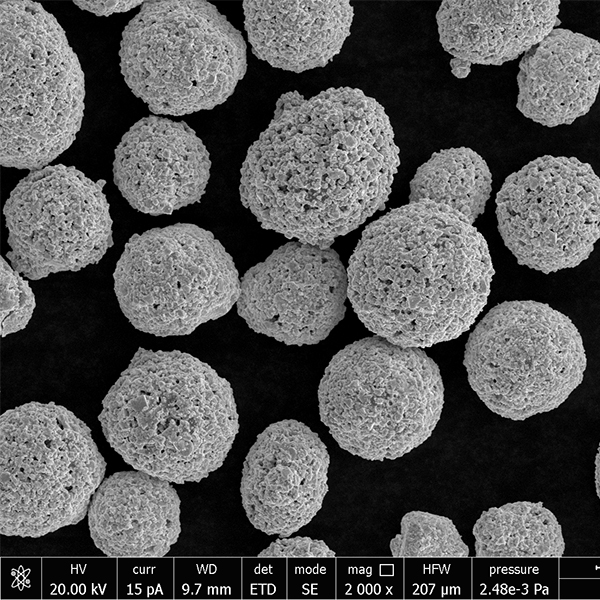

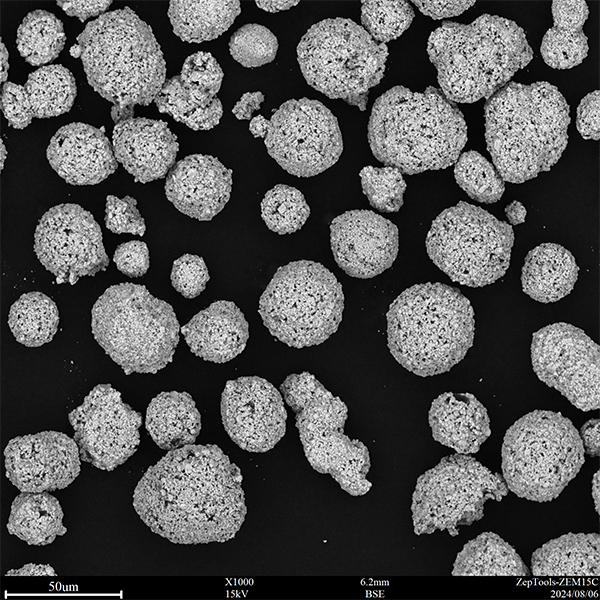

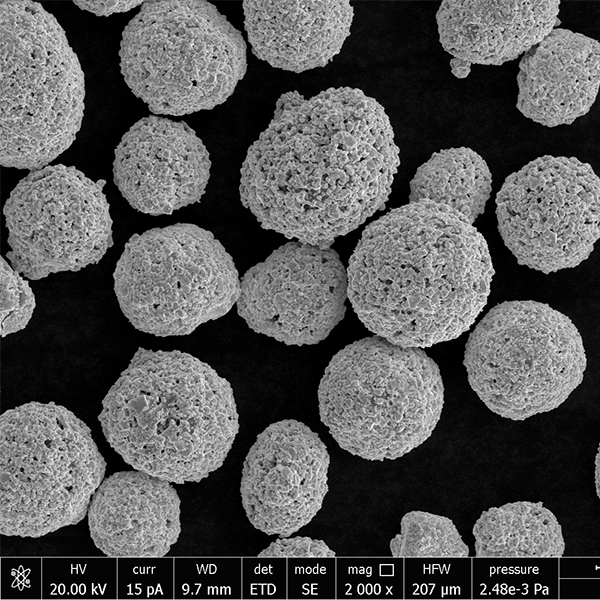

Ni60CuMo similar metco 16C, High hardness nickel-based alloy with better corrosion resistance

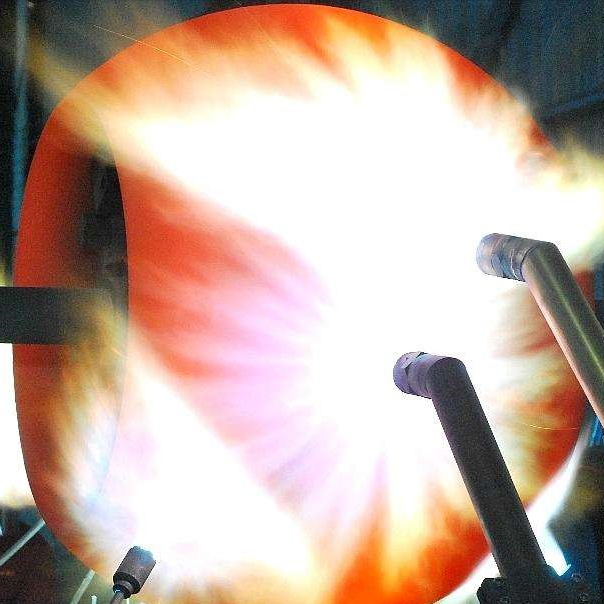

Processing Technology Adaptability

Typical Application Cases

Typical Application Cases

· Offshore Platform Equipment:

· Christmas Tree Valves: In mud environments with Cl⁻ ≤5000 ppm and pH 3–5, service life triples compared to stainless steel.

· Subsea Pipe Fittings: MoS₂ lubrication reduces friction torque under deep-sea pressure, minimizing maintenance.

· Chemical Storage Tanks:

· In sulfuric acid storage tanks (≤10% concentration), combined with sacrificial anodes, achieves >10 years of maintenance-free operation.

Future Research Directions

· Nanomaterial Reinforcement: Add 0.1–0.3% SiC nanoparticles to enhance hardness and wear resistance.

· Eco-Friendly Coatings: Develop low-temperature plasma spraying to reduce VOC emissions.

· Digital Simulation: Use CALPHAD to optimize composition design and predict failure modes under various working condition.

(Note: Data based on ASTM standards and published literature; field validation required for specific applications.)

This translation maintains technical accuracy while ensuring readability for international audiences. Let me know if further refinements are needed!

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.